High-reflection and high-velvet-degree back electrode based on AlOx/Ag/ZnO structure

A high-reflection, back-electrode technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problem of low reflectivity, achieve the effect of enhancing scattering ability, improving quantum efficiency, and enhancing reflection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

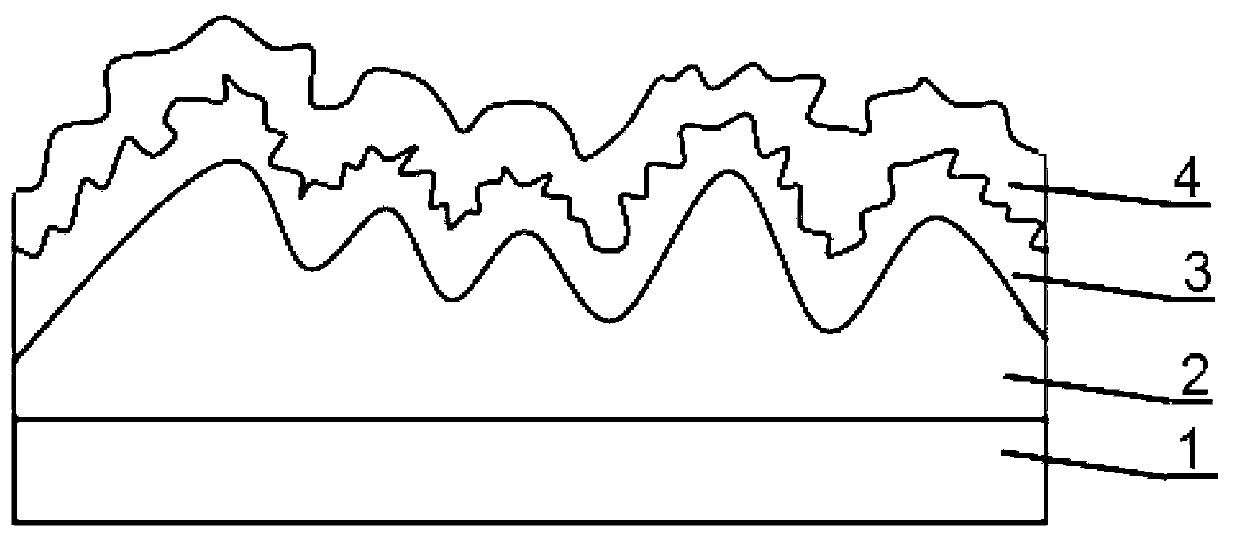

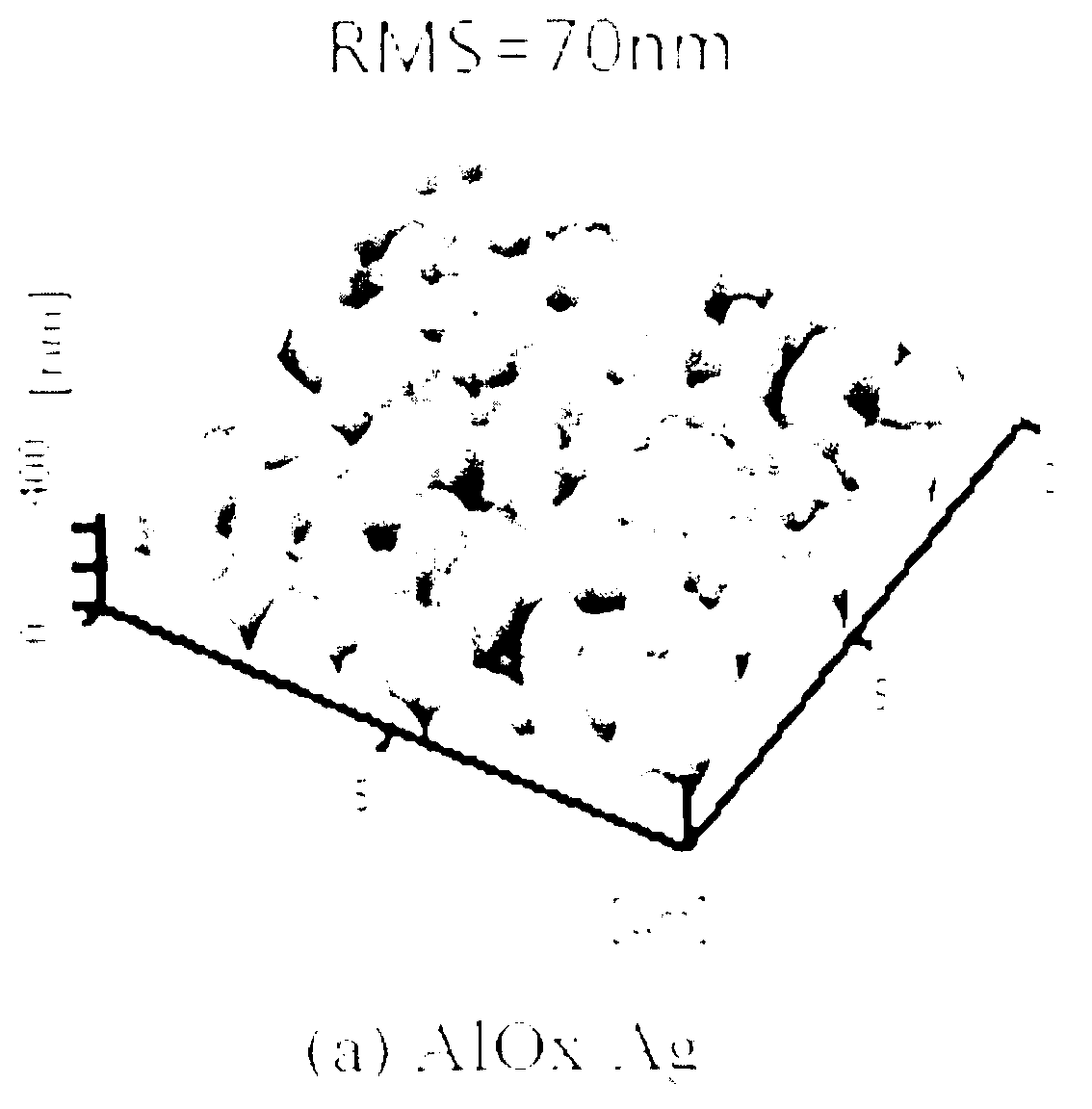

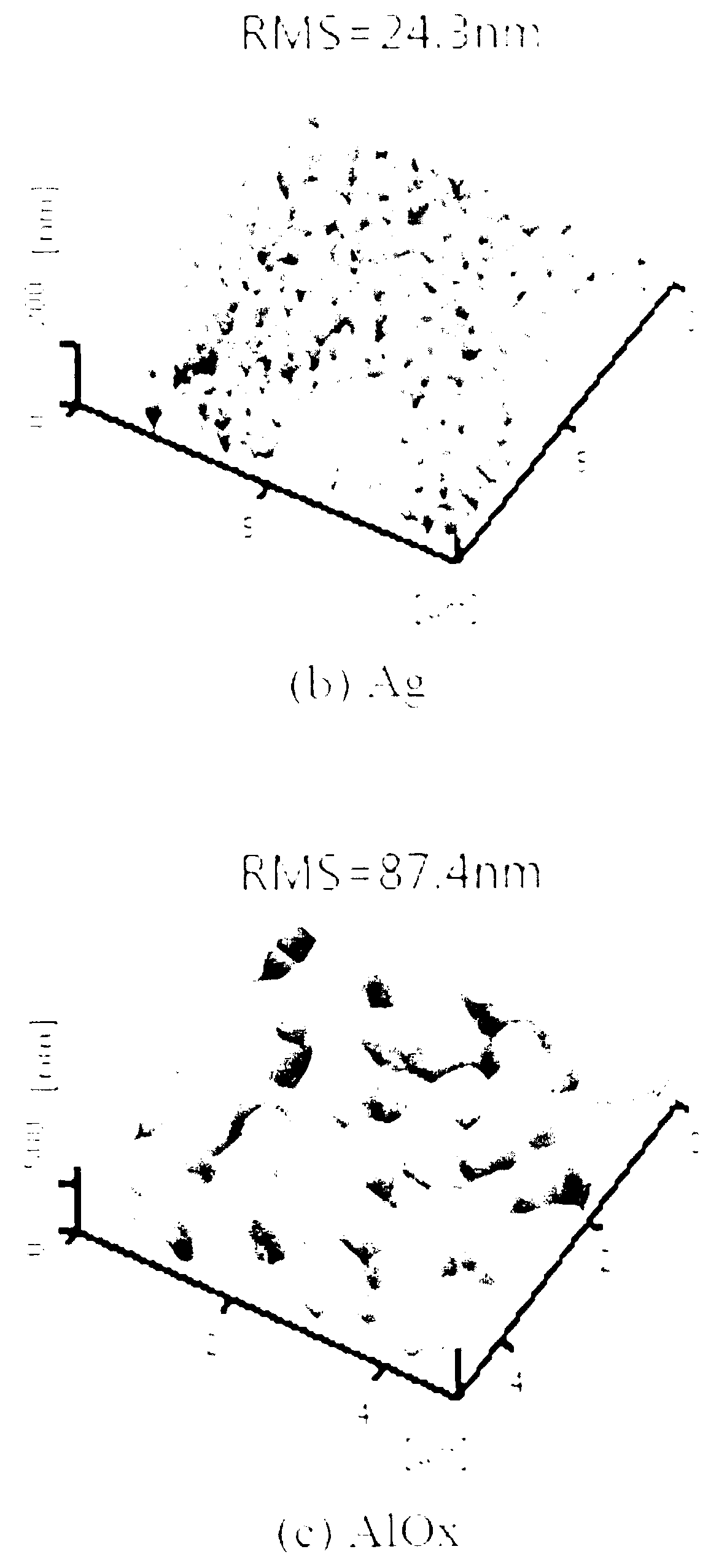

[0022] An AlO-based x / Ag / ZnO structure of high reflective high-textured back electrode, made of substrate 1, AlO x Thin film 2, Ag thin film 3 and dielectric layer ZnO thin film 4 are composed and form a laminated structure, and the AlO x The film has a large textured structure with a significant effect on long-wave light trapping, AlO x where x is 0x The amount of oxygen introduced in the thin film process determines the value of x. The surface particle size is about 1200nm, and the surface root mean square roughness is 87.4nm; the metal Ag thin film has broad-spectrum domain high reflection characteristics to sunlight, and its surface particle size is 150nm, and the surface root mean square roughness is 24.3 nm; the thickness of the ZnO thin film is 120nm.

[0023] One of the AlO-based x / Ag / ZnO structure of the preparation method of high-reflection high velvet back electrode, the steps are as follows:

[0024] 1) Put the cleaned stainless steel substrate into the magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface root mean square roughness | aaaaa | aaaaa |

| Surface root mean square roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com