Board hot pressing device

A hot-pressing equipment and board technology, which is applied to veneer presses, plywood presses, wood processing equipment, etc., can solve problems such as energy consumption, board processing system interruption, and reduced hot-pressing efficiency, so as to achieve uniform heating and easy maintenance , the effect of fast feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

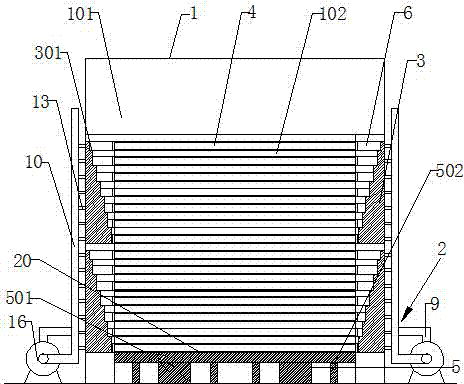

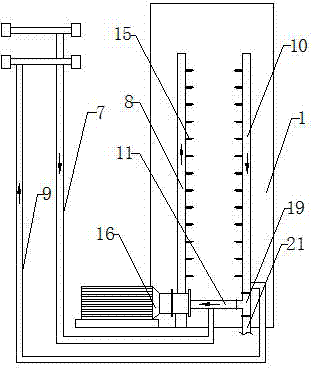

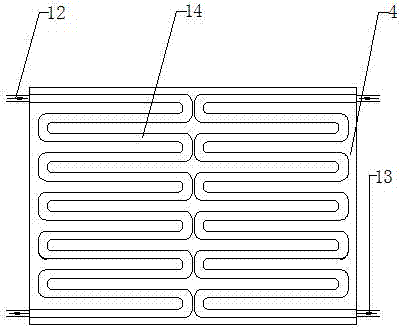

[0017] Embodiment: refer to attached Figure 1-4 The plate hot-pressing equipment shown includes a hot-pressing body 1, the hot-pressing body 1 is composed of a machine frame 101 and a hot-pressing cavity 102, and two gradients are set on the front sides of the two support legs of the machine frame 101 Positioning groove 3, two gradient positioning grooves 3 are arranged up and down, each gradient positioning groove 3 is composed of 5 to 7 press ears 301, and a hydraulic cylinder driving system 5 is fixedly installed at the bottom of the hot-pressing cavity 102, and the hydraulic cylinder drives The system 5 consists of two main hydraulic jacks 501 and two auxiliary hydraulic jacks 502. The combination of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com