Nano crystal silicon and non crystal germanium mixed absorption layer for multi-node light voltage part based on film silicon

A nanocrystalline silicon and photovoltaic device technology, applied in photovoltaic power generation, semiconductor devices, electrical components, etc., can solve the problem of low open circuit voltage, poor stability, and high defect density of amorphous silicon germanium solar cells. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

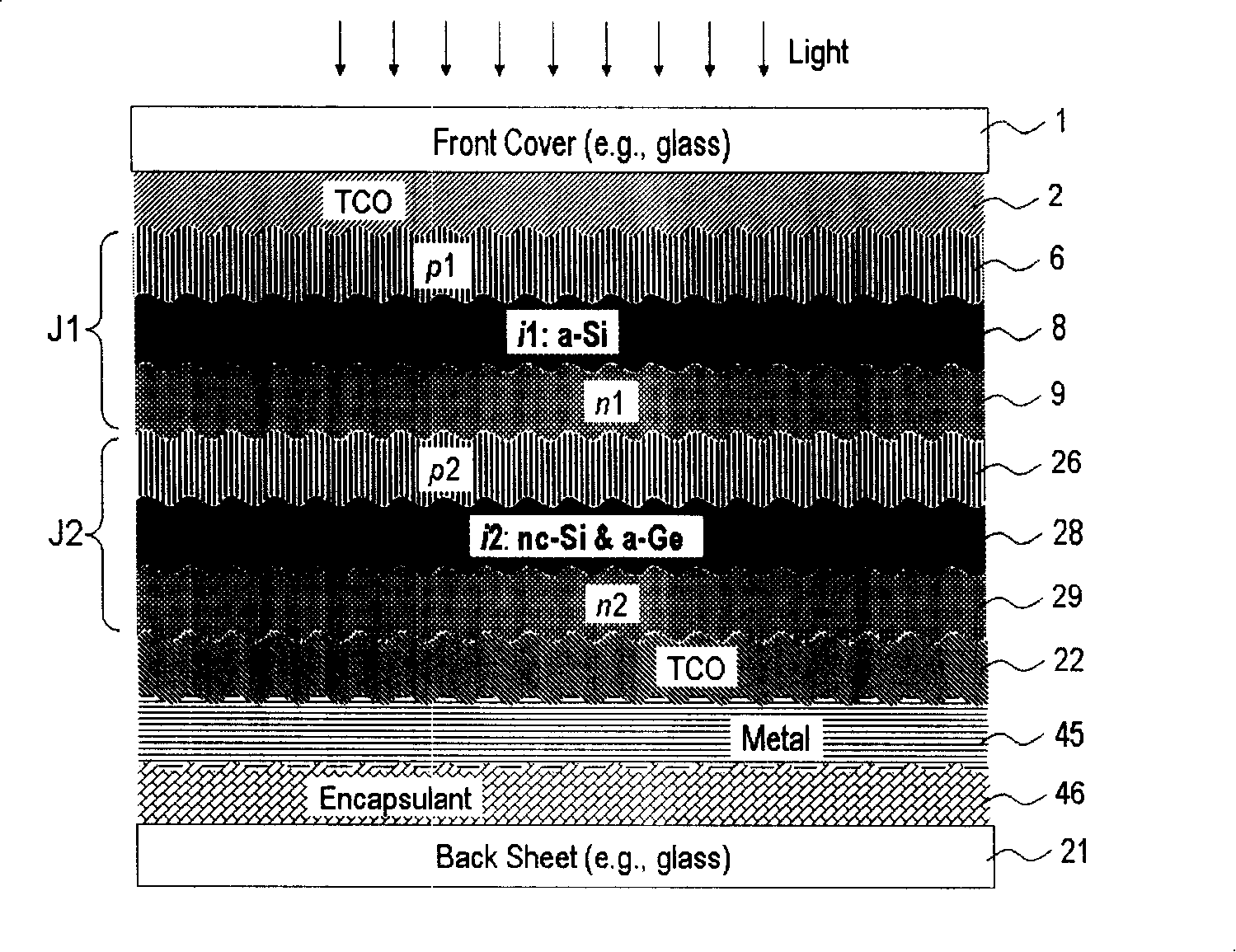

[0038] Figure 2 relates to a double-junction thin-film silicon-based photovoltaic device. The device comprises two junction photovoltaic cells, a junction top cell 6-8-9 (p1-i1-n1) and a junction bottom cell 26-28-29 (p2-i2-n2). The double-junction photovoltaic cell is placed on a transparent electrode 2 supported by a substrate 1 . Transparent electrodes are generally made of fluorine-doped tin oxide (SnO 2 ) such a transparent conductive oxide (TCO) film. The rough (textured) surface of tin oxide is suitable for scattering light, thus enhancing the light absorption capacity of the photovoltaic layer. The transparent conductive oxide film layer 22 and the metal film layer 45 together form the light reflective electrode on the back of the photovoltaic device. This device is encapsulated in film layer 46 and protective film 21 . The p1 layer 6 material of the top cell is usually a boron-doped wide-bandgap amorphous silicon alloy, such as amorphous silicon carbon, amorphous ...

Embodiment 2

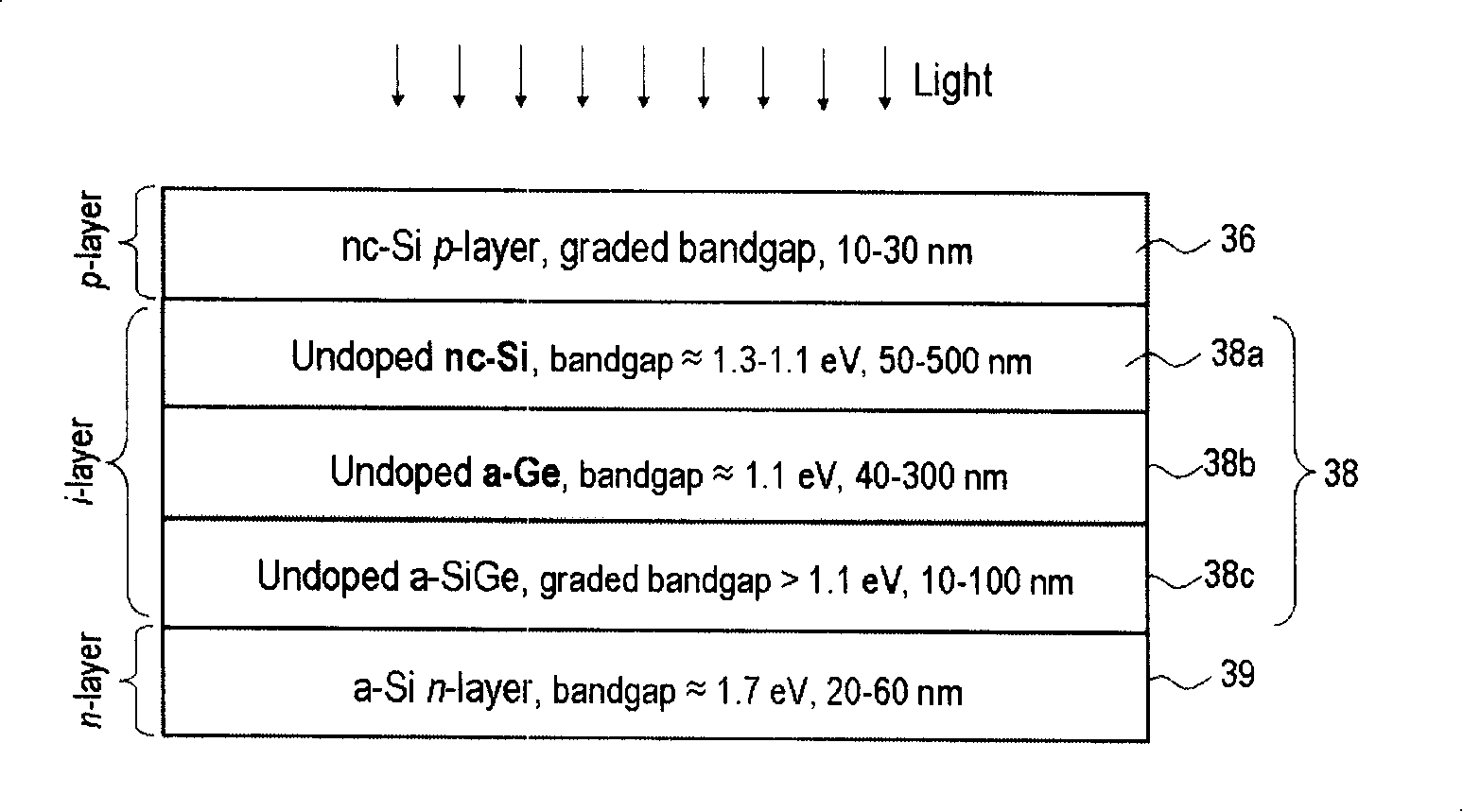

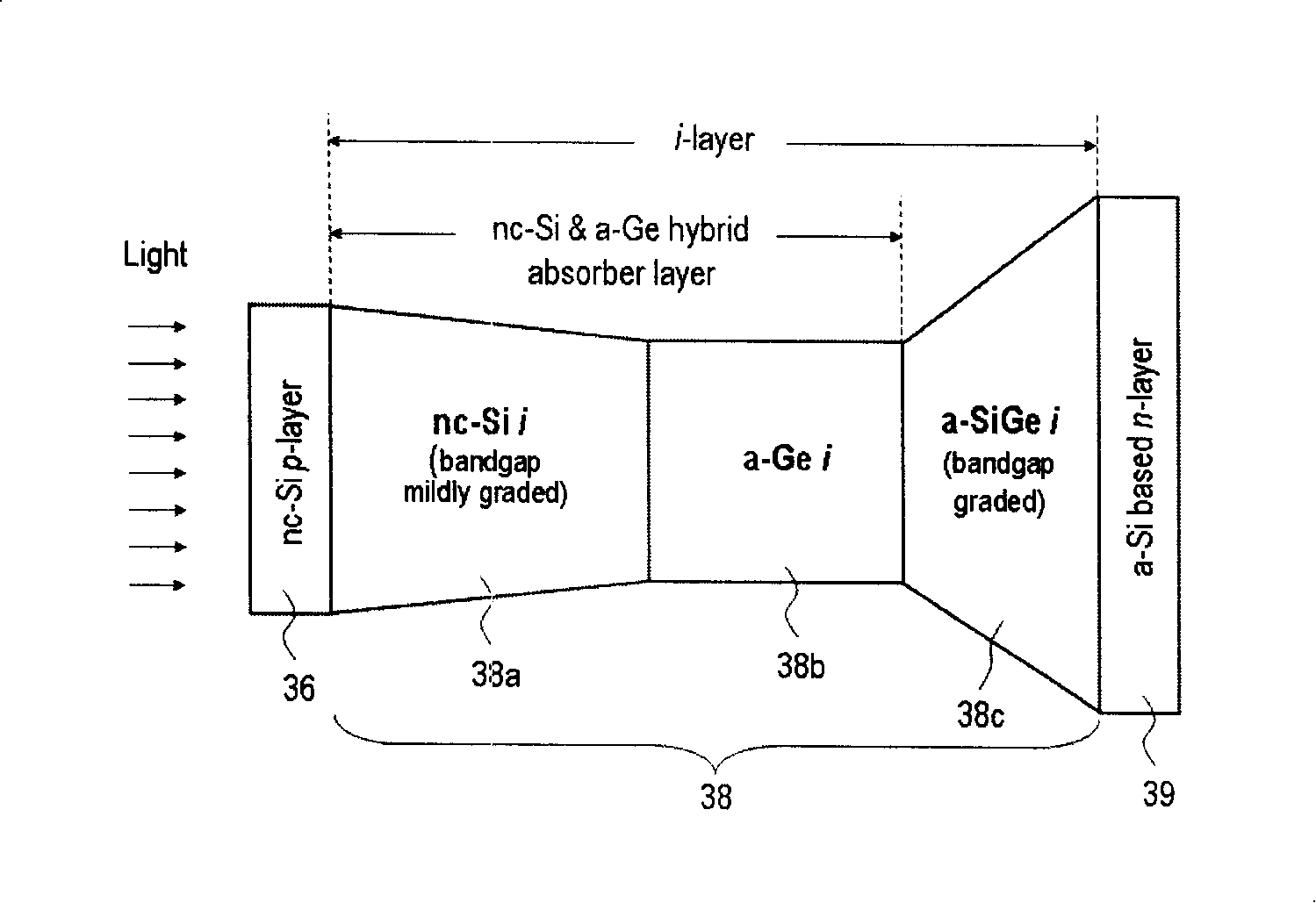

[0042] A triple-junction photovoltaic device based on thin-film silicon consists of three stacked p-i-n photovoltaic cells with the same optical path and the same electrical path. The bandgaps of the i-layers in each junction photovoltaic cell can be the same but preferably are different. Such as image 3 As shown, a triple-junction thin-film silicon-based photovoltaic device includes three p-i-n cells J1, J2 and J3 arranged together. The front electrode 2 is deposited on the substrate 1, the light-reflecting electrodes 22 and 45, the encapsulant 46 and the back protection sheet 21 are the same as in the double junction photovoltaic device shown in FIG. 2 . The top, middle and bottom cells contain p1-i1-n1(6-8-9), p2-i2-n2(26-28-29), and p3-i3-n3(36-38-39), respectively. The absorber or intrinsic layers i1, i2(8,28) of the top and middle cells are preferably made of amorphous silicon and amorphous silicon germanium, or amorphous silicon and nanocrystalline silicon (amorphous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com