Growing device of gas inner circulation type hot wire chemical vapor deposition (CVD) diamond films

A diamond film and growth device technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of small growth area, low growth rate, low film quality, etc., to reduce consumption, hydrogen The effect of consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

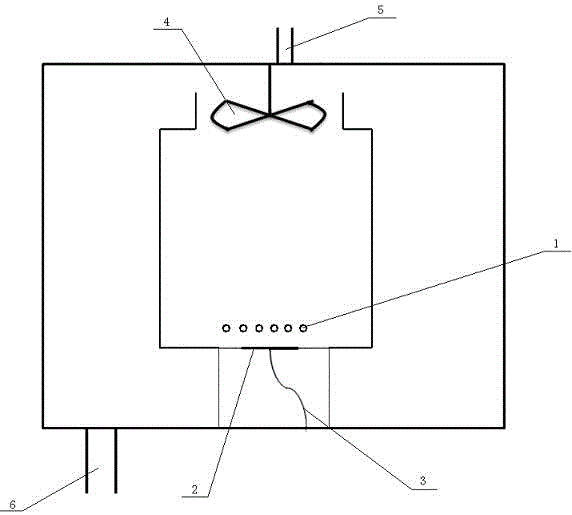

[0014] A gas internal circulation type hot wire CVD diamond film growth device, the device includes a closed vacuum chamber with a reaction chamber inside. A fan 4 is arranged on the top of the inner wall of the reaction chamber, and a hot wire array 1 composed of multiple parallel straight tungsten wires is arranged under the fan 4; 2 is provided with a thermocouple 3; the outer wall of the vacuum chamber above the side of the fan 4 is provided with an air inlet 5;

[0015] Wherein: the air intake flow rate of the air inlet 5 and the suction flow rate of the air extraction port 6 are both 0~200 sccm.

[0016] During work, the pre-cleaned silicon wafer substrate is placed on the substrate tray 2, and then the pressure in the reaction chamber is pumped to 10 with a mechanical pump and a molecular pump. -3 ~10 -4 Pa. Heat the wire array 1 to 1800~2000°C by increasing the voltage of direct current, and inject 200 sccm of CH from the air inlet 5 4 +H 2 (The volume ratio is 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com