Method for increasing laser thermal response speed and multi-terminal pump solid state laser

A thermal response, laser crystal technology, used in lasers, laser parts, phonon exciters, etc., can solve the problem of slow laser thermal response, avoid laser damage, increase flexibility, and achieve the function of Q-switched laser pulse energy attenuation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

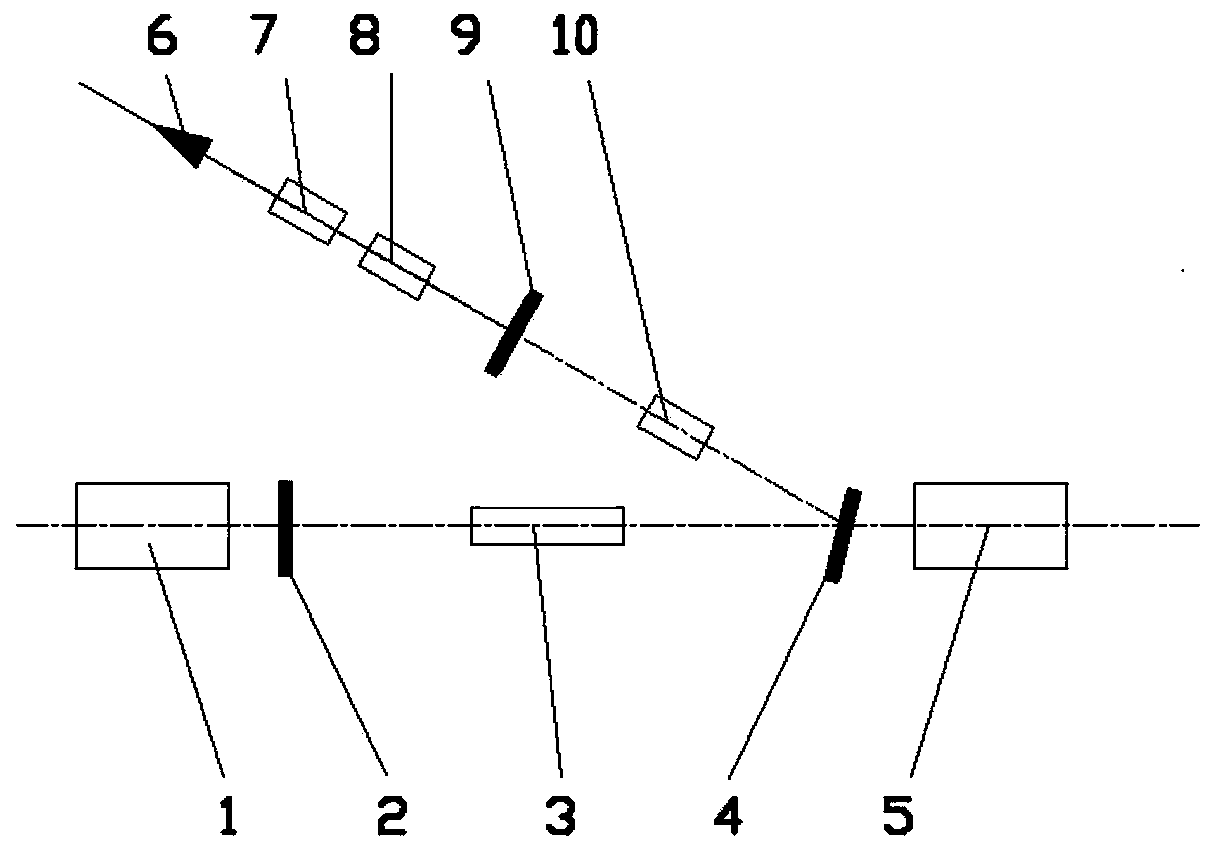

[0044] figure 1 A schematic diagram of the structure used in a fiber-coupled double-ended pumped acousto-optic Q-switched solid-state laser for the method of improving the laser thermal response speed, such as figure 1 As shown: the double-end pumped acousto-optic Q-switched solid-state laser in this embodiment includes a laser resonator, a laser crystal group, a pump source group, a Q-switched switch module, an externally modulated optical switch group, a substrate (not marked in the figure) and Laser controller (not marked in the figure). Among them, the laser resonator includes a front cavity mirror 2, a rear cavity mirror 9, and a folding mirror 4, all of which are fixed on the substrate. The rear cavity mirror 9 reflects 95% of the fundamental frequency laser and transmits 5%; the laser crystal group includes YVO4 Laser crystal 3, this embodiment is a fundamental-frequency laser crystal, in fact, two or more fundamental-frequency laser crystals with the same or different...

Embodiment 2

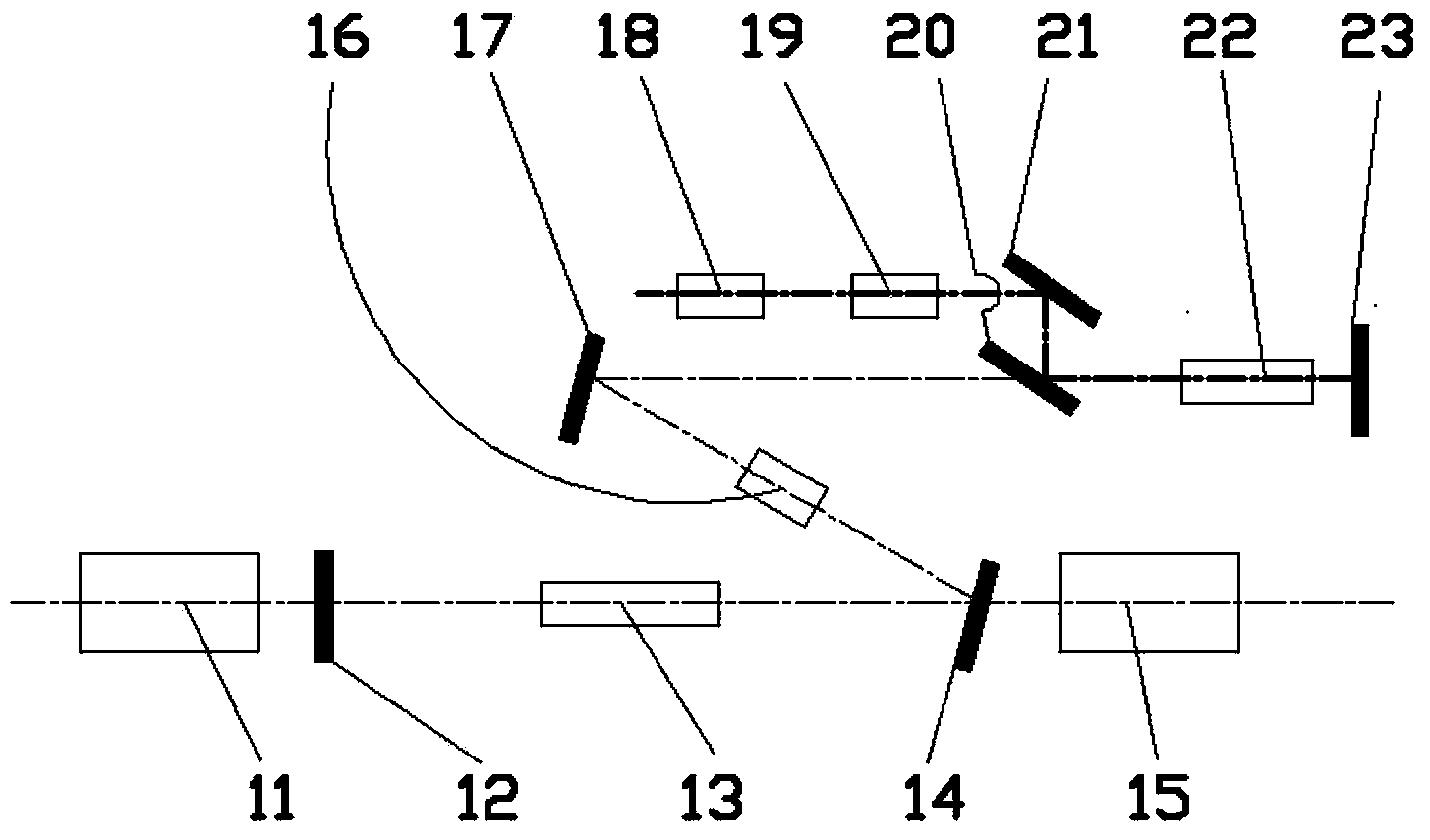

[0055] figure 2 A schematic diagram of the structure used in a fiber-coupled double-ended pumped acousto-optic Q-switched solid-state harmonic laser for the method of improving the laser thermal response speed, such as figure 2 As shown: the double-end pumped acousto-optic Q-switched solid harmonic laser in this embodiment includes a laser resonator, a laser crystal group, a pump source group, a Q-switched switch module, an externally modulated optical switch group, and a substrate (not marked in the figure) ), laser controller (not marked in the figure). Wherein, the laser resonant cavity includes a front cavity mirror 12, a rear cavity mirror 23, a folding mirror 14, a folding mirror 17, and a Brewster plate 20, all of which are fixed on the substrate, and the rear cavity mirror 23 is opposite to the fundamental frequency laser 95% reflection, 5% transmission; the laser crystal group includes YVO4 laser crystal 13 and frequency-doubled laser crystal 22, and the frequency-...

Embodiment 3

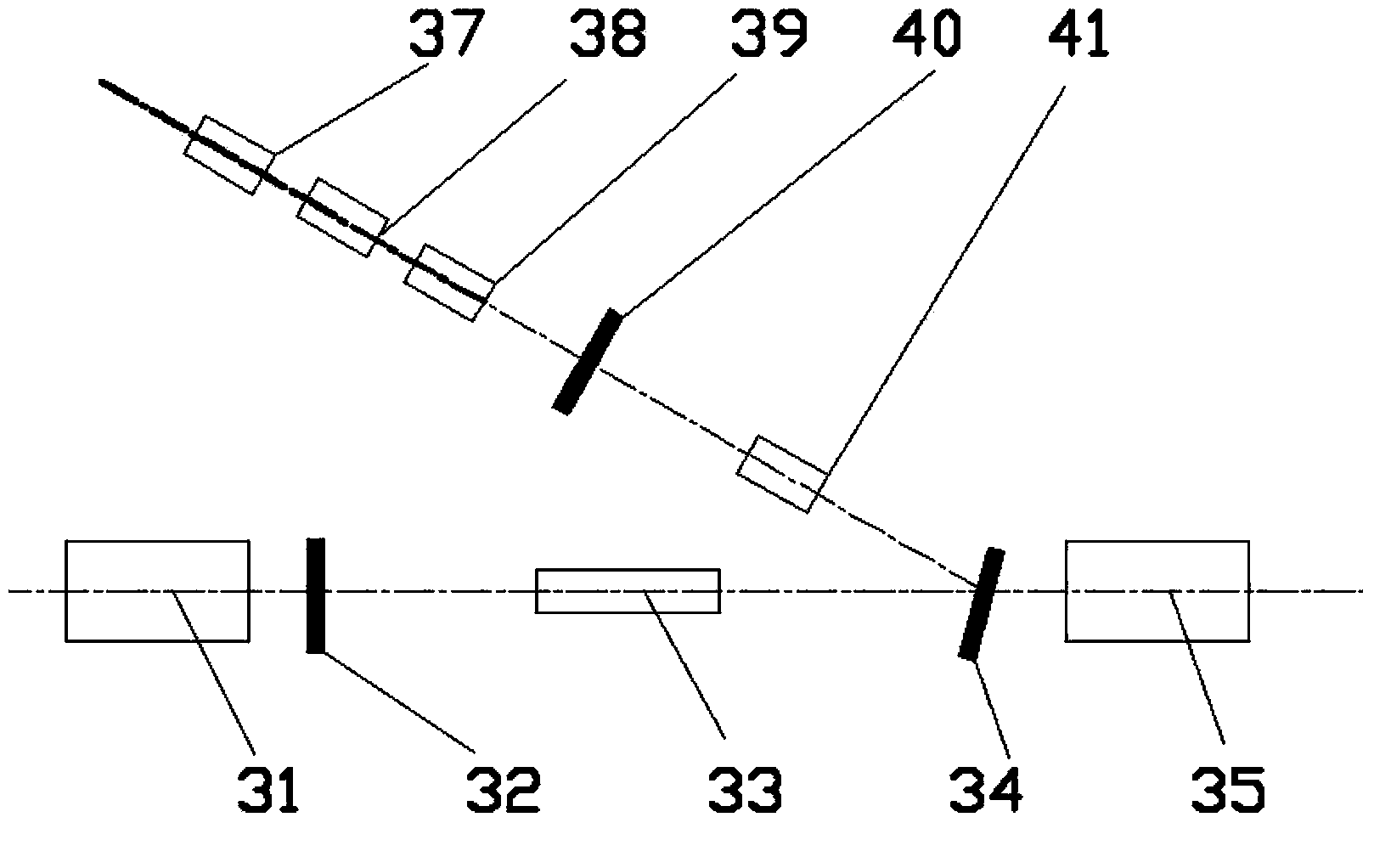

[0065] image 3 A schematic diagram of the structure used in a fiber-coupled double-ended pumped acousto-optic Q-switched solid-state harmonic laser for the method of improving the laser thermal response speed, such as image 3 As shown: the double-end pumped acousto-optic Q-switched solid harmonic laser in this embodiment includes a laser resonator, a laser crystal group, a pump source group, a Q-switched switch module, an externally modulated optical switch group, and a substrate (not marked in the figure) ), laser controller (not marked in the figure). Wherein, the laser resonator includes a front cavity mirror 32, a rear cavity mirror 40, and a folding mirror 34, all of which are fixed on the substrate, and the rear cavity mirror 40 reflects 95% of the fundamental frequency laser and transmits 5%; the laser crystal group Including YVO4 laser crystal 33 and frequency doubled laser crystal 39, said frequency doubled laser crystal 39 is a laser nonlinear conversion crystal, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com