Patents

Literature

46 results about "Lignocellulosic hydrolysates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lignocellulosic hydrolysates as feedstocks for isobutanol fermentation

InactiveUS20130035515A1Improved production of butanolOrganic compound preparationBiofuelsCelluloseIsobutanol

The invention relates generally to the field of industrial microbiology and butanol production from sources of 5-carbon sugars such as lignocellulosic hydrolysates. More specifically, the invention relates to the use of an xylulose or xylulose-5-phosphate-producing enzyme and micro-aerobic or anaerobic conditions to increase butanol production from such sugars and recovery of said butanol through ins situ product recovery methods.

Owner:BUTAMAXTM ADVANCED BIOFUELS

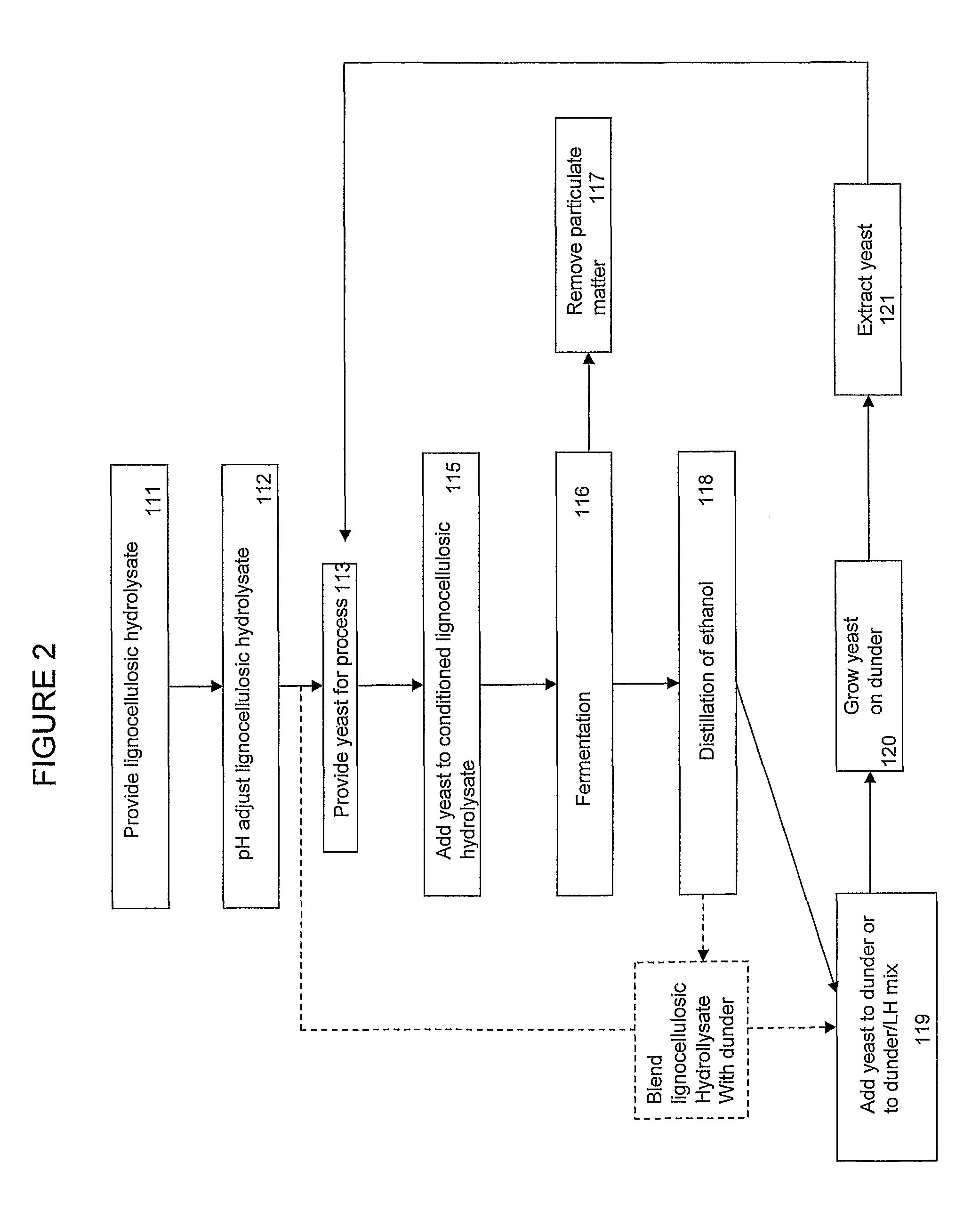

Method of producing yeast biomass

InactiveUS20110183394A1Reduces biological oxygen demandReducing chemical and biological oxygen demandFungiBiofuelsCelluloseYeast biomass

The invention relates to use of a substrate comprising C5 compound-containing material, in the growth of Saccharomyces yeast or the production of a product of Saccharomyces yeast, wherein the C5 compound-containing material is: (a) C5 compound-containing material obtained from lignocellulosic hydrolysate; (b) C5 compound-containing material obtained from fermentation of lignocellulosic hydrolysate; or (c) a mixture of (a) and (b). The invention also relates to a method of producing Saccharomyces yeast biomass or a product of Saccharomyces yeast using the substrate, and to methods of producing ethanol comprising incubating Saccharomyces yeast produced by the use or method. The invention further relates to strains of Saccharomyces yeast suitable for the use or methods.

Owner:MICROBIOGEN PTY LTD

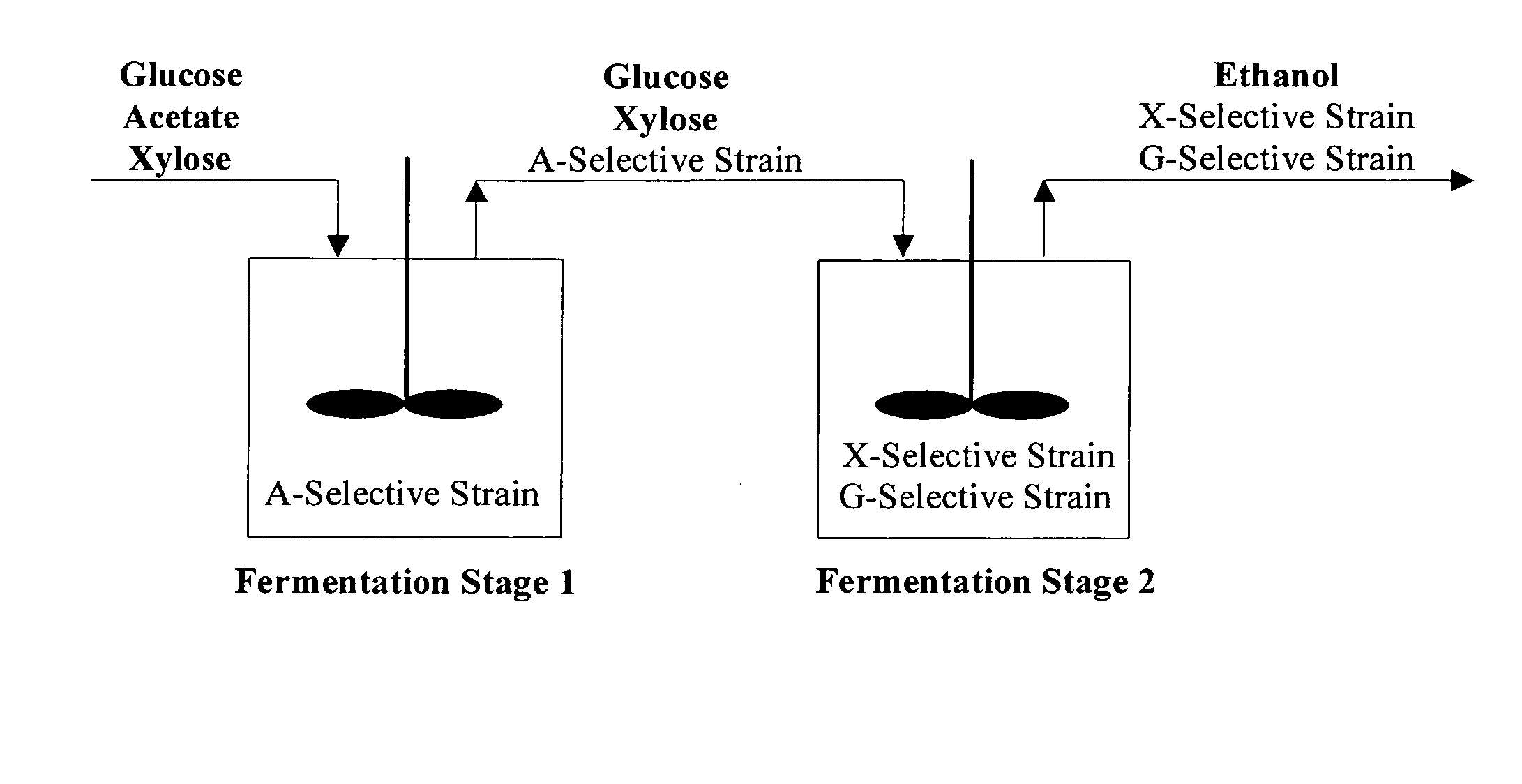

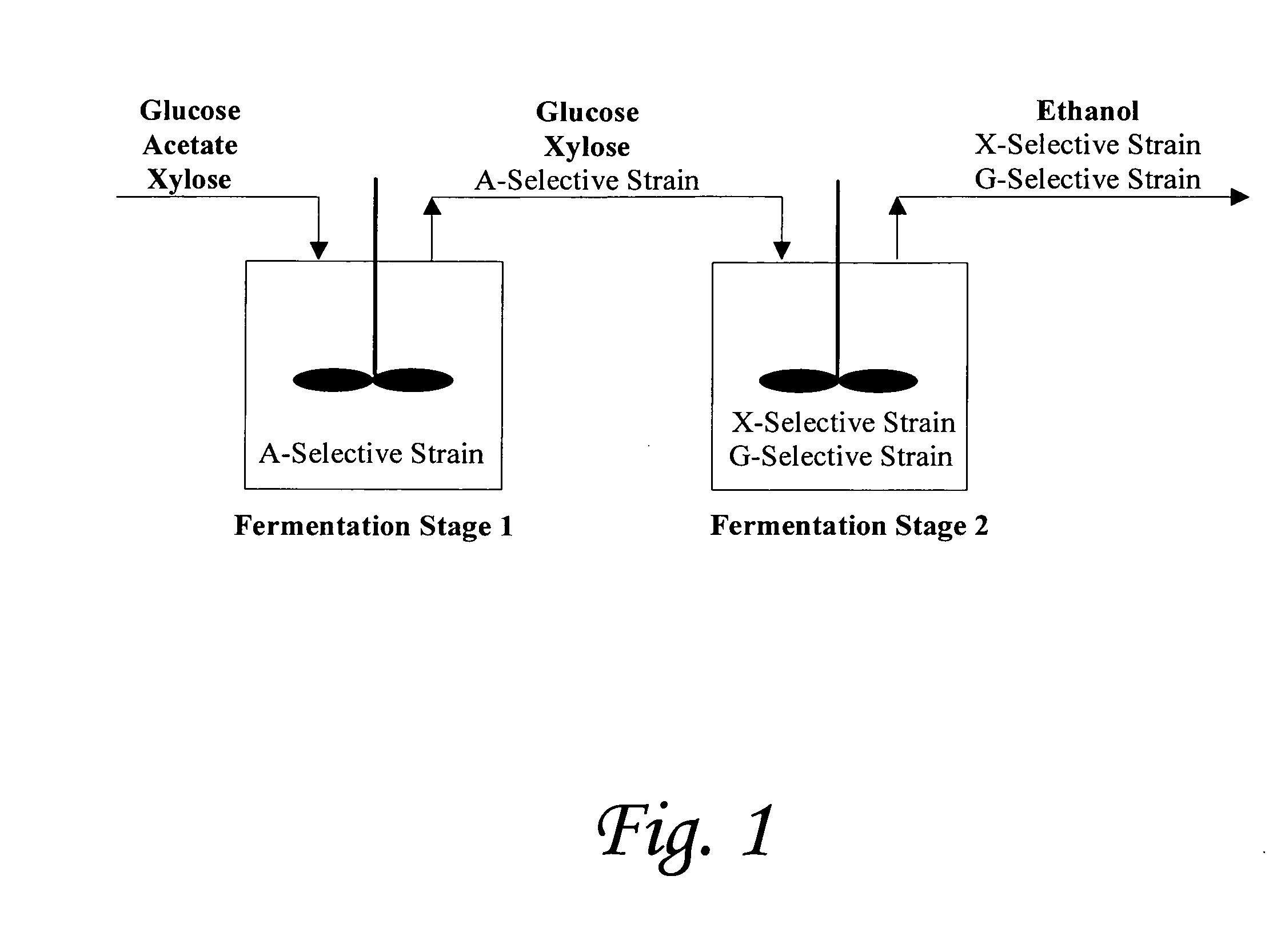

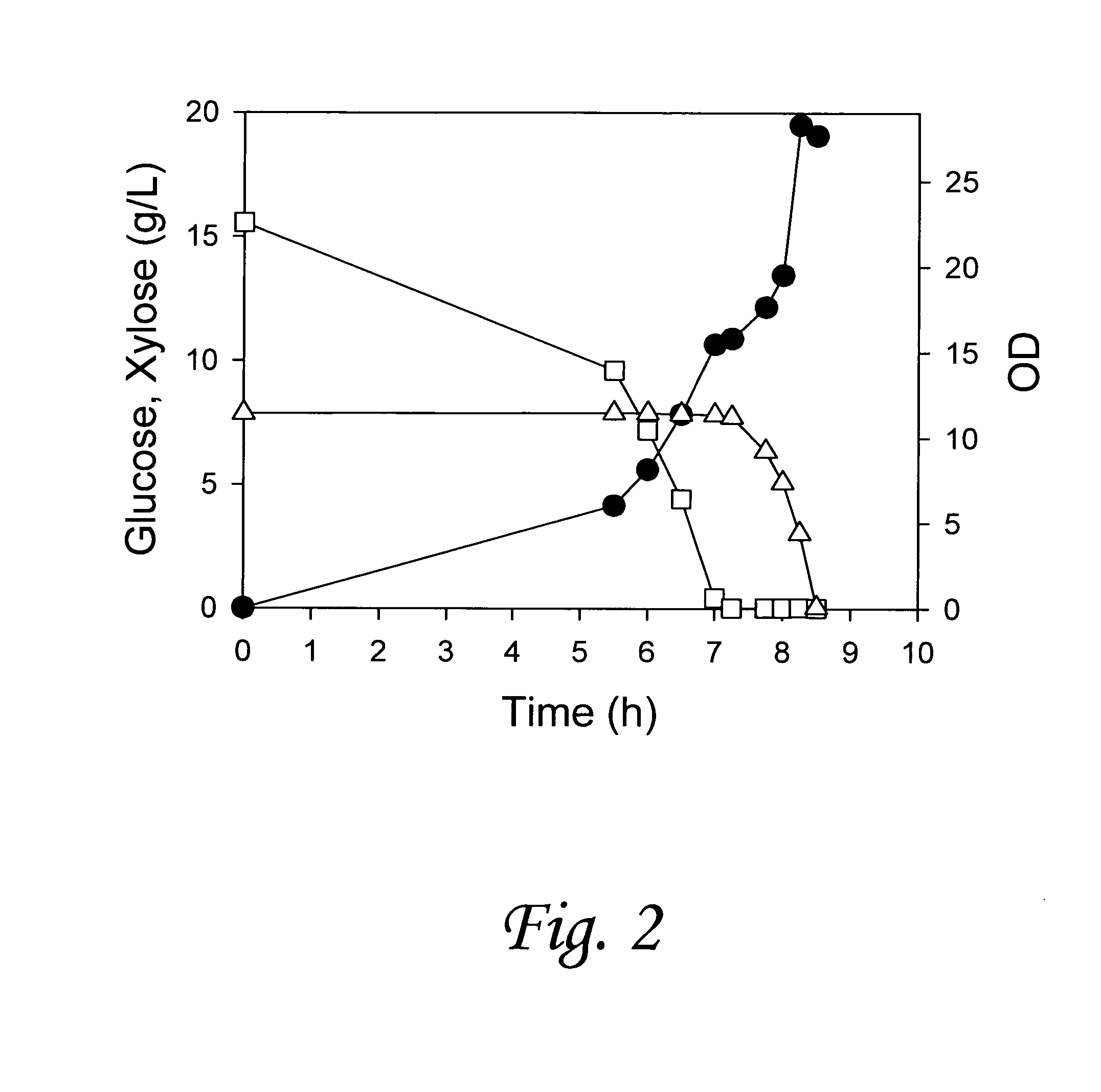

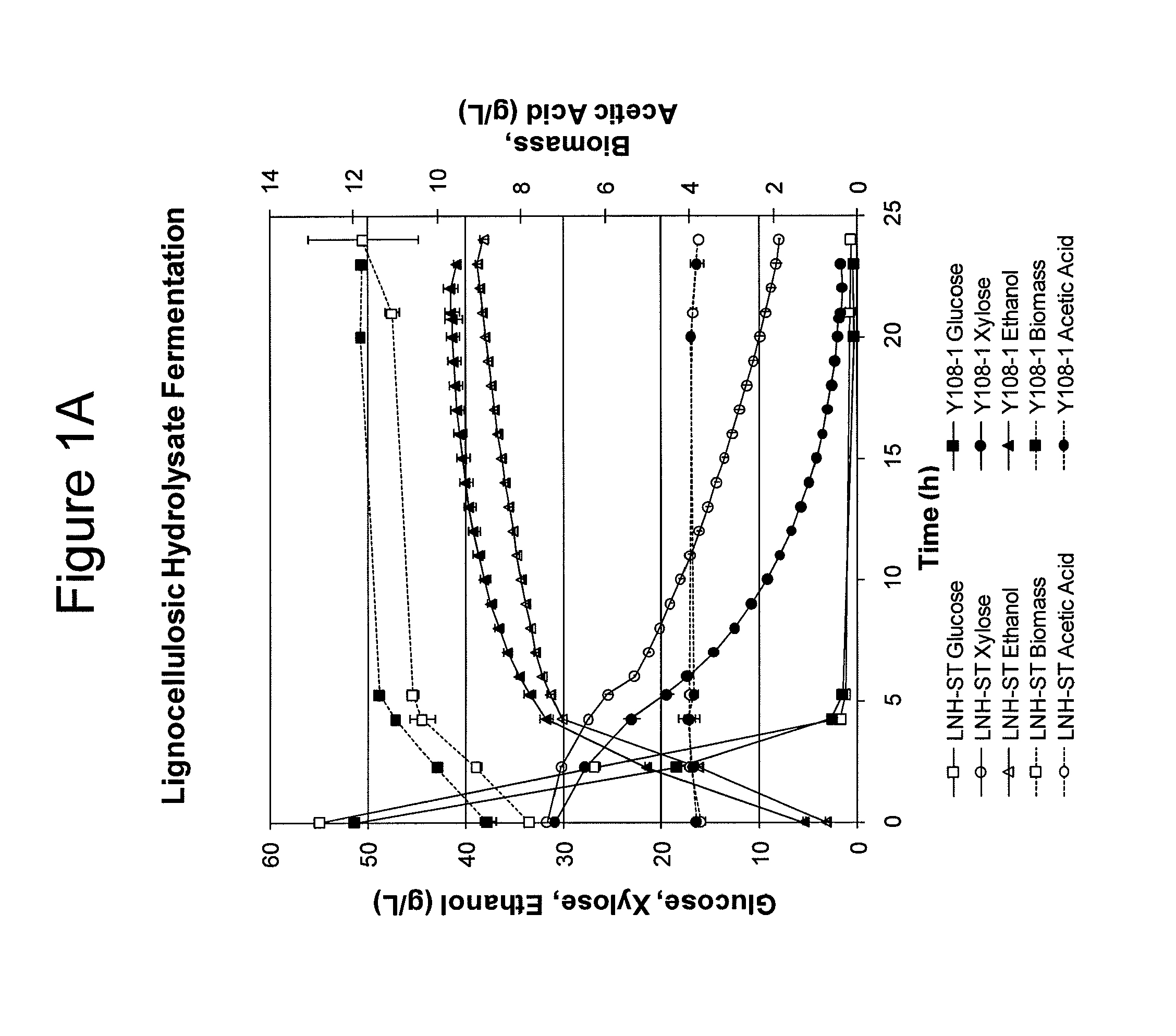

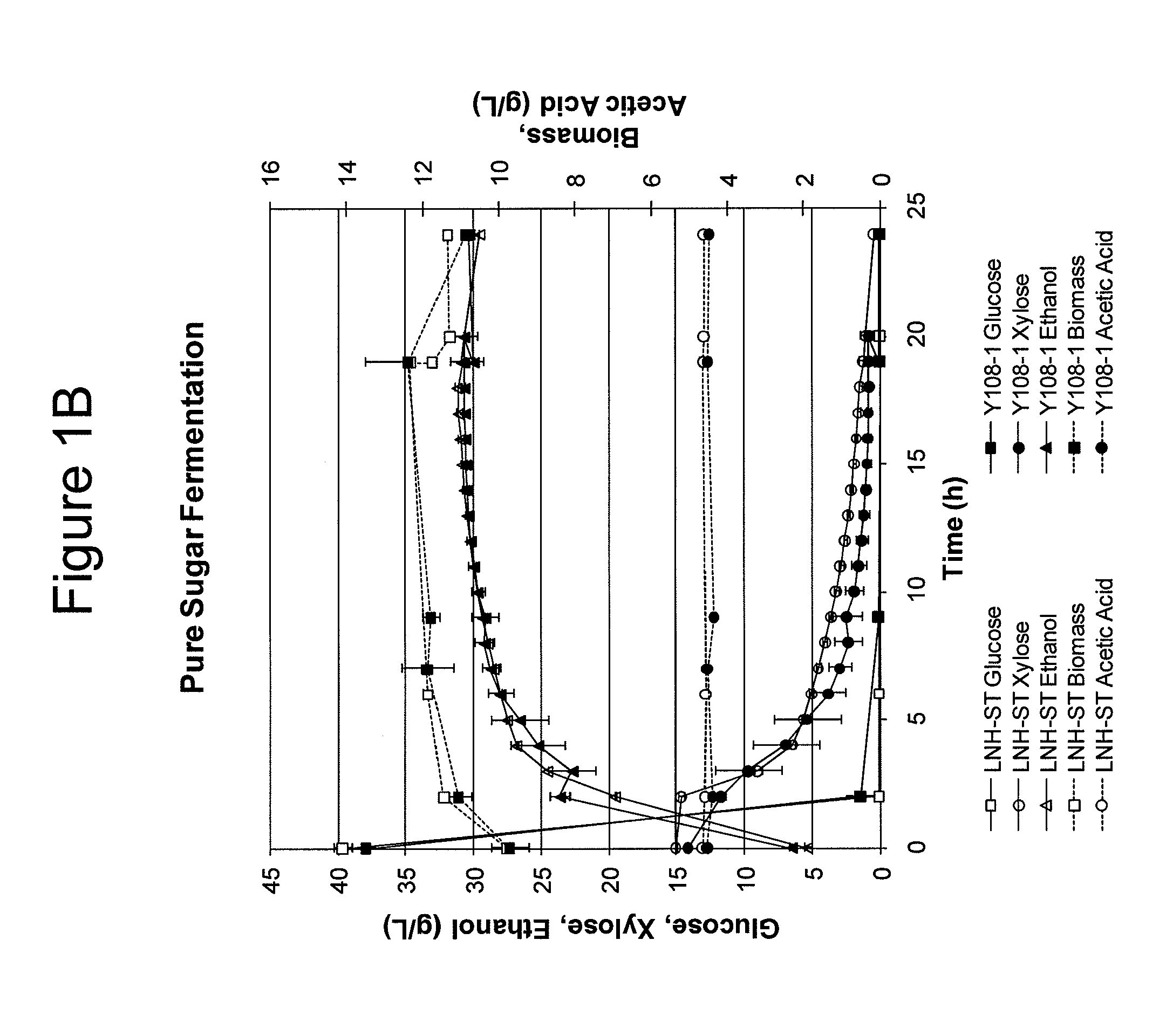

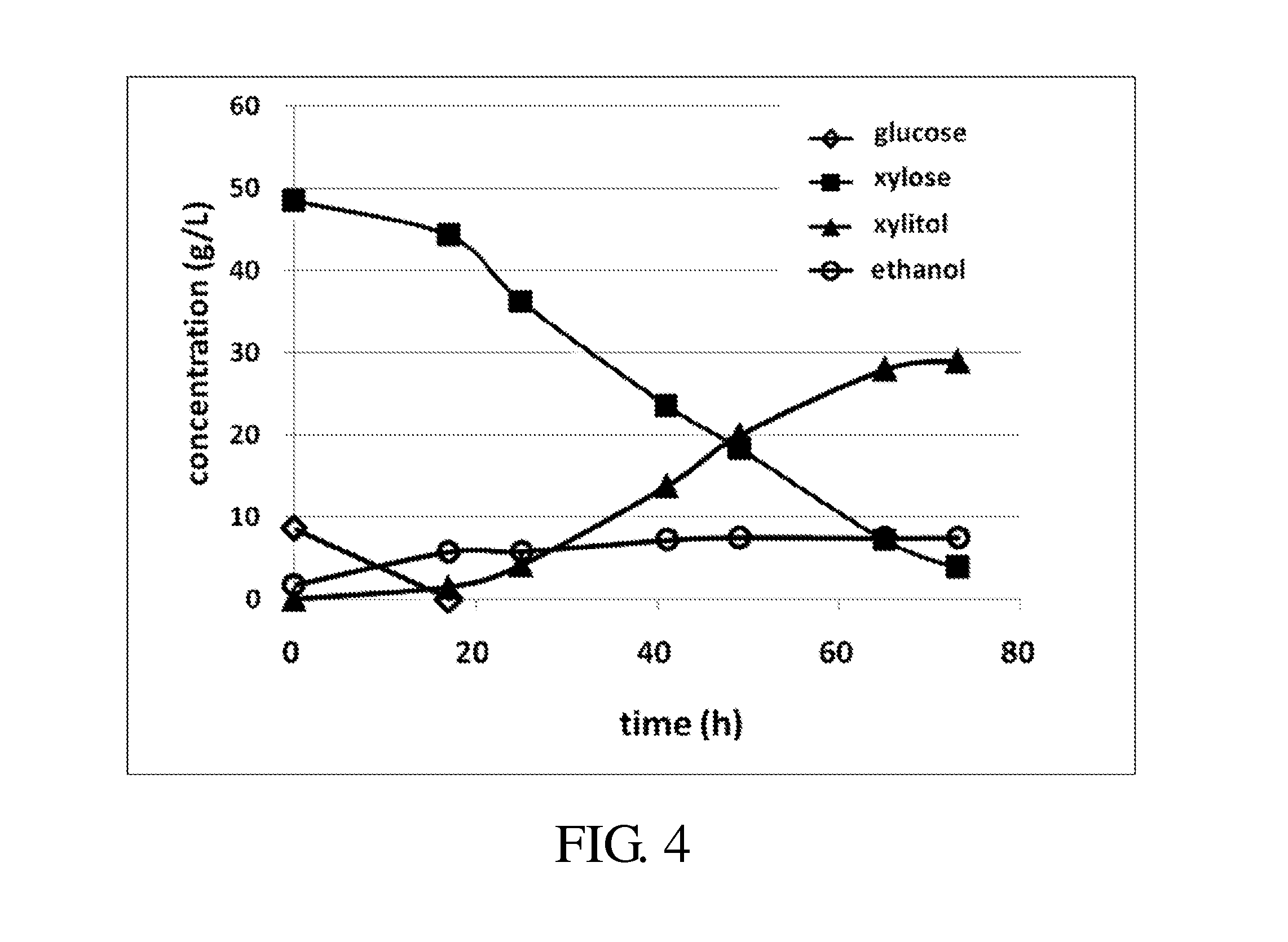

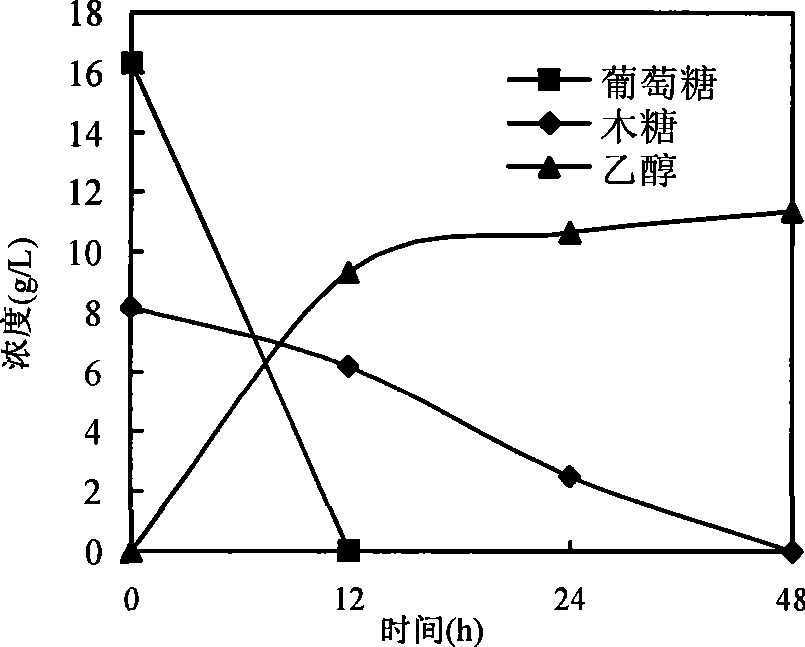

Substrate-selective co-fermentation process

Biological method for conversion of a lignocellulosic hydrolysate into a desired biochemical product. Use of a plurality of substrate-selective cells allows different sugars in a complex mixture to be consumed concurrently and independently. The method can be readily extended to remove inhibitory compounds from hydrolysate.

Owner:UNIV OF GEORGIA RES FOUND INC

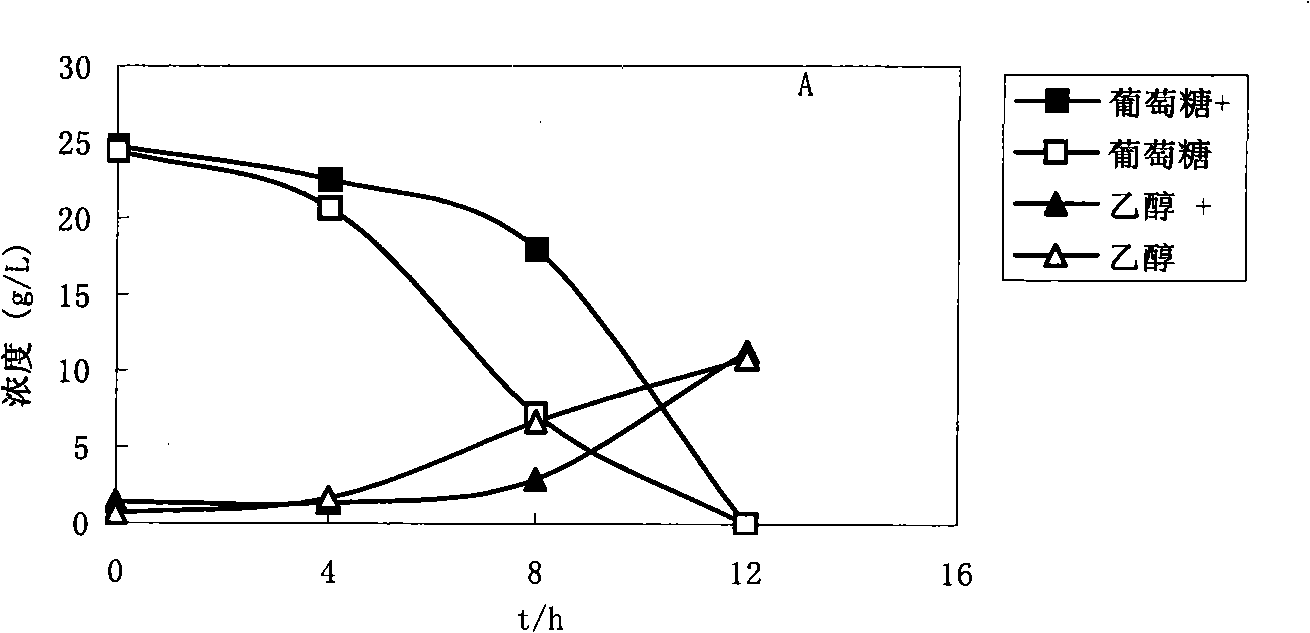

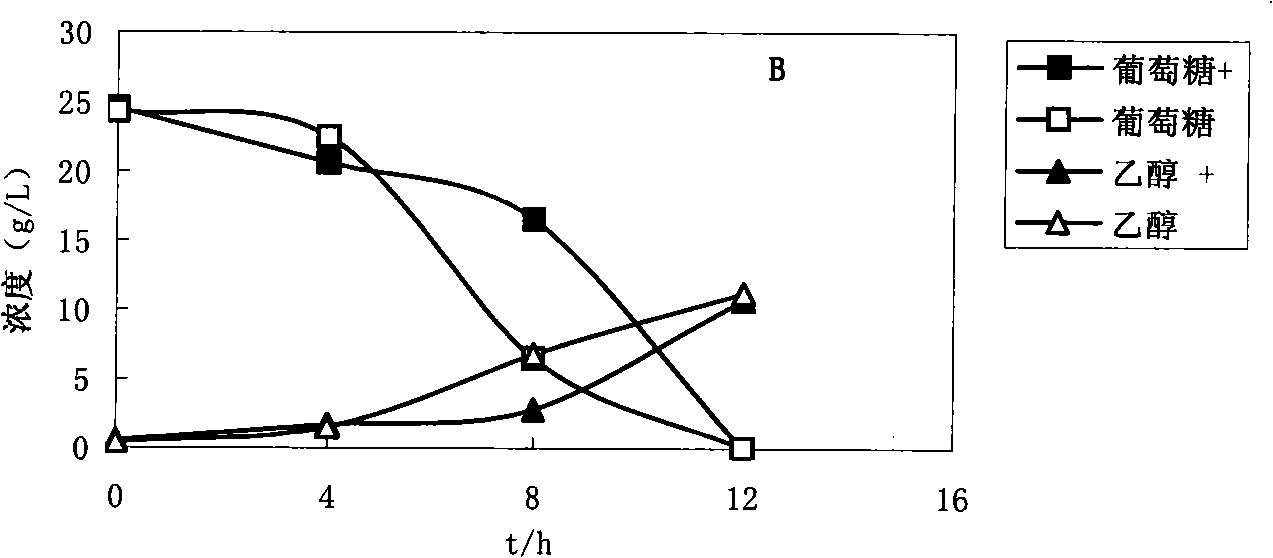

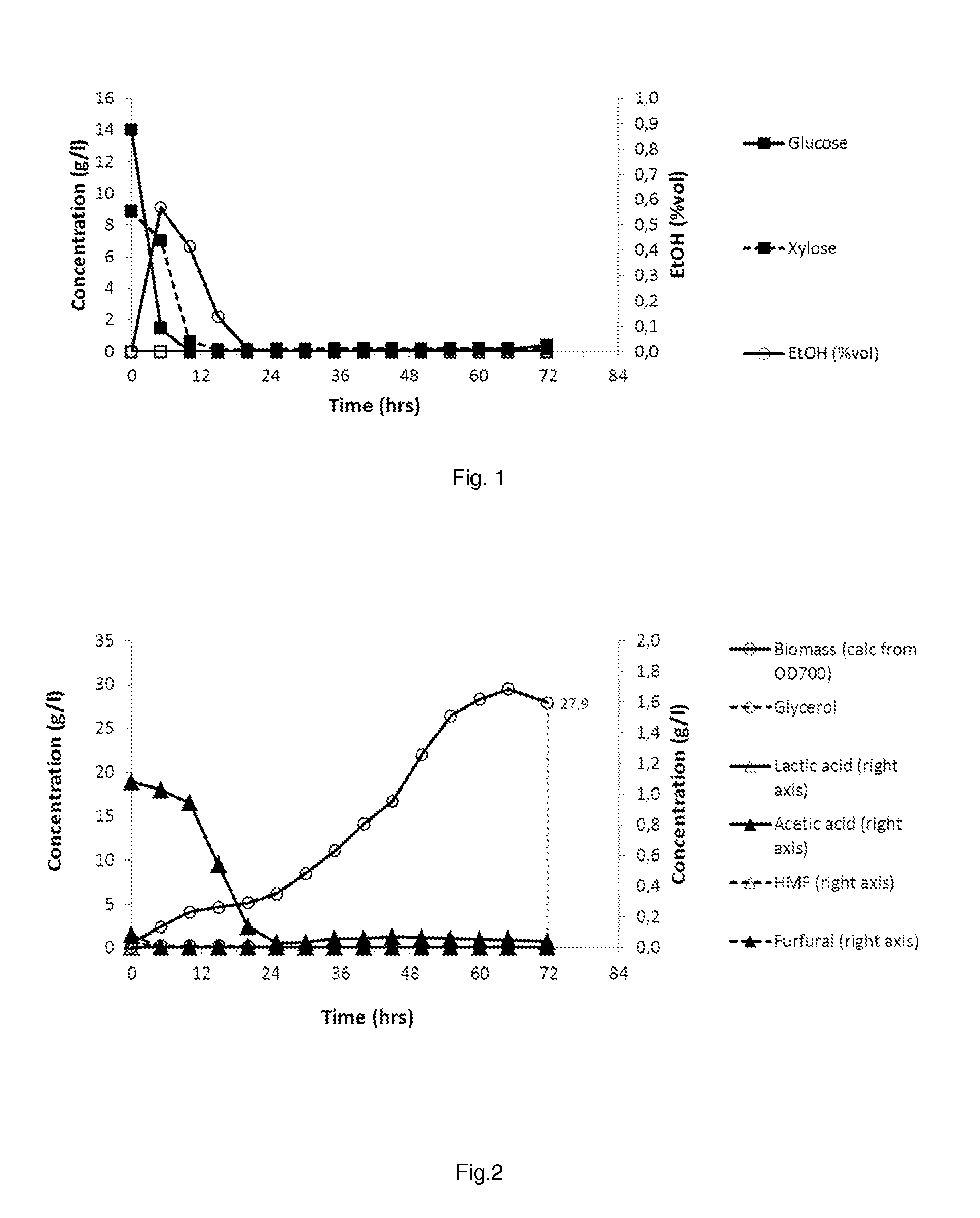

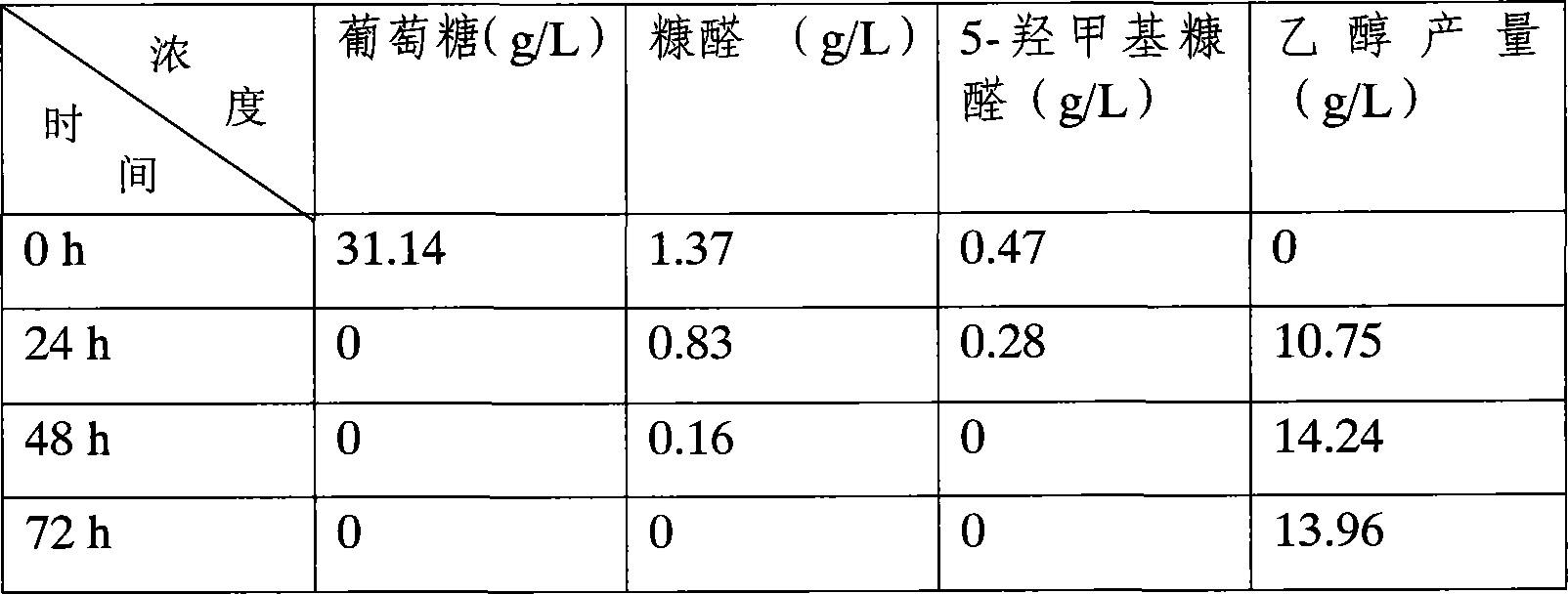

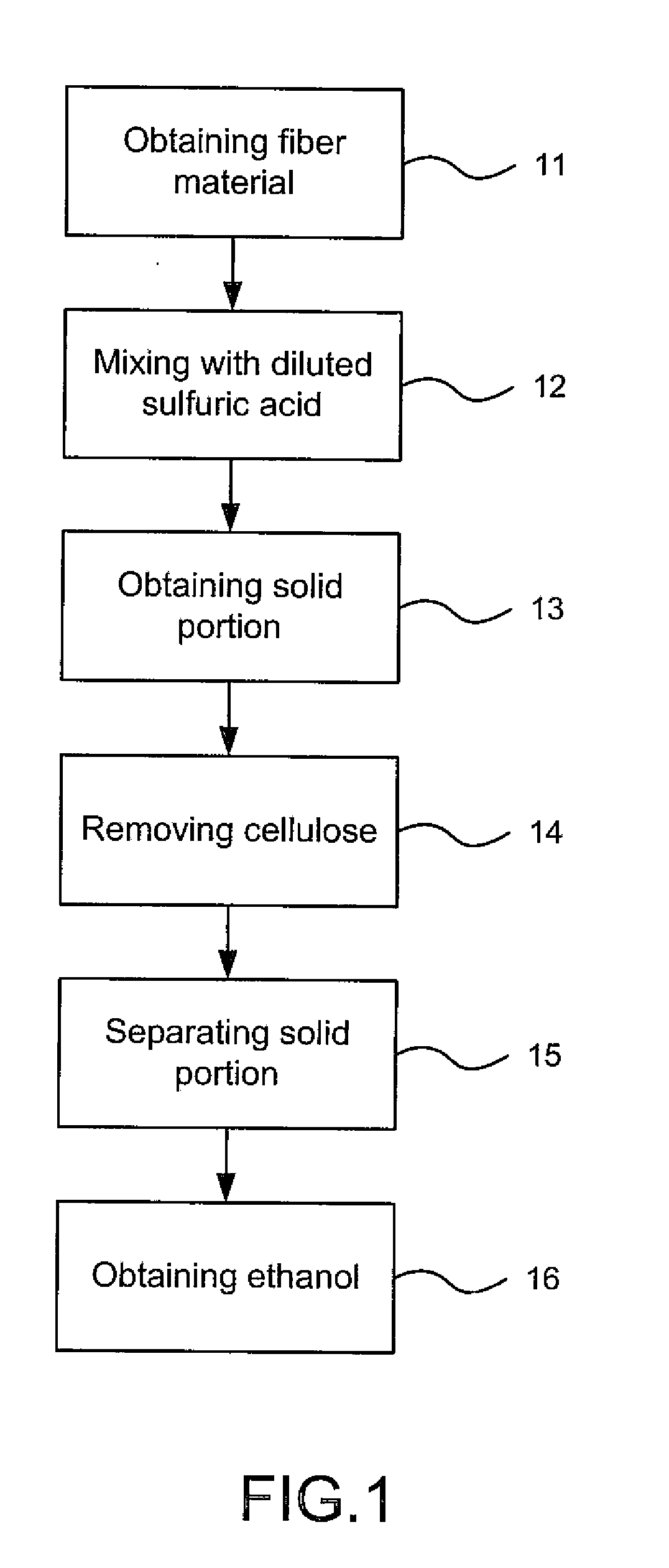

Virus-free in situ and alcohol fermentation method of composite bacteria for lignocellulose hydrolysis product

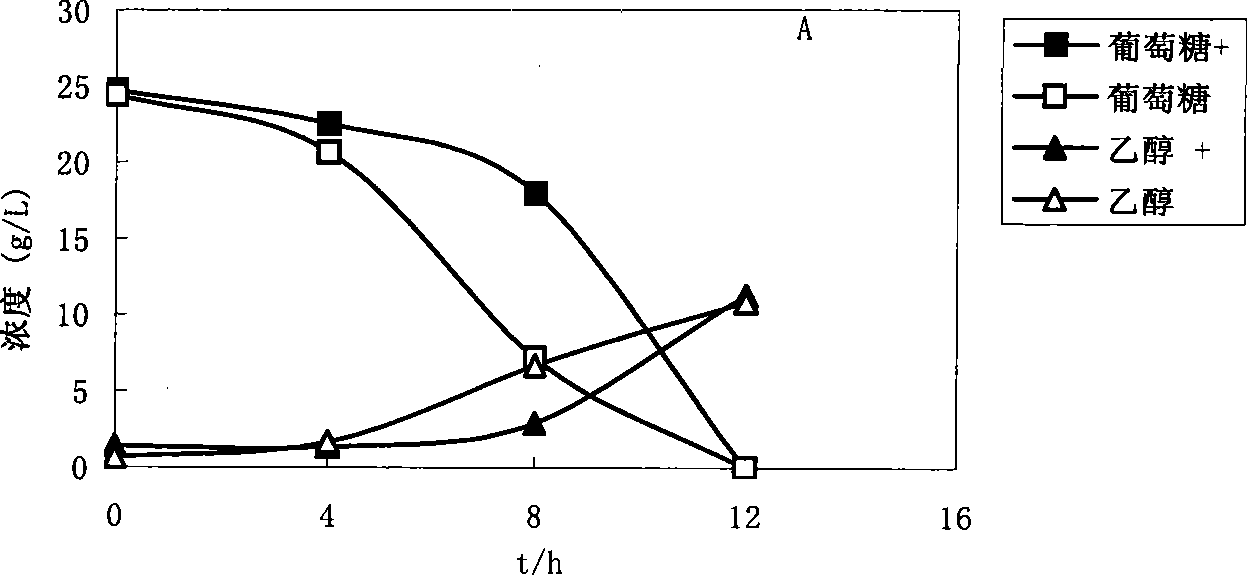

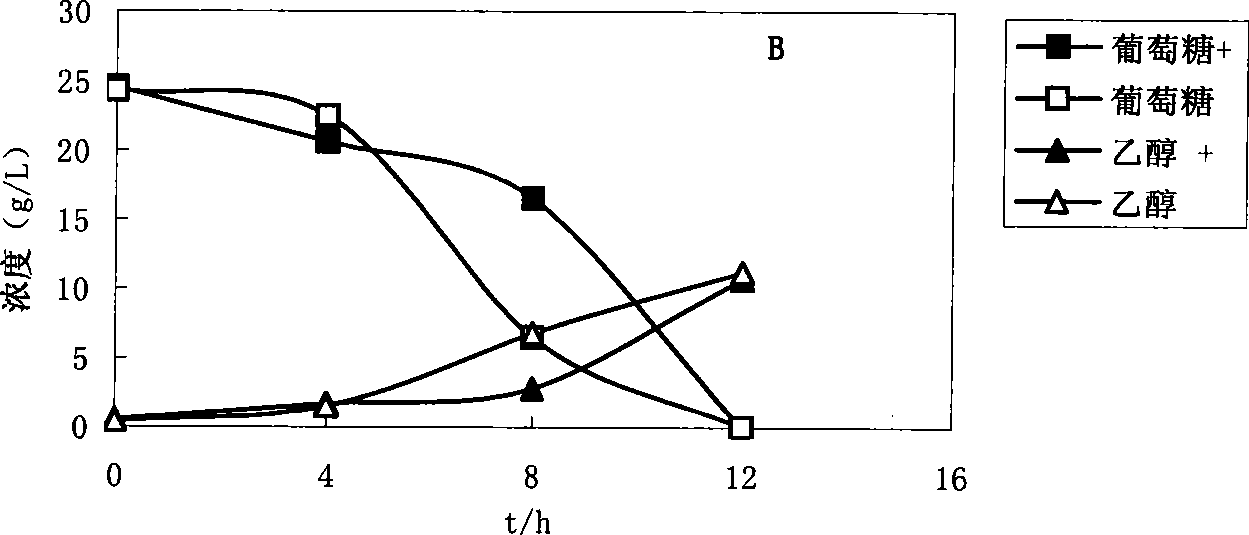

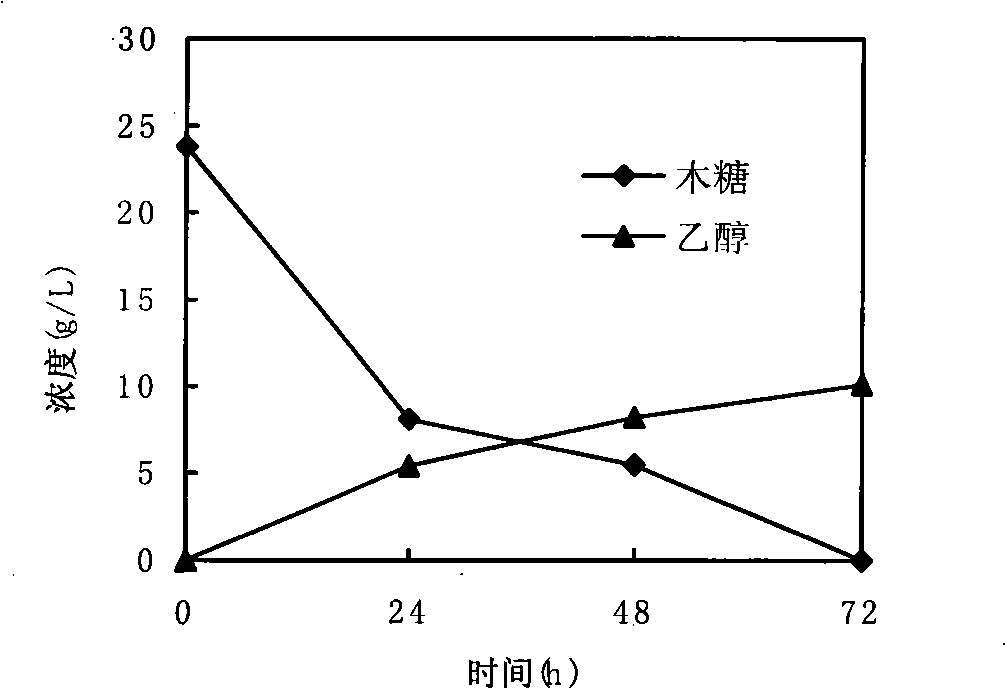

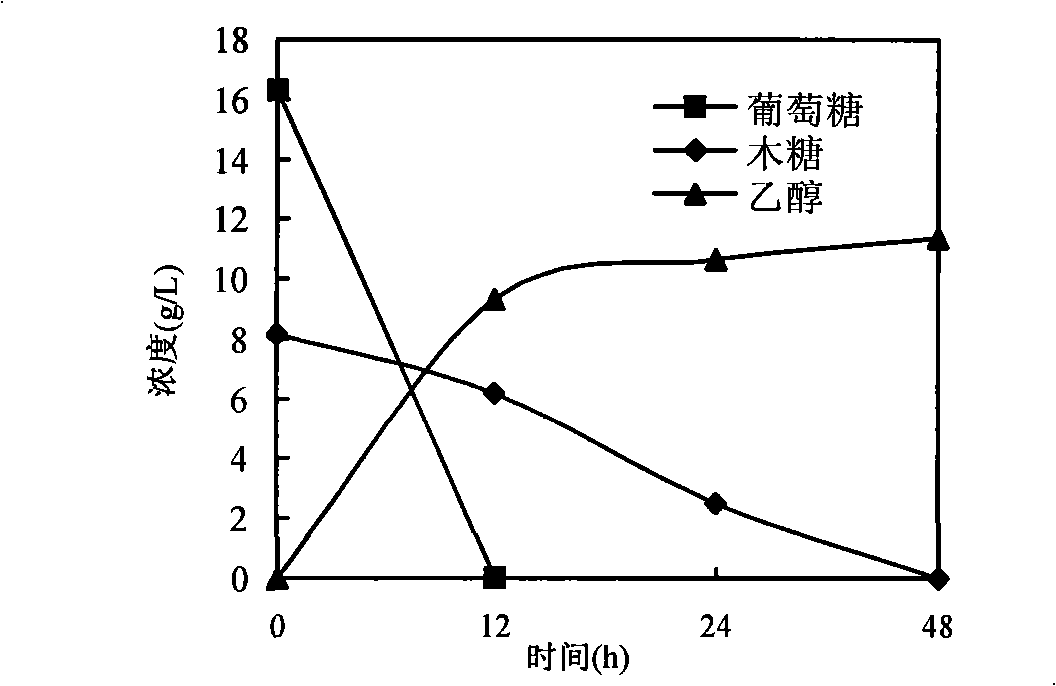

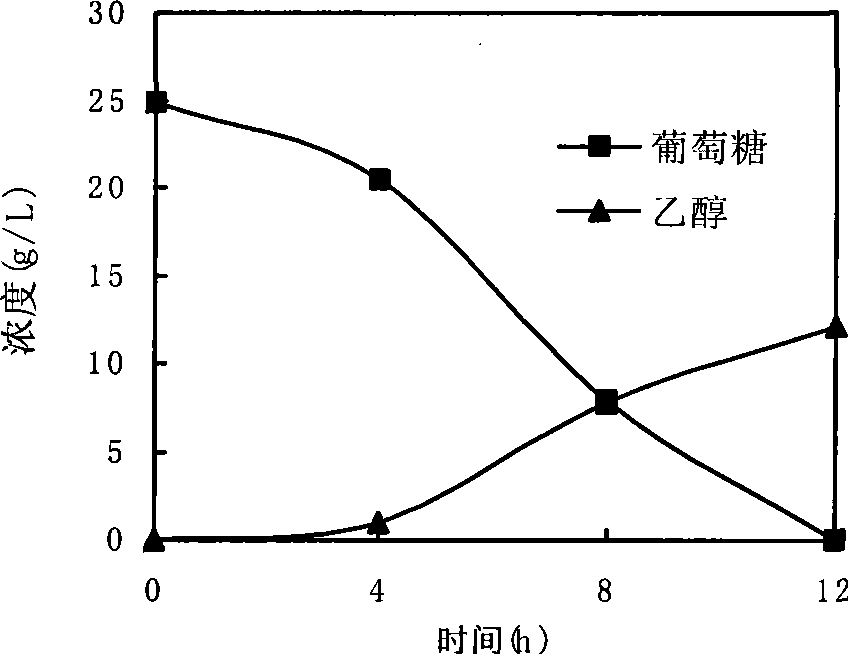

The present invention relates to an in-situ detoxification ethanol fermentation method of lignocellulose hydrolysate, which respectively inoculates Y5 and CBS6054 into fermentation culture medium containing dilute acid lignocellulose hydrolysate to carry out in-situ detoxification alcoholic fermentation. The method can efficiently metabolize glucose and xylose in the dilute acid lignocellulose hydrolysate to produce ethanol, and rapidly metabolize furfural and 5-hydroxymethylfurfural. The yield of ethanol is 0.44g / g, reaching 87.5 percent of the theoretical value. Moreover, any detoxification processing is not needed, the requirement on equipment is low, the operation is convenient, and the cost is low.

Owner:CAPITAL NORMAL UNIVERSITY

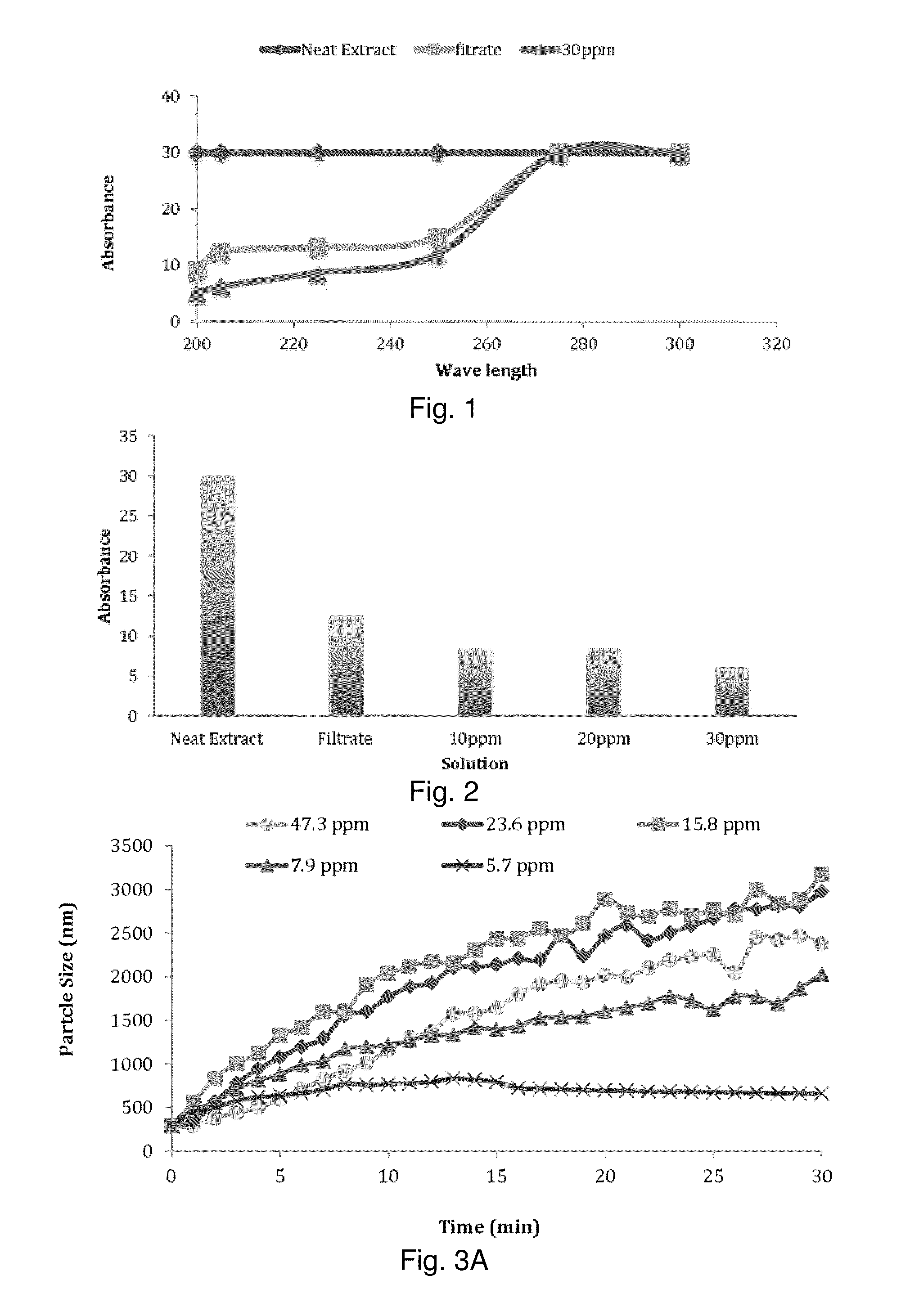

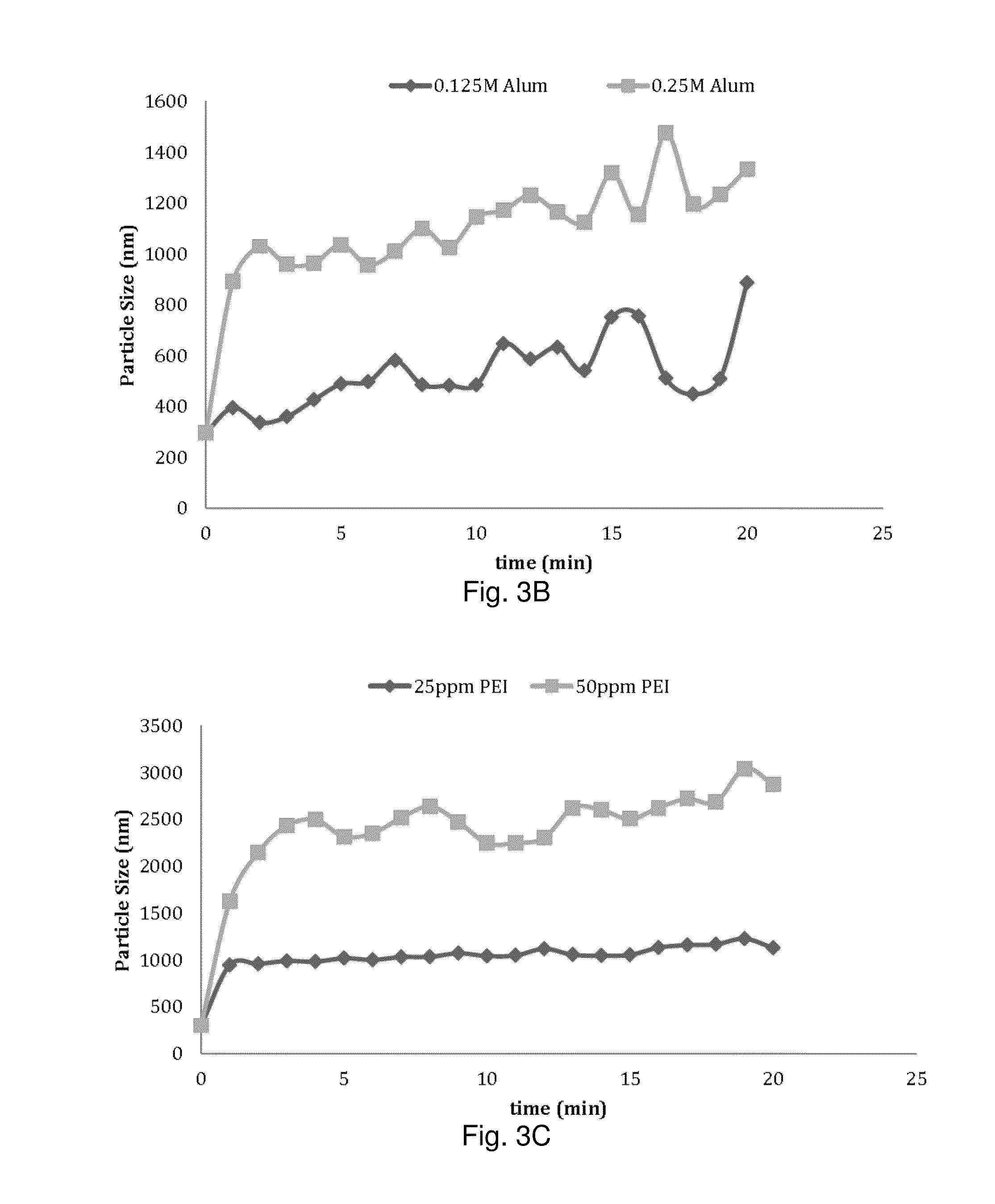

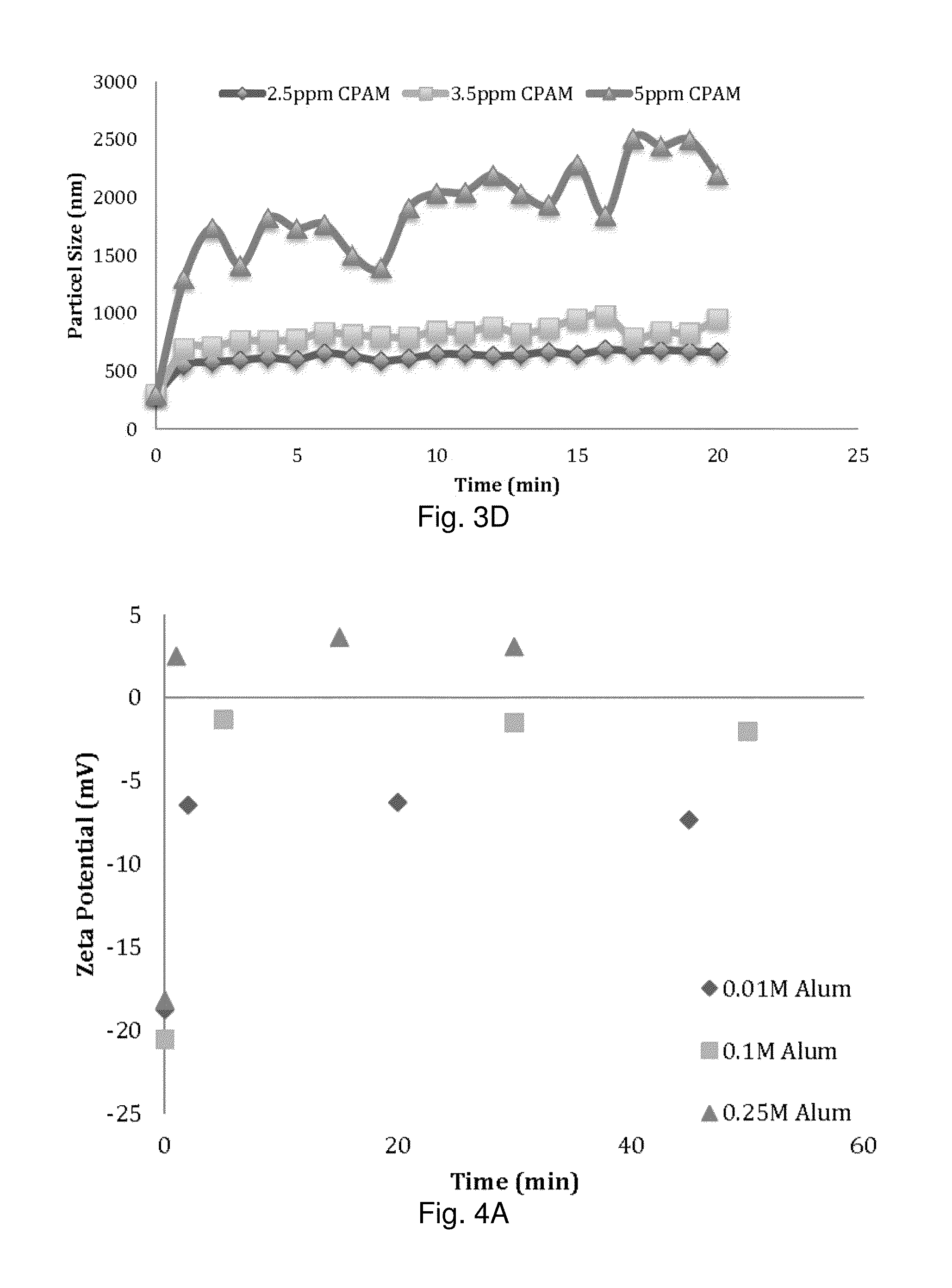

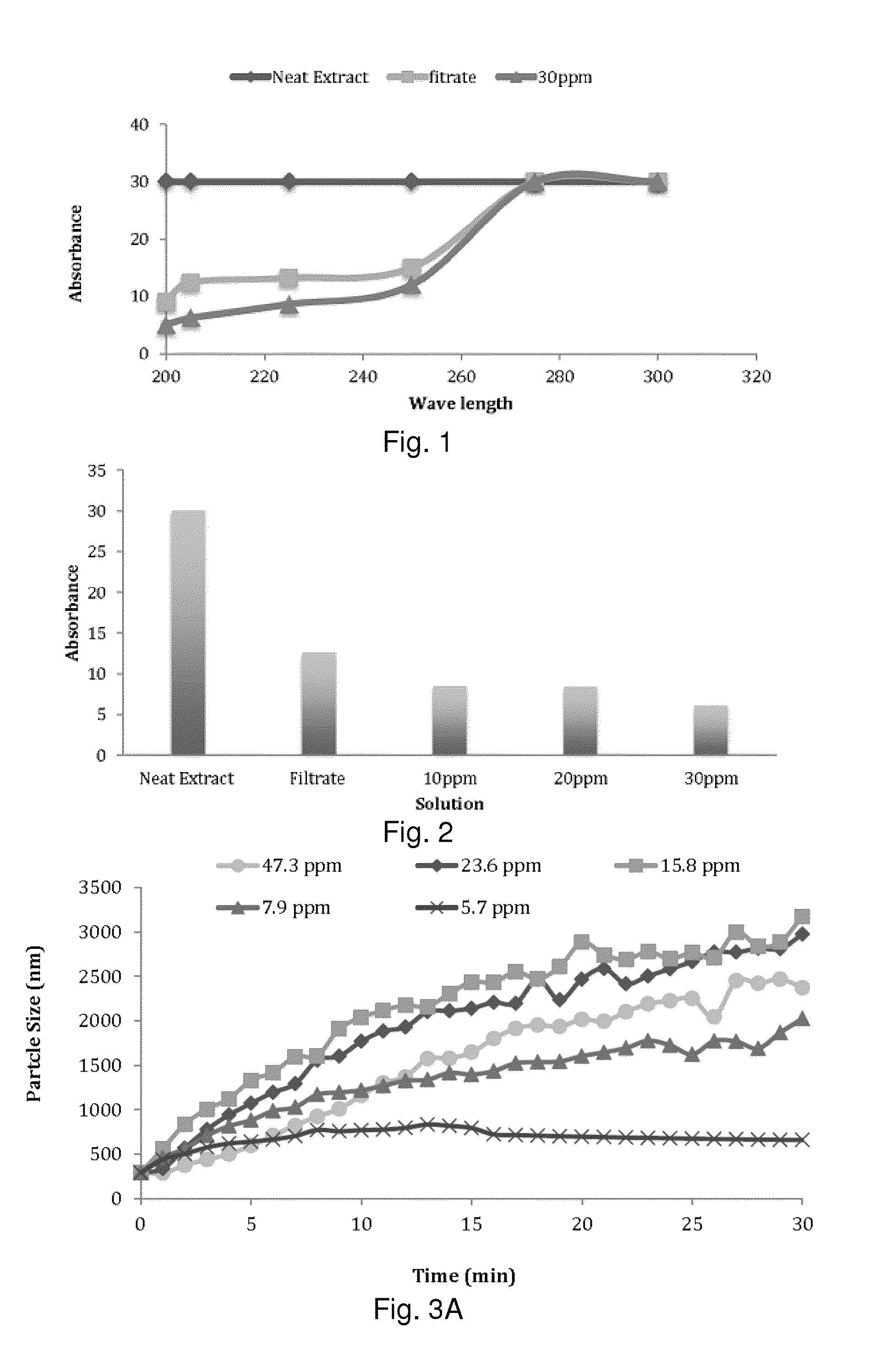

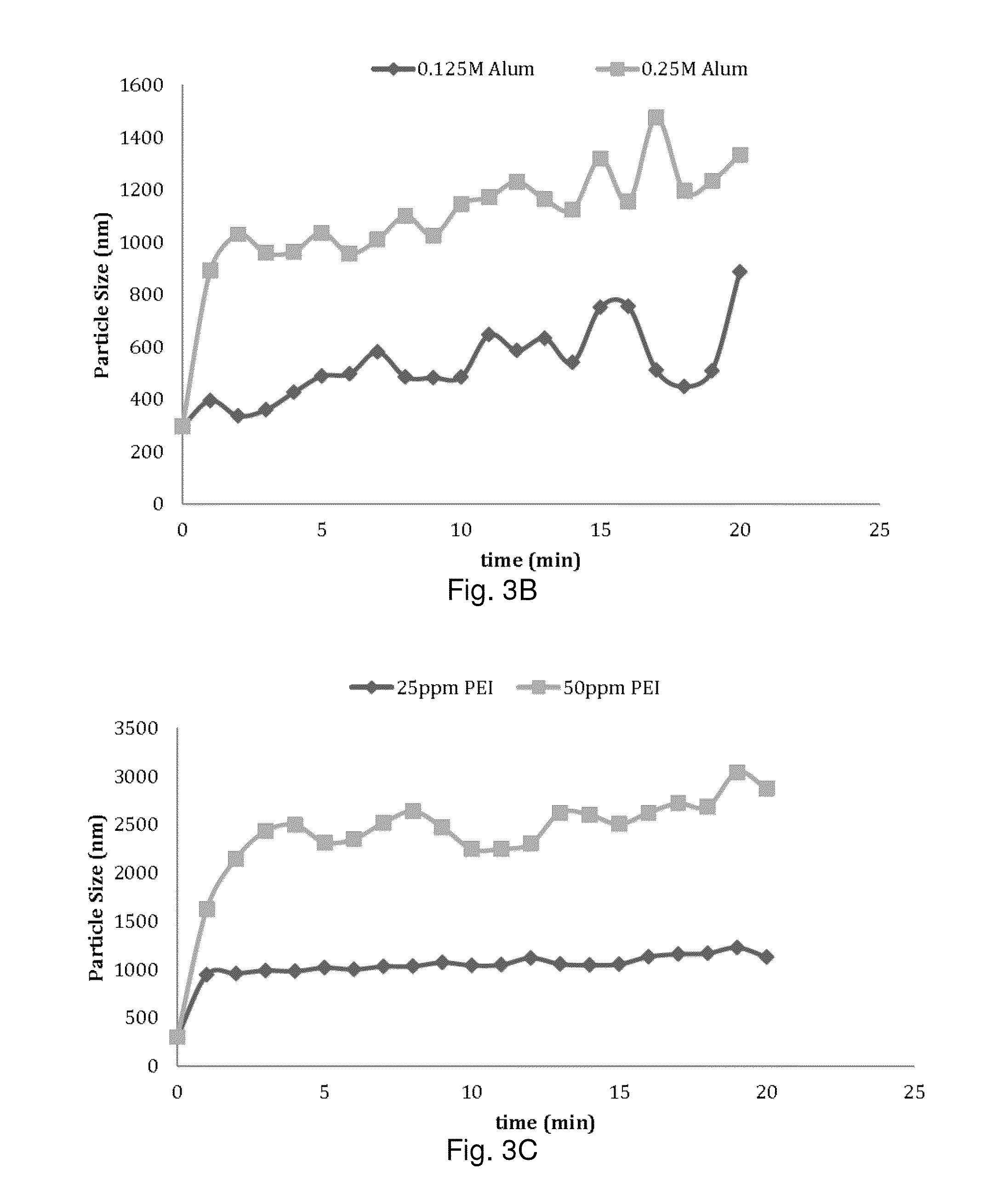

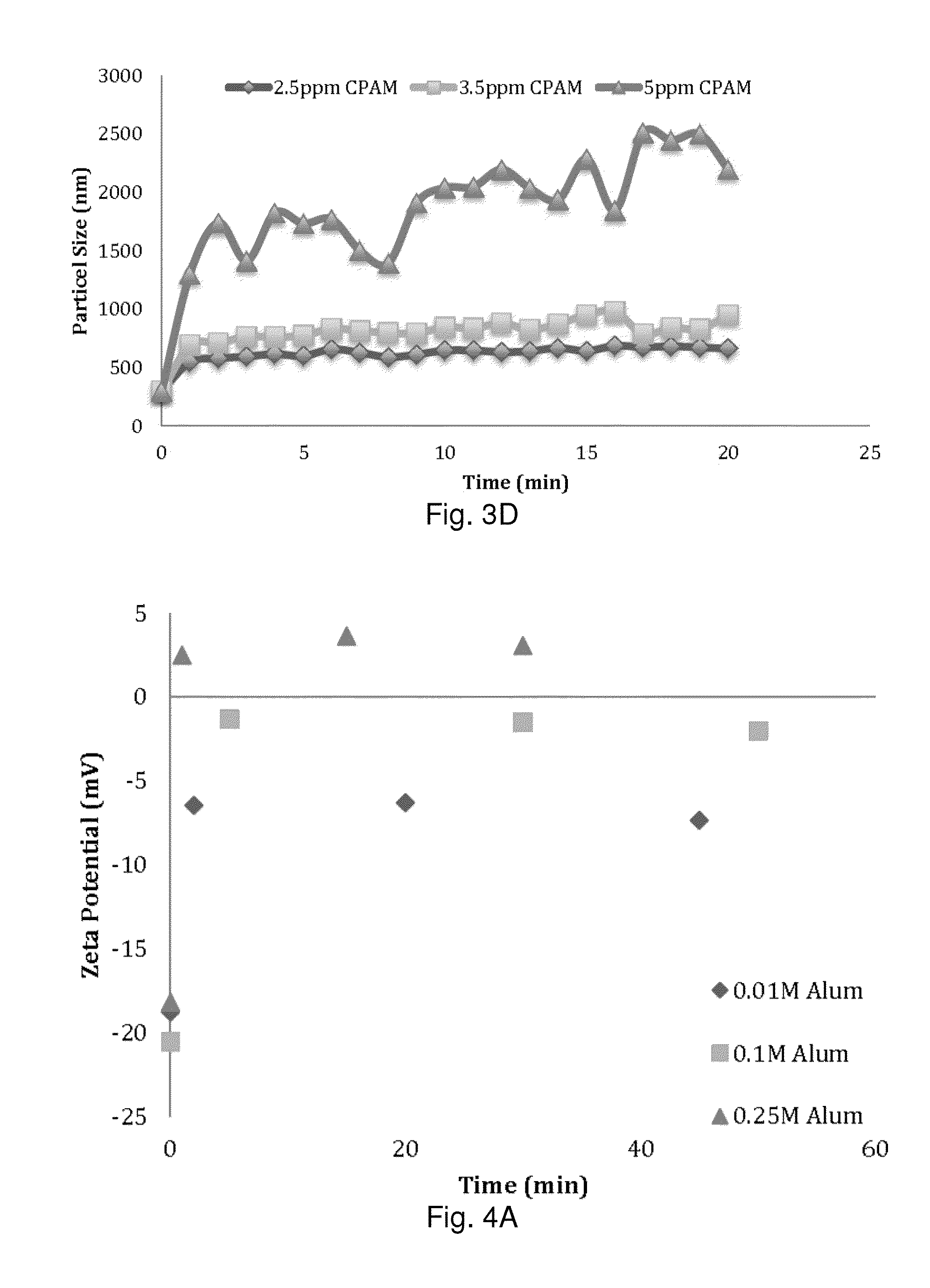

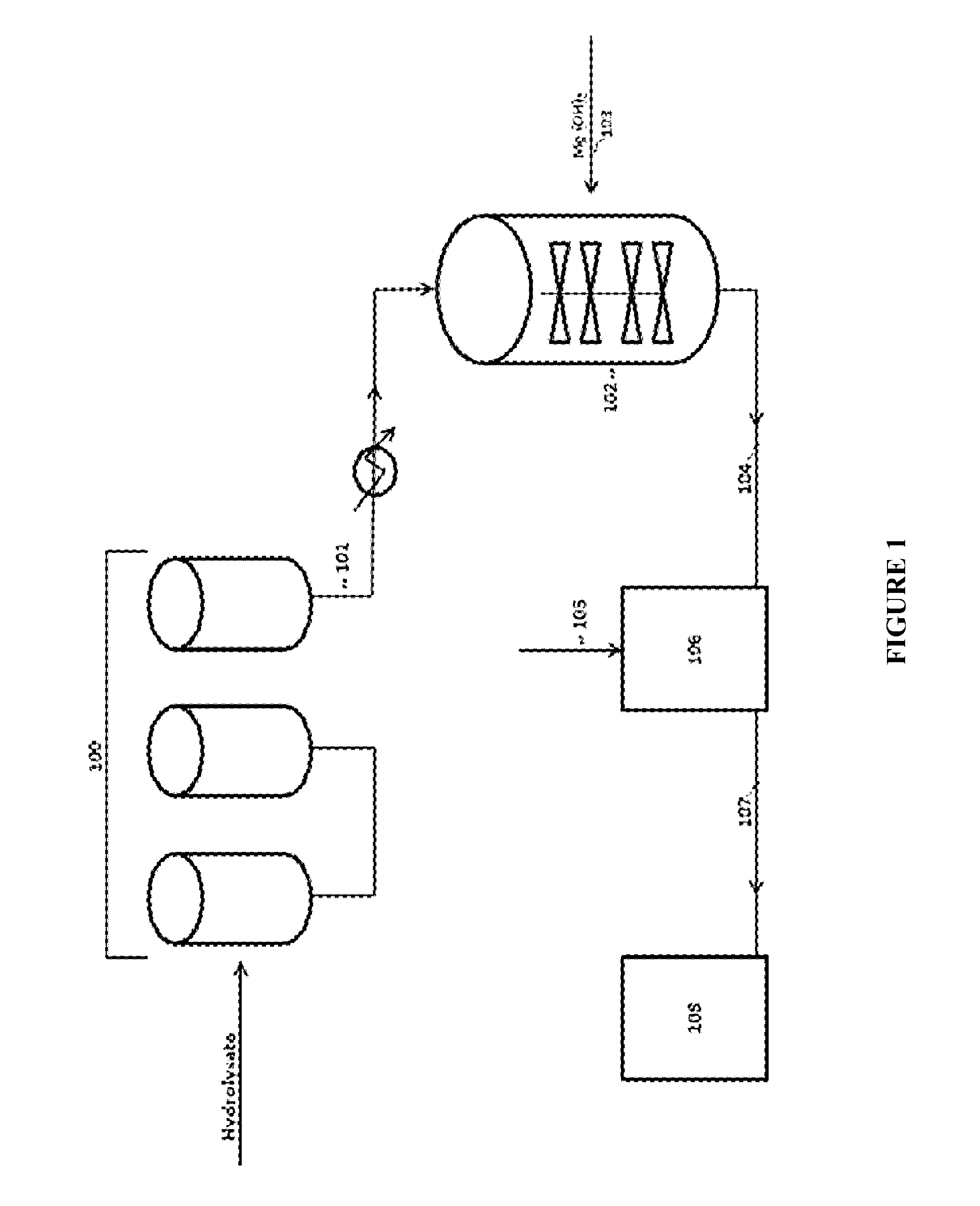

Controlled flocculation of lignocellulosic hydrolyzates

InactiveUS20160083808A1Improve fermentation effectImprove filtering effectSugar productsBiofuelsFlocculationCellulose

A method of flocculating a lignin-containing hydrolyzate solution, comprising adding at least two agents, comprising at least one flocculant, effective for flocculating the hydrolyzate, resulting in a cake having a solids content greater than a solids content of a cake obtained from a hydrolyzate treated with an optimum flocculating amount of the flocculant alone

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

pH CONTROLLED YEAST PROPAGATION

InactiveUS20150252319A1Avoids excess productionImprove performanceFungiBiofuelsCelluloseBiotechnology

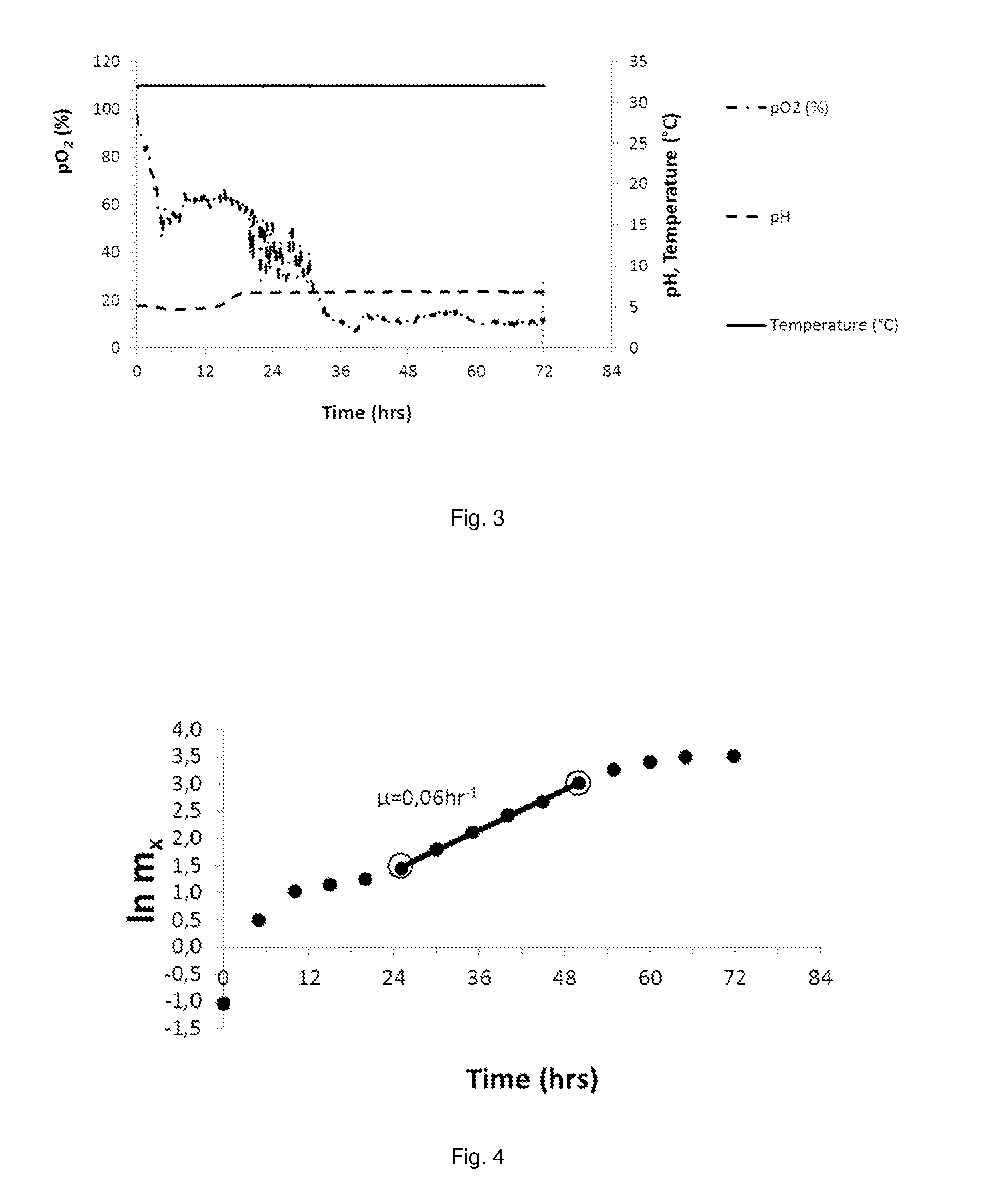

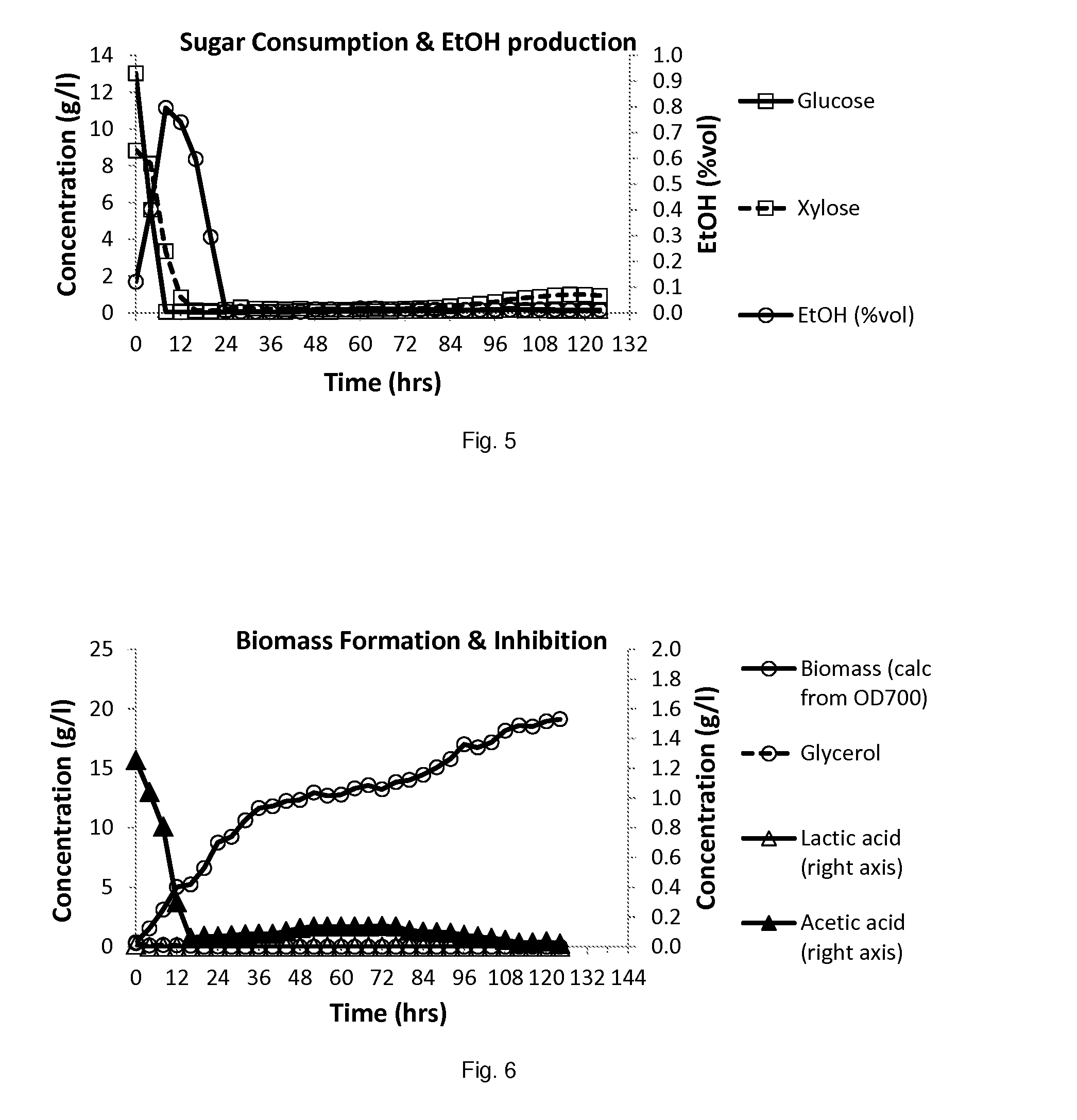

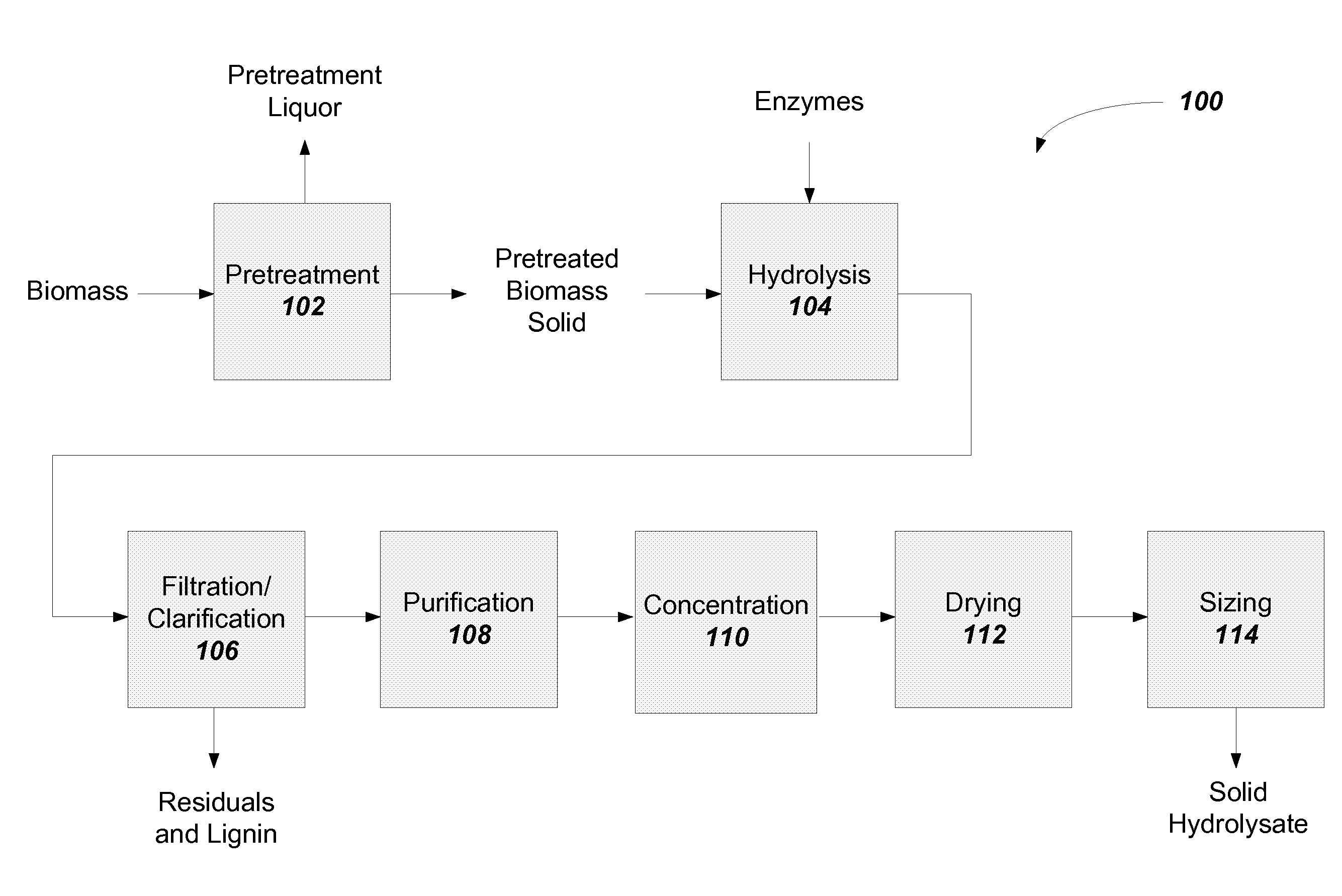

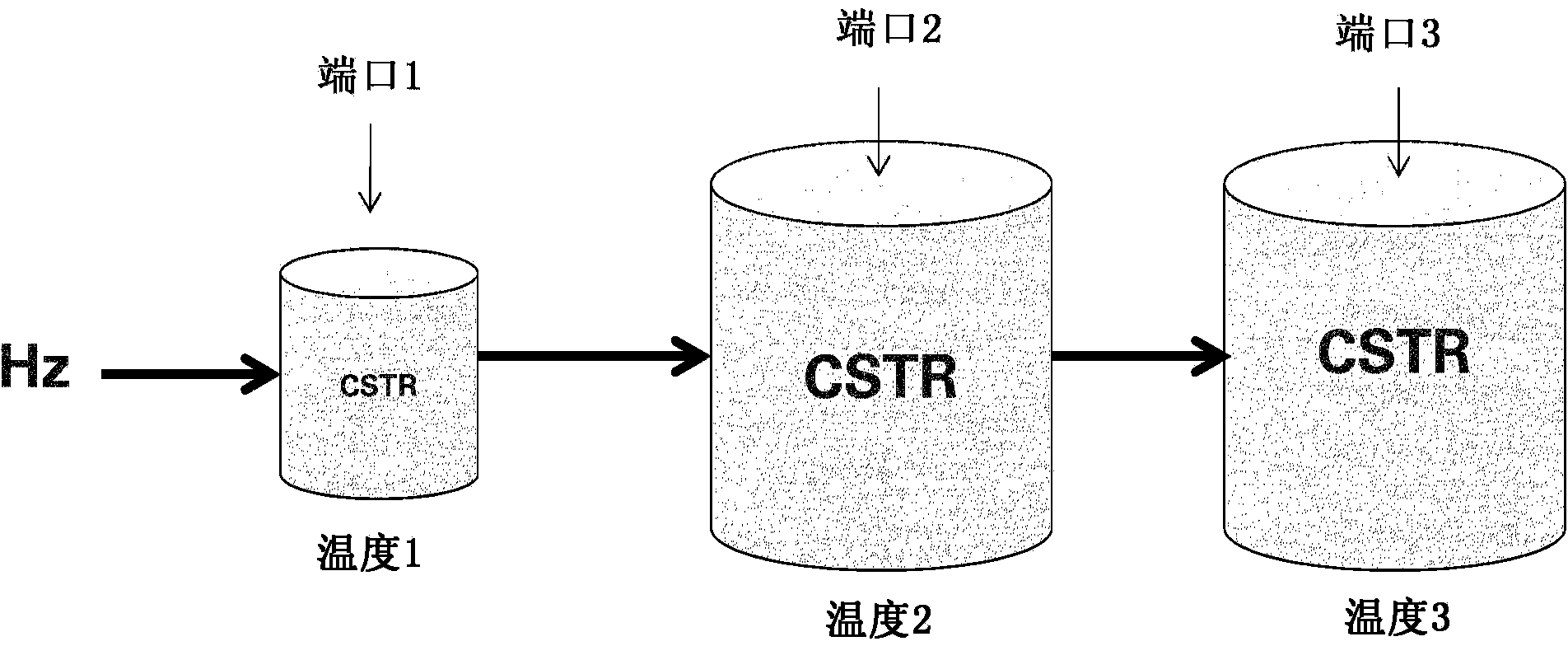

The invention relates to a process for the aerobic propagation of yeast wherein the yeast is grown in a reactor, comprising the following steps:a) filling the reactor with carbon source and an initial yeast population,b) optionally growing the initial yeast population in the reactor in batch mode,c) measuring the pH in the reactor,d) adding lignocellulosic hydrolysate to the reactor in fed batch mode at a rate to set the pH in the reactor at a predetermined value,ande) after sufficient propagation, isolation of yeast from the reactor.The invention further relates to yeast propagated according to that propagation process and to a process for the production of fermentation product wherein sugar comprising hexose and pentose is anaerobically fermented to fermentation product with the propagated yeast.

Owner:DSM IP ASSETS BV

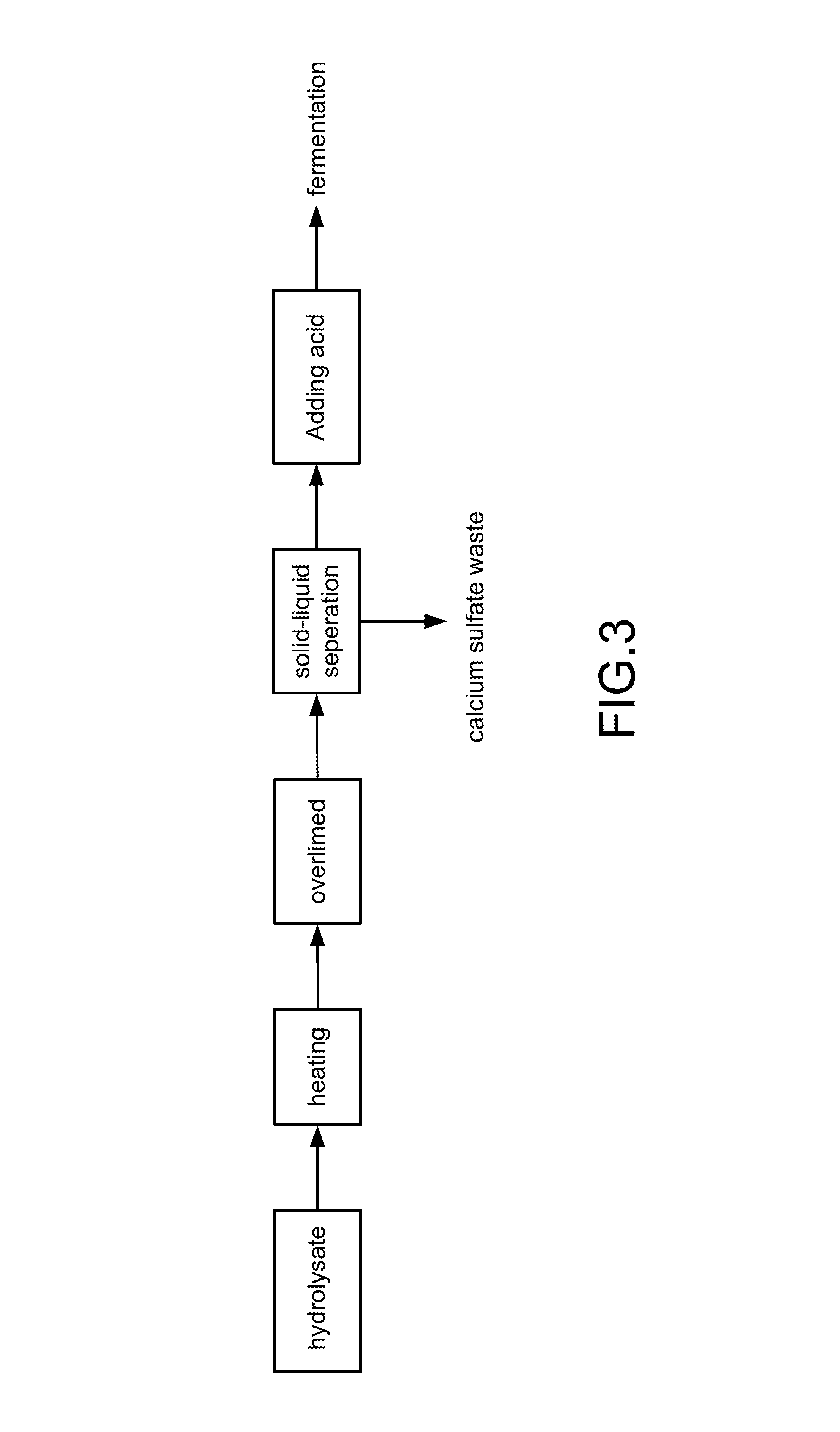

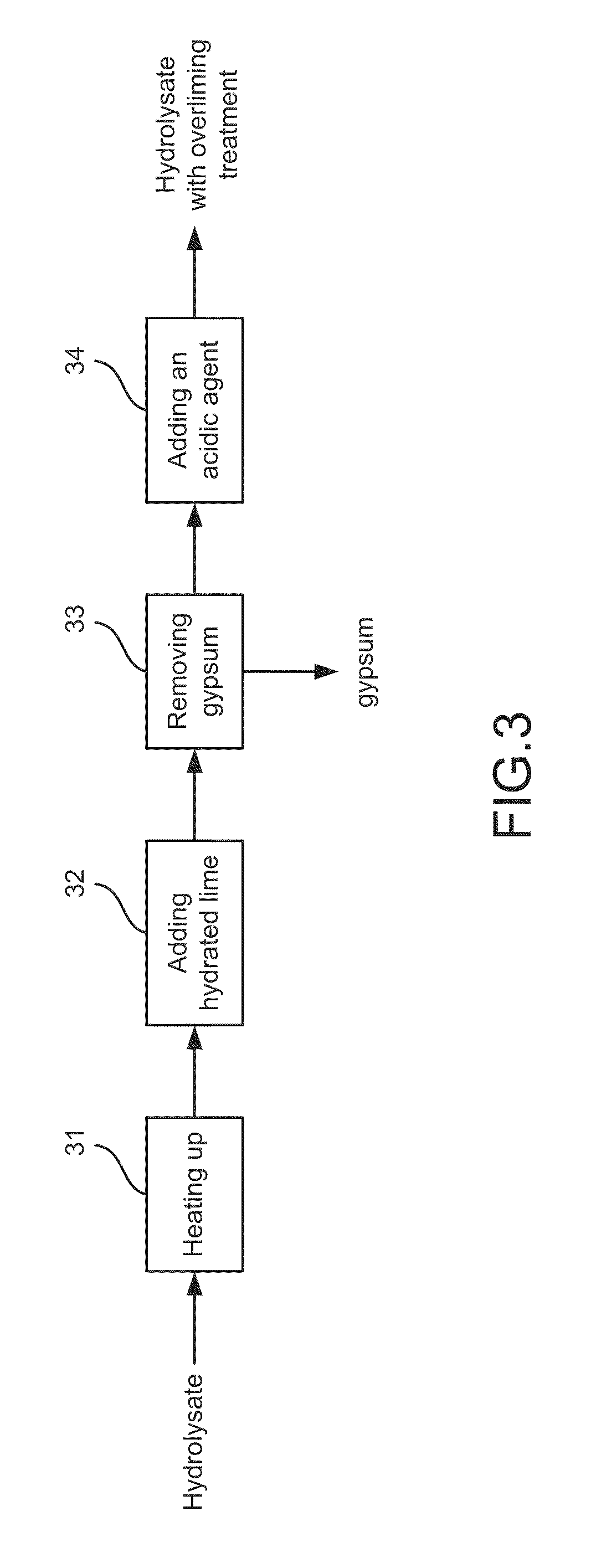

Method for producing microbial oil by fermenting corn stalk hydrolysate

InactiveCN102719499AReduce or inhibit fermentation inhibitorsPromote fermentationBiofuelsMicroorganism based processesMicroorganismMicrobial oil

The invention relates to a method for producing a microbial oil by fermenting corn stalk hydrolysate. The method comprises the following steps: (1) hydrolyzing corn stalks with acid to obtain the corn stalk hydrolysate; (2) adding Ca(OH)2 into the hydrolysate, regulating the pH to 10 to 11, centrifuging the solution for 10 to 20 min at a speed of 3,800 r / min, taking the supernatant, regulating the pH back to 6.0 with phosphoric acid, centrifuging the solution for 10 to 20 min at a speed of 3,800 r / min, taking the supernatant, sterilizing and filtering the supernatant, and regulating the pH of the obtained filtrate with NaOH to 6.0; (3)fermenting and cultivating oleaginous microorganism; and (4)crushing and extracting the dried bacteria in step (3) to obtain the microbial oil. According to the method for producing the microbial oil, the corn stalks are hydrolyzed by dilute sulphuric acid to obtain lignocellulosic hydrolysate, which is detoxified by Ca(OH)2 to effectively reduce or inhibit the fermentation inhibitor in the hydrolysate, so as to promote the fermentation of the microorganism and obtain a large amount of microbial oils which can be further transformed into biodiesel.

Owner:TIANJIN UNIV OF SCI & TECH

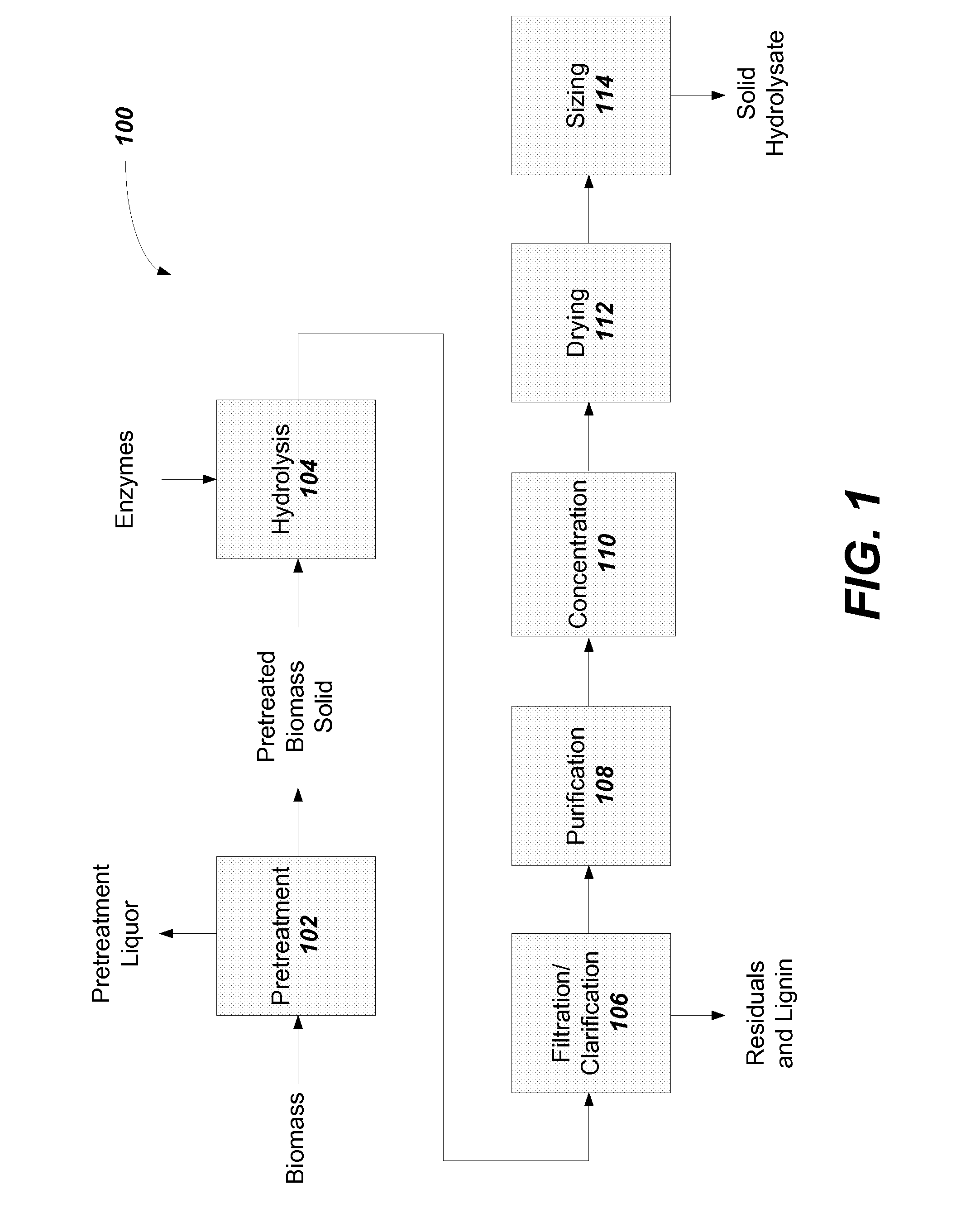

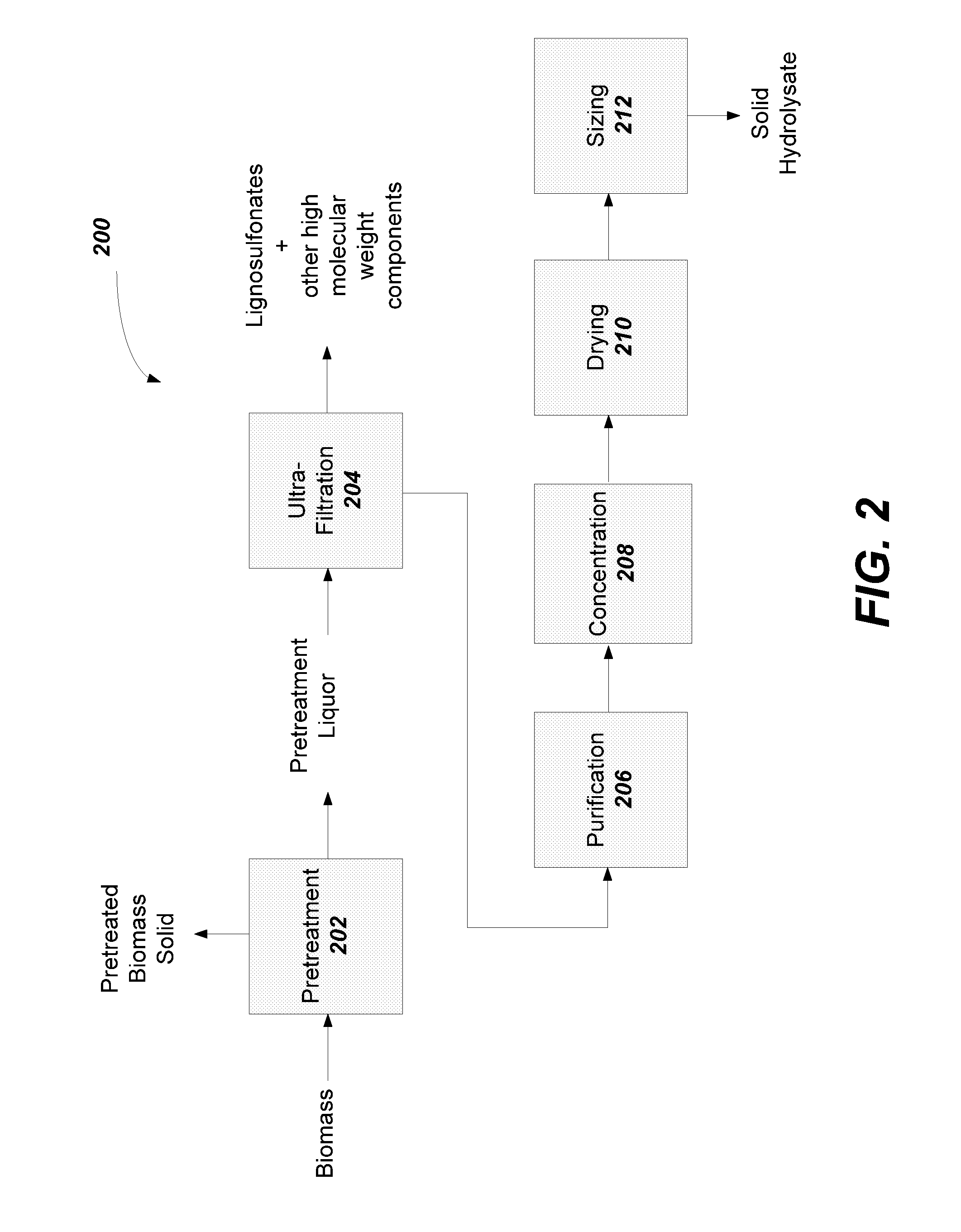

Solid lignocellulosic hydrolysate and methods to prepare a solid lignocellulosic hydrolysate

InactiveUS20130118483A1High in sugarIncrease in sizeSugar productsPretreatment with acid reacting compoundsCelluloseSolubility

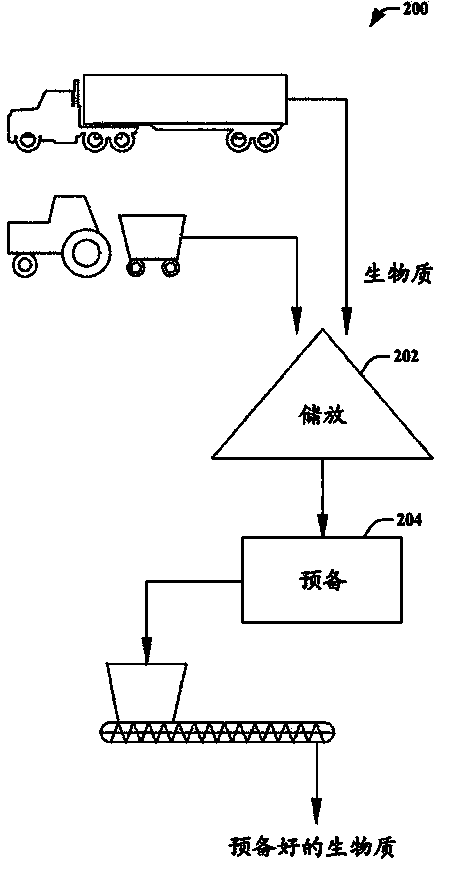

The present disclosure provides a solid lignocellulosic hydrolysate and methods to prepare the solid lignocellulosic hydrolysate from a woody biomass or an herbaceous biomass. The solid lignocellulosic hydrolysate may be used in the production of biofuels, bioproducts, and food products. The solid lignocellulosic hydrolysate allows for ease of storage, ease of transportation and handling of the solid lignocellulosic hydrolysate, and ease of use in biological or fermentation processes or chemical processes for the production of biofuel, bioproducts, chemicals and food products due to the bulk handling characteristics (e.g., solubility and rate of dissolution) of the solid lignocellulosic hydrolysate.

Owner:WEYERHAEUSER NR CO

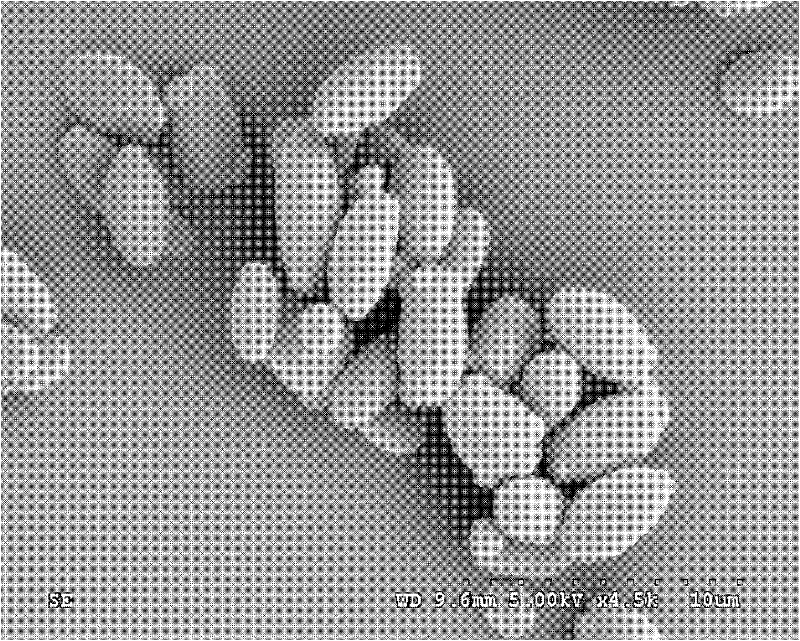

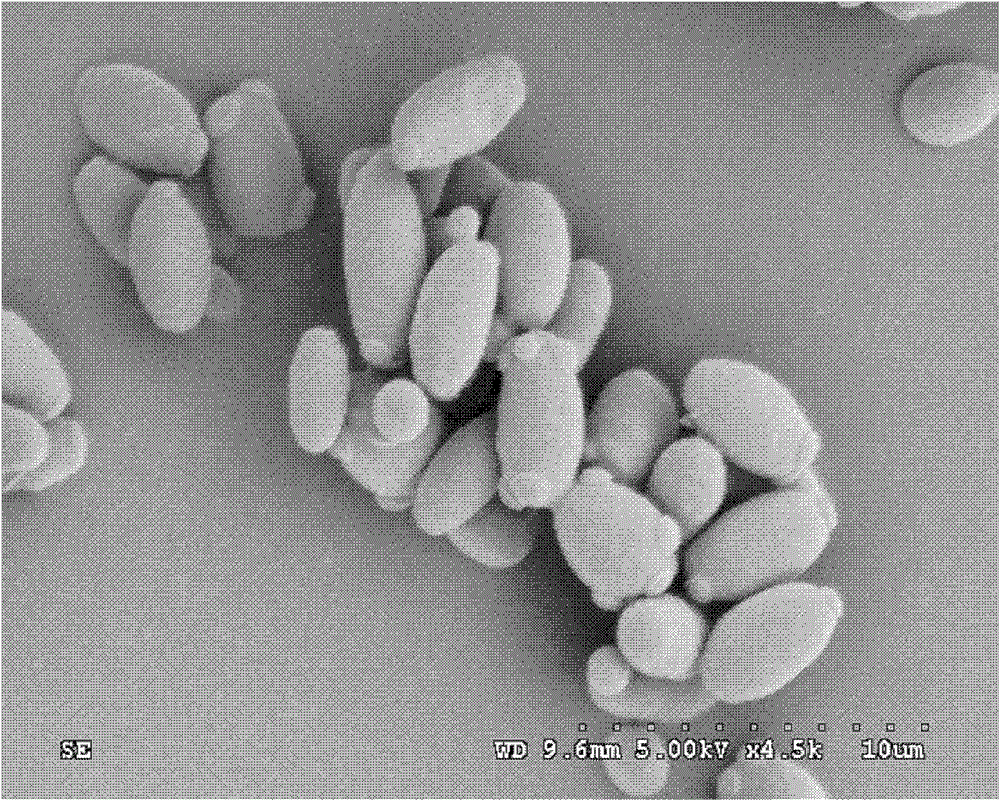

High temperature resistant Issatchenkia orientalis, application thereof and method for producing ethanol through fermentation

InactiveCN102268382AThe fermentation process is simpleReduce fermentation costsFungiBiofuelsCelluloseHydrolysis

The invention relates to the field of fermentation, in particular to a strain of high temperature resistant Issatchenkia orientalis, application thereof and a method for producing ethanol through fermentation. The strain of high temperature resistant Issatchenkia orientalis IPE100 is separated and screened from farmland crop waste, has a number of CGMCC (China General Microbiological Culture Collection Center) No.4927, has the capacity of fermenting ethanol at high temperature, and can be applied to high temperature fermentation of ethanol by using lignocelluloses hydrolysis products and high temperature solid fermentation of ethanol by using sweet sorghum.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

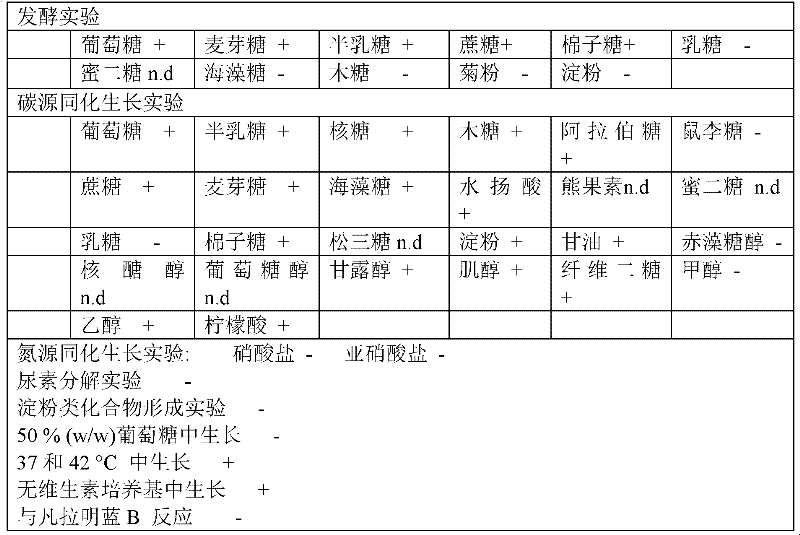

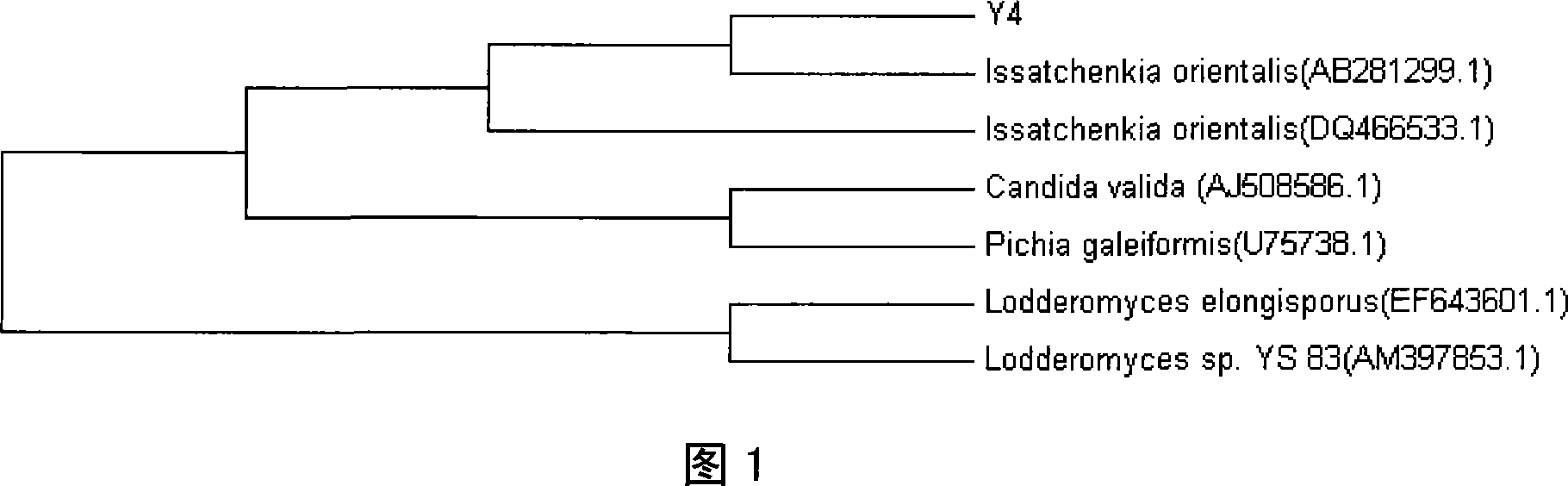

Novel use for issatchenkia orientalis

The present invention provides the application of Issatchenkia orientalis in fermenting lignocellulose hydrolysate. Issatchenkia orientalis and its domesticated strain is applied in fermenting lignocellulose hydrolysate to degrade the fermentation inhibitor fast, to metabolize glucose for producing ethanol and to lower the cost of producing ethanol with lignocellulose. The present invention lays foundation of large scale industrial production, and provides also one Issatchenkia orientalis strain Y4 with high fermentation efficiency.

Owner:CAPITAL NORMAL UNIVERSITY

Flocculation of lignocellulosic hydrolyzates

ActiveUS20150044733A1Improve fermentation effectImprove filtering effectBiological substance pretreatmentsBiofuelsCelluloseFlocculation

A method of separating a lignin-rich solid phase from a solution, comprising: pretreating a lignocellulosic biomass with a pretreatment fluid having to remove soluble components, colloidal material and primarily lignin containing particles; separating the pretreated lignocellulosic biomass from the pretreatment fluid with soluble components, colloidal material and primarily lignin containing particles; flocculating the separated pretreatment fluid with soluble components, colloidal material and primarily lignin containing particles using PEO or CPAM as a flocculating agent; and filtering the flocculated separated pretreatment fluid with soluble components, colloidal material and primarily lignin containing particles to remove agglomerates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

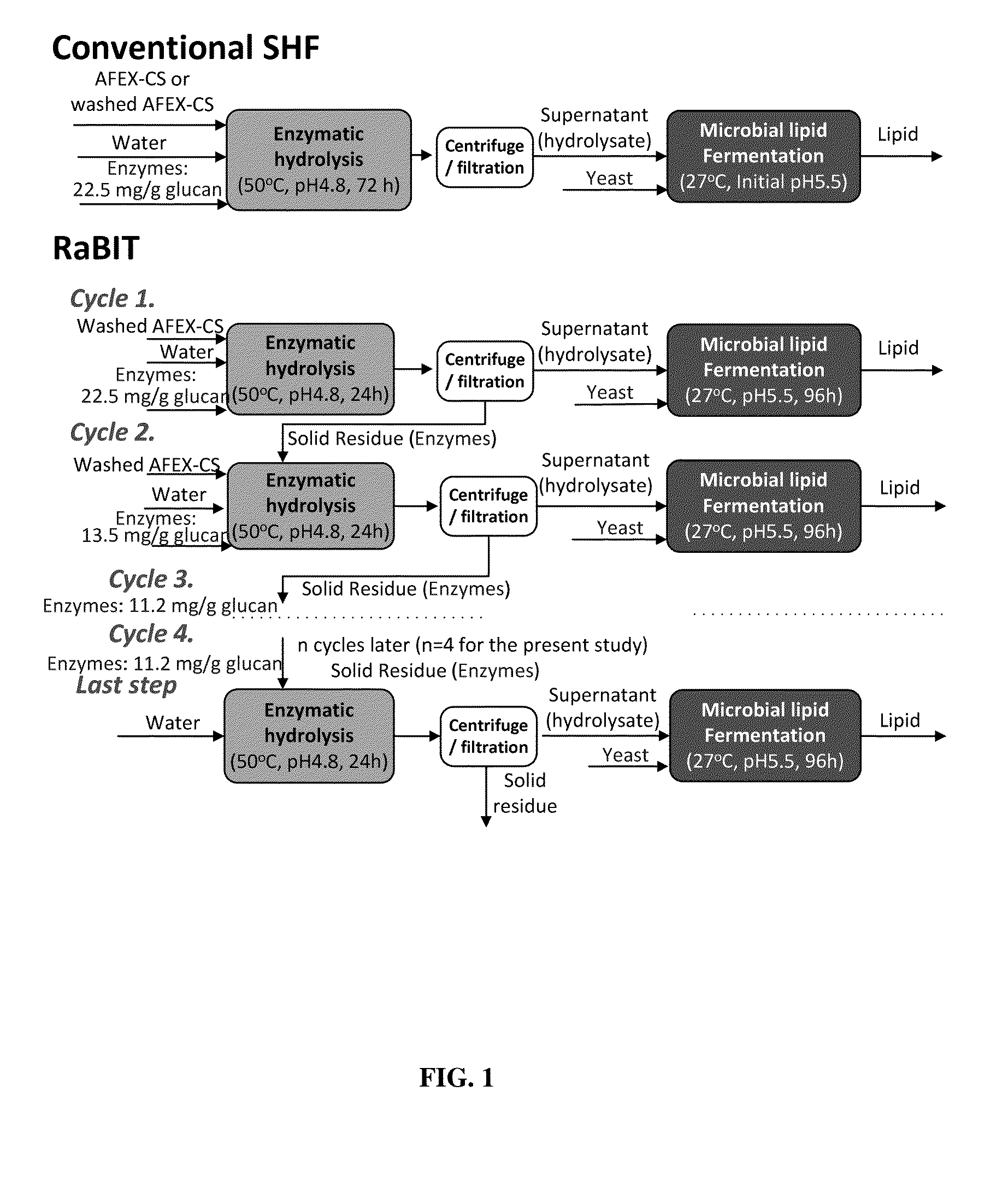

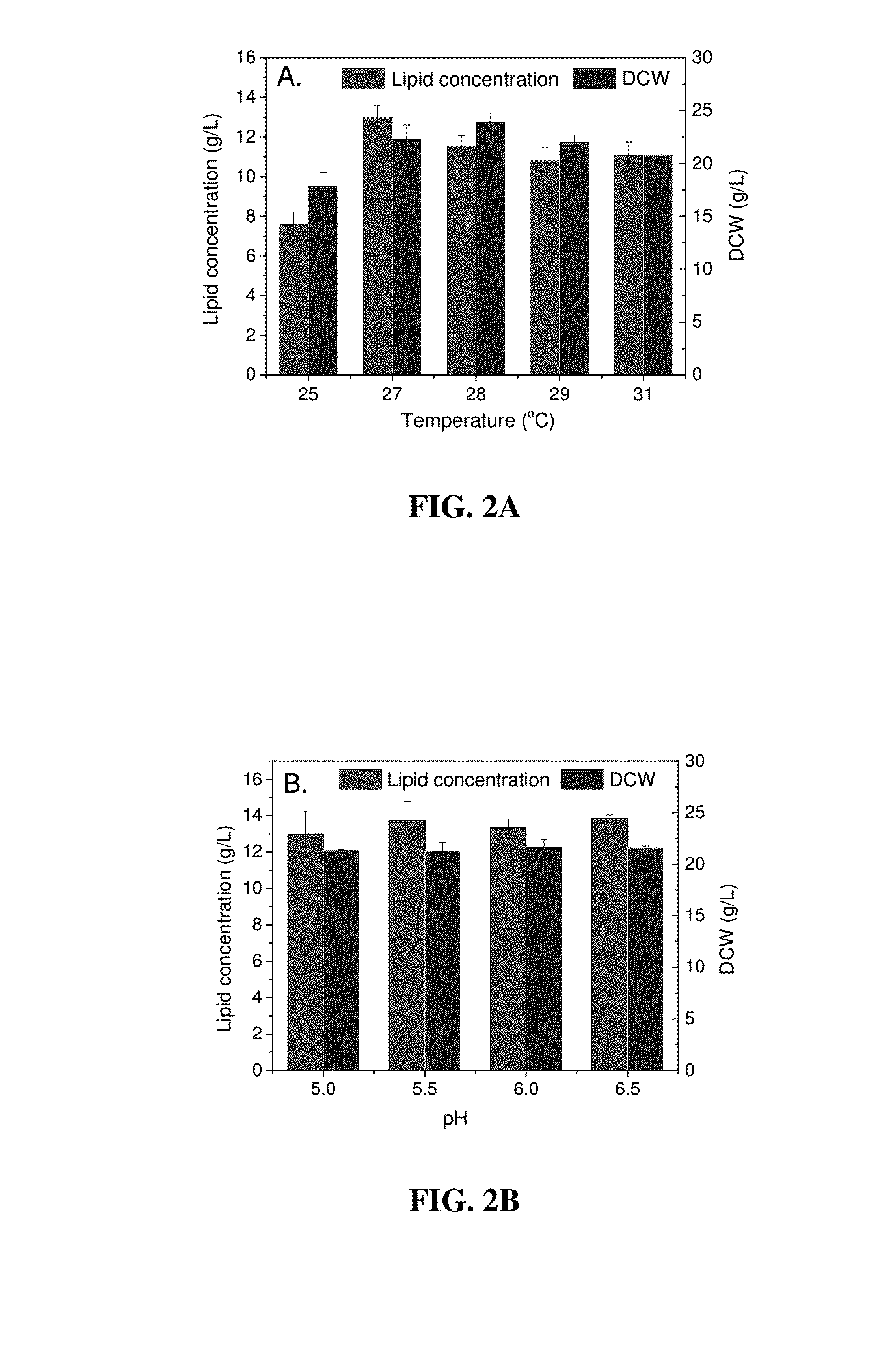

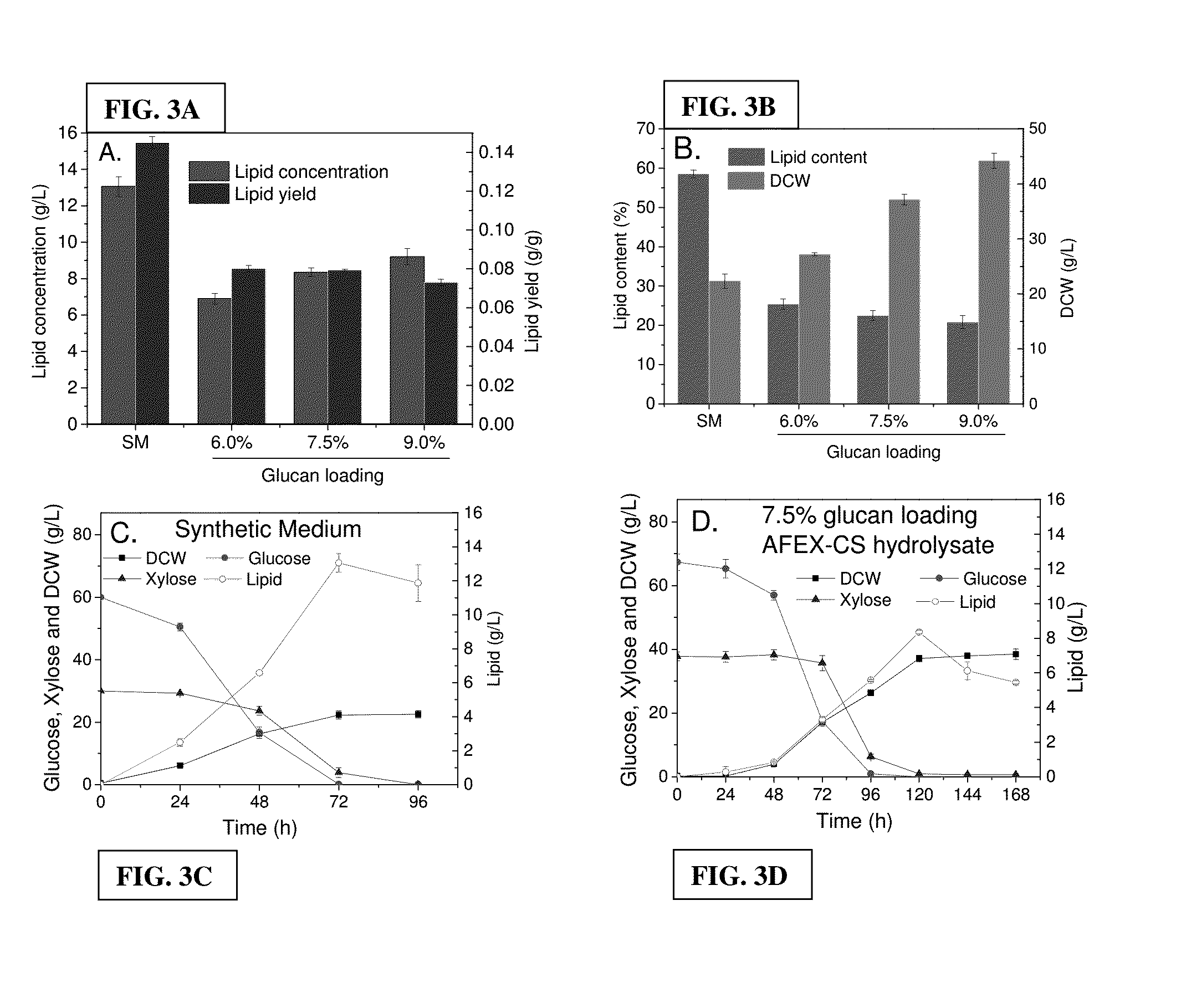

Methods and yeast strains for conversion of lignocellulosic biomass to lipids and carotenoids

The present invention provides for the use of oleaginous yeast strains that are capable of converting lignocellulosic hydrolysates to lipids. More specifically, under specific molar carbon to nitrogen ratios of treated biomass hydrolysates, oleaginous yeasts are able to accumulate lipids that are suitable for the manufacture of biofuels and other products of interest. Additionally, some yeast species provided herein produce carotenoids when grown utilizing the disclosed methodologies.

Owner:US SEC AGRI

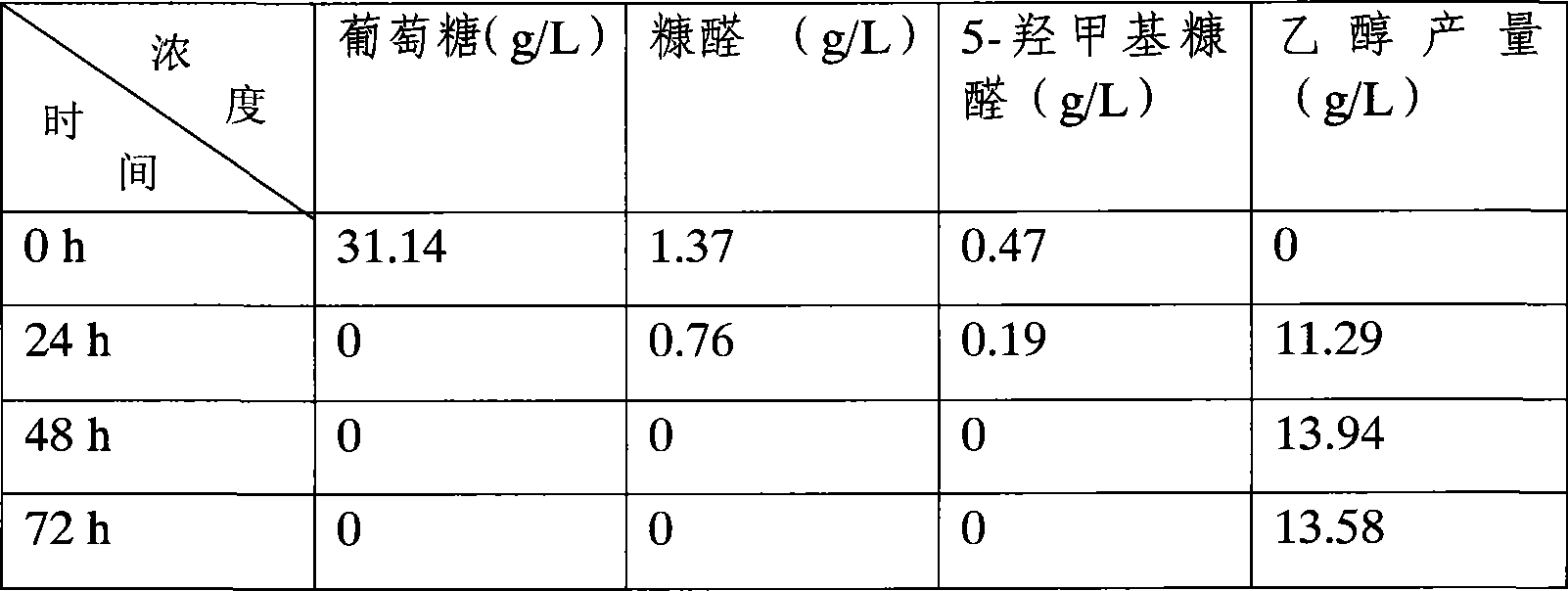

Virus-free in situ and alcohol fermentation method of composite bacteria for lignocellulose hydrolysis product

The present invention relates to an in-situ detoxification ethanol fermentation method of lignocellulose hydrolysate, which respectively inoculates Y5 and CBS6054 into fermentation culture medium containing dilute acid lignocellulose hydrolysate to carry out in-situ detoxification alcoholic fermentation. The method can efficiently metabolize glucose and xylose in the dilute acid lignocellulose hydrolysate to produce ethanol, and rapidly metabolize furfural and 5-hydroxymethylfurfural. The yield of ethanol is 0.44g / g, reaching 87.5 percent of the theoretical value. Moreover, any detoxificationprocessing is not needed, the requirement on equipment is low, the operation is convenient, and the cost is low.

Owner:CAPITAL NORMAL UNIVERSITY

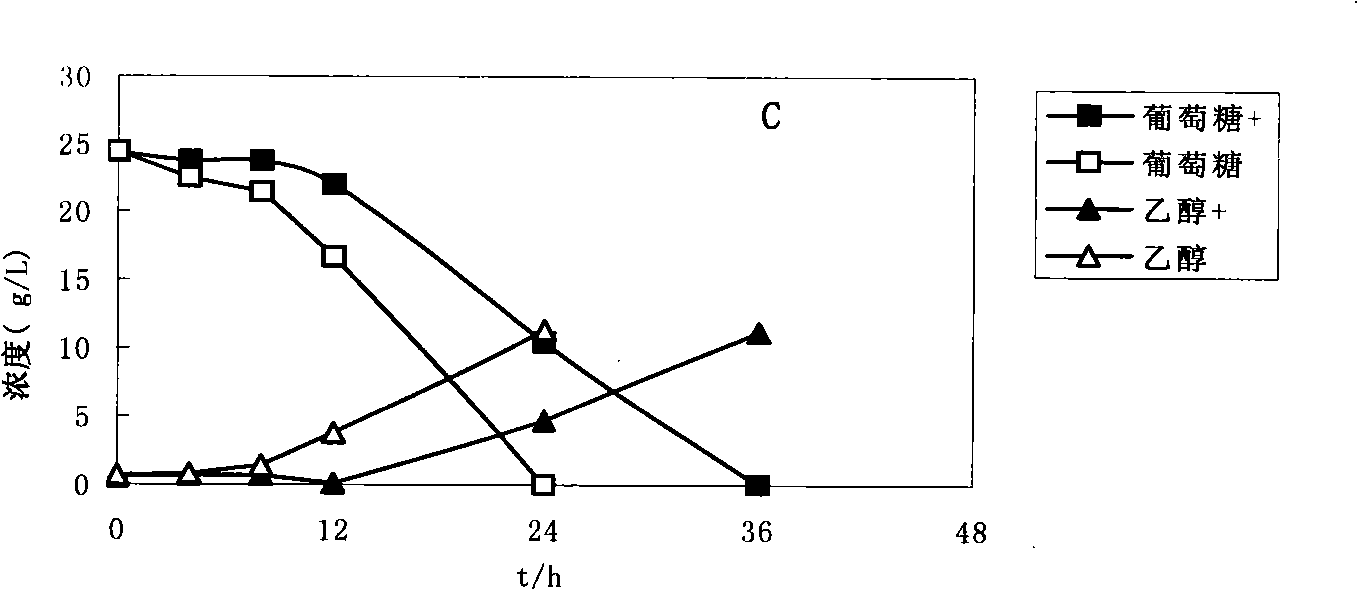

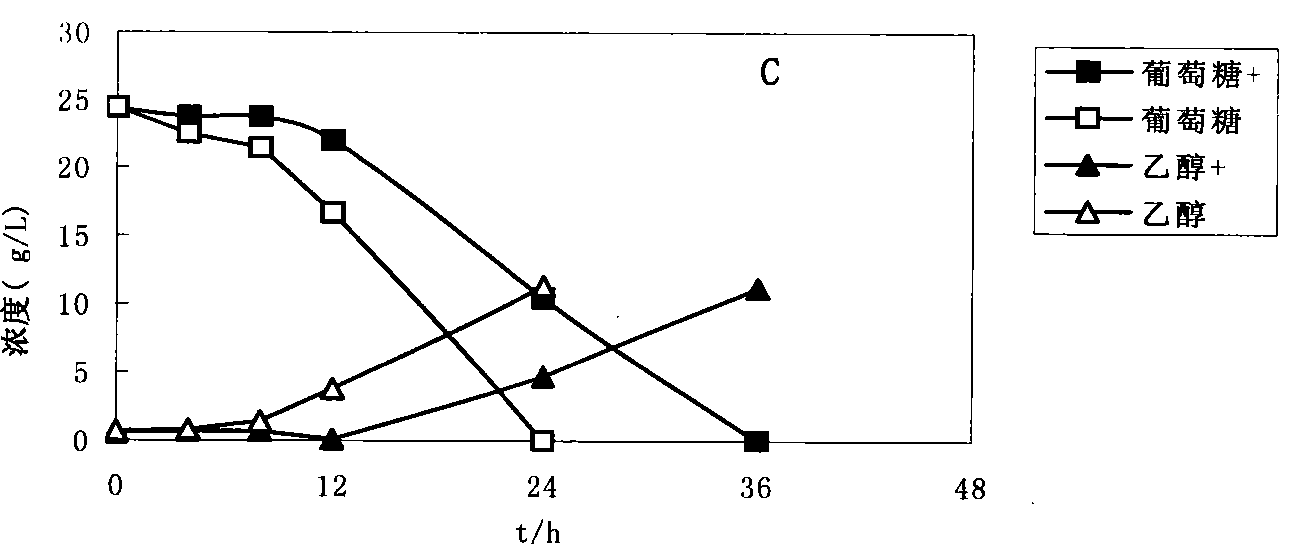

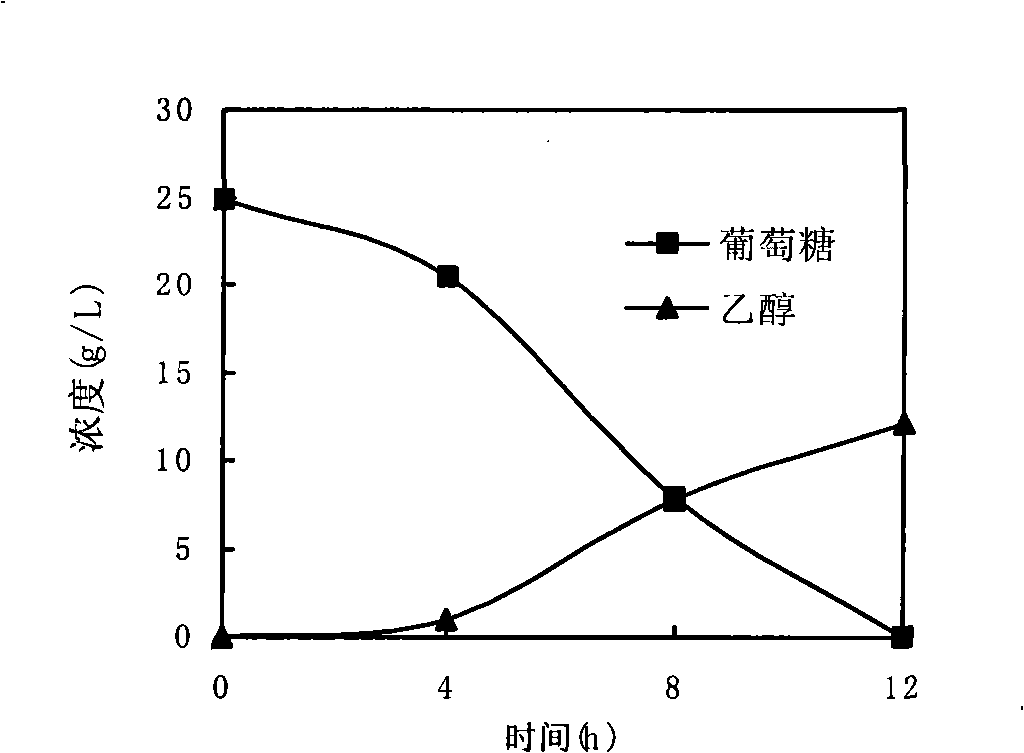

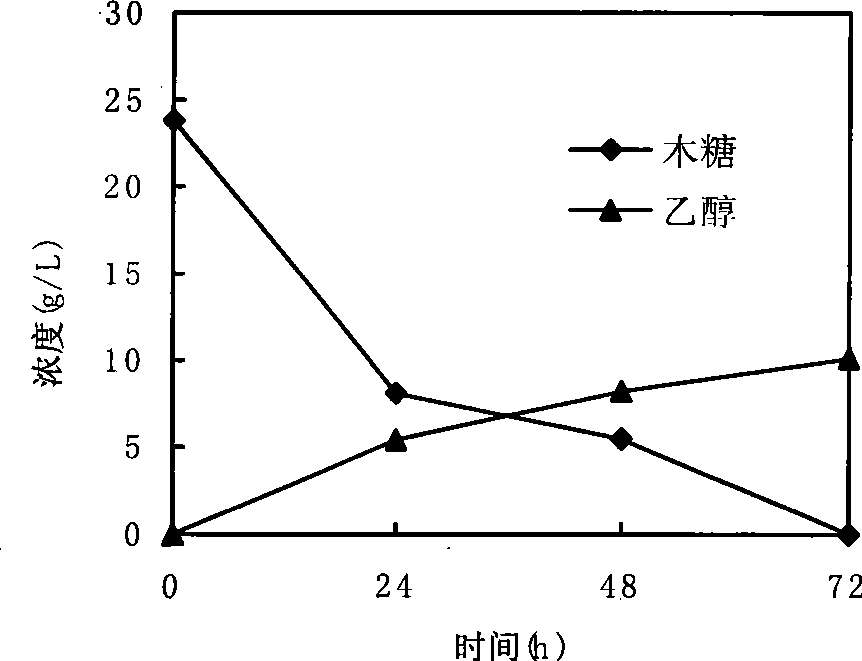

In situ detoxication alcohol fermentation method of ligno-cellulose hydrolysate using single culture

The invention provides a method for adopting single strains to carry out fermentation to in-situ virus-eliminated alcohol of hydrolyzate of lignocellulose; therefore, the invention firstly provides a new strain of pichia stipitis of trunks and the preservation number is CGMCC No.2661; the experiment proves that the strain can carry out detoxification in situ to lignocellulose diluted acid hydrolyzate, can transform glucose and xylose in lignocellulose diluted acid hydrolysate into ethanol effectively and reach 92.4 percent of the highest theoretical value of the ethanol. The use of the strain can simplify the technique that the lignocellulose is used as materials to produce the ethanol, reduces the production cost of the ethanol and has significant theoretical and practical significance to the commercialization of the production of lignocellulose ethanol.

Owner:CAPITAL NORMAL UNIVERSITY

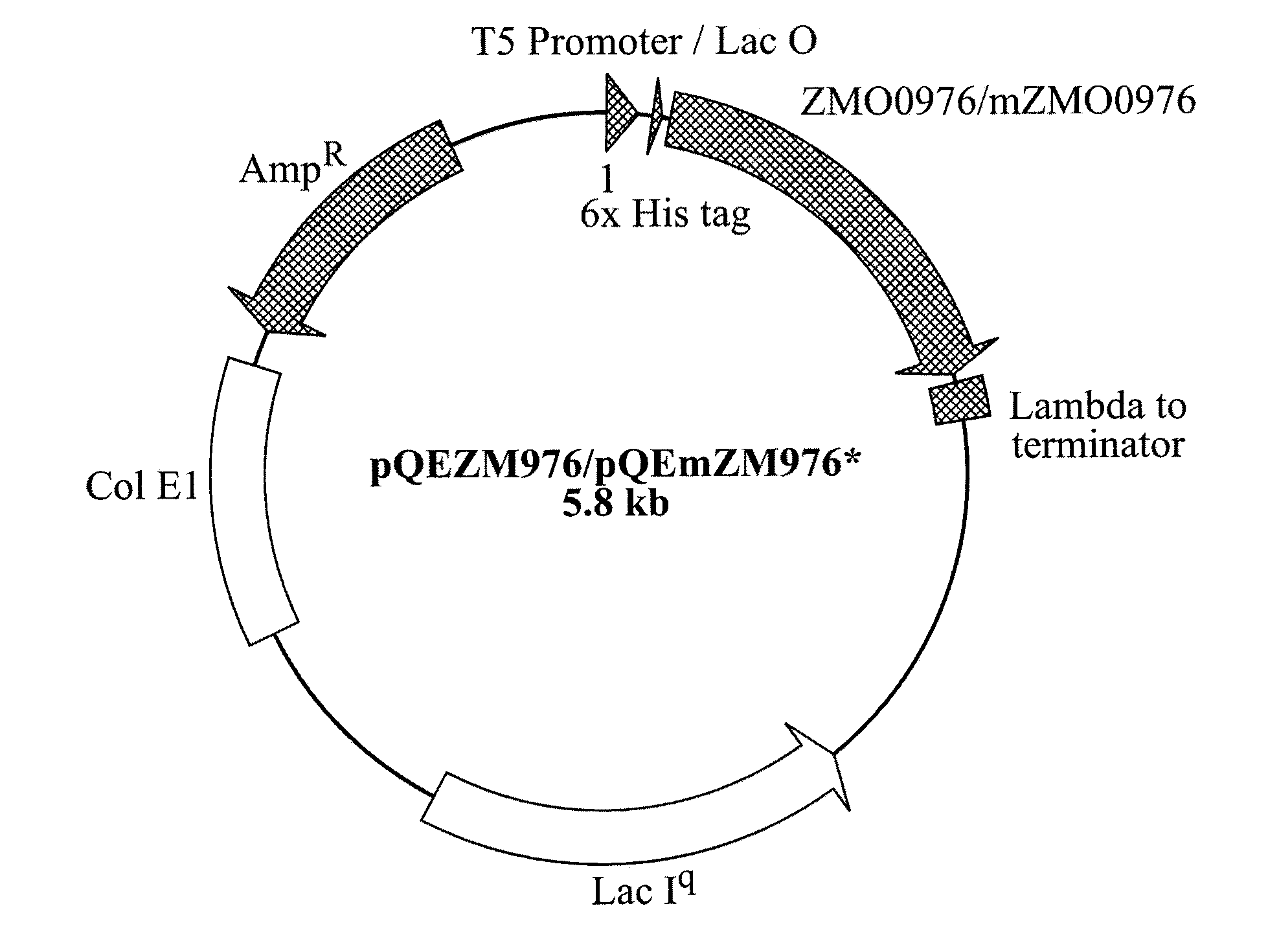

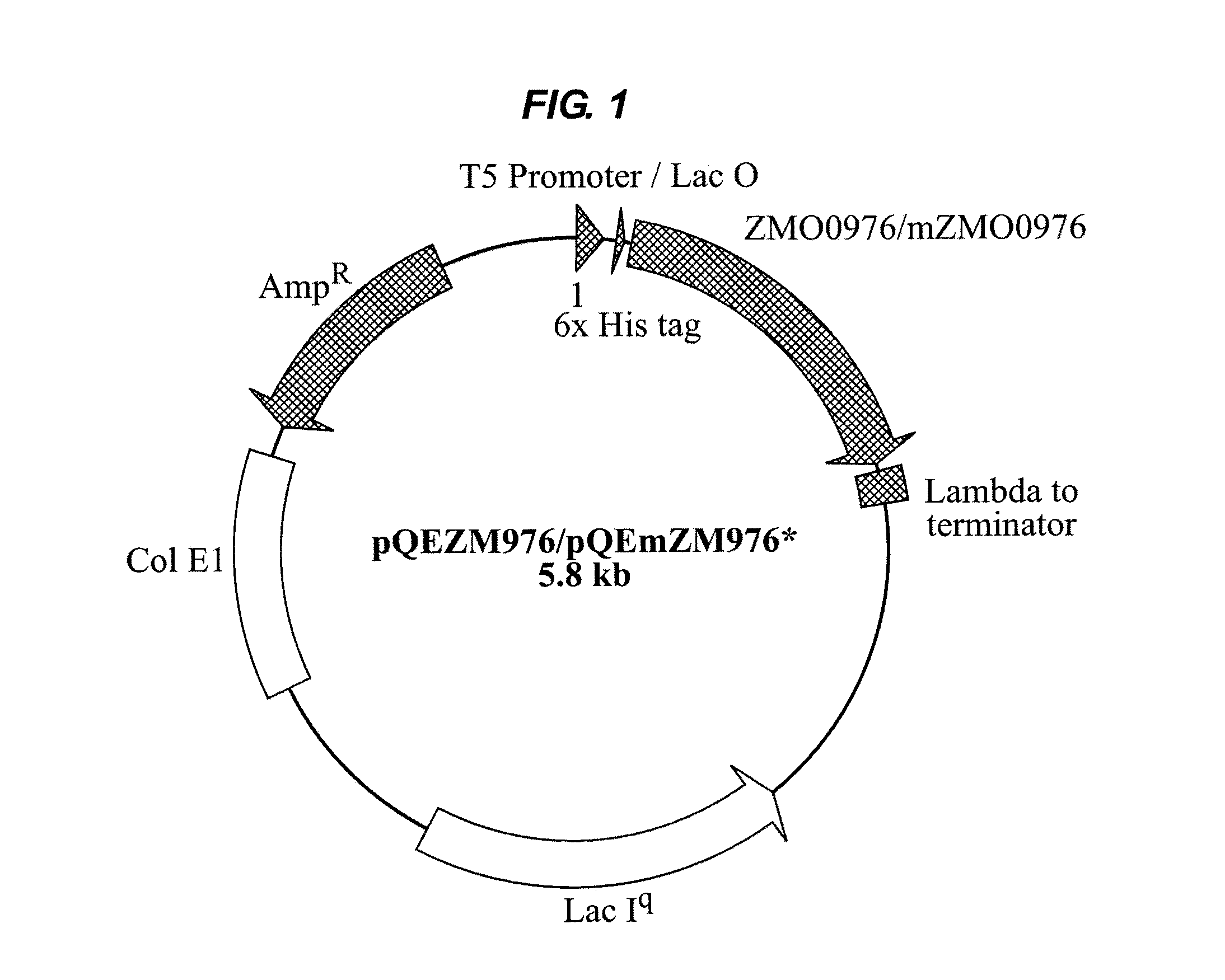

Industrial Applications of A Novel Aldo/Keto Reductase Of Zymomonas Mobilis

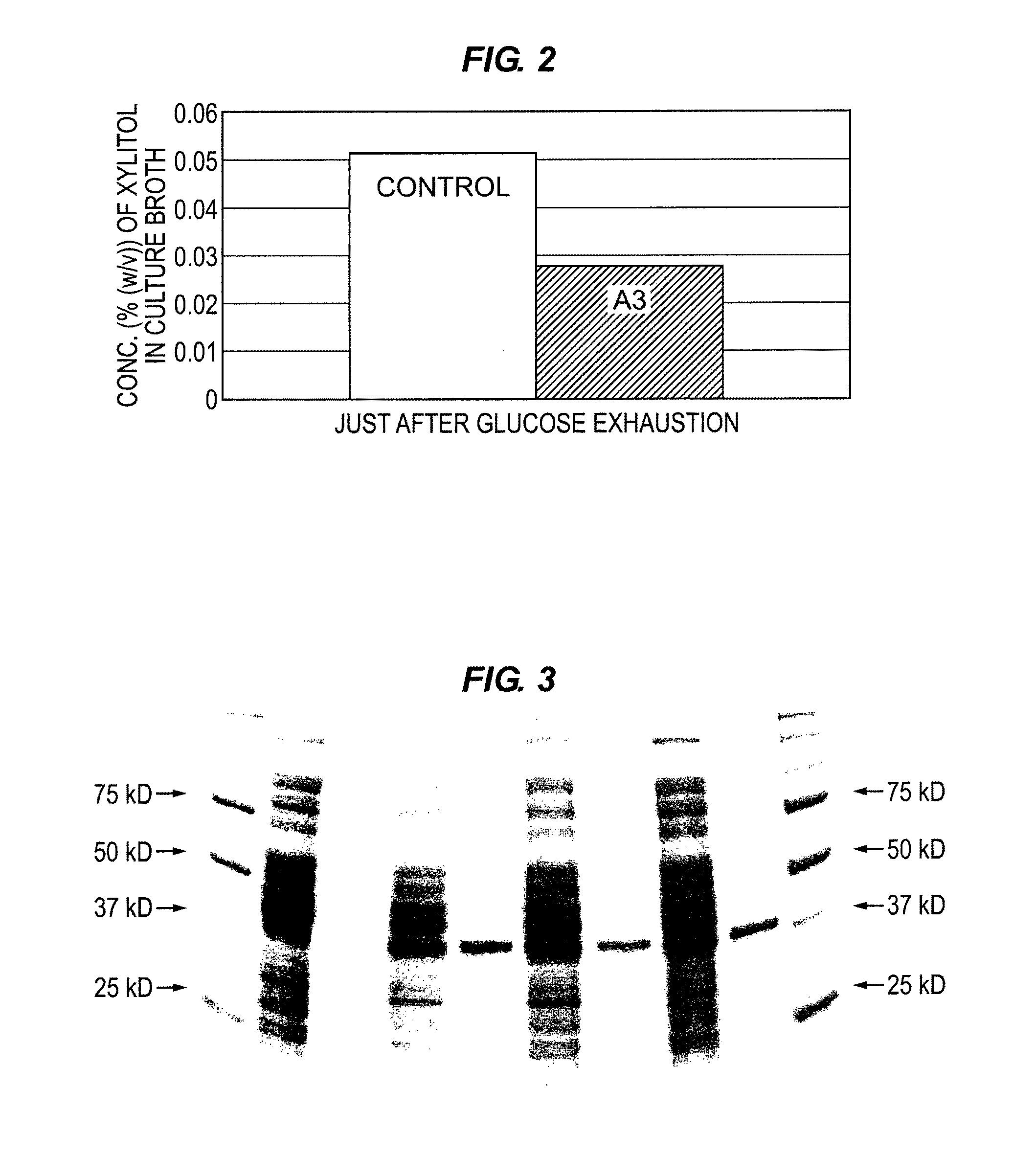

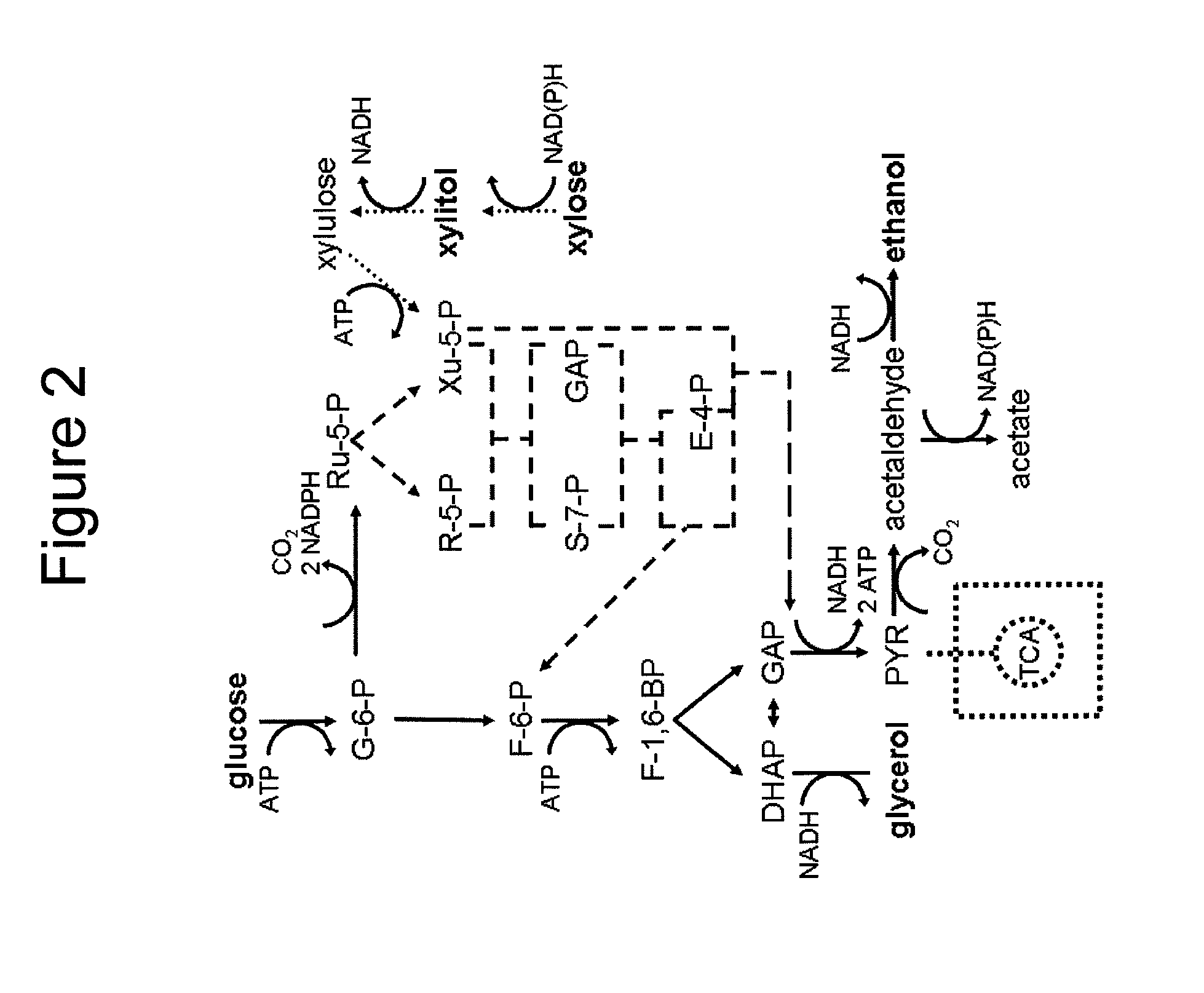

InactiveUS20120196342A1Reducing xylitol productionIncreased ethanol yieldBacteriaBiofuelsXylose fermentationFurfural

The present invention relates to methods of reducing the toxicity of lignocellulosic hydrolysates which comprise one or more inhibitors. One method reduces the amount of furfural inhibitor leading to a more effective process. Another method reduces the amount of xylitol produced during the fermentation of xylose present in lignocellulosic hydrolysates. Naturally occurring aldo / keto reductase enzymes, as well as, enzymes produced by recombinant cells or by selective adaptation may be employed.

Owner:GEORGIA TECH RES CORP

Modified yeast strains exhibiting enhanced fermentation of lignocellulosic hydrolysates

InactiveUS8603788B2High copy numberIncreasing expression and activitySugar derivativesBacteriaCelluloseBiotechnology

The present invention relates to novel xylose-fermenting yeast strains (for example, yeast of the genus Saccharomyces, e.g., S. cerevisiae) with an enhanced ability to ferment the xylose (and / or another pentose sugar) present in a lignocellulosic hydrolysate to a fermentation product(s) (for example, an alcohol (e.g., ethanol) or a sugar alcohol (e.g., xylitol)).

Owner:IOGEN ENERGY CORP

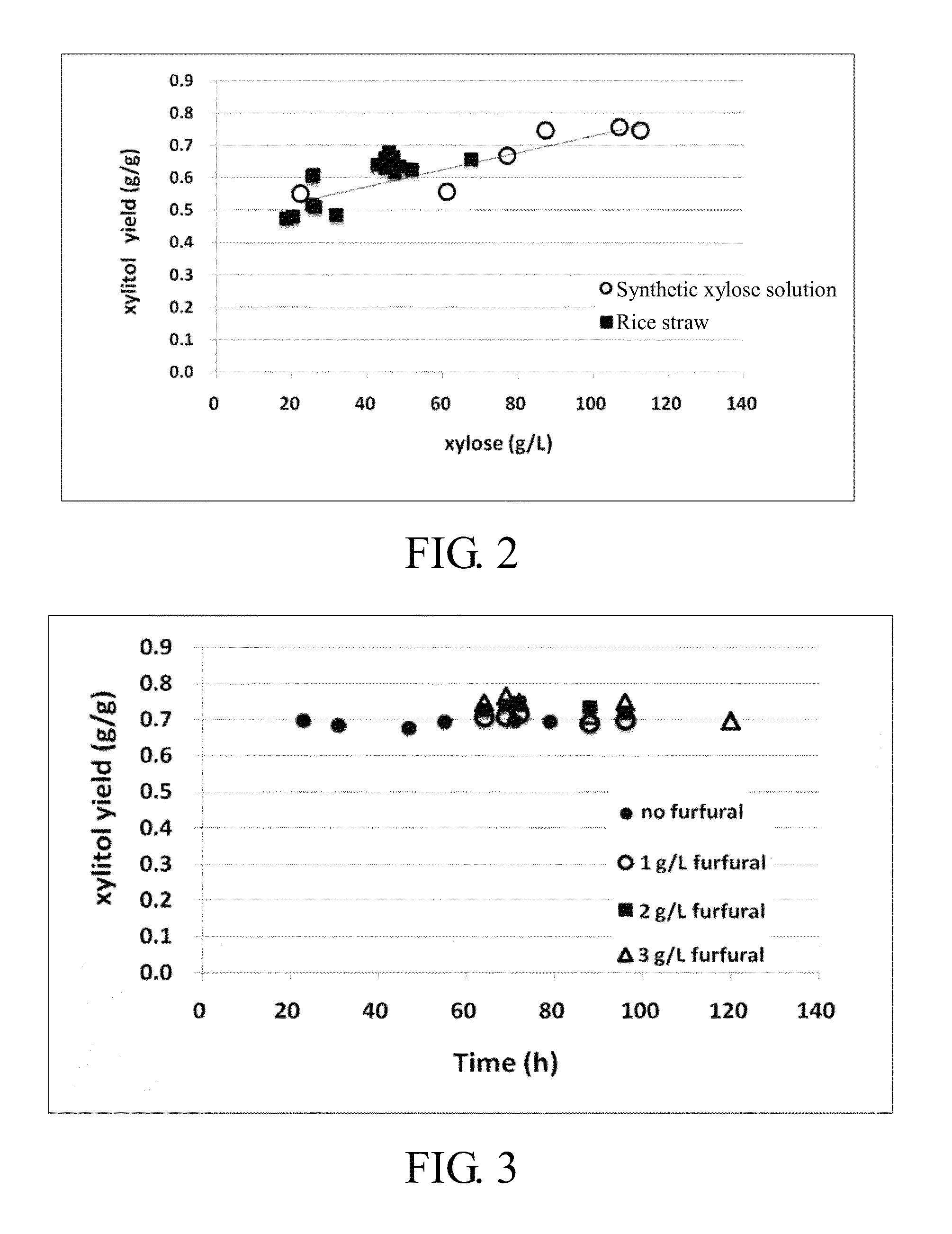

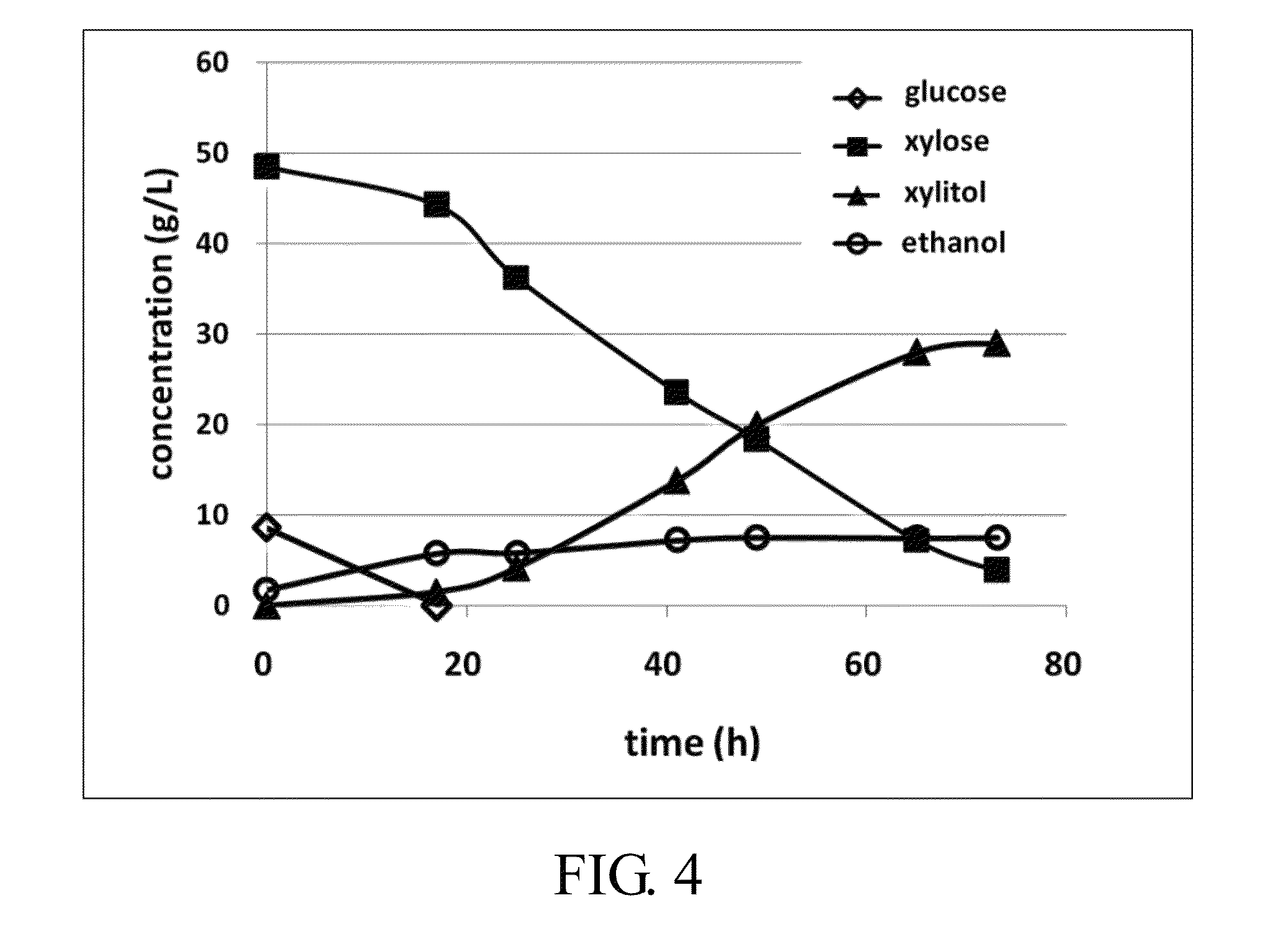

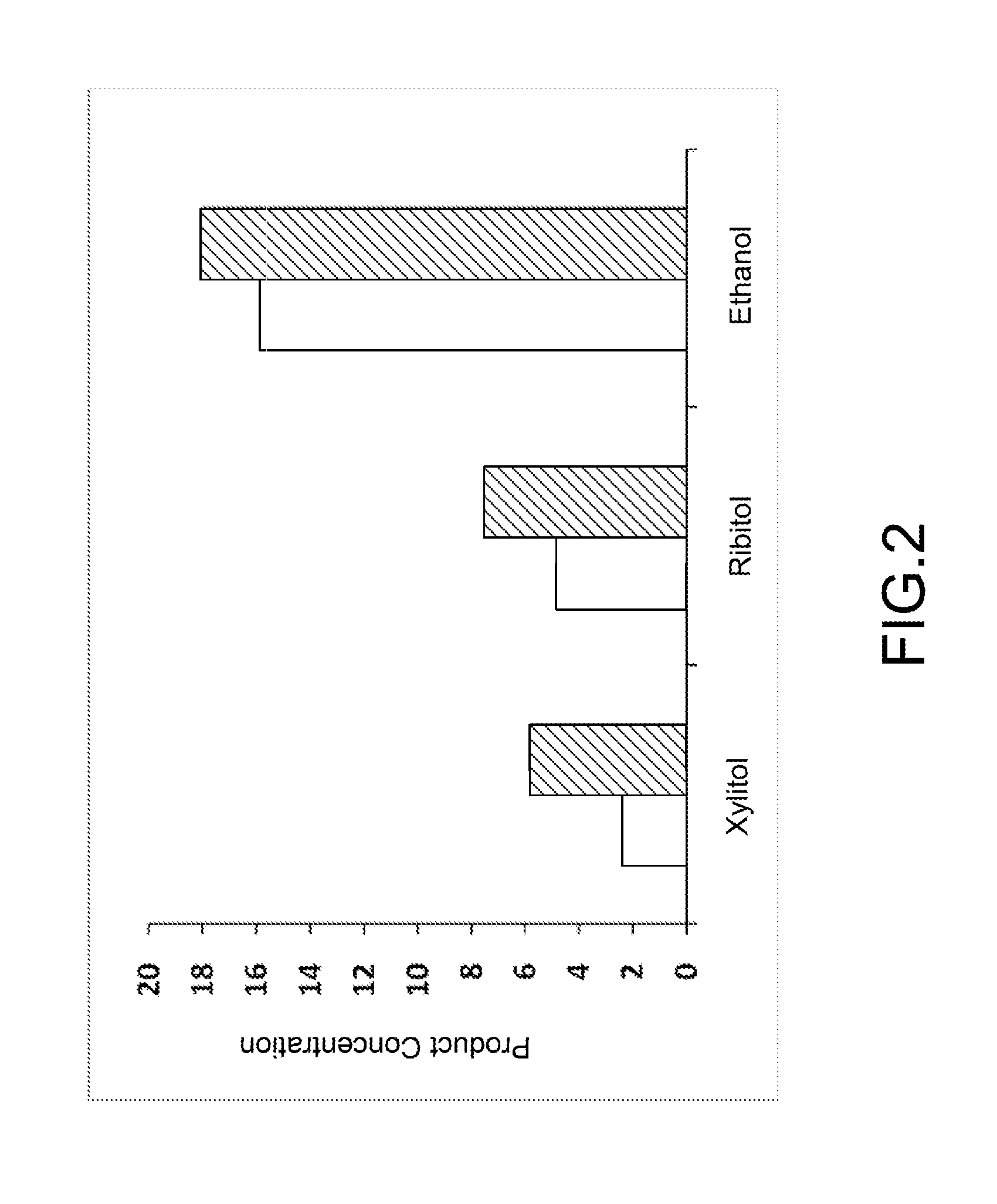

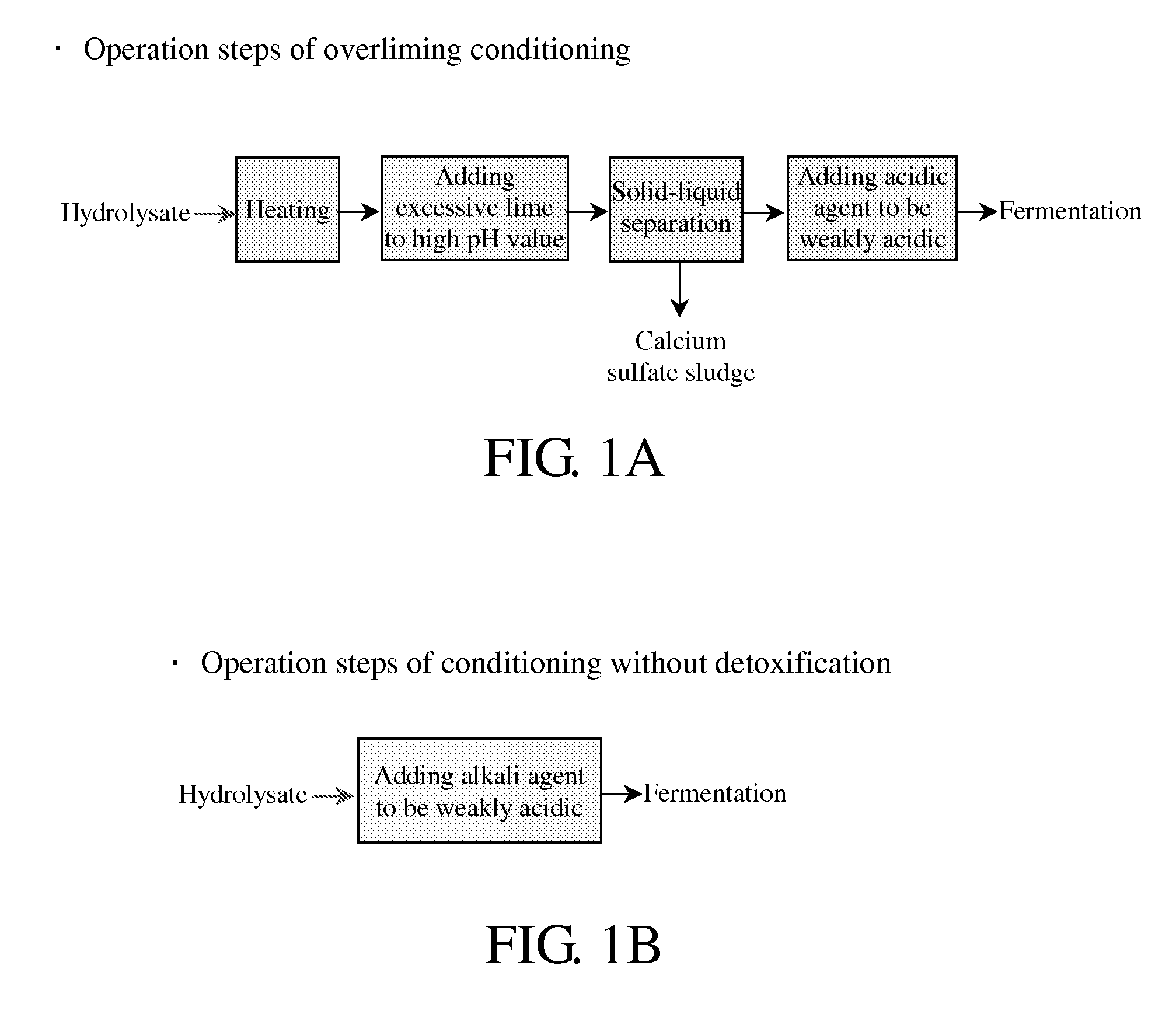

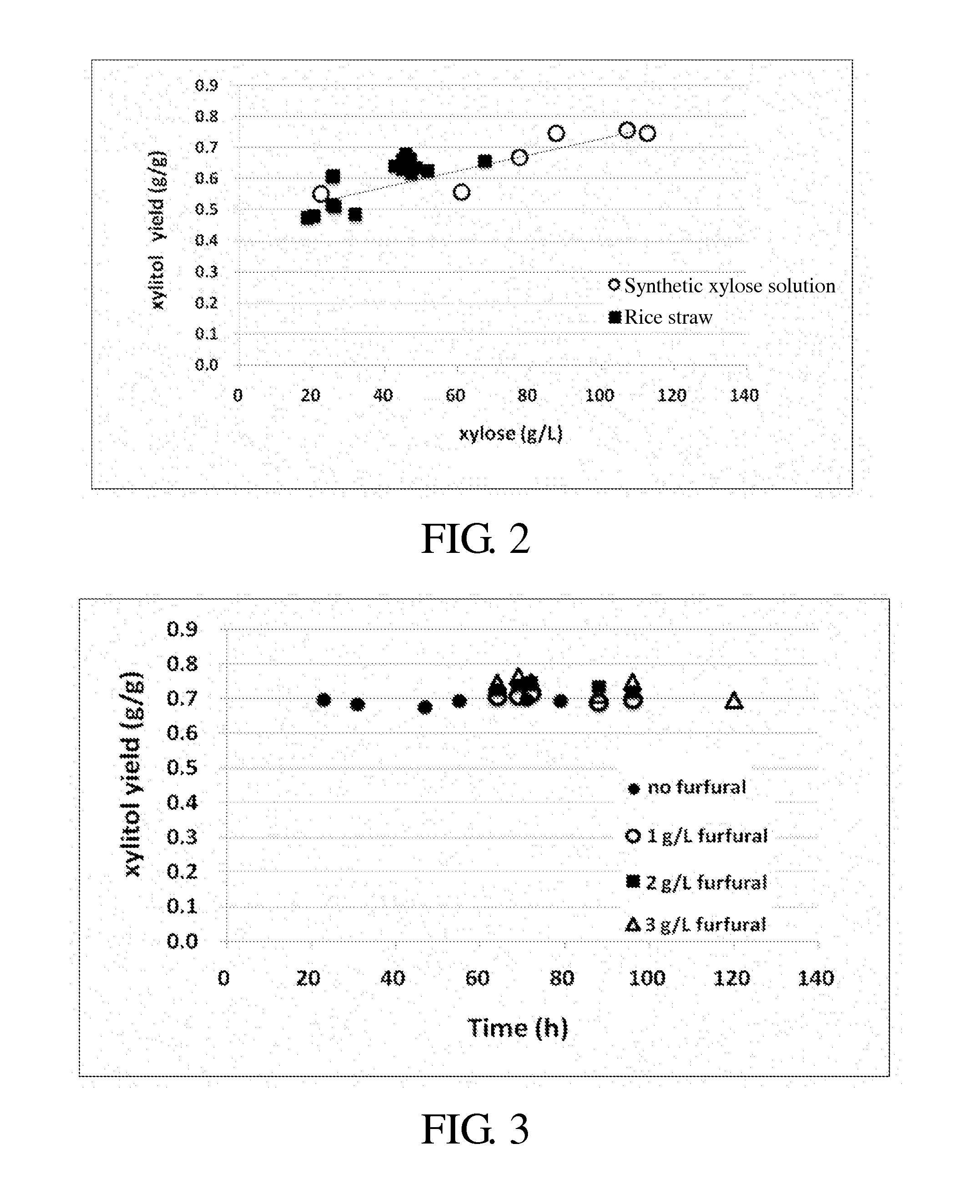

Method for producing xylitol from lignocellulosic hydrolysates without detoxification

InactiveUS8409835B2Improve toleranceValid conversionSugar derivativesMicroorganismsCelluloseHydrolysate

A method for producing xylitol by fermentation of lignocellulosic hydrolysates without detoxification is provided. By using the originally isolated yeast Candida sp., xylose can be effectively converted into xylitol. The invention also provides the Candida strain having high furfural tolerance, and is capable to produce xylitol from various types of non-detoxified lignocellulosic hydrolysates, in which the overall utilization of xylose in hydrolysate can reach over 95%.

Owner:INST NUCLEAR ENERGY RES ROCAEC

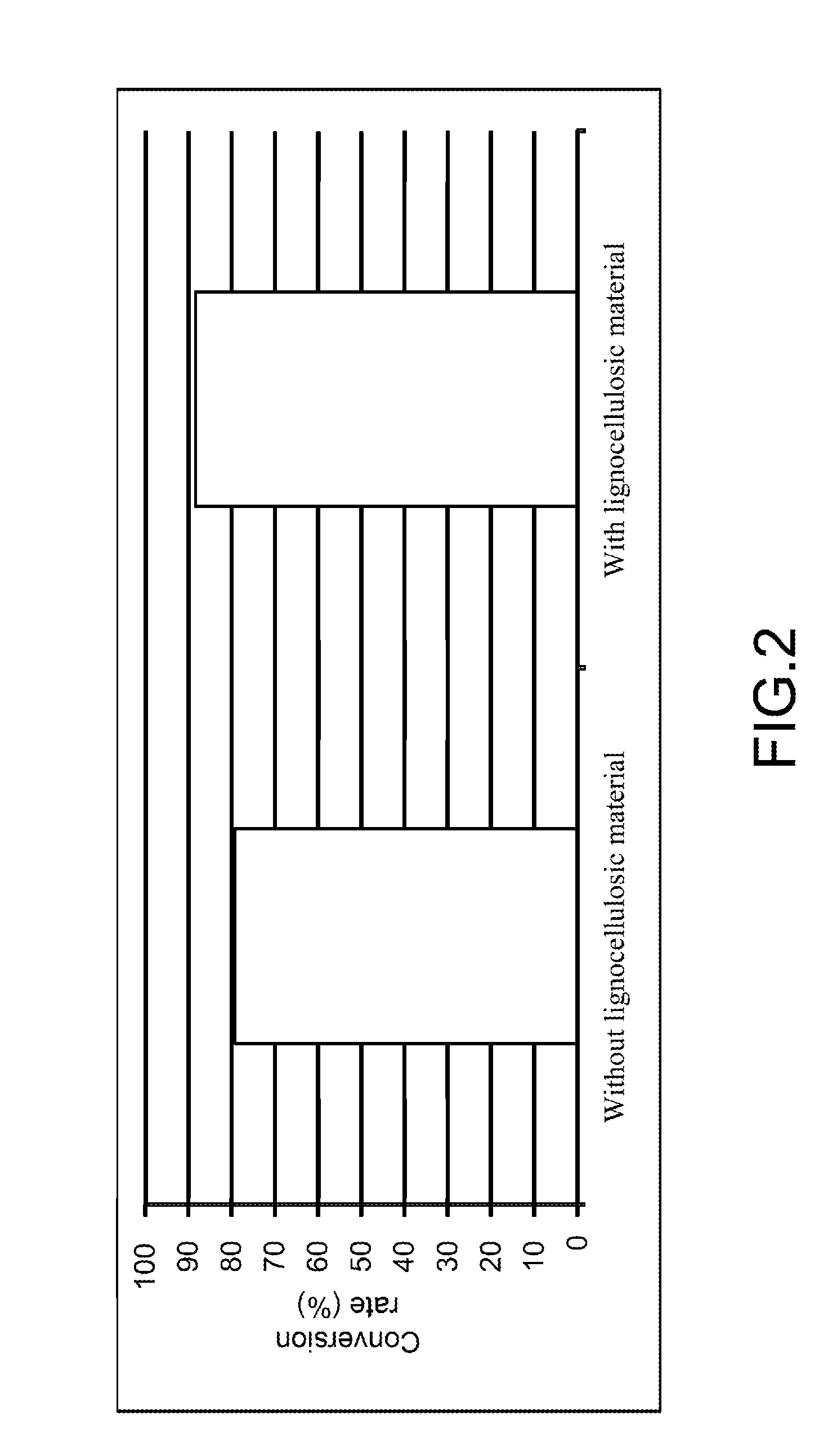

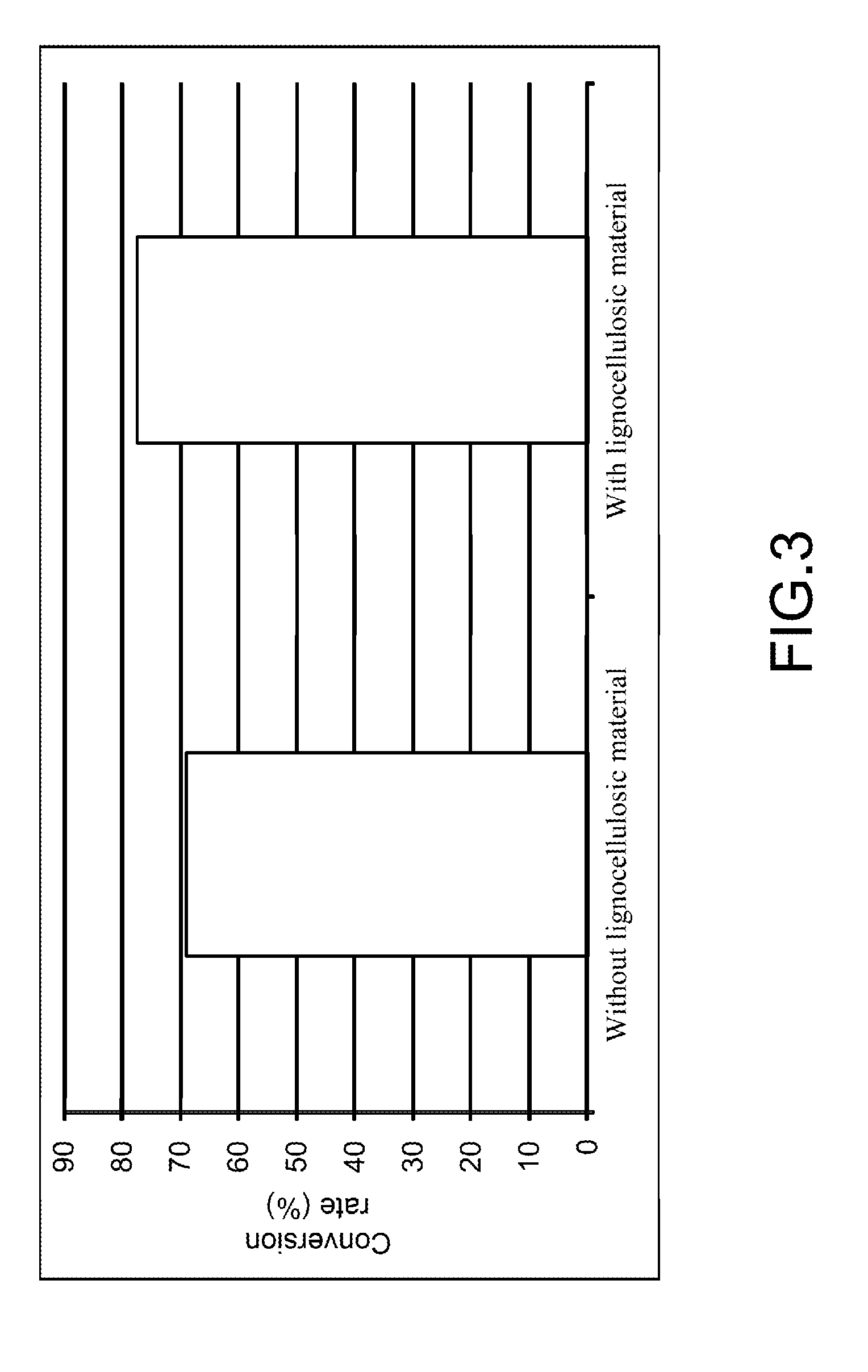

Method of Xylose Fermentation Having Enhanced Conversion Rate in Fiber Solution

InactiveUS20110097780A1Increased ethanol productionSpeed up the conversion processFungiBiofuelsCelluloseFiber

A method is provided for improving the efficiency of xylose fermentation in lignocellulosic hydrolysate. The disclosed embodiment raises the efficiency of xylose conversion by adding a specific lignocellulosic material during fermentation. In particular, a 10% enhancement in the efficiency of xylose conversion for ethanol production was given, and the ethanol yield is achieved 90% after adding the specific lignocellulosic material.

Owner:INST NUCLEAR ENERGY RES ROCAEC

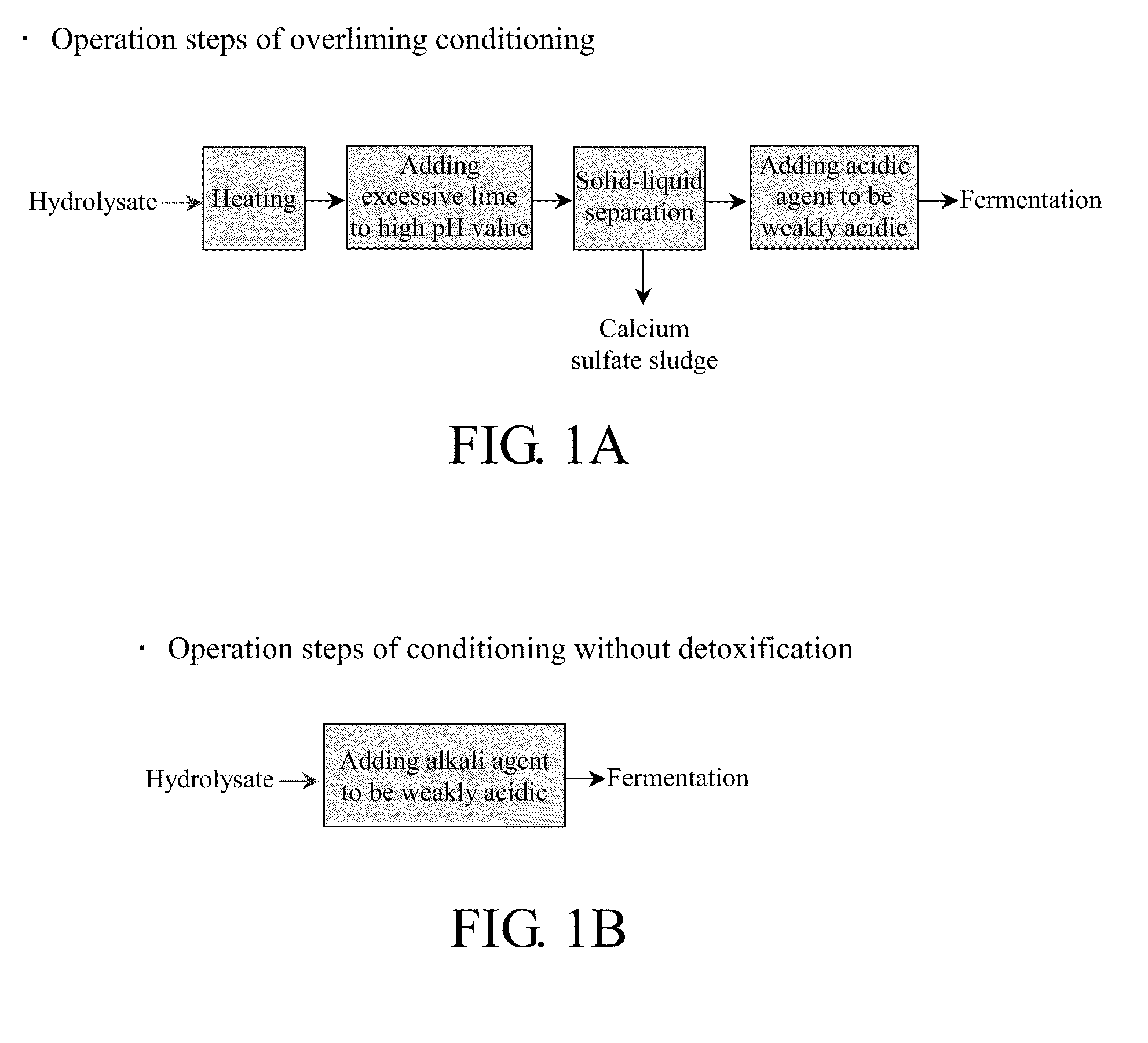

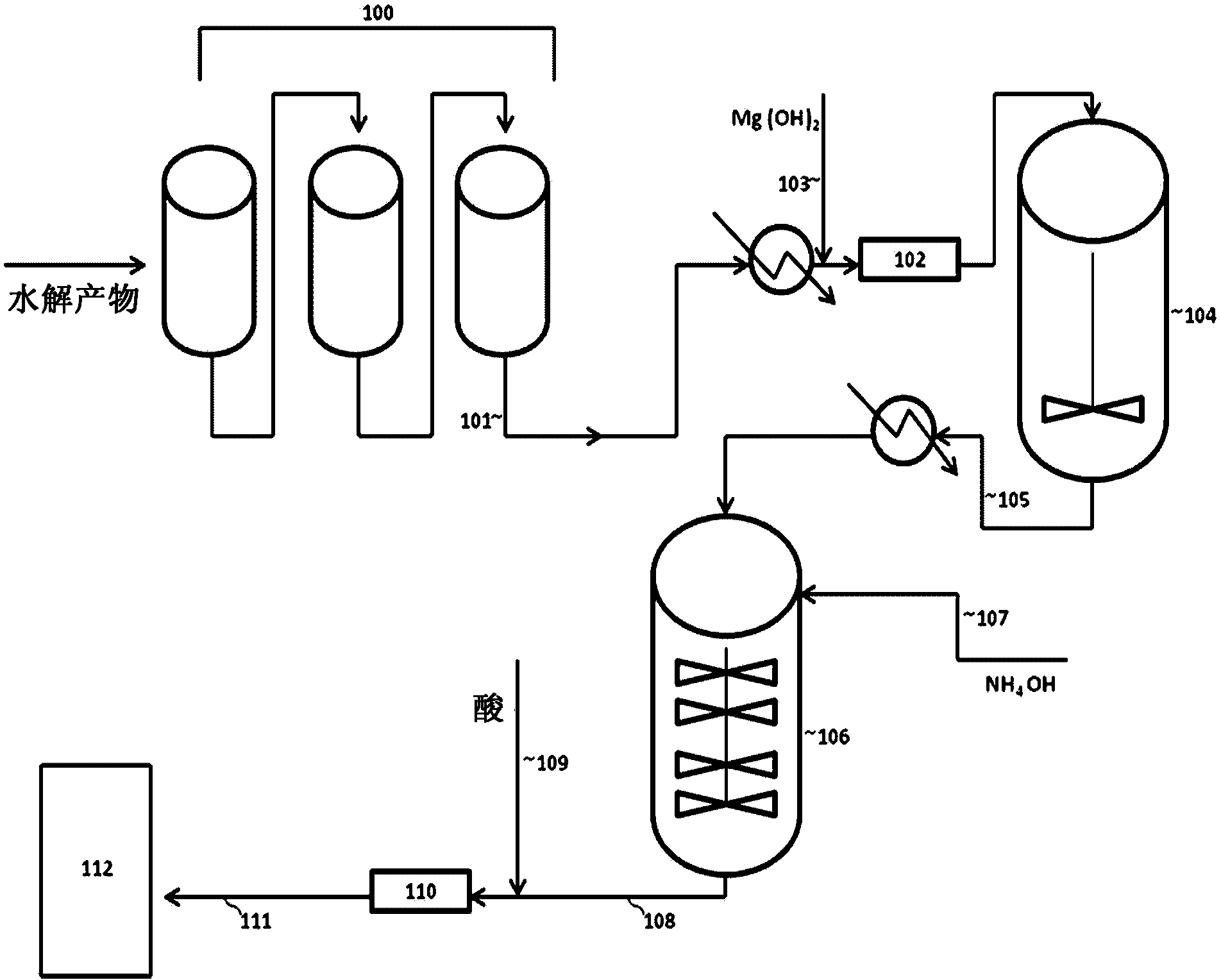

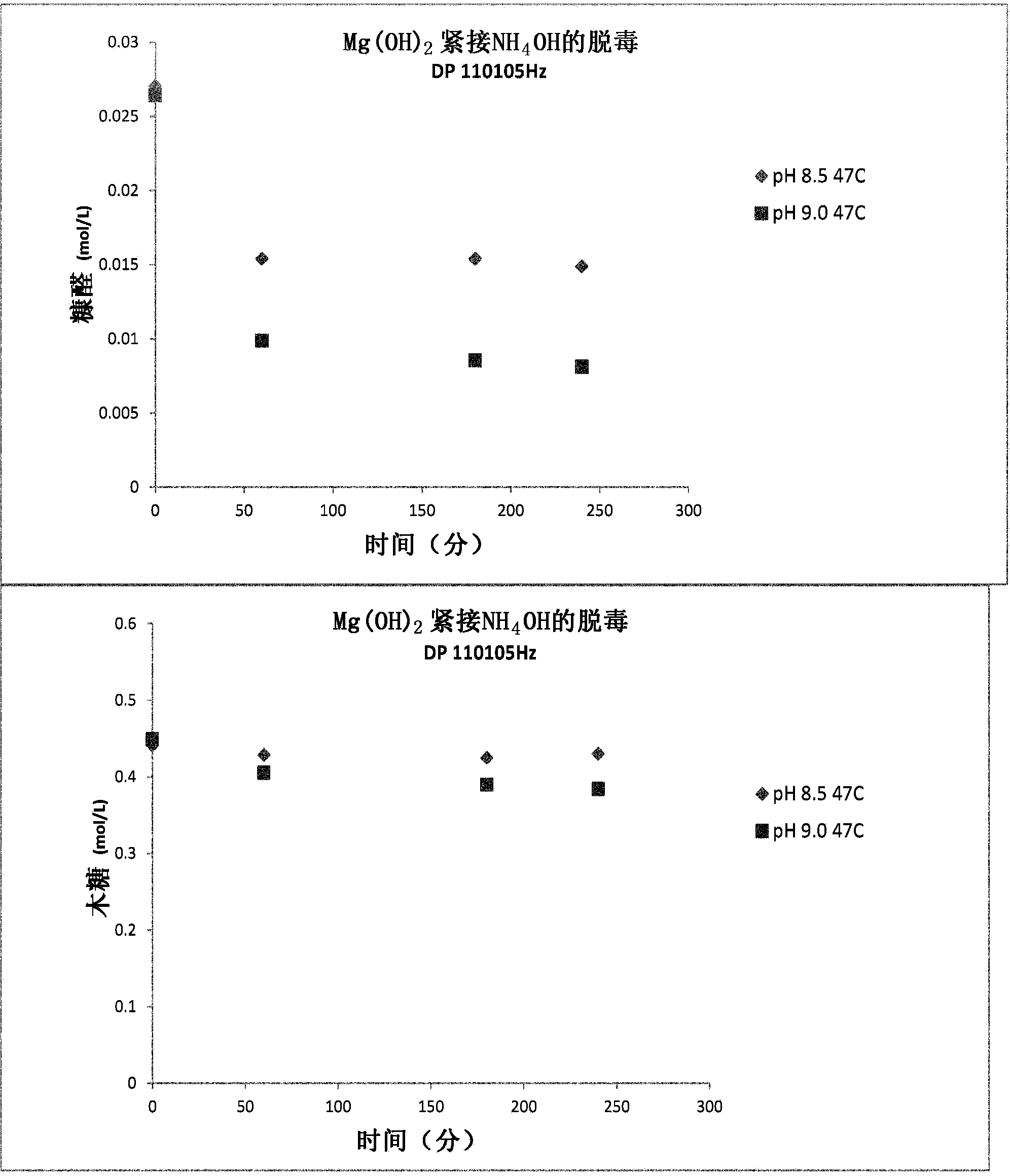

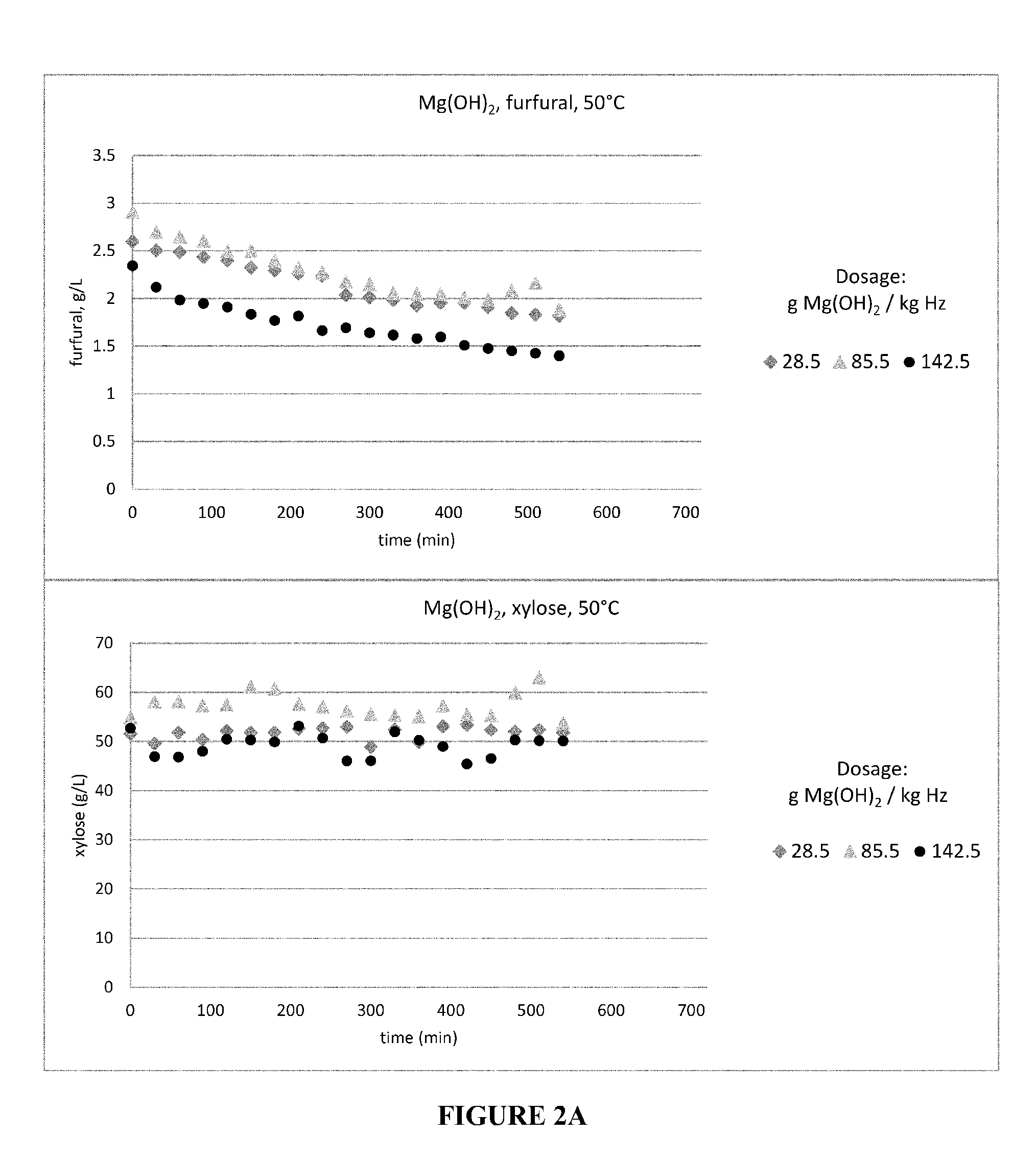

Methods for detoxifying a lignocellulosic hydrolysate

The present disclosure relates to methods for detoxifying a hydrolysate obtained from a lignocellulosic biomass and methods of producing ethanol from the detoxified hydrolysate. The present methods provide detoxified hydrolysates in which the quantity of compounds that are deleterious to fermenting microorganisms are substantially reduced relative to the starting hydrolysate and in which the amount of total fermentable sugars loss is minimal.

Owner:BP CORP NORTH AMERICA INC

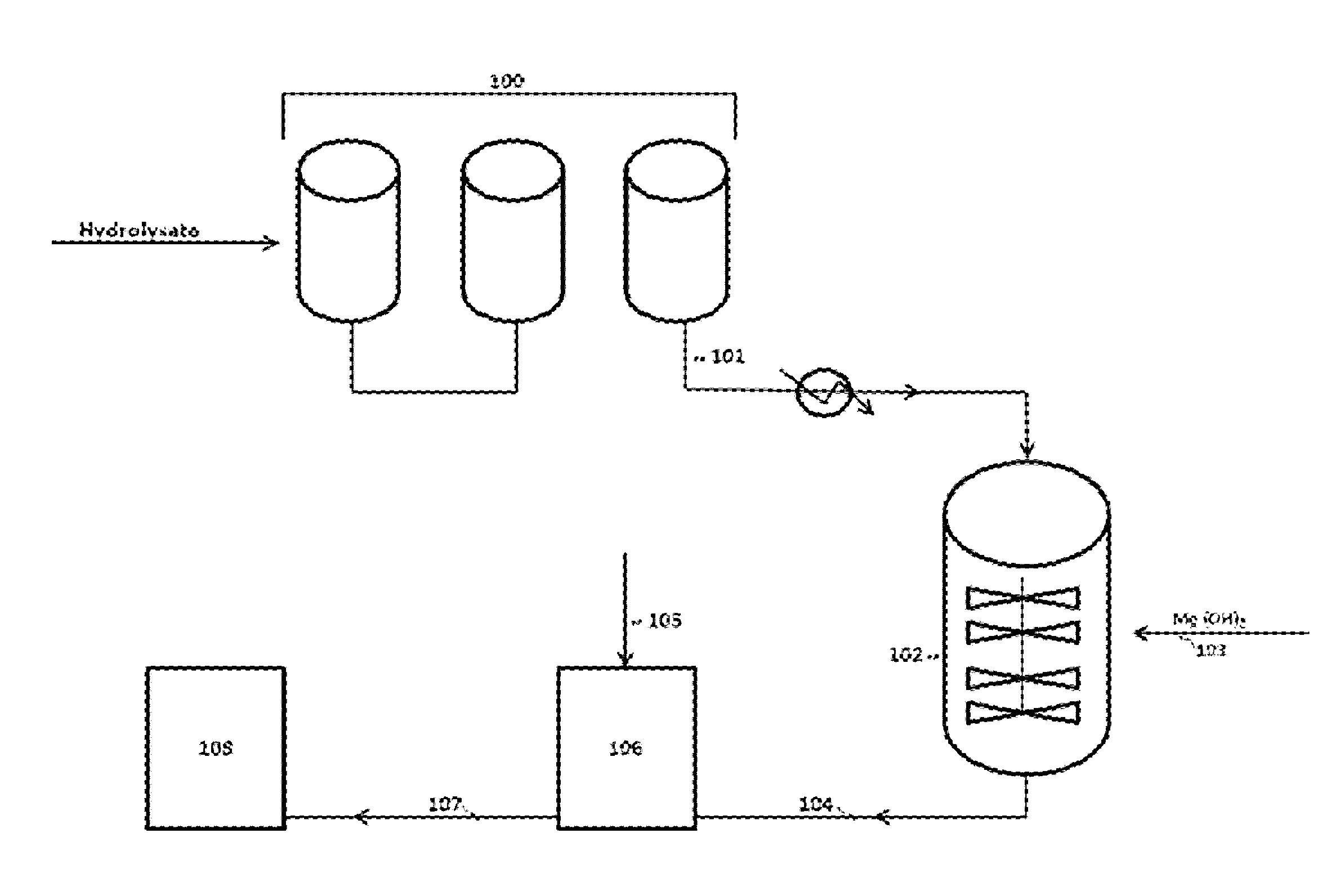

Systems and methods for improving fermentation

Systems and methods for increasing fermentation efficiency of a lignocellulosic hydrolysate are disclosed. The system comprises a filter configurable to remove matter having a particle size of larger than about 25 to 100 microns from the liquid component, and at least one nanofilter configurable to remove acids from the liquid component. An apparatus is used to adjust the pH of the nanofiltered liquid component using a calcium hydroxide composition to a pH of about 5.5 to 6.0. The calcium hydroxide composition includes calcium hydroxide alone or in combination with either ammonium hydroxide and / or potassium hydroxide. The biomass comprises lignocellulosic material including at least one of corncob, corn plant husk, corn plant leaves, and corn plant stalks.

Owner:POET RES INC

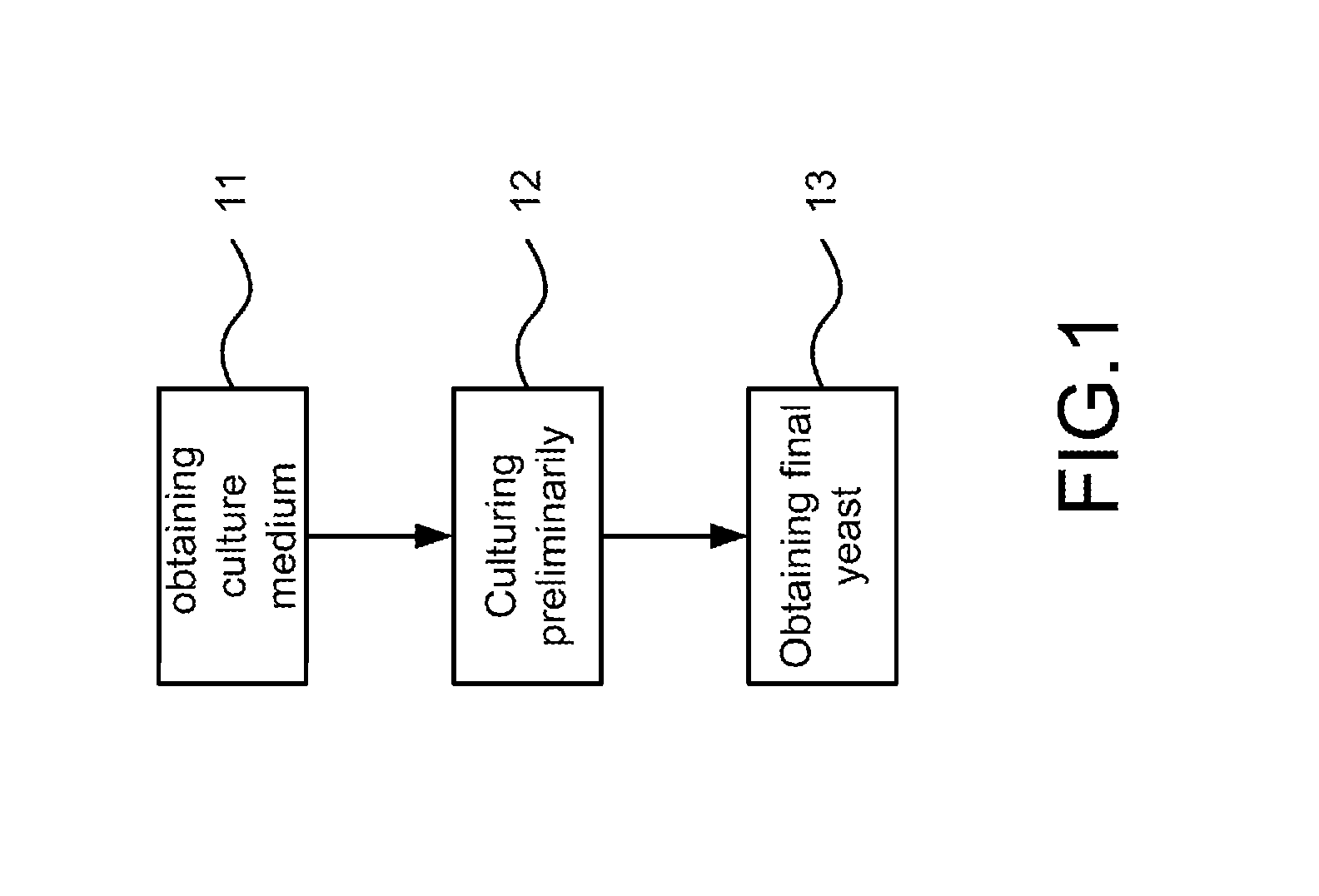

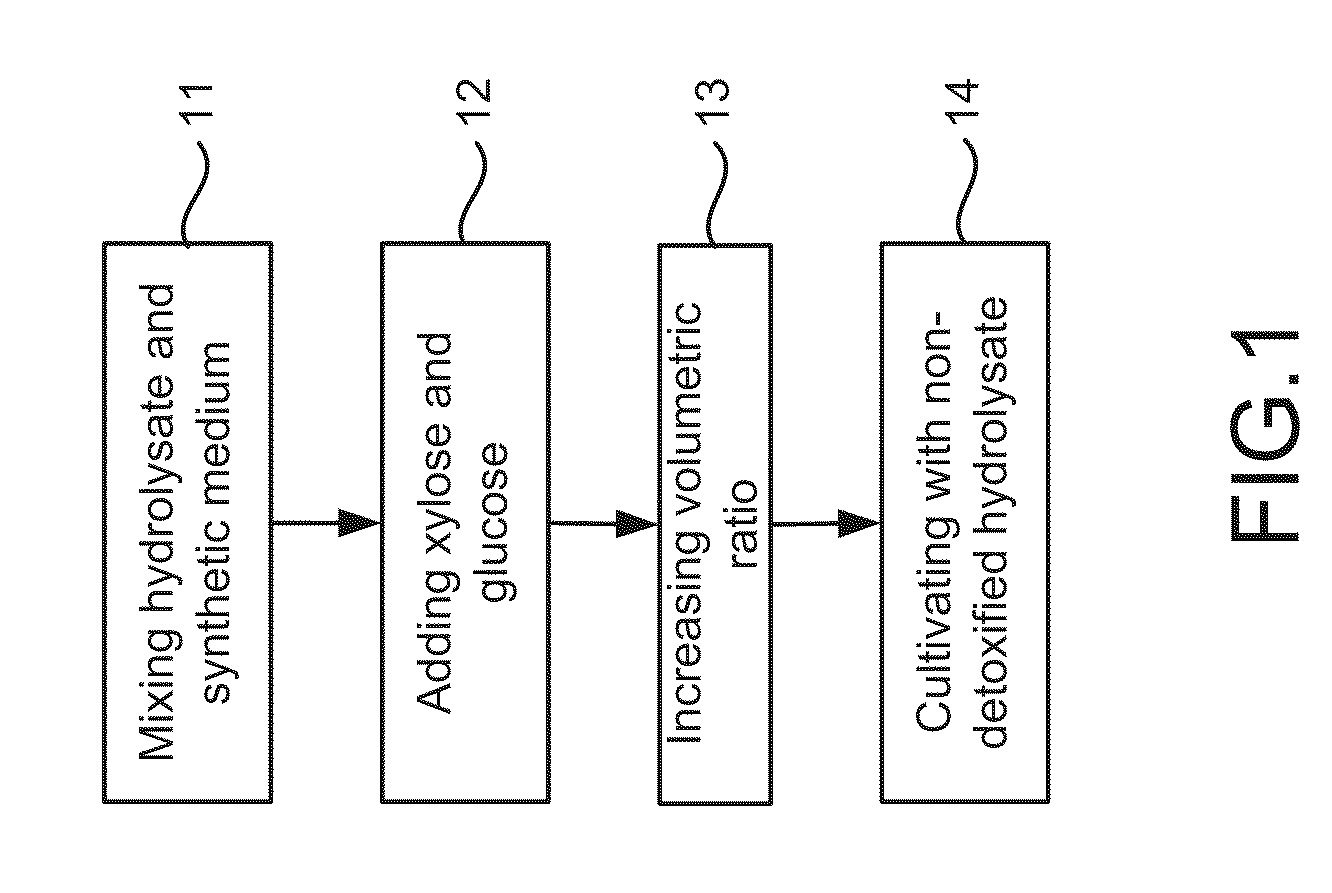

Method of cultivating yeast for enhancing pentitol production

InactiveUS8278078B2Improve production yieldMeet the blocking requirementsFungiFermentationCelluloseYeast

Owner:INST NUCLEAR ENERGY RES ROCAEC

High temperature resistant Issatchenkia orientalis, application thereof and method for producing ethanol through fermentation

InactiveCN102268382BThe fermentation process is simpleReduce fermentation costsFungiBiofuelsCelluloseSweet sorghum

The invention relates to the field of fermentation, in particular to a strain of high temperature resistant Issatchenkia orientalis, application thereof and a method for producing ethanol through fermentation. The strain of high temperature resistant Issatchenkia orientalis IPE100 is separated and screened from farmland crop waste, has a number of CGMCC (China General Microbiological Culture Collection Center) No.4927, has the capacity of fermenting ethanol at high temperature, and can be applied to high temperature fermentation of ethanol by using lignocelluloses hydrolysis products and hightemperature solid fermentation of ethanol by using sweet sorghum.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

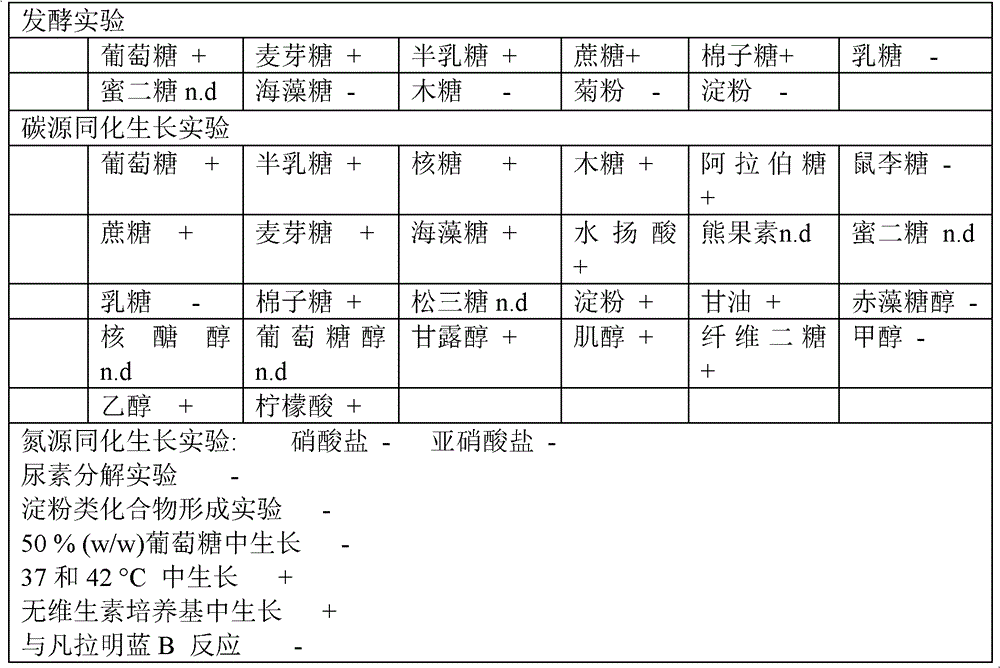

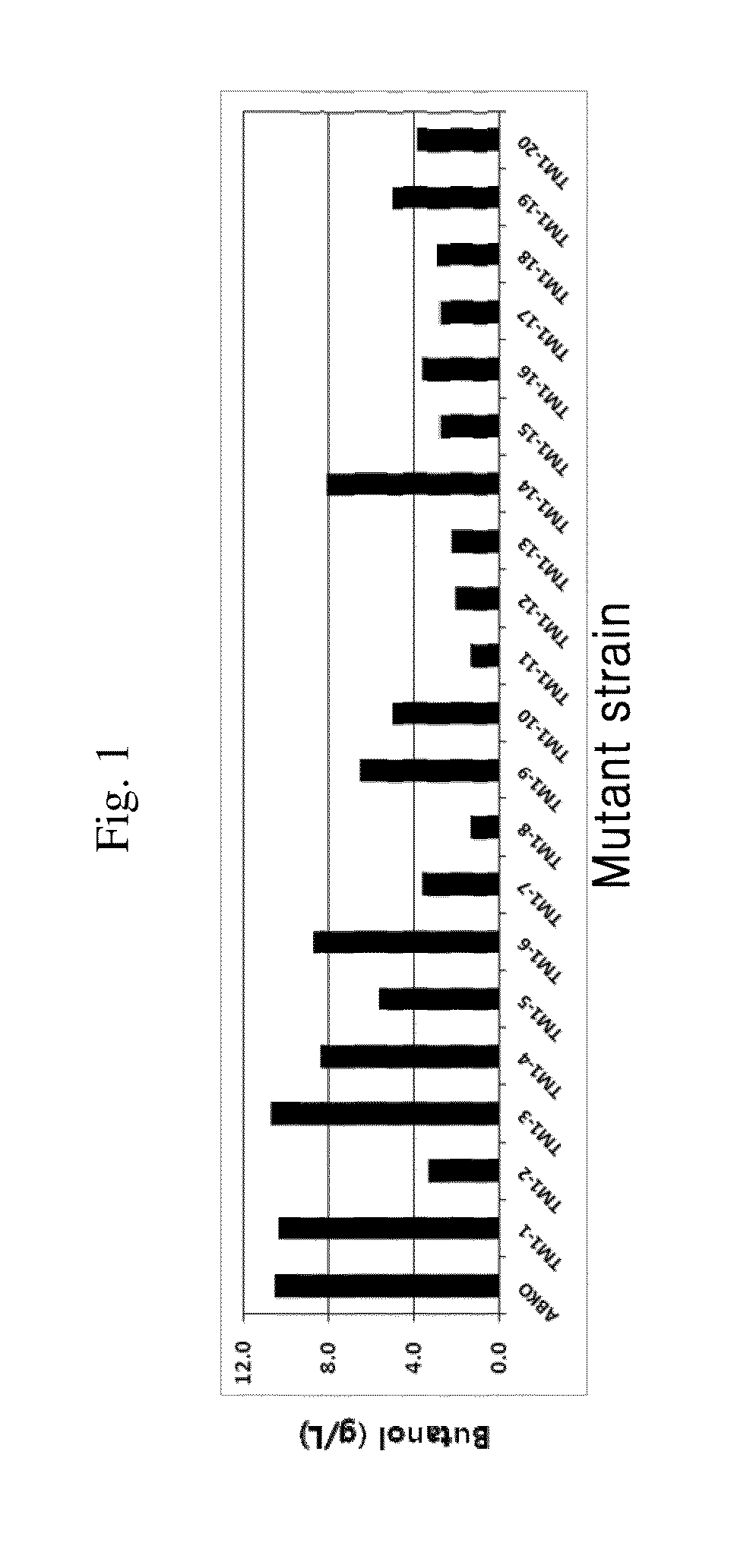

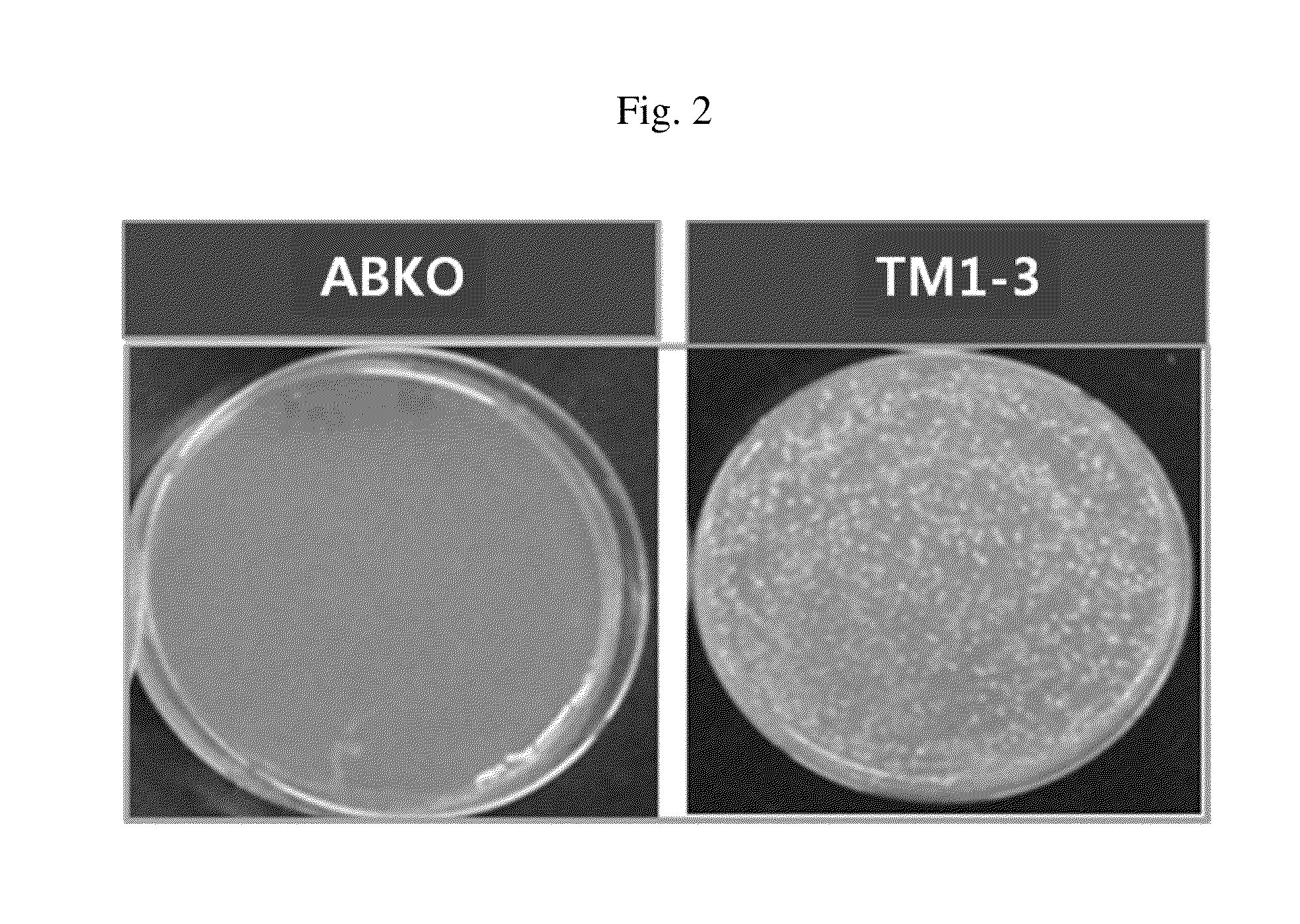

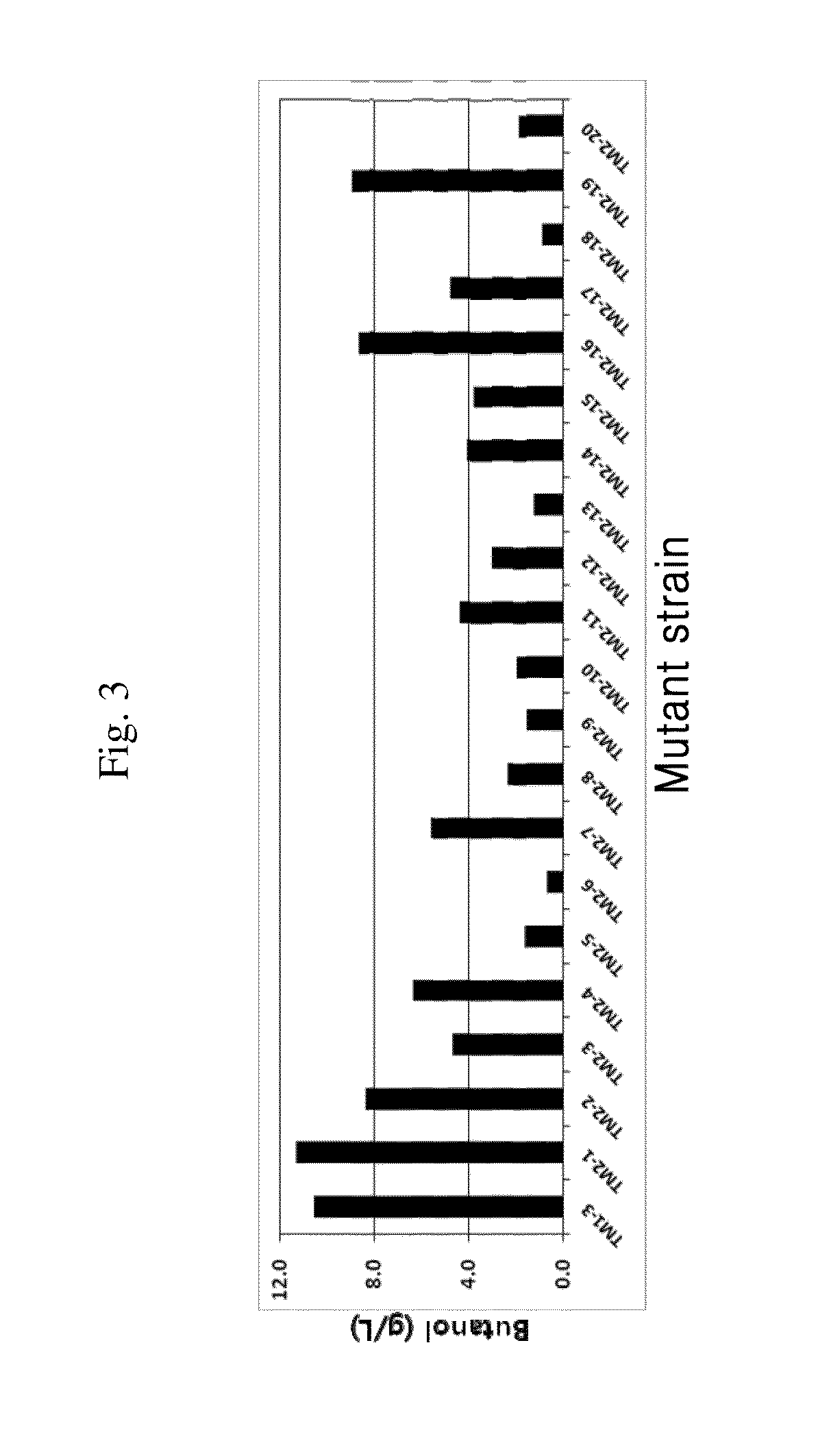

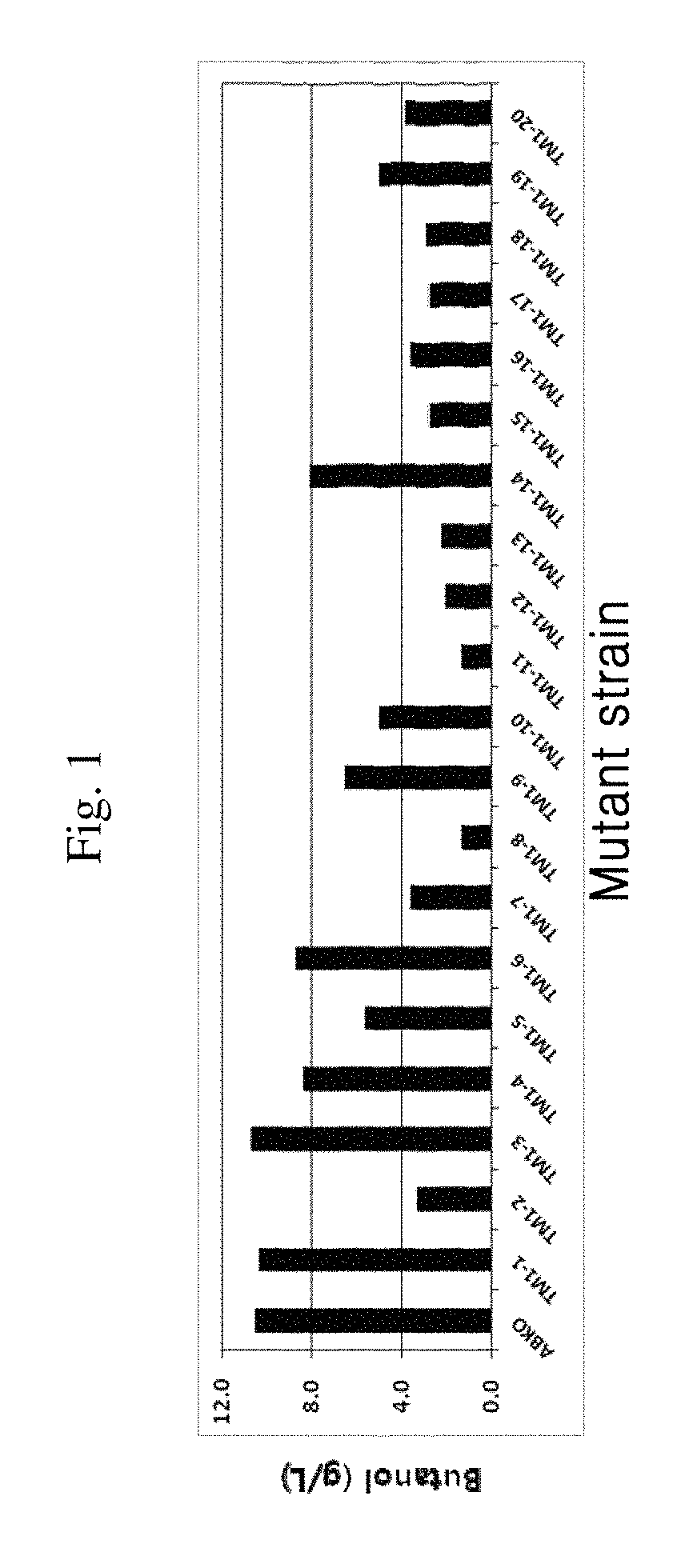

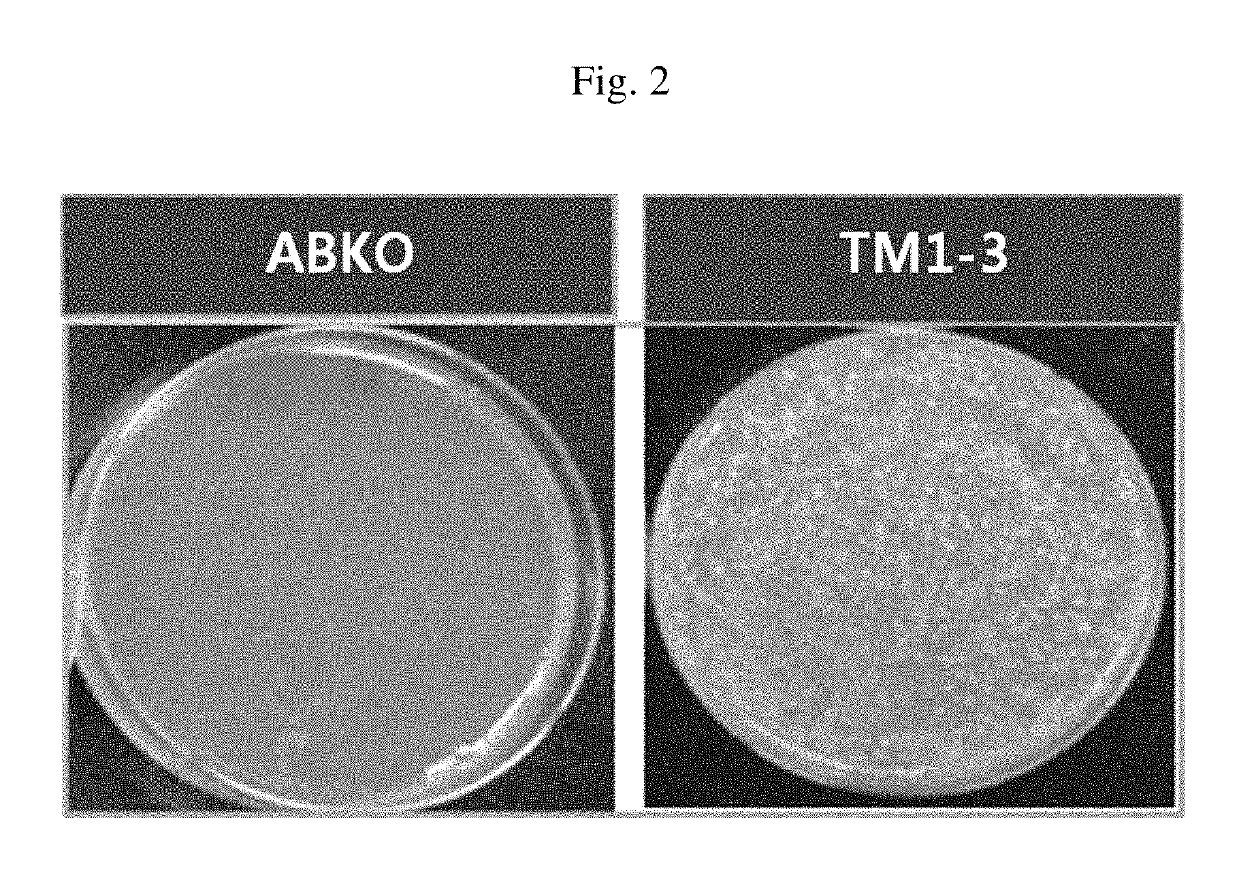

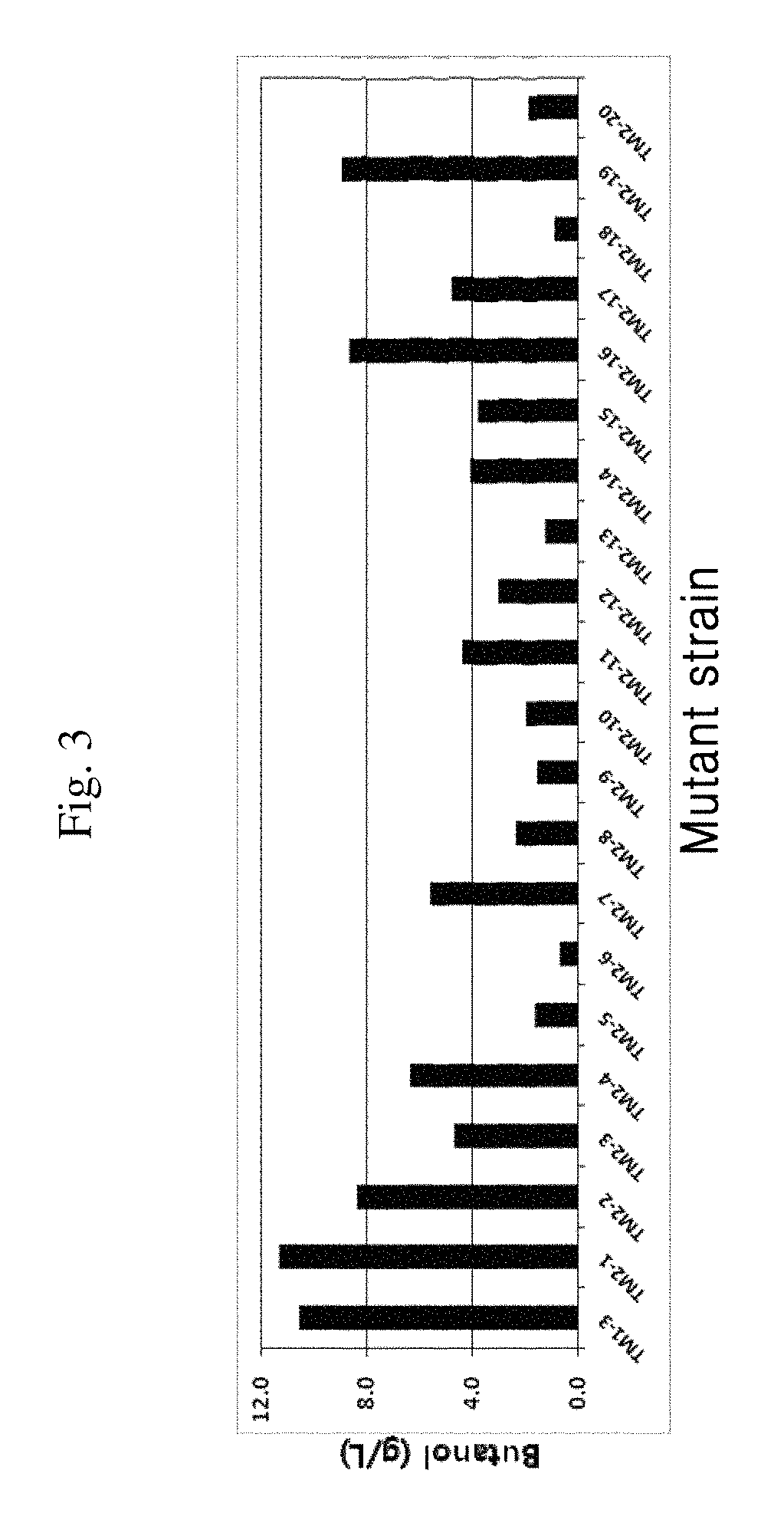

Microorganism capable of simultaneous co-fermentation of mixed sugars and production method of butanol using the same

Embodiments of the invention provide a microorganism capable of simultaneous co-fermentation of two or more sugars in a lignocellulosic hydrolysate and having tolerance against microorganism growth inhibitory substances in the lignocellulosic hydrolysate and further having butanol productivity. In addition, embodiments of the invention provide a recombinant microorganism in which a pathway converting butyryl-CoA into butanol or a pathway converting butyrate into butyryl-CoA is promoted, and butanol productivity is increased. Further, a method for producing butanol using the microorganisms is provided.

Owner:GS CALTEX CORP

Method of Cultivating Fermentative Yeast Used for Xylose Fermentation of Non-Detoxified Lignocellulosic Hydrolysate

A hydrolysate-adapted yeast, Pichia stipitis INER 1128, is cultivated according to the present invention. The adapted yeast can effectively convert xylose into ethanol in lignocellulosic hydrolysate, which is not even detoxified. Well ethanol yield is obtained while xylose is not wasted and thus cost is reduced.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Methods for detoxifying a lignocellulosic hydrolysate

InactiveUS20160002359A1Minimal lossLess sugar burnPretreatment with alkaline reacting compoundsBiofuelsMicroorganismCellulose

The present disclosure relates to methods for detoxifying a hydrolysate obtained from a lignocellulosic biomass and methods of producing ethanol from the detoxified hydrolysate. The present methods provide detoxified hydrolysates in which the quantity of compounds that are deleterious to fermenting microorganisms are substantially reduced relative to the starting hydrolysate and in which the amount of fermentable sugars loss is minimal.

Owner:BP CORP NORTH AMERICA INC

Microorganism capable of simultaneous co-fermentation of mixed sugars and production method of butanol using the same

Owner:GS CALTEX CORP

Method for producing xylitol from lignocellulosic hydrolysates without detoxification

A method for producing xylitol by fermentation of lignocellulosic hydrolysates without detoxification is provided. By using the originally isolated yeast Candida sp., xylose can be effectively converted into xylitol. The invention also provides the Candida strain having high furfural tolerance, and is capable to produce xylitol from various types of non-detoxified lignocellulosic hydrolysates, in which the overall utilization of xylose in hydrolysate can reach over 95%.

Owner:INST NUCLEAR ENERGY RES ROCAEC

In situ detoxication alcohol fermentation method of ligno-cellulose hydrolysate using single strain

The invention provides a method for adopting single strains to carry out fermentation to in-situ virus-eliminated alcohol of hydrolyzate of lignocellulose; therefore, the invention firstly provides a new strain of pichia stipitis of trunks and the preservation number is CGMCC No.2661; the experiment proves that the strain can carry out detoxification in situ to lignocellulose diluted acid hydrolyzate, can transform glucose and xylose in lignocellulose diluted acid hydrolysate into ethanol effectively and reach 92.4 percent of the highest theoretical value of the ethanol. The use of the straincan simplify the technique that the lignocellulose is used as materials to produce the ethanol, reduces the production cost of the ethanol and has significant theoretical and practical significance to the commercialization of the production of lignocellulose ethanol.

Owner:CAPITAL NORMAL UNIVERSITY

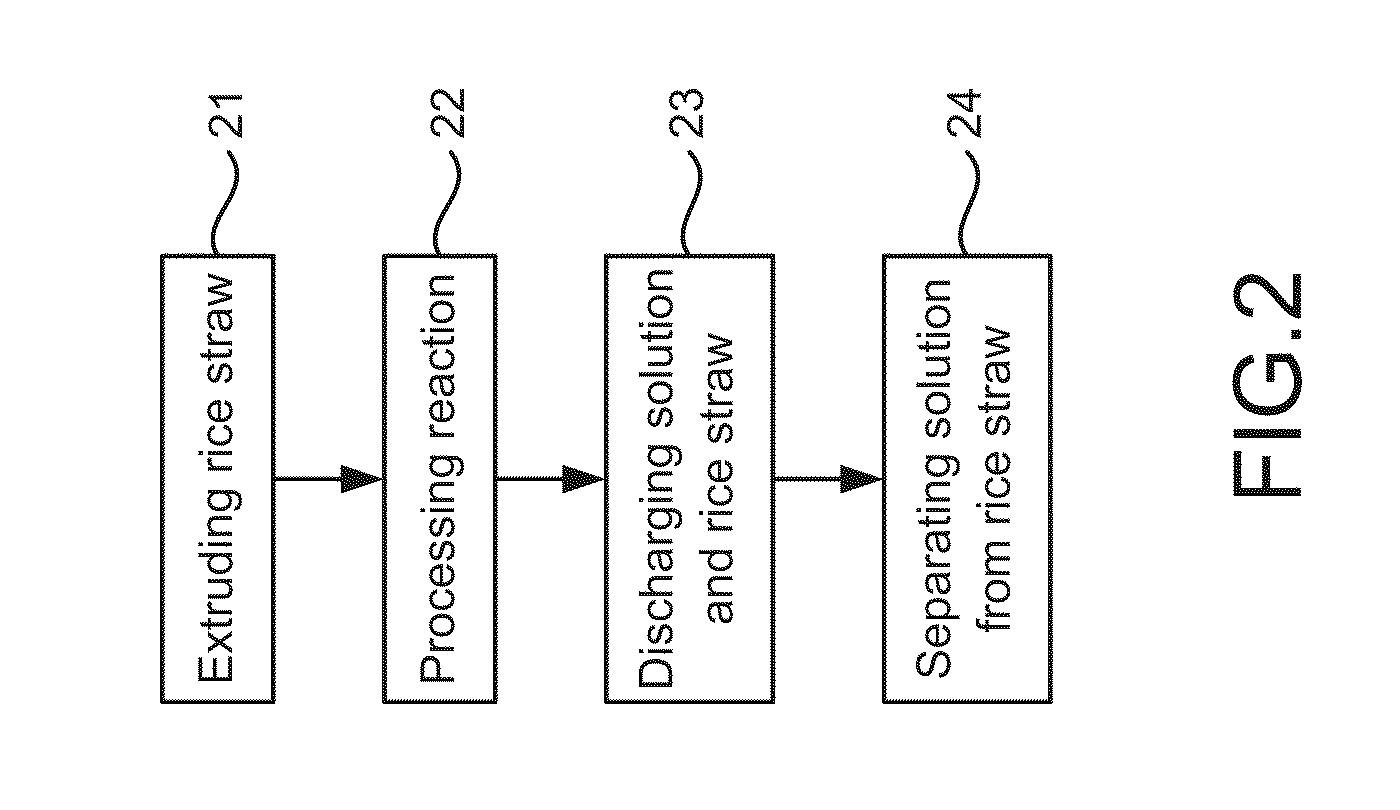

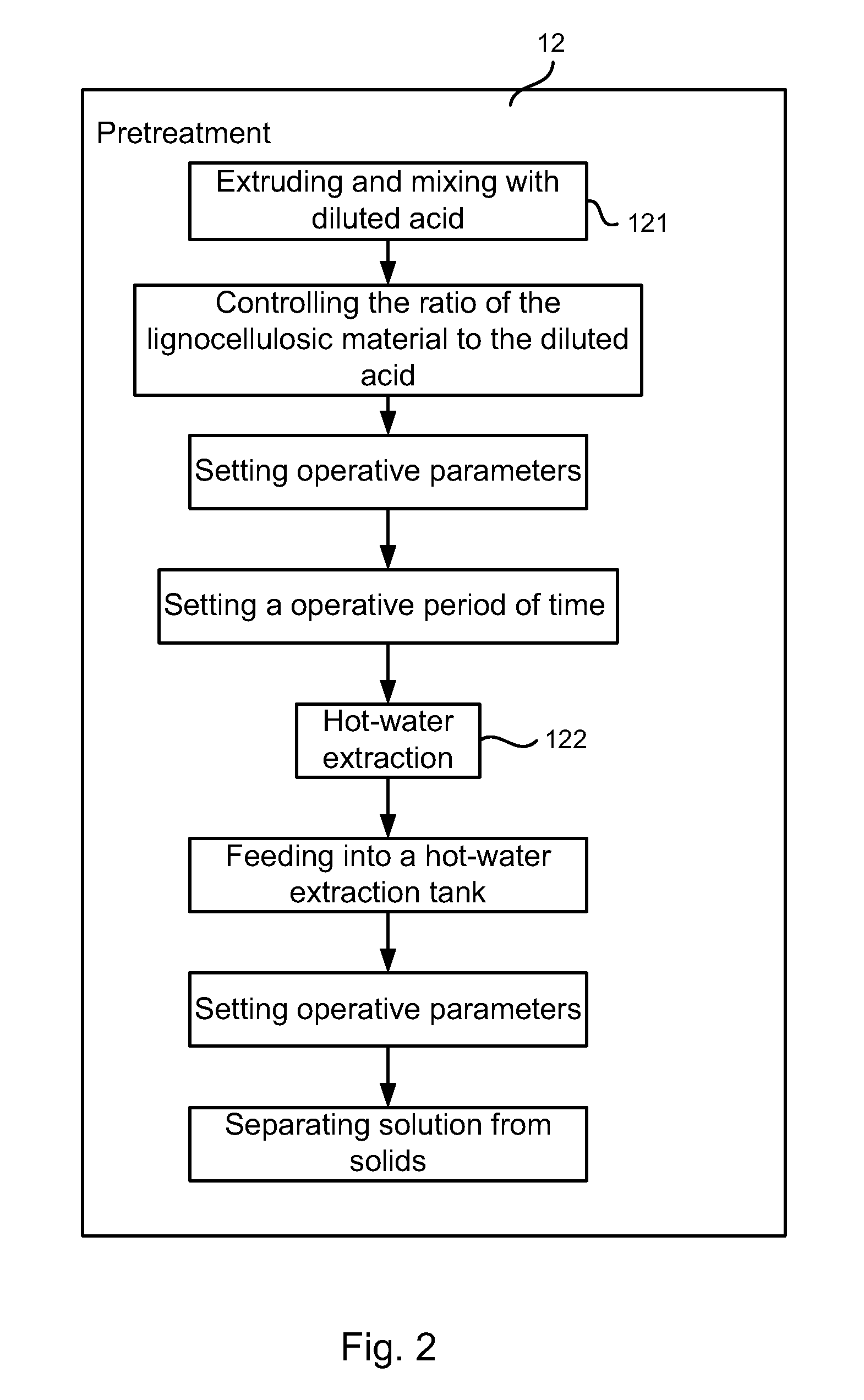

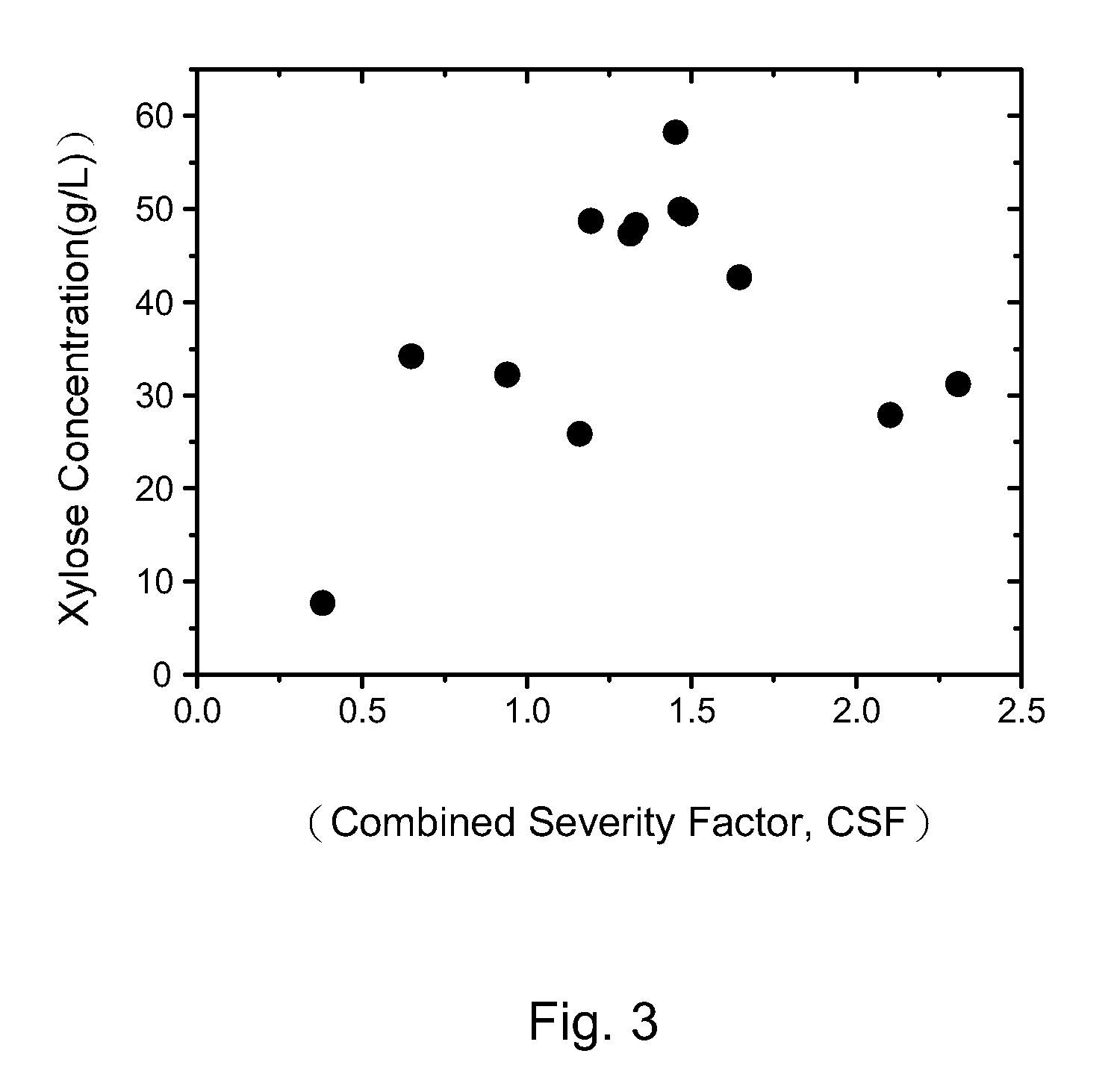

Method for increasing the concentration of xylose in lignocellulosic hydrolysate

InactiveUS8080128B2Increase concentrationHigh yieldNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseHigh concentration

Disclosed is a method for increasing the concentration of xylose in lignocellulosic hydrolysate. The method includes the step of extruding lignocellulosic material and mixing the lignocellulosic material with diluted acid and the step of conducting hot-water extraction on the mixture. Hence, the concentration of the xylose in the lignocellulosic hydrolysate can achieve a high concentration of 60 g / L, and the yield of the xylose can reach to 90%.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Production of arabitol

ActiveUS10428355B2Increase productionMinimization requirementsFermentationMicroorganismStationary phase

A method for producing arabitol may include providing a fermentation culture having a microorganism and a carbon source; allowing the microorganism to ferment the carbon source; monitoring a process condition of said step of allowing the microorganism to ferment the carbon source; and collecting a product from the fermentation culture after said step of monitoring a process condition indicates that a predetermined change in the process condition has occurred. Other methods may include steps of providing soybean-based lignocellulosic hydrolysate as a carbon source for a fermentation culture, and modifying the pH of one or more of the growth phase and the stationary phase of a fermentation process.

Owner:THE UNIVERSITY OF AKRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com