Micro-channel electronic cigarette atomization chip and preparation method thereof

An electronic cigarette and micro-channel technology, applied in the field of electronic cigarettes, can solve the problems of uneven heating of atomization chips, and achieve the effects of facilitating mass production, uniform heating, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

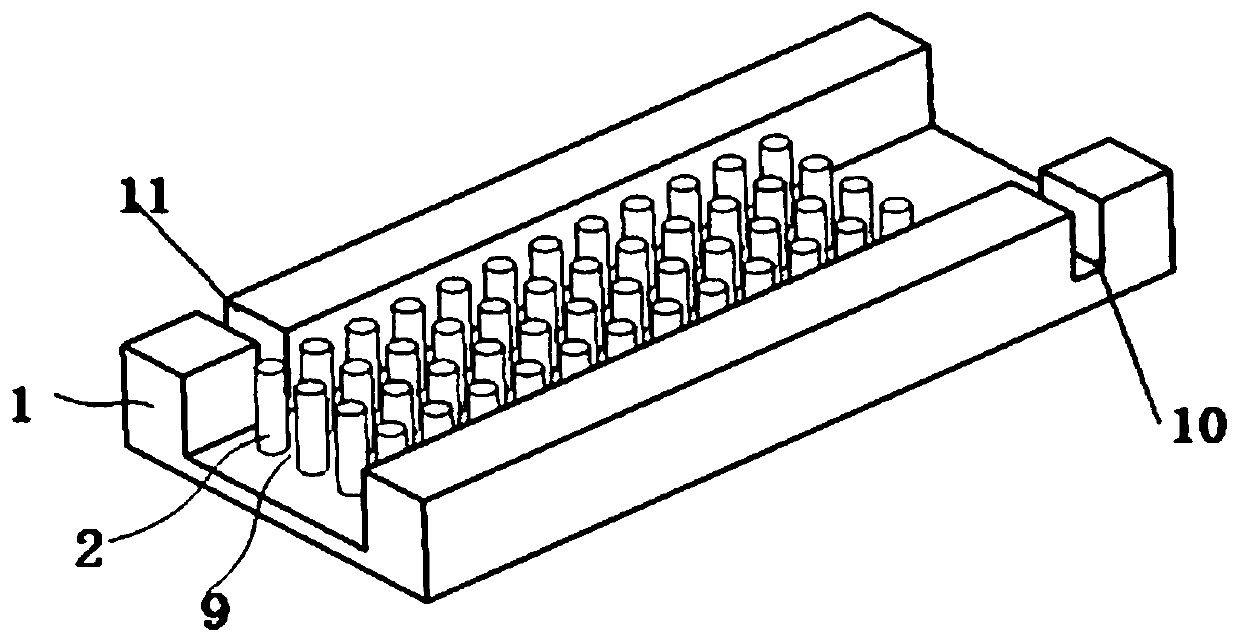

[0034] In this embodiment, the structure of the microchannel electronic atomization chip is as follows:

[0035] A silicon substrate 1 is provided with an array of micropillars 2 and an inlet port 10 and an outlet port 11 on the silicon substrate 1, and the array of micropillars 2 defines several microfluidic channels 9;

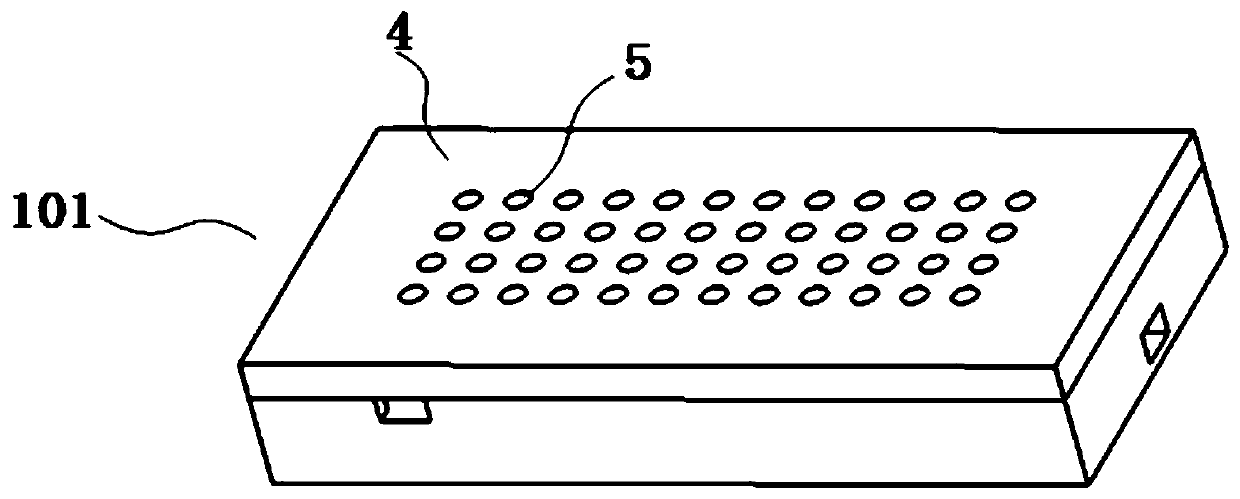

[0036] A glass cover 4, which is provided with an air hole 5 passing through the glass cover 4;

[0037] The glass cover 4 is fixedly connected to the silicon substrate 1 by anodic bonding process.

[0038] This embodiment also provides a method for preparing a microfluidic electronic atomization chip, including the following steps:

[0039] a. Etching an array of micropillars 2 or an array of microholes 3 and an inlet port 10 and an outlet port 11 on the silicon substrate 1;

[0040] b. On the glass cover 4, an array of air holes 5 penetrating therethrough is produced;

[0041] c, using a bonding process to bond the silicon substrate 1 prepared in step a...

Embodiment 2

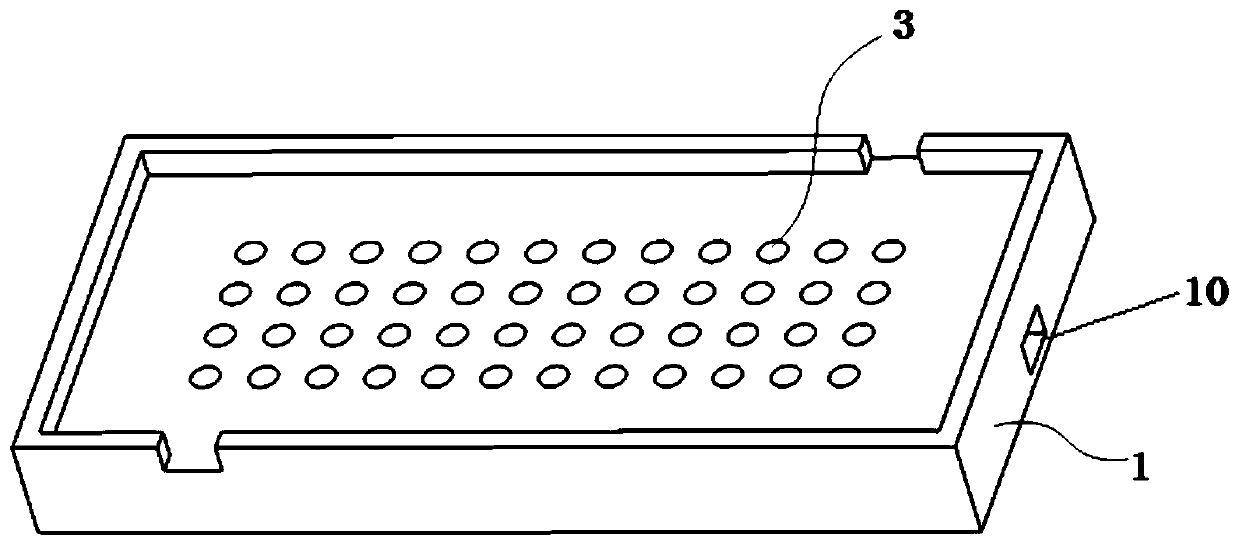

[0045] In this embodiment, the structure of the microchannel electronic atomization chip is as follows:

[0046] A silicon substrate 1, an array of microholes 3 and an inlet port 10 and an outlet port 11 are arranged on the silicon substrate 1, and an e-liquid flow channel penetrating through the microholes 3 is arranged on the silicon substrate 1;

[0047] A glass cover 4, which is provided with an air hole 5 passing through the glass cover 4;

[0048] The glass cover 4 is fixedly connected to the silicon substrate 1 by anodic bonding process.

[0049] This embodiment also provides a method for preparing a microfluidic electronic atomization chip, including the following steps:

[0050] a. Etching an array of micropillars 2 or an array of microholes 3 and an inlet port 10 and an outlet port 11 on the silicon substrate 1;

[0051] b. On the glass cover 4, an array of air holes 5 penetrating therethrough is produced;

[0052] c, using a bonding process to bond the silicon su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com