Novel use for issatchenkia orientalis

A technology of ESAB yeast and yeast extract, which is applied in the application field of lignocellulose hydrolyzate fermentation to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

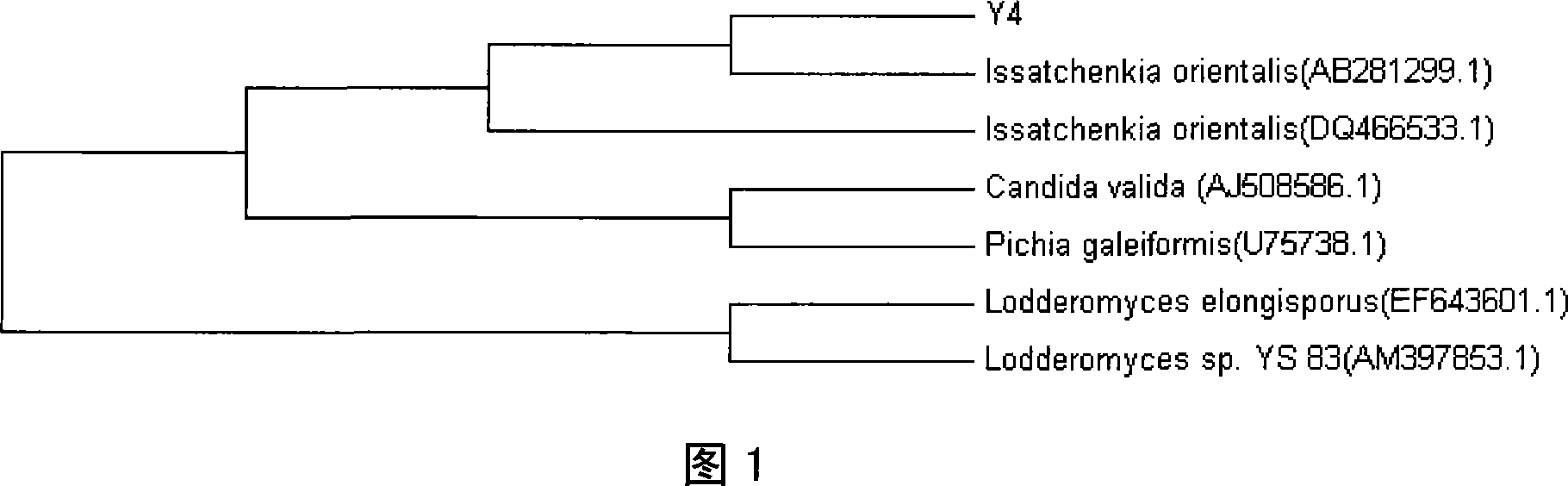

[0030] Example 1 Isolation and identification of Y4

[0031] Y4 separation method: collect soil samples from a depth of 1-5 cm below the surface of the soil near a furfural plant, activate the collected soil samples and add them to YPD medium for enrichment culture, and then take 10 mL of the enriched bacteria The solution was connected to the medium containing 90mL hydrolysate (yeast extract 3g / L, KH 2 PO 4 3g / L, malt extract 3g / L, (NH 4 ) 2 SO 4 1g / L, MgSO 4 .7H 2 O1g / L, tryptone 3g / L, the rest is lignocellulose hydrolysate stock solution, adjust the pH to 5.0-6.0) in a 250mL Erlenmeyer flask, incubate at 80rpm and 30℃ for 48h, then take 10mL of this culture solution and connect it to 90mL In the same fresh medium, continue to incubate for 48 hours at 80 rpm and 30°C. Repeat this procedure. After 4-5 transfers, take 10 uL of the culture solution after a certain gradient dilution and spread it on the solid plate of the same medium. After 48 hours of culture at 30°C, a single colo...

Embodiment 2

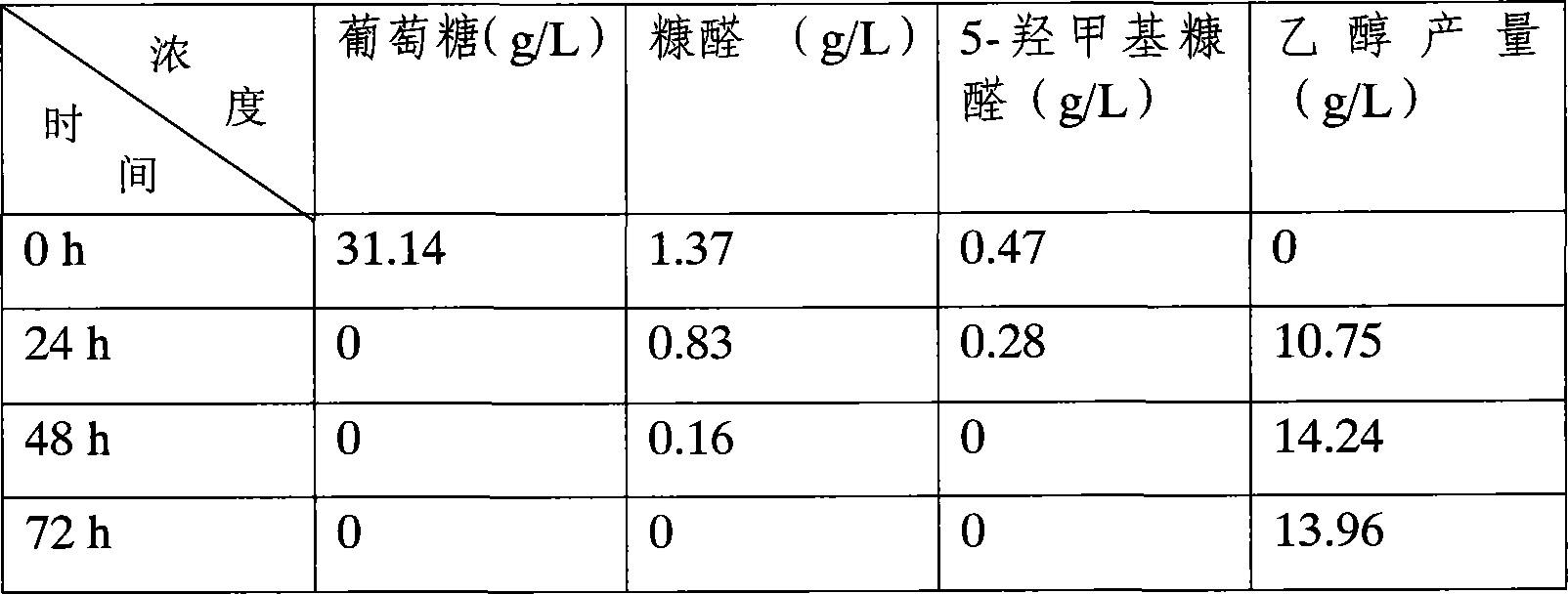

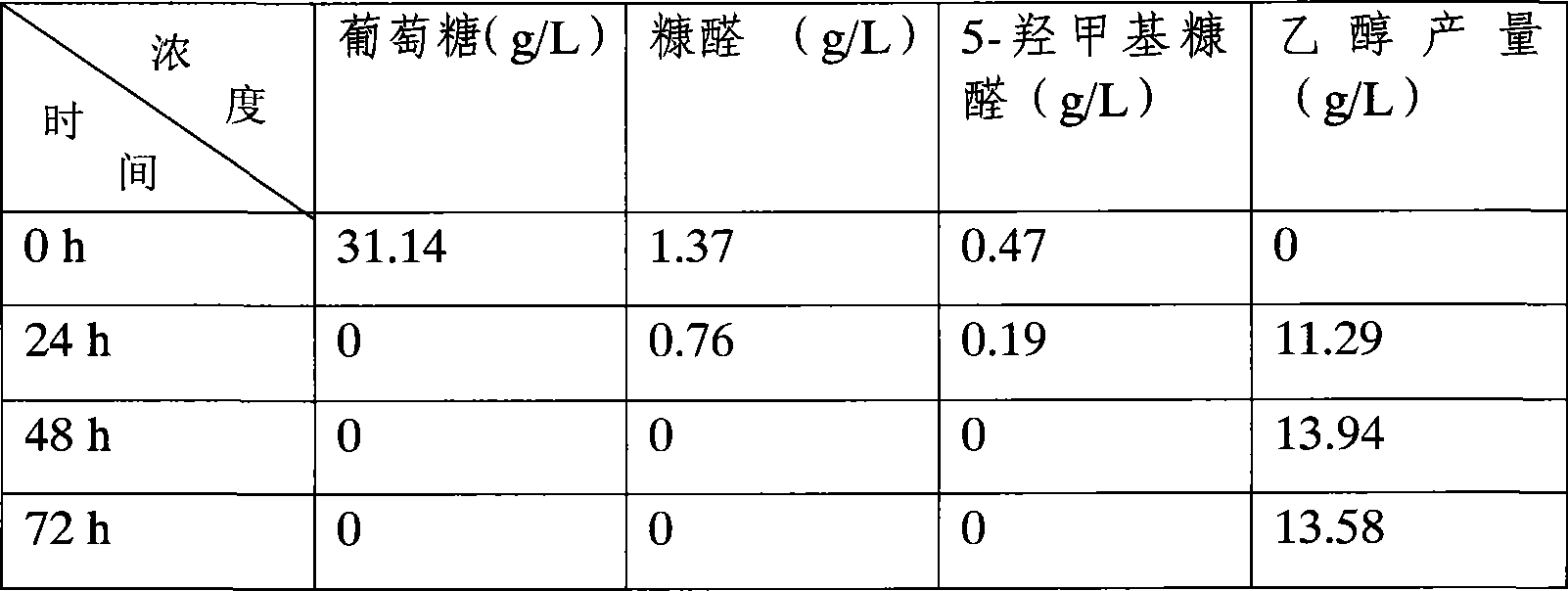

[0049] Example 2 Ethanol fermentation of Y4

[0050] The Y4 strain was inoculated to 3g / L, KH containing yeast extract 2 PO 4 3g / L, malt extract 3g / L, (NH 4 ) 2 SO 4 1g / L, MgSO 4 .7H 2 O 0.5g / L, tryptone 3g / L, hydrolysate stock solution, pH5.0 culture medium, 30℃, 80rpm culture, the glucose is used up within 24h, and during the fermentation process, the xylose is also gradually reduced, after 72 After hours, xylose was completely consumed. The highest yield of ethanol reached 96.1% of the theoretical value (theoretical yield was 0.51 g / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com