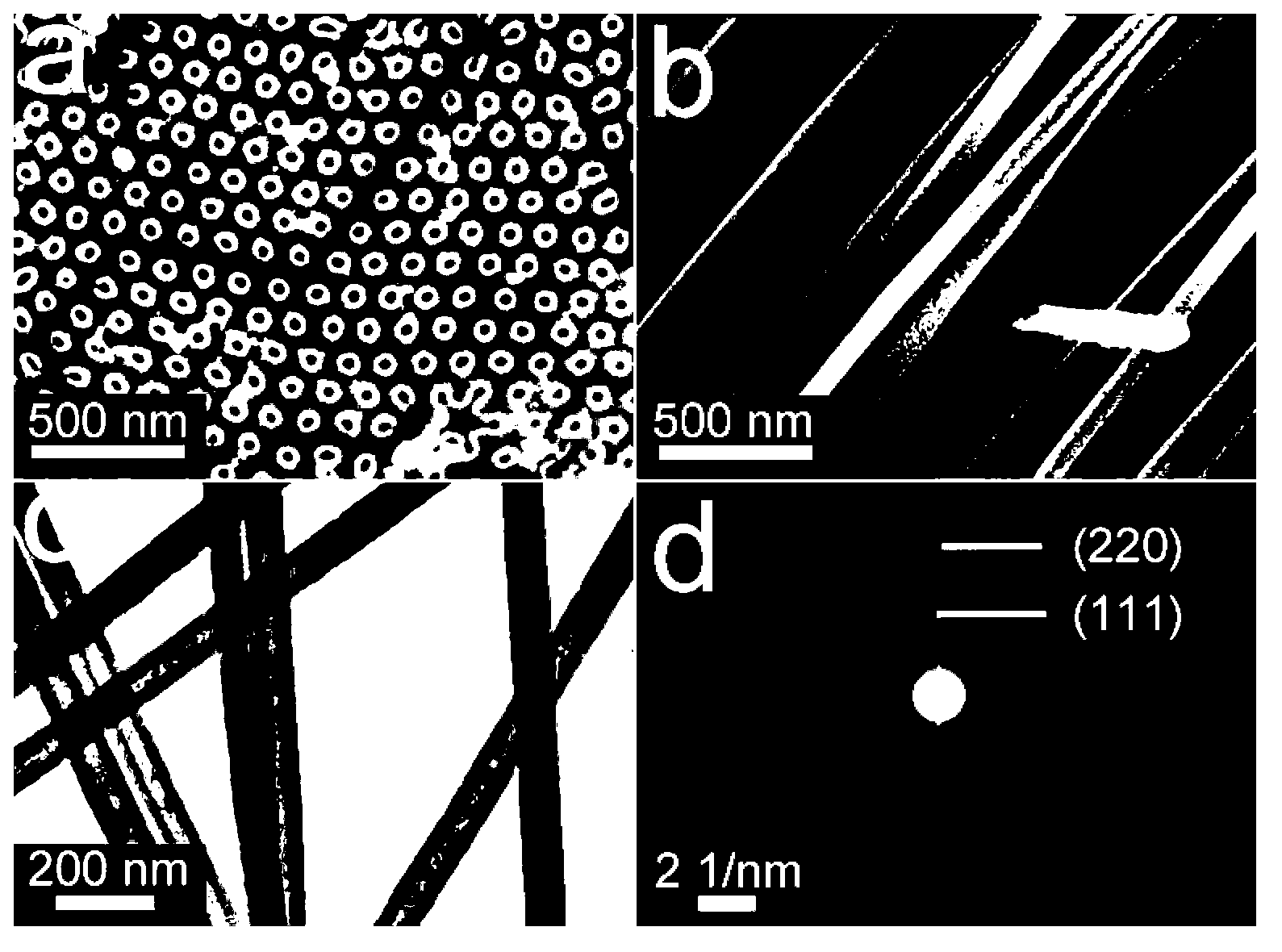

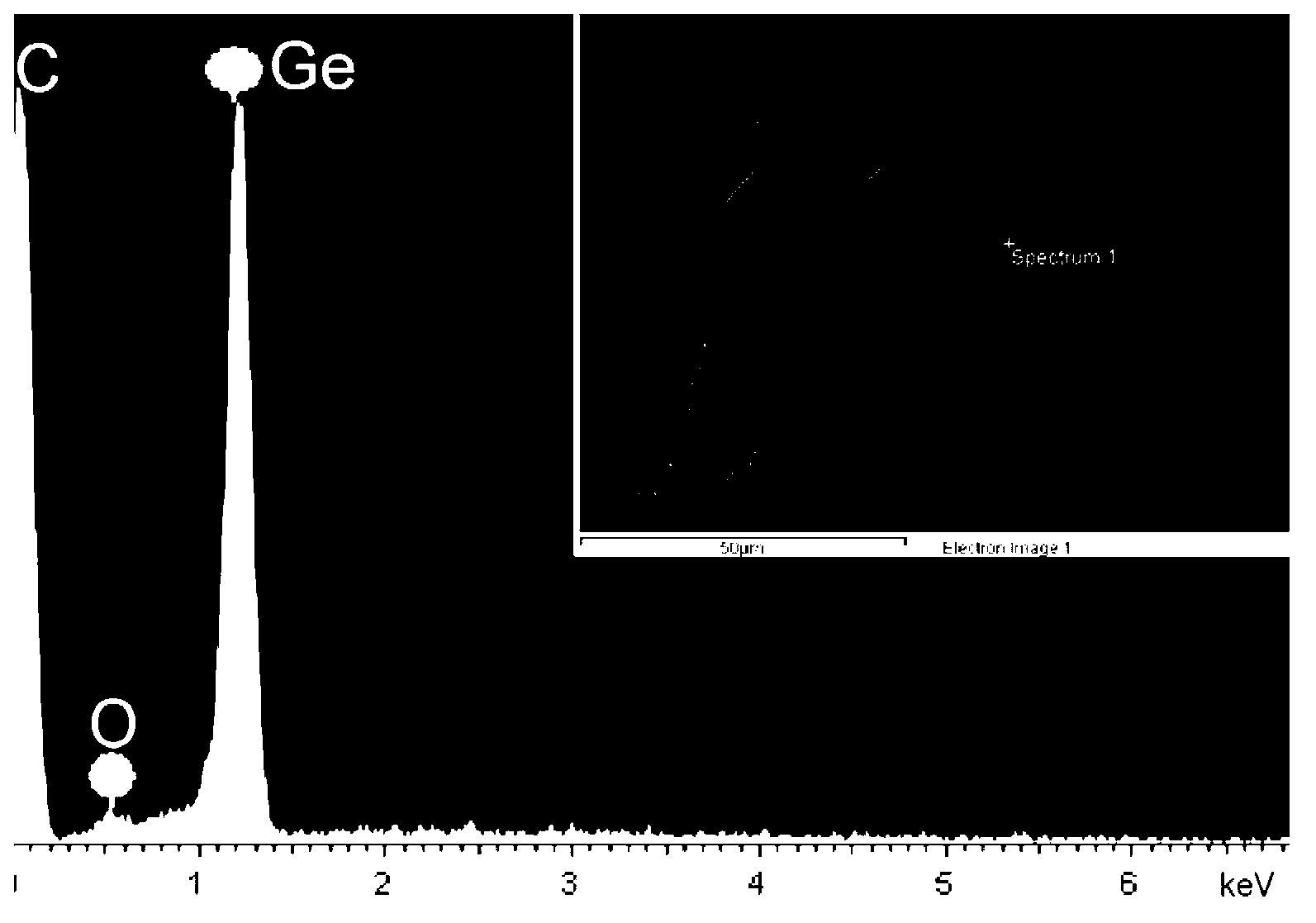

Method for preparing germanium nanotubes

A technology of nanotubes and germane, which is applied in the field of preparation of nanotubes, can solve the problems of complex processes, energy consumption, and time-consuming, and achieve the effects of simple and convenient processes, scientific preparation methods, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] In step 1, a through-hole alumina template with a pore diameter of 80 nm is firstly obtained by a secondary anodic oxidation method. Put the through-hole alumina template into the nickel nitrate aqueous solution with a concentration of 100g / L and soak for 60min, then use deionized water to rinse the surface of the through-hole alumina template to remove the nickel nitrate on the surface, and obtain the nickel nitrate in the hole. through-hole alumina stencil.

[0022] Step 2, first place the through-hole alumina template with nickel nitrate in the hole in a hydrogen-argon mixed atmosphere, and perform a reduction reaction at 300°C for 30 minutes; wherein, the heating rate to the reduction reaction temperature is 10°C / min. Then it was placed in a germane-hydrogen-argon mixed atmosphere, and vapor deposition was performed at 300° C. for 30 min; wherein, the germane, hydrogen and argon flow ratio in the germane-hydrogen-argo...

Embodiment 2

[0025] The concrete steps of preparation are:

[0026]In step 1, a through-hole alumina template with a pore diameter of 120 nm is firstly obtained by a secondary anodic oxidation method. Put the through-hole alumina template into the nickel nitrate aqueous solution with a concentration of 150g / L and soak for 53min, then use deionized water to rinse the surface of the through-hole alumina template to remove the nickel nitrate on the surface, and obtain the nickel nitrate in the hole. through-hole alumina stencil.

[0027] Step 2, first place the through-hole alumina template with nickel nitrate in the hole in a hydrogen-argon mixed atmosphere, and perform a reduction reaction at 320°C for 25 minutes; wherein, the heating rate to the reduction reaction temperature is 10°C / min. Then it was placed in a germane-hydrogen-argon mixed atmosphere, and vapor-phase deposited at 320°C for 25 minutes; wherein, the flow ratio of germane, hydrogen and argon in the germane-hydrogen-argon mi...

Embodiment 3

[0030] The concrete steps of preparation are:

[0031] In step 1, a through-hole alumina template with a pore diameter of 165 nm is firstly obtained by a secondary anodic oxidation method. Put the through-hole alumina template into the nickel nitrate aqueous solution with a concentration of 200g / L and soak for 45min, then use deionized water to rinse the surface of the through-hole alumina template to remove the nickel nitrate on the surface, and obtain the nickel nitrate in the hole. through-hole alumina stencil.

[0032] Step 2, first place the through-hole alumina template with nickel nitrate in the hole in a mixed atmosphere of hydrogen and argon, and perform a reduction reaction at 340°C for 20 minutes; wherein, the heating rate to the reduction reaction temperature is 10°C / min. Then it was placed in a germane-hydrogen-argon mixed atmosphere, and vapor deposition was performed at 340° C. for 20 min; wherein, the germane, hydrogen and argon flow ratio in the germane-hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com