Process for producing SiC single crystal

一种制造方法、单晶的技术,应用在单晶生长、单晶生长、化学仪器和方法等方向,能够解决无助于降低等问题,达到提高C过饱和度、高速生长的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Growth of SiC single crystal was carried out in the following procedure.

[0039] Basic Crystal Growth Process

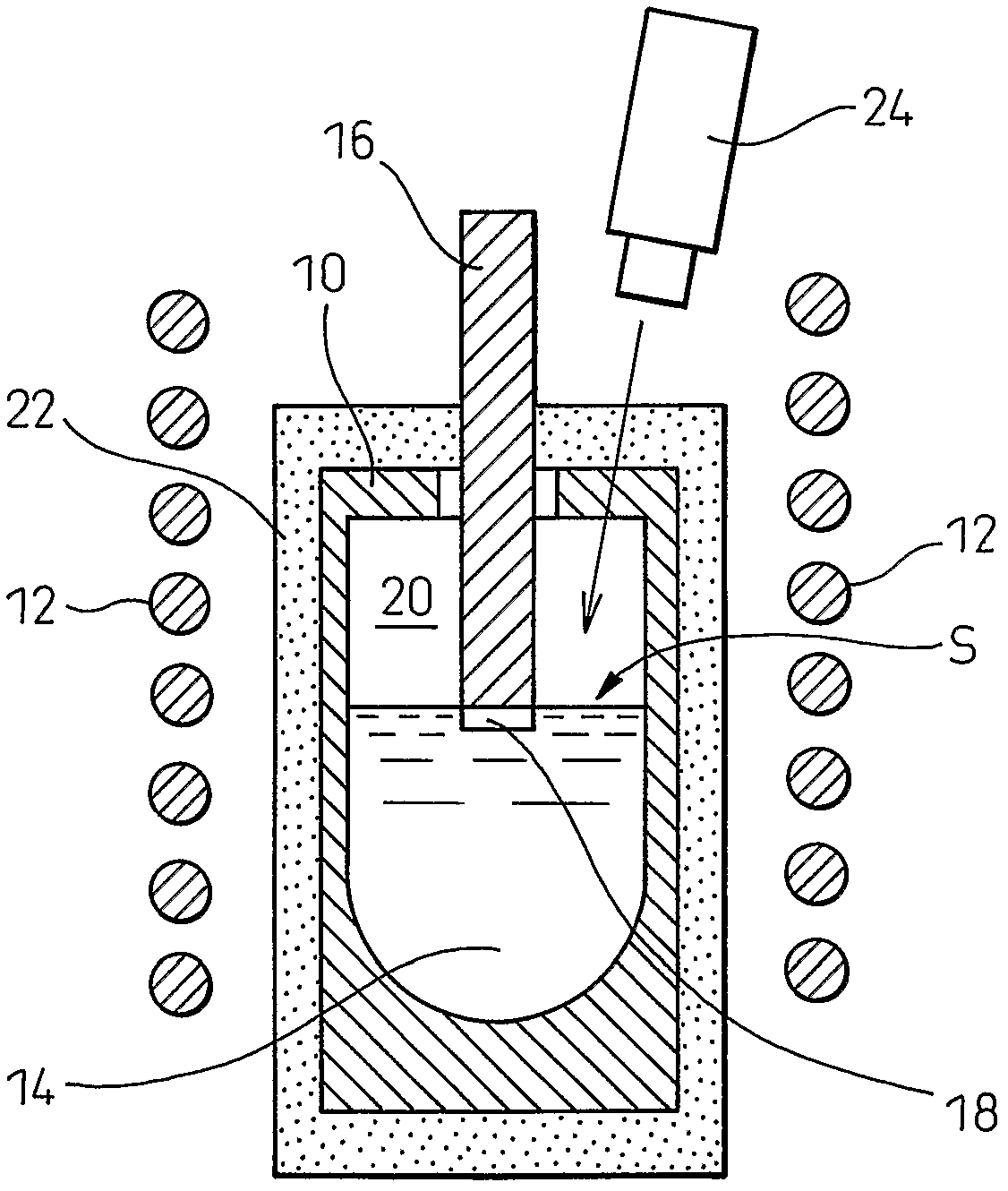

[0040] · Growth preparation (refer to figure 1 )

[0041] (1) The 4H—SiC seed crystal 18 is bonded to the support shaft 16 made of graphite.

[0042] (2) Putting raw materials into the graphite crucible 10 .

[0043] (3) Put them as figure 1 constituted as shown.

[0044] (4) Ar20 at atmospheric pressure is introduced.

[0045] (5) Raise the temperature to the desired temperature.

[0046] ·Seed contact

[0047] (1) When the temperature of the melt 14 reaches a sufficient temperature, the support shaft 16 is lowered.

[0048] (2) The seed crystal 18 is brought into contact with the melt 14, the shaft 16 is lowered to a desired depth (*), and then the shaft is stopped. (*: In the present embodiment, stop at the position where the seed crystal 18 touches the liquid surface of the melt 14. In general, the seed crystal 18 sometimes sinks into the melt 14...

Embodiment 1

[0073] The growth temperature was set at 1800° C., and the seed crystal contact was performed when the temperature was raised to this temperature. After the contact of the seed crystal, the temperature was raised to 1900°C, and then the temperature was lowered to the growth temperature of 1800°C, and the growth was carried out for 1 hour. The etch pit density of the obtained crystal is the same as that of the seed crystal (1×10 4 cm -2 ).

[0074] The technological process of embodiment 1 is shown in Figure 6 . In the form (A), the seed crystal contact was performed after maintaining the temperature at the growth temperature of 1800° C., and in the form (B), the seed crystal contact was performed without maintaining the temperature at the growth temperature. Any of the forms (A) and (B) may be used as long as the process H of temporarily raising the temperature is performed after the contact of the seed crystals.

[0075] Table 1 summarizes the results obtained in the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| dislocation density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com