Methods for detoxifying a lignocellulosic hydrolysate

a technology of lignocellulosic hydrolysate and detoxification method, which is applied in the direction of cellulose treatment using microorganisms/enzymes, application, pulping with inorganic bases, etc., can solve the problems of significant drive up maintenance costs, and achieve the effect of minimising the loss of fermentable sugar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Hydrolysis of Lignocellulosic Biomasses

[0079]A lignocellulosic biomass (e.g., energy cane or sugar cane) was harvested and sized using a forage chopper, inoculated with a preparation of Lactobacillus bacteria and stored in agricultural bags until use. Prior to dilute acid hydrolysis, the lignocellulosic biomass was removed from bags and washed with process water to remove organic acids and then dewatered with a screw press. The biomass was then conveyed to a pressurized reaction chamber (i.e., hydrolyzer) along with water and sulfuric acid (0.2% to 3%). The liquid / solid ratio of the slurry was minimized to maximize the dissolved sugar concentration in the hydrolysate following hydrolysis. The retention time in the hydrolyzer and the temperature of the hydrolyzer was dependent on parameters of the biomass (e.g., moisture and glucan levels). In general, the temperature of the hydrolyzer ranged from 120° C. to 180° C. and the retention time ranged from 3 minutes to 2 hours.

[0080]Follow...

example 2

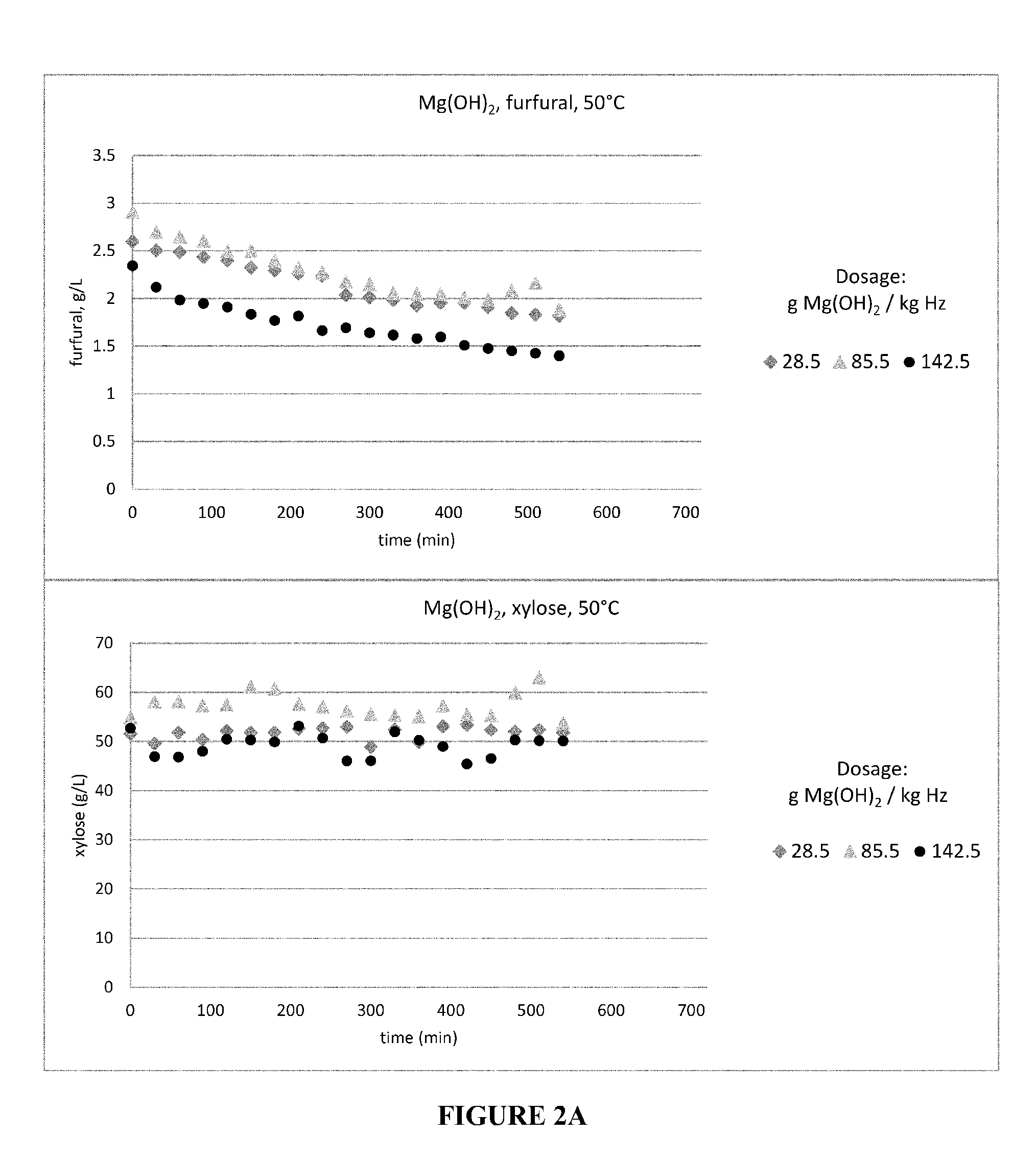

Detoxification of Hydrolysates with Magnesium Hydroxide—Batch Reactor

5.2.1. Materials and Methods

[0082]5.2.1.1. Sorghum Hydrolysate DP 100309

[0083]Hydrolysate DP 100309 was placed in a 1L three necked round bottom flask equipped with stir bars. The round bottom flask was placed in oil bath and heated to 70° C. While the hydrolysate solution was warming, target amounts of magnesium hydroxide slurry (i.e., supersaturated solution of magnesium hydroxide in water) were weighed. The total quantity of magnesium hydroxide added to the hydrolysate was determined from the titration of the hydrolysate solution with sodium hydroxide (see FIG. 3 and Example 6). Also, see Martinez et al., 2001, Biotechnol. Prog. 17(2):287-293. After the hydrolysate solution was heated to the desired temperature, the magnesium hydroxide slurry was added rapidly to the hydrolysate solution at a dosage of 22.86 g / Kg hydrolysate at 70° C. The solution was stirred vigorously with a magnetic stirrer for 3 hours. The p...

example 3

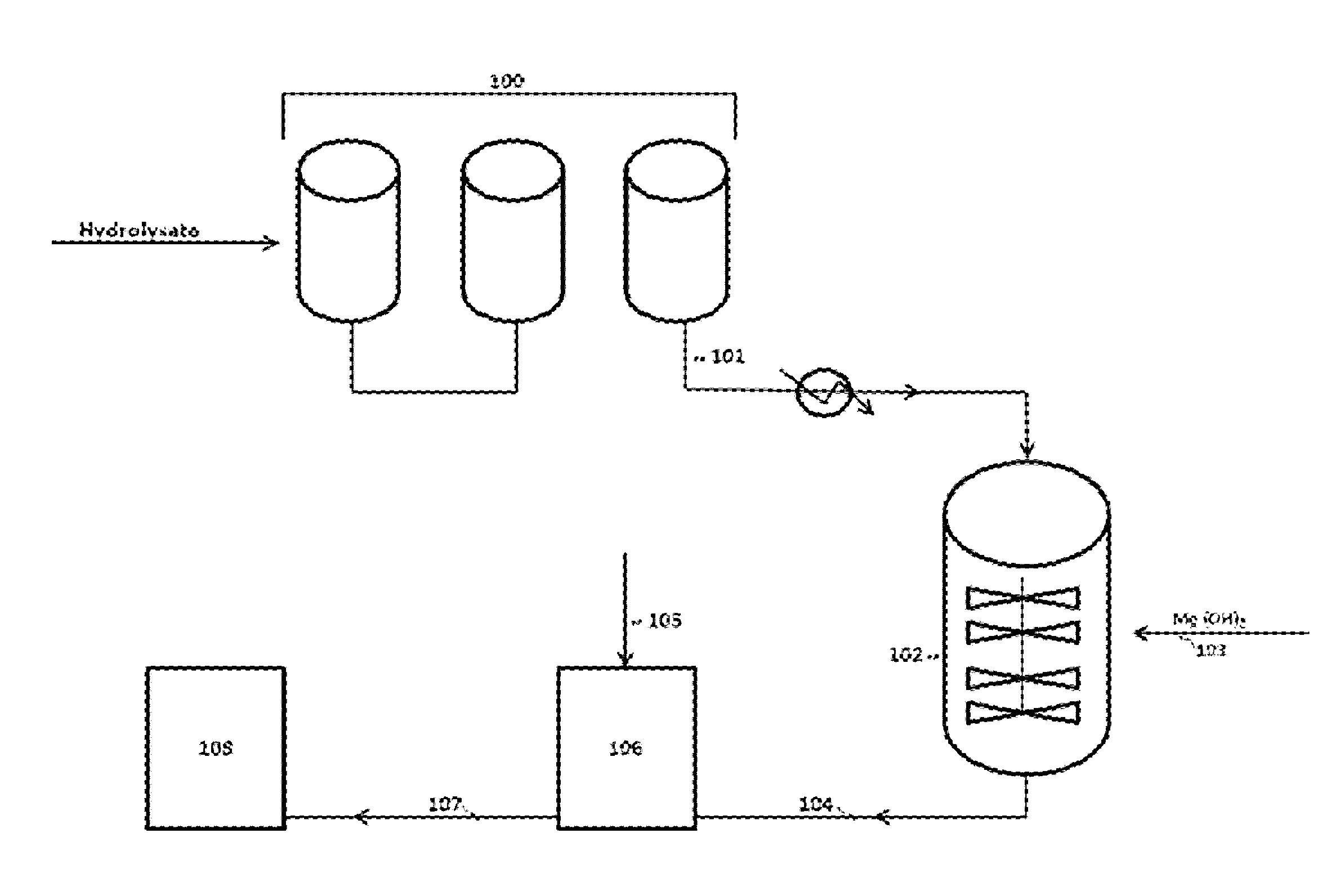

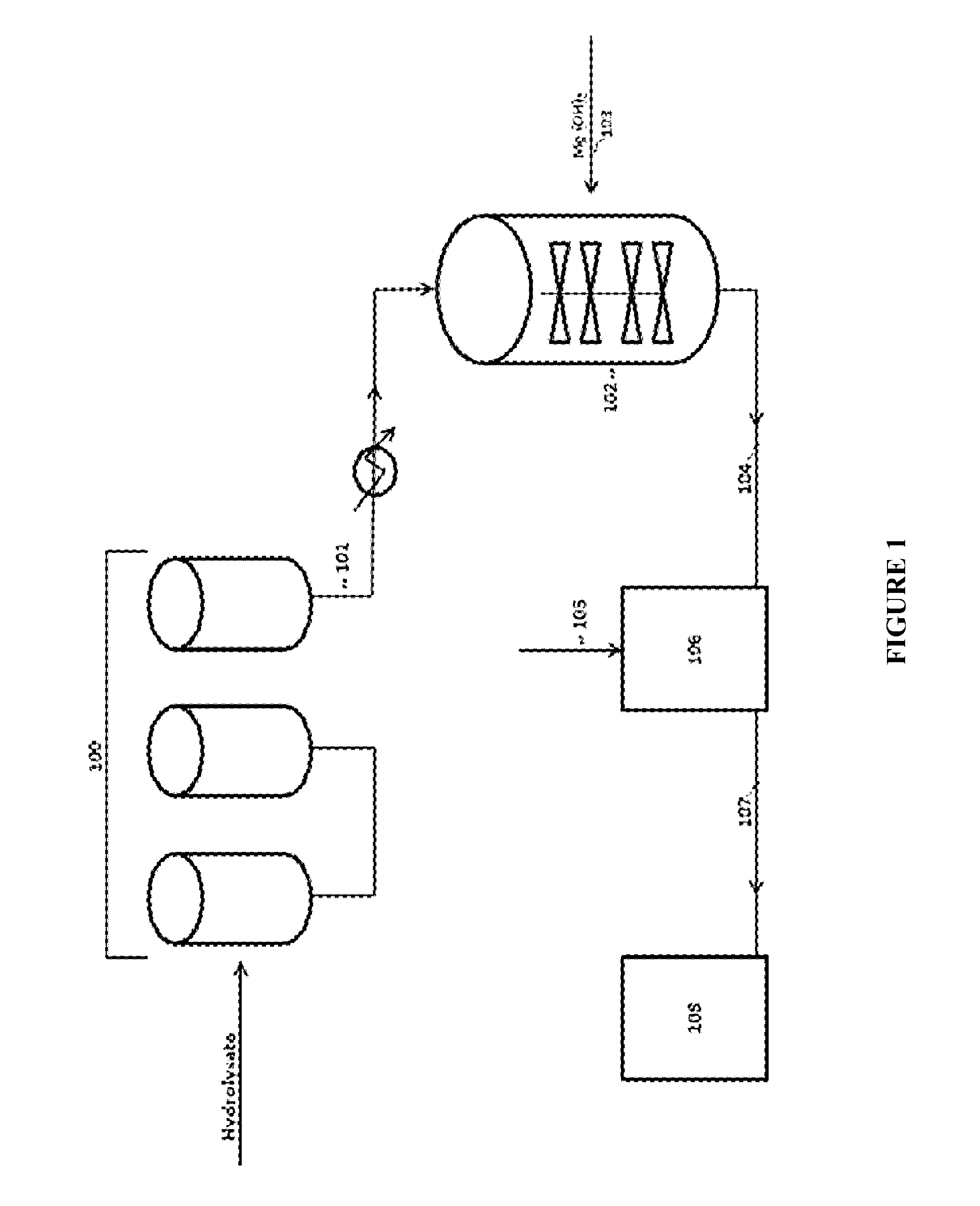

Detoxification of Hydrolysates—Series of CSTRS

[0097]The detoxification process is carried out using a series of continuously stirred tank reactors (CSTRs). The hydrolysate solution is heated to the target temperature with heating mantles and / or recirculating water bath and delivered by peristaltic pump to the first of a series of stirred reactors (1, 2, or 4L sizes) connected in series to which magnesium hydroxide slurry is previously added. The ratio of hydrolysate solution to magnesium hydroxide slurry added to the reactor is based on titration dosage (e.g., 1 ml / min of base slurry to 20 ml / min of hydrolysate). The resultant mixture is then pumped to one or more additional CSTRs. Additional base slurry is added to each successive CSTR reactor if the pH of the mixture fell below a certain level. Retention time in each reactor is constrained by fixing the target volume and maintaining a target flow rate (where rate multiplied by volume equals the retention time). To prevent build-up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com