Stepless speed change tea leaf strip tidying machine

A tea organizer and continuously variable speed technology, applied in the direction of tea processing before extraction, can solve problems such as inapplicability, and achieve the effects of small occupied space, fast heating speed, and low noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

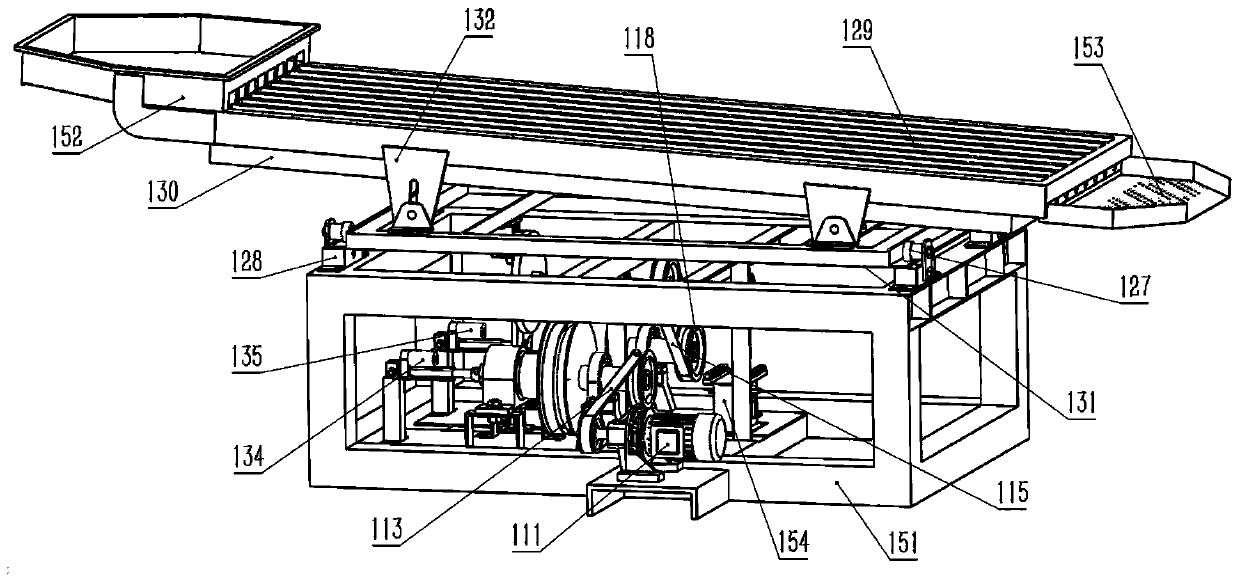

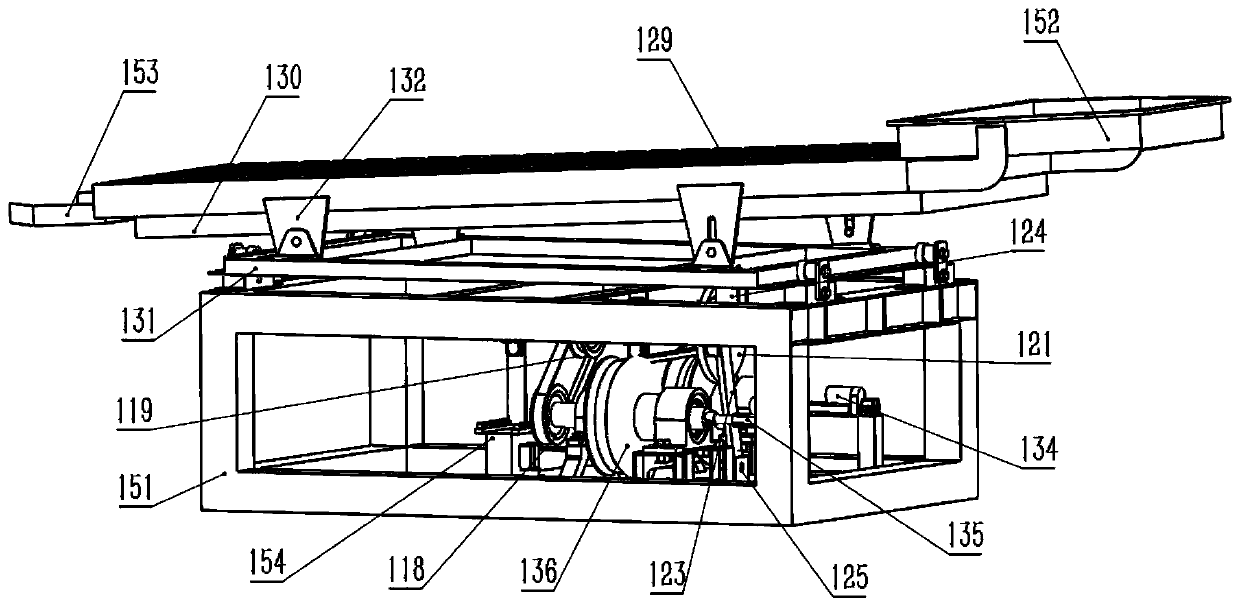

[0040] Such as figure 1 , 2 Shown: the present invention includes a frame, a transmission assembly, a strip assembly, and a heating assembly;

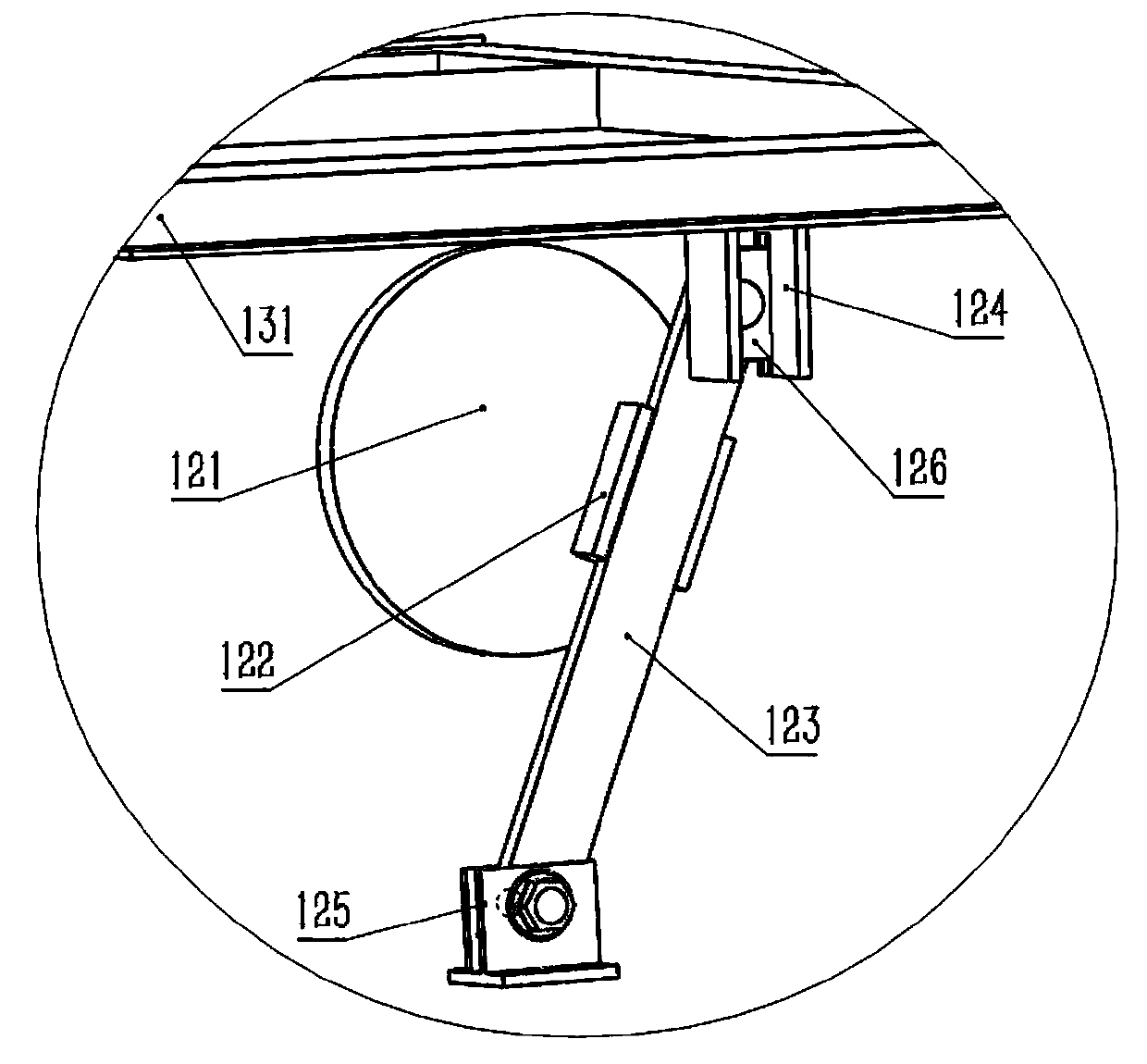

[0041] Described transmission assembly is made of bar motor 111, motor base 112, first belt 113, second belt 114, the 3rd belt 115, first pulley 116, second pulley 117, the 5th pulley 118, the 6th pulley 119, drive shaft 120. The planar swing guide rod mechanism is formed.

[0042] The strip assembly is composed of rubber roller 127, roller support 128, U-shaped pot 129, pot seat 130, pot support 131, pot support 132, feed hopper 152, and discharge hopper 153.

[0043] The heating assembly includes a silicone rubber heating sheet 133, a transformer 154 and cables (not shown in the figure).

[0044] Such as figure 1 , 2 , shown in 7: the described strip motor 111 is fixedly installed on the frame 151 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com