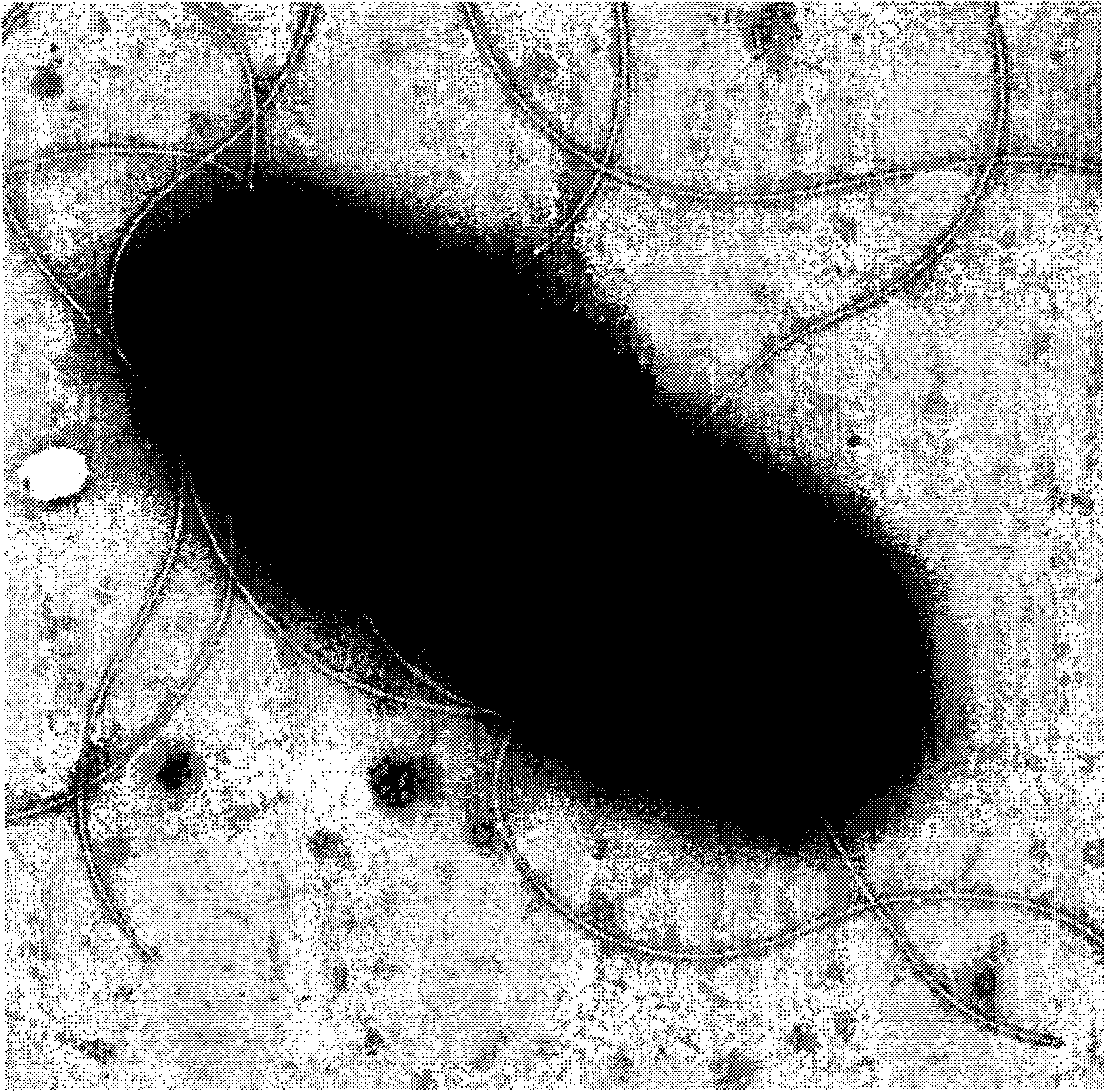

Lipopeptide-producing bacillus pumilus and application thereof

A technology of Bacillus pumilus and lipopeptide, which is applied in the field of lipopeptide-producing Bacillus pumilus, can solve the problems of poor water solubility, long biodegradation cycle, and slow bioremediation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

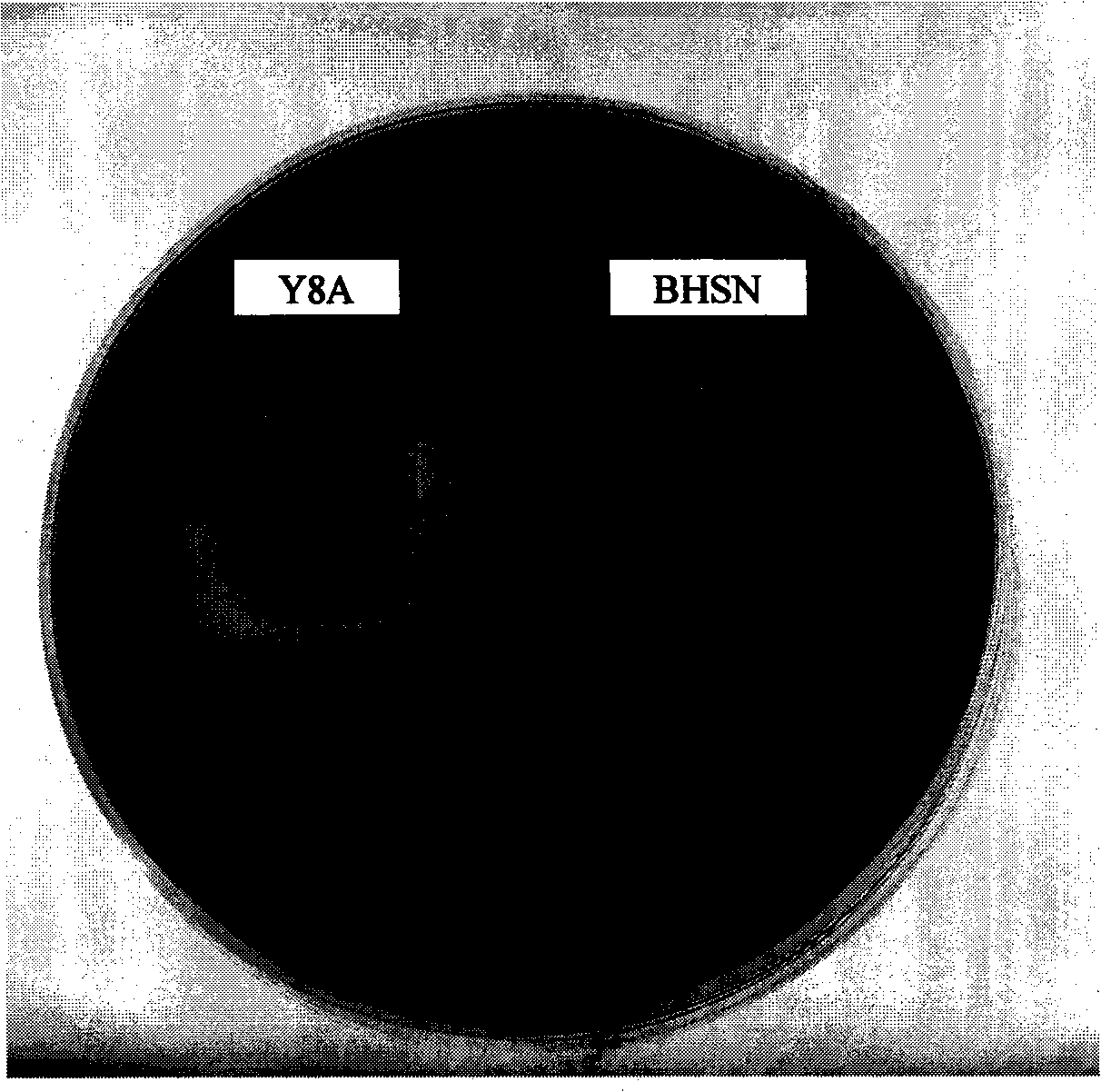

Embodiment 1

[0059] Add 20mg·L to LB medium -1 Fe 2+ and Ca 2+ Can significantly promote the growth of Y8A and the production of surfactants; 10g L -1 Lactose can significantly promote the production of surfactants; strain Y8A has a strong ability to grow and produce surfactants in the range of 20-30°C and pH5-12; in a 250mL Erlenmeyer flask, liquid seeds are inoculated at 1% Add the amount to 50mL LB medium (add 10g·L -1 Lactose, 20mg·L -1 Fe 2+ and Ca 2+ , pH7.5), cultured on a shaker at 170 rpm at 30°C for 24h. After the fermentation is over, measure the surface tension value of the bacterial fermentation broth, and the value can reach a minimum of 23.5mN m -1 .

Embodiment 2

[0061] The oil-contaminated soil was air-dried, sieved and mixed, sterilized at 121°C for 30 minutes, and dried. Divided into six groups for comparative experiments, each group designed three parallels: (A) adding lipopeptide-producing strain Y8A bacterial liquid, (B) adding alkane-degrading bacteria Chryseobacterium sp.ATCC 11642), (C) adding Aromatic hydrocarbon-degrading bacteria Sphingomonas chlorophenolica ATCC 39723) bacterial liquid, (D) added Y8A and Chryseobacterium strain bacterial liquid, (E) added Y8A and Sphingomonas chlorophenolic bacteria solution, (F) adding Y8A, Chryseobacterium strains and Sphingomonas chlorophenes bacteria solution. The inoculation amount is 1.1×10 8 a·g -1 , mixed well, and the soil without bacterial solution was used as the control (CK). Cover the surface of the container with a plastic film, pierce the holes for ventilation, incubate at 30°C for 30 days, and measure the residual crude oil in the soil by gravimetric method. The test re...

Embodiment 3

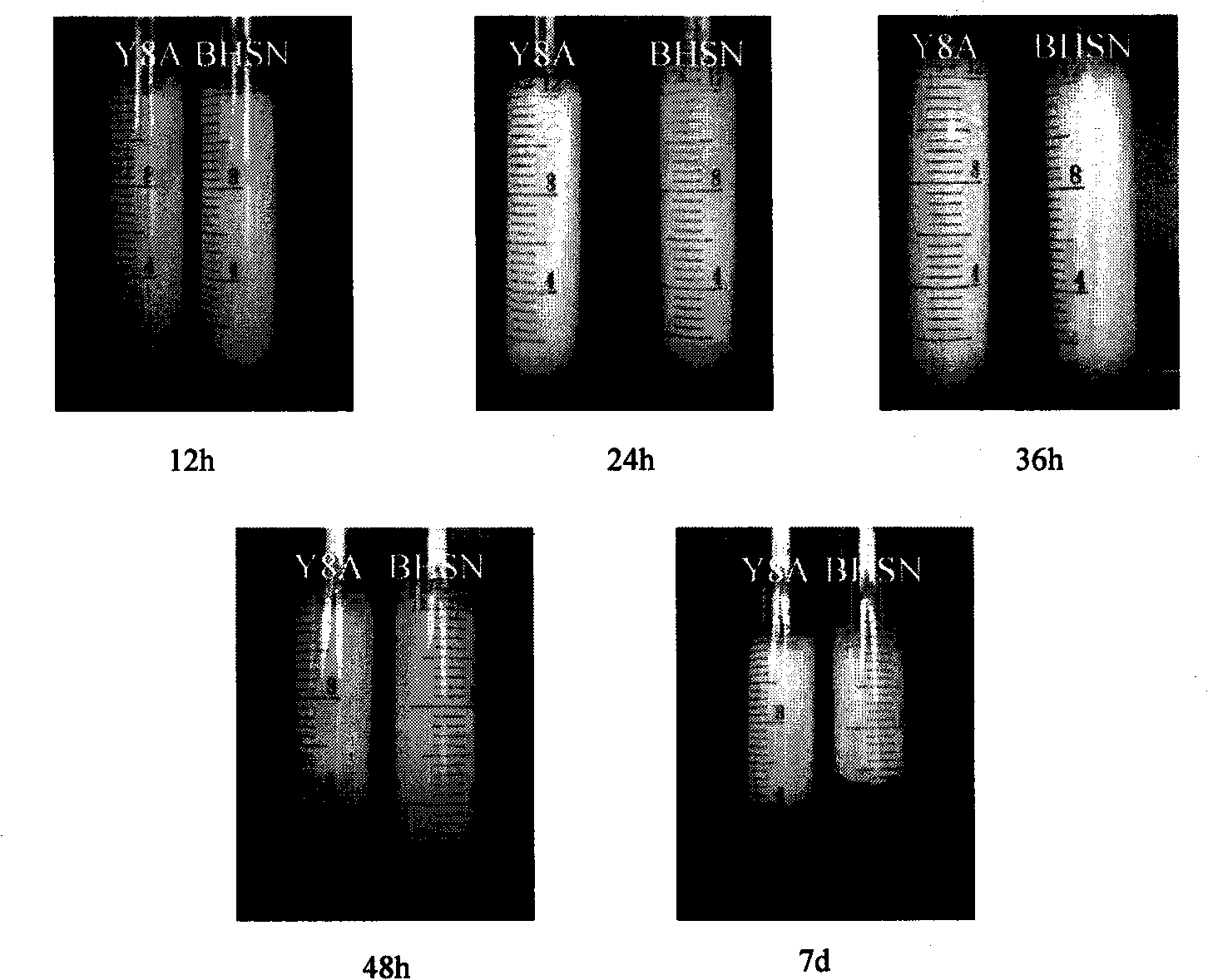

[0065] In 1 / 10LB containing kaufthrin (final concentration is 100mg·L -1 ) into the culture medium of kaufthrin-degrading bacteria Bacillus cereus ATCC7039 and the lipopeptide-producing strain Y8A of the present invention at the same time, the inoculation ratio is 1:1, and the inoculation amount is 1%. Determination of fermentation broth OD 600 and kung fu permethrin residues. Compared with the growth of Bacillus cereus strains and the degradation rate of kaufthrin when cultured alone, the degradation rate of kaufthrin was significantly accelerated in mixed culture, and the maximum degradation amount was reached in 34 hours, which was 7 hours earlier than that without Y8A. hour, the degradation process was shortened by nearly 1 / 6. After 2 days of cultivation, the measurement results showed that when the kaufthrin-degrading bacterium Bacillus cereus was cultured alone, the degradation rate of kaufrin was 38.7%, and when Bacillus cereus and Y8A were co-cultured, the degradatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com