Wide spectrum high reflectivity irregularly shaped distributed Brag reflector (IDBR) and manufacturing method thereof

A distributed Bragg, high reflectivity technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, gaseous chemical plating, etc., can solve the problems that have not been reported in the literature, complex process, expensive photolithography process, etc., to increase The effect of light energy capture, high reflectivity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

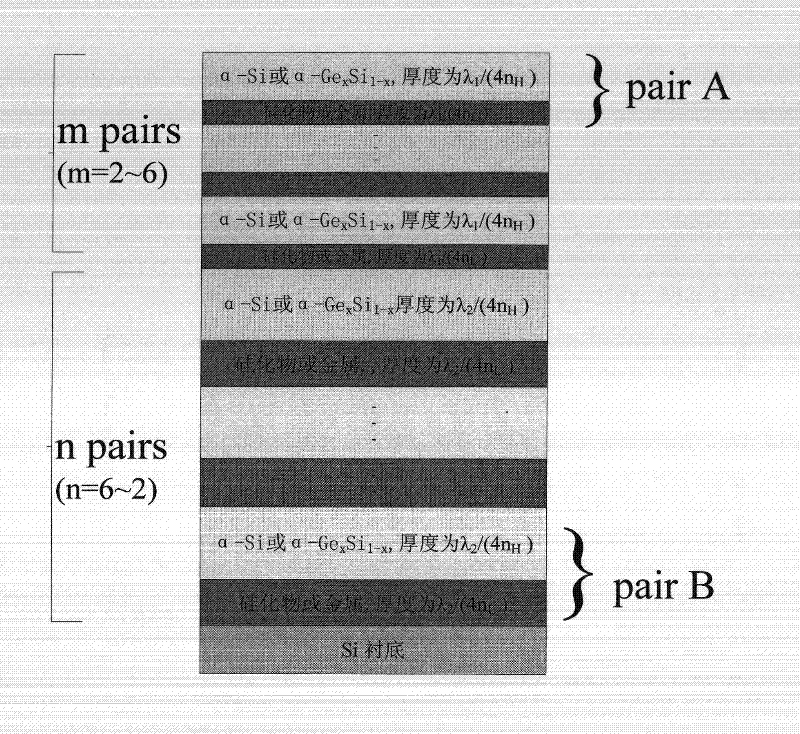

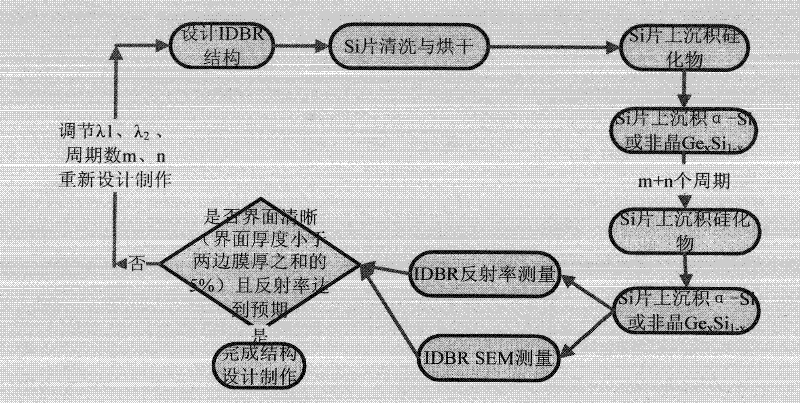

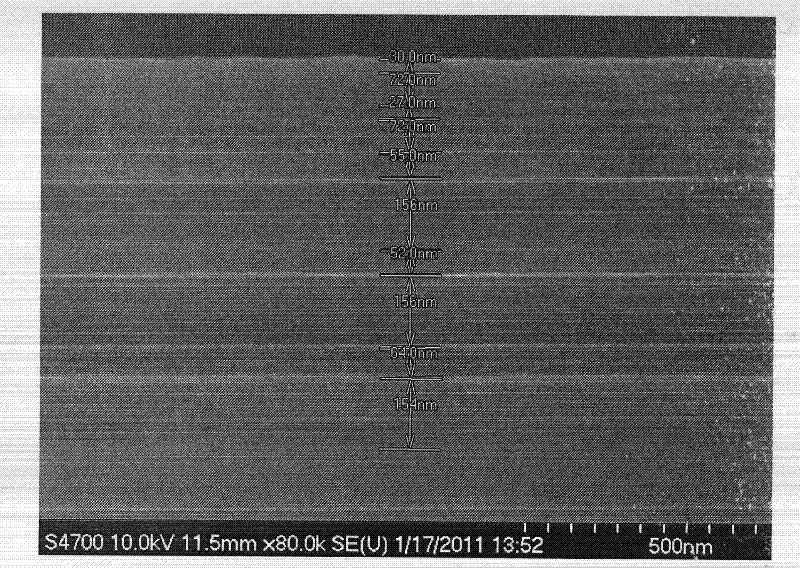

[0046] A-Si / SiO 2 Taking IDBR as an example, the present invention will be further described in conjunction with the drawings and specific embodiments. Here PairA, m=2, PairB, n=3. Other types of IDBR (such as amorphous silicon germanium / SN, amorphous silicon / SN, amorphous silicon germanium / SiO 2 ) and amorphous silicon or amorphous germanium silicon / metal Al or Ag can be obtained by similar methods. Only the process parameters of PECVD deposition of amorphous germanium silicon or SN are different from SiO 2 or amorphous silicon. This embodiment provides the steps of designing and making, such as figure 2 Shown:

[0047] The first step, based on the formula T=λ 0 / (4n), where λ 0 Indicates the central wavelength, n indicates the refractive index of a single-layer film, the selected central wavelength is 500nm and 1000nm, calculate and design the thickness of each layer of IDBR, when the central wavelength is 500nm, t SiO2 =81nm,t Si =36.5nm; when the center waveleng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com