High temperature resistant Issatchenkia orientalis, application thereof and method for producing ethanol through fermentation

An Isaac yeast and high-temperature fermentation technology, applied in the field of fermentation, can solve the problems of reduced ethanol fermentation capacity, ethanol tolerance, inability to perform the fermentation process normally, and unsuitable for industrial production, and achieves the convenience of industrial production, reduction of fermentation costs, and reduction of energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

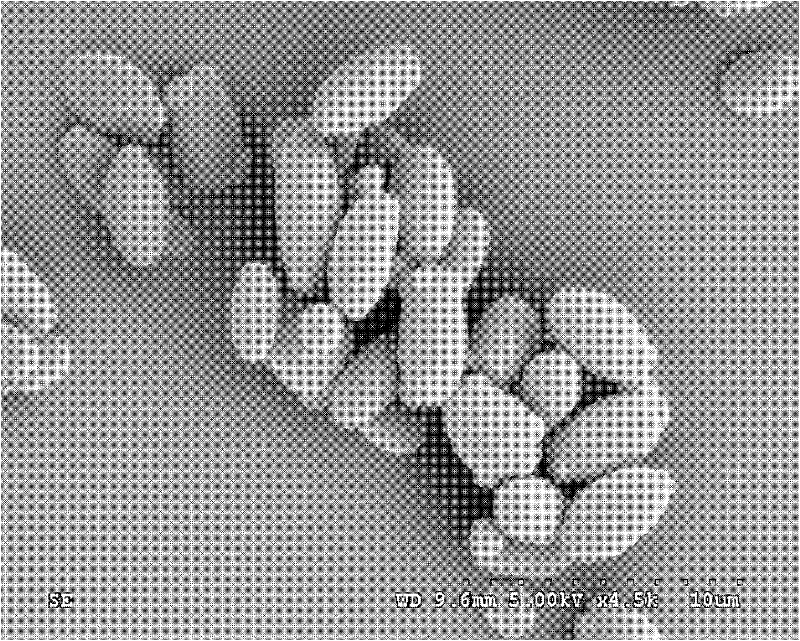

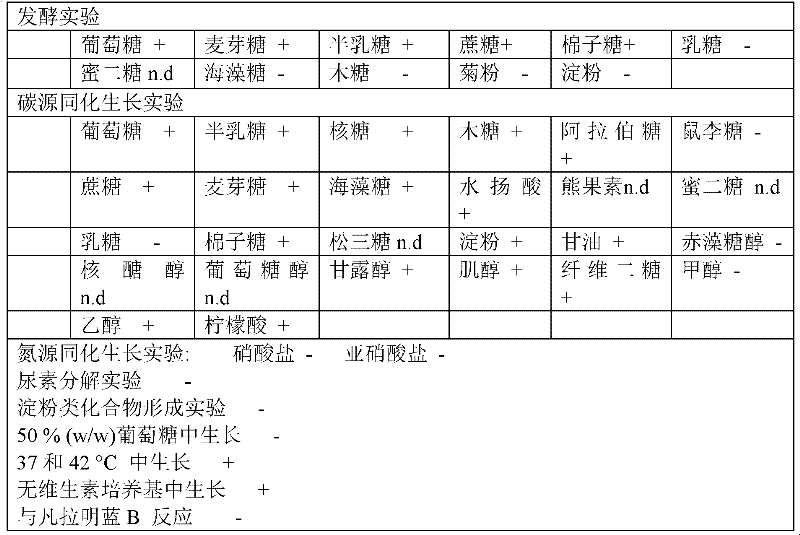

[0027] Example 1 Screening of high temperature resistant Issahia orientalis IPE100

[0028] Separation and screening of IPE100: collect samples from crop (corn stalk) waste in Daxing, Beijing, and activate the collected samples, take 1g of them and add 100mL to YPG medium supplemented with ampicillin, 250mL Erlenmeyer flask shaker Shaking culture, 42°C, 150rpm. After 48 hours of enrichment culture, the culture solution was diluted in a certain gradient, and spread on the solid plate of the same medium. After culturing at 42°C for 48 hours, a single colony of typical yeast form was picked, and then repeatedly streaked on the solid plate of the same medium. After three line purifications, they were stored at 4°C. Then, the ethanol yield and fermentation cycle were measured through ethanol fermentation experiments at different temperatures, and the detoxification ability of the strains to inhibitors was detected through inhibitor degradation experiments, and finally the strains ...

Embodiment 2

[0035] Example 2 Carry out high-temperature ethanol fermentation of lignocellulose hydrolyzate with the high-temperature-resistant Issahia orientalis IPE100 of the present invention

[0036] Using the liquid seed medium, the thermostable I. orientalis IPE100 was shaken at 42° C. and 150 rpm for 16 hours to obtain liquid seeds. The liquid seeds were inoculated to containing (NH 4 ) 2 SO 4 1g / L, MgSO 4 0.02g / L, K 2 HPO 4 0.03g / L, lignocellulose hydrolyzate, in the fermentation medium of pH 6.0, 42°C, 150rpm culture for 48h, the ethanol yield reached the maximum, which was 93.8% of the theoretical value (0.51g / g). The composition of lignocellulose hydrolyzate used is as follows: glucose 95.70g / L, furfural 0.05g / L, 5-hydroxymethylfurfural 0.15g / L.

Embodiment 3

[0037] Example 3 Carry out high-temperature ethanol fermentation of lignocellulose hydrolyzate with the high-temperature-resistant Issahia orientalis IPE100 of the present invention

[0038] Using the liquid seed medium, the thermostable I. orientalis IPE100 was shaken at 42° C. and 150 rpm for 16 hours to obtain liquid seeds. The liquid seeds were inoculated to containing (NH 4 ) 2 SO 4 1.2g / L, MgSO 4 0.03g / L, K 2 HPO 4 0.04g / L, lignocellulose hydrolyzate, in the fermentation medium of pH 7.0, 38°C, 180rpm for 48h, the ethanol yield reached the maximum, which was 90.3% of the theoretical value (0.51g / g). The composition of the lignocellulose hydrolyzate used is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com