Efficient woodworking drilling machine for costly furniture

A woodworking drilling and furniture technology, applied in fixed drilling machines, manufacturing tools, metal processing equipment, etc., can solve the problems of working environment and personnel hazards, carbonation and blackening of furniture panels, and the need for manual lifting to ensure the environment Healthy, prevent dust pollution, improve the effect of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

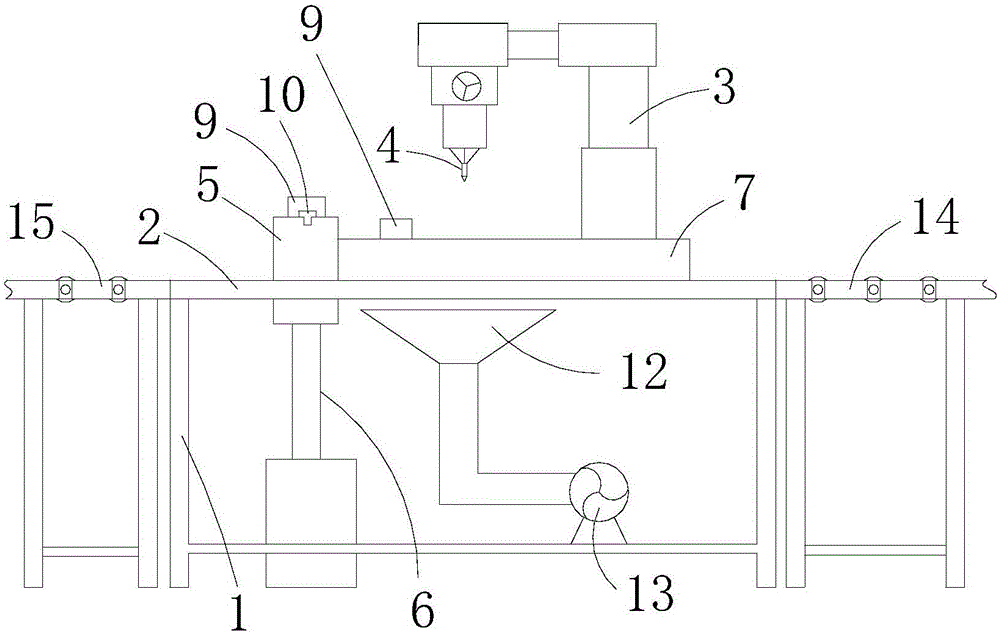

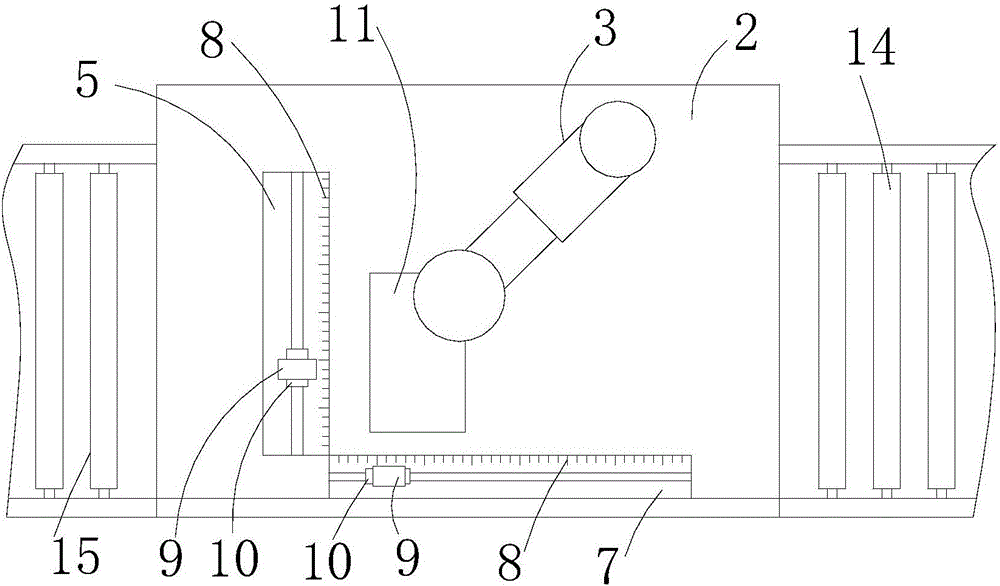

[0017] Such as Figure 1 to Figure 2 As shown, the present invention provides a high-efficiency woodworking drilling machine for high-grade furniture, comprising a support 1, a drilling platform 2 installed on the support 1, a rotating arm 3 installed on the drilling platform 2 and a drill bit installed on the rotating arm 3 4. The rear of the drilling platform 2 is equipped with a feed slide 14, the front of the drilling platform 2 is equipped with a discharge slide 15, and the front end of the drilling platform 2 is provided with a lifting block 5 that runs through the drilling platform 2. The bottom of the block 5 is connected with the elevating rod 6, and the side of the drilling platform 2 is fixed with a side stopper 7, and the elevating stopper 5 and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com