Upper cover with detergent box of washing machine

A technology for detergent boxes and washing machines, which is applied to other washing machines, washing devices, household appliances, etc., can solve the problems of increasing the number of parts, complicated assembly procedures, inability to disassemble and assemble quickly, etc., and achieves fast sliding in and out and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in more detail below on the basis of the embodiments shown in the drawings.

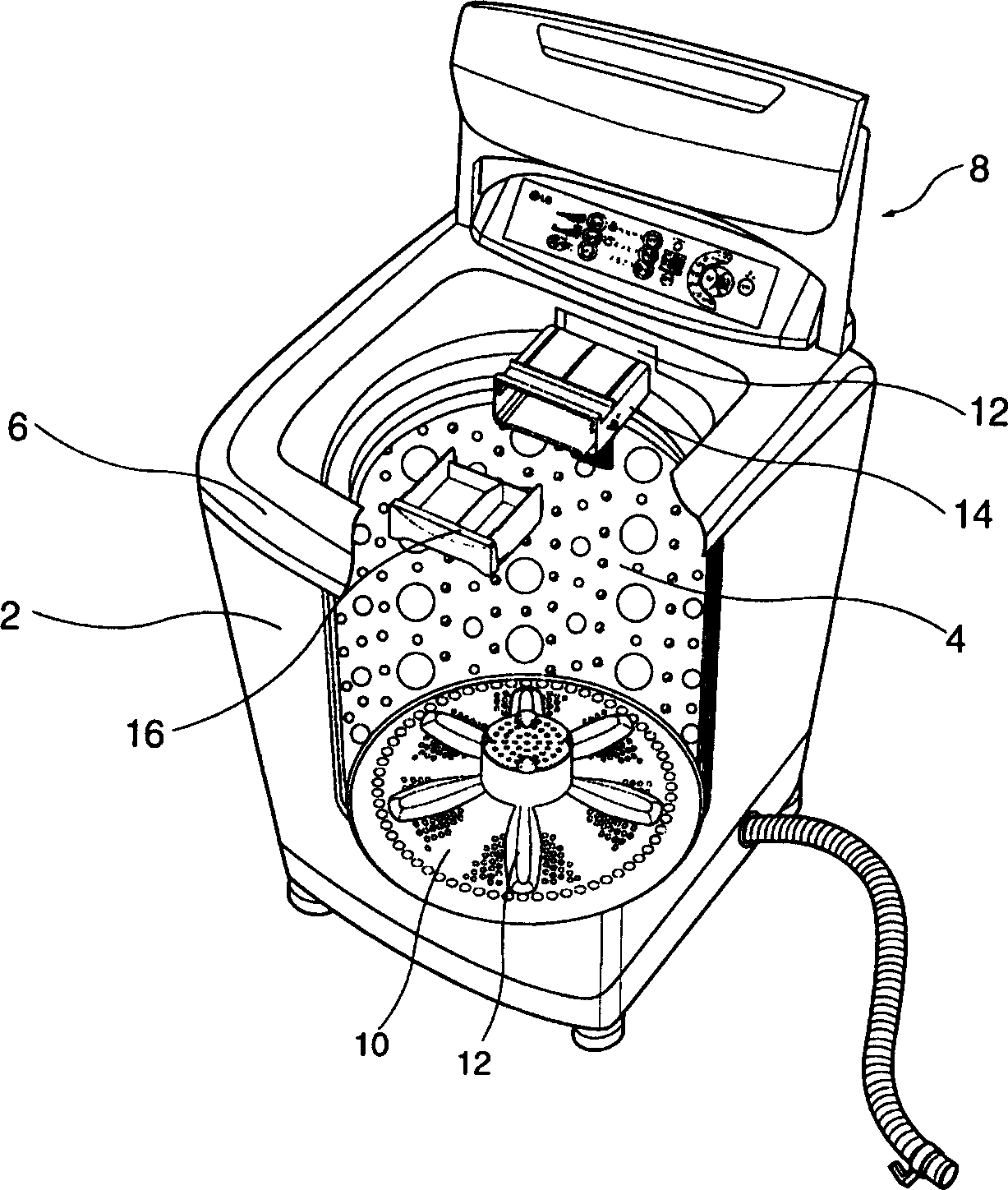

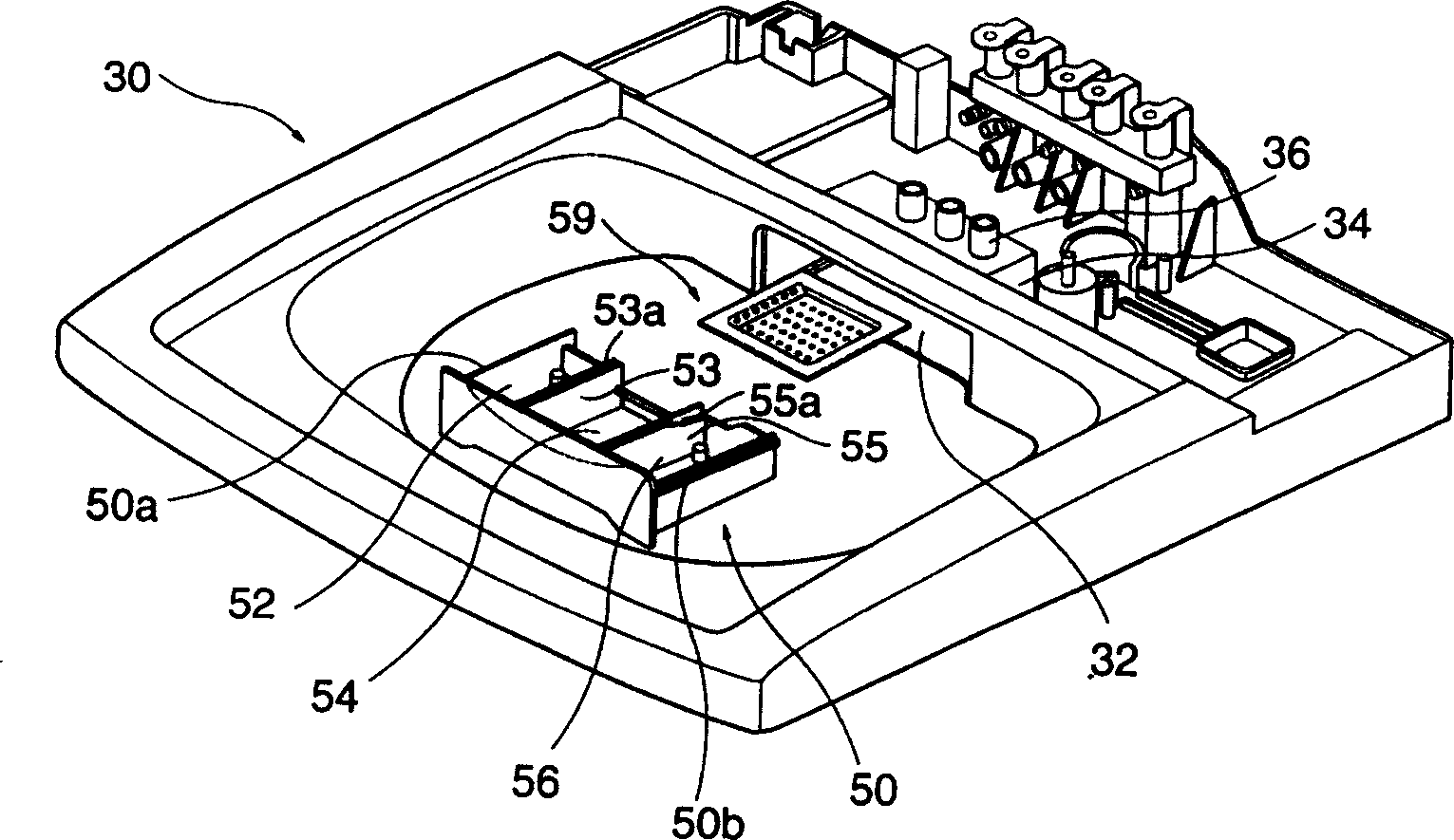

[0030] like figure 2 As shown, the rear of the central opening of the upper cover (30) of the present invention forms an installation space (32) where the detergent box (50) can be installed. The above-mentioned installation space (32) is a part integrally formed with it when the upper cover (30) is made. When the above-mentioned installation space (32) is made and shaped, a box-shaped protrusion (34) has been formed behind it, and a plurality of water supply holes (36) are formed on the top of the protrusion (34). The water injected through the water supply hole (36) flows into the inside of the detergent box (50), thereby flowing into the washing machine together with the detergent.

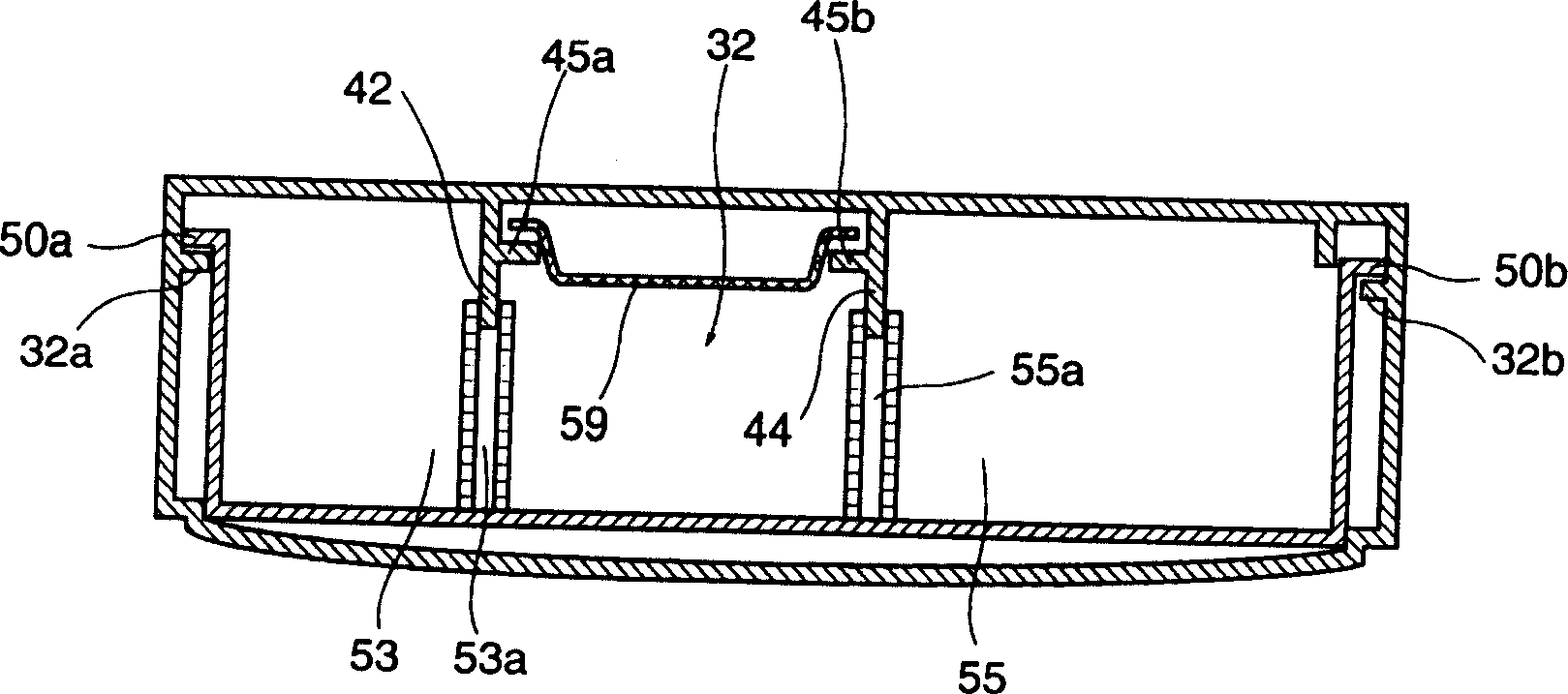

[0031] In the present invention, the upper ends of the two side walls of the above-mentioned installation space (32), such as image 3 As shown, supporting cross bars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com