Method for controlling uniform heating of switch device of switch power source

A switching device and switching power supply technology, which is applied in the direction of electrical components, control/regulation systems, instruments, etc., can solve the problem of uneven heating of switching devices, and achieve the effect of prolonging life and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

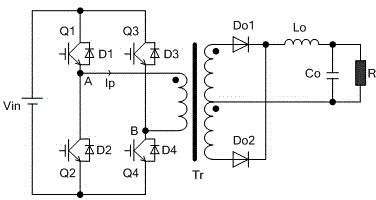

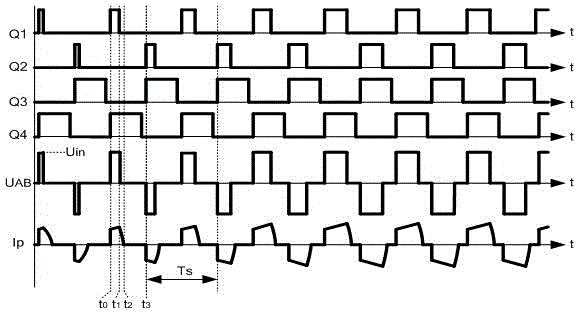

[0017] Embodiment 1: The purpose of this embodiment is to overcome the problem of uneven heating of each switching tube in a switching power supply including switching tubes, and provide a control method for uniform heating of switching tubes in a switching power supply. The switching power supply includes a full-bridge converter. The structure of the full bridge converter is as follows figure 1 As shown, the four switching devices Q1 (first switching device), Q2 (second switching device), Q3 (third switching device), and Q4 (fourth switching device) in the full-bridge converter are all switching tubes , the switching device sequence (that is, the turn-on or turn-off sequence) of each switching device in the full-bridge converter is alternately changed periodically, that is, the switching device used as the leading arm and the switching device used as the lagging arm are alternately changed periodically, The alternating period Tp is twice the switching control period Ts of eac...

Embodiment 2

[0020] Embodiment 2: as Figure 4As shown, each switching device in the full-bridge converter is composed of two or more switching tubes connected in parallel, and the control pulses of the two or more switching tubes forming each switching device are consistent. That is, the switching tubes Q11~Q1n are connected in parallel to receive the same switching tube control pulse; Q21~Q2n are connected in parallel to receive the same switching tube control pulse; Q31~Q3n are connected in parallel to receive the same switching tube control pulse; Q41~Q4n are connected in parallel to receive the same switching tube control pulse. Switch tube control pulse; four groups of pulse signals can be pressed image 3 The control pulse generation method shown can realize parallel connection of IGBTs.

Embodiment 3

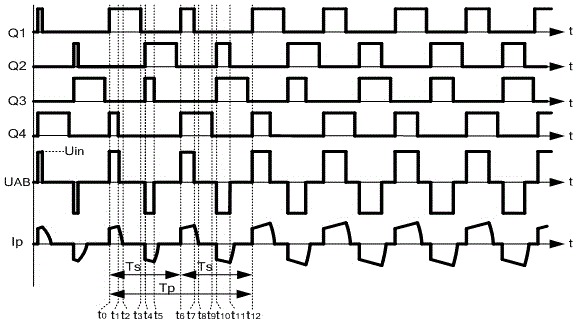

[0021] Embodiment 3: This embodiment provides a control method for uniform heating of switching tubes of switching power supplies. The switching power supply includes a full-bridge converter, and the structure of the full-bridge converter is as follows: figure 1 As shown, the four switching devices Q1 (first switching device), Q2 (second switching device), Q3 (third switching device), and Q4 (fourth switching device) in the full-bridge converter are all switching tubes , in the full-bridge converter, the switching device as the super forearm and the switching device as the lagging arm are periodically alternately transformed, and its alternating period Tp is 6 times of the switching control period Ts of each switching device; that is, an alternating period Tp includes 6 switching control periods Ts, among them, if Q1 and Q2 form the lagging arm in the first three switching control periods Ts in an alternate period Tp, and Q3 and Q4 form the super forearm, then in the same alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com