Preparation method of anode material for power lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low cycle life, poor discharge rate performance of negative electrode materials, etc., and achieve good adhesion, high capacity and charge and discharge Efficiency, good structural stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

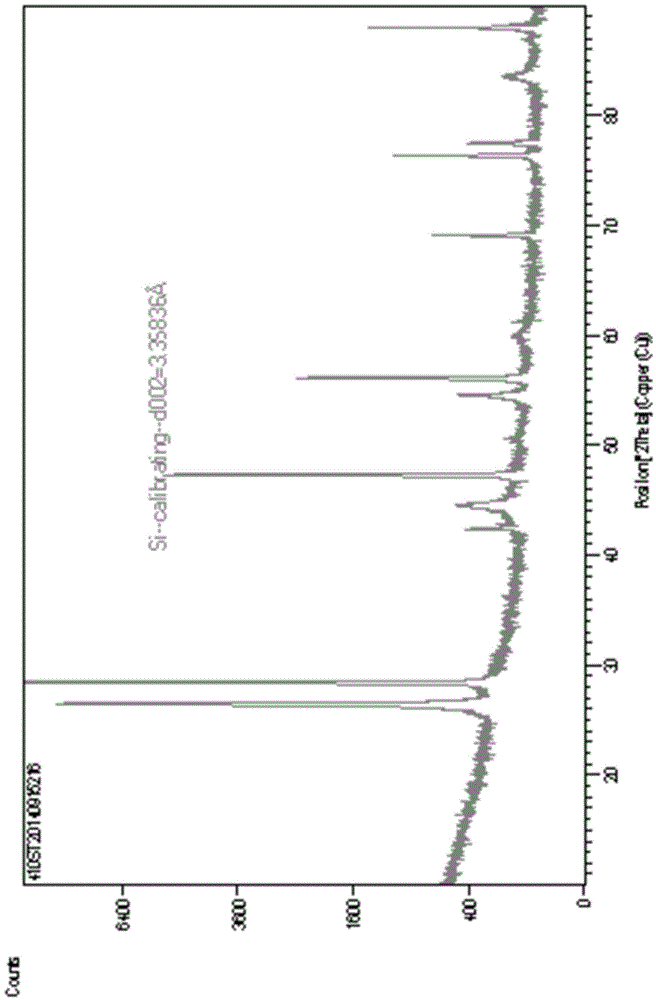

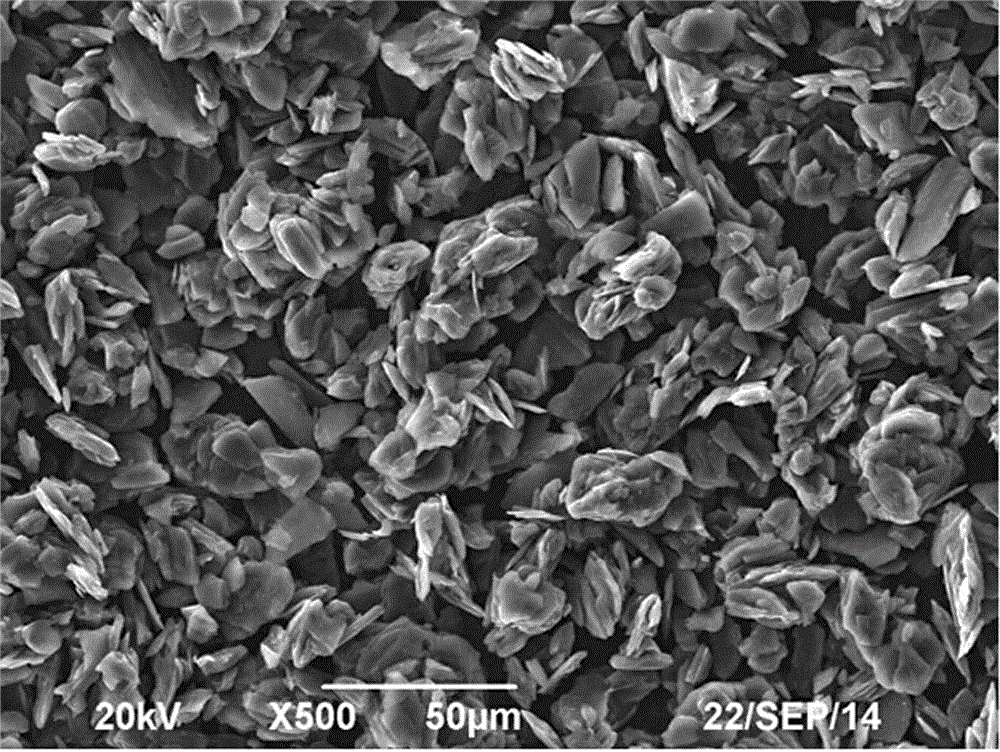

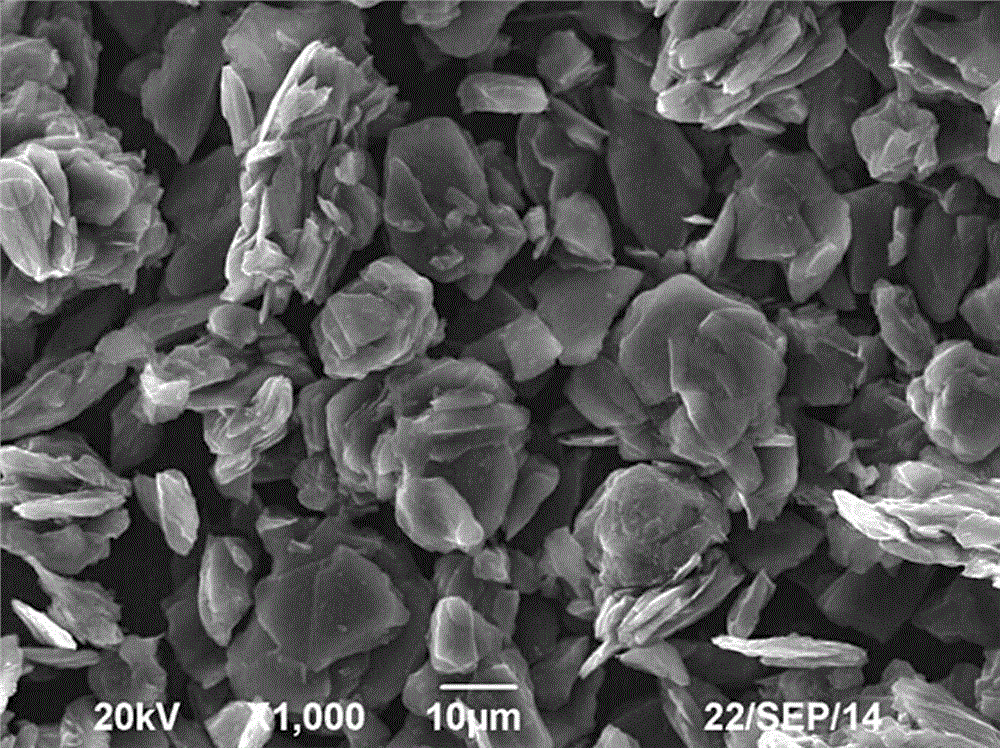

[0030] Take 100KG needle coke as raw material, after crushing and processing, process it to 6μm, put it into the reaction kettle for high temperature carbonization coating treatment, the heating curve is normal temperature -200°C for 30 minutes, 200°C-600°C for 60 minutes, 600°C-1000°C 90 minutes at 1000°C constant temperature for 6 hours, and then ultra-high temperature graphitization treatment above 3200°C. After graphitization, the obtained material is added with 10KG of petroleum pitch, and then enters the carbonization furnace for secondary coating. The coating temperature control curve is normal temperature -350 ℃ for 60 minutes, 350℃-600℃ for 150 minutes, 600℃-1200℃ for 150 minutes, and 1200℃ for 1 hour to obtain a spherical artificial graphite material coated and bonded by small particles. The D50 is 13.2μm, which is extremely Tablet compaction density 1.62g / cm3, specific surface area 1.55m2 / g, first discharge capacity 352mAh / g, first discharge efficiency 94.3%, rate pe...

Embodiment 2

[0032] Take 100KG needle coke as raw material, grind it to 6μm, add 1KG H 3 BO 3Mix and add to the reaction kettle for high-temperature carbonization coating treatment. The temperature rise curve is -200°C for 30 minutes, 200°C-600°C for 60 minutes, 600°C-1000°C for 90 minutes, 1000°C for 6 hours, and then 3200°C or more. Ultra-high temperature graphitization treatment, the material obtained after graphitization is added with 10KG of petroleum pitch, and then enters the carbonization furnace for secondary coating. The coating temperature control curve is normal temperature -350°C for 60 minutes, 350°C-600°C, 600°C -1200°C for 150 minutes, constant temperature at 1200°C for 1 hour; obtain a spherical artificial graphite material coated and bonded by small particles, with a D50 of 13.5μm, a pole piece compacted density of 1.65g / cm3, and a specific surface area of 1.53m2 / g, the first discharge capacity is 363mAh / g, the first discharge efficiency is 94.1%, the rate performance...

Embodiment 3

[0034] Take 100KG of petroleum coke as raw material, after crushing and processing, process it to 4μm, put it into the reaction kettle for high-temperature carbonization coating treatment, the heating curve is -200°C for 30 minutes, 200°C-600°C for 60 minutes, 600°C-1000°C for 90 minutes Minute 1000 ℃ constant temperature for 6 hours, and then carry out ultra-high temperature graphitization treatment above 3200 ℃. After graphitization, the obtained material is added with 15KG of petroleum pitch, and then enters the carbonization furnace for secondary coating. The coating temperature control curve is normal temperature -350 ℃ After 60 minutes, 350°C-600°C, 600°C-1200°C for 150 minutes, 1200°C constant temperature for 1 hour; a spherical artificial graphite material made of small particles coated and bonded, the D50 of the finished product is 12.3μm, Electrode compaction density 1.58g / cm3, specific surface area 1.75m2 / g, initial discharge capacity 350mAh / g, initial discharge effi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com