Virus-free in situ and alcohol fermentation method of composite bacteria for lignocellulose hydrolysis product

A lignocellulose and ethanol fermentation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of ethanol fermentation process complexity and cost increase, and achieve low cost, simple equipment requirements, and long fermentation time The effect of shortening

Inactive Publication Date: 2010-11-10

CAPITAL NORMAL UNIVERSITY

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The hydrolyzate is usually detoxified before fermentation, which requires the addition of treatment equipment, and the detoxification equipment must be well integrated with the fermentation process, thus increasing the complexity of the entire ethanol fermentation process and increasing the production cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

experiment example 1

experiment example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

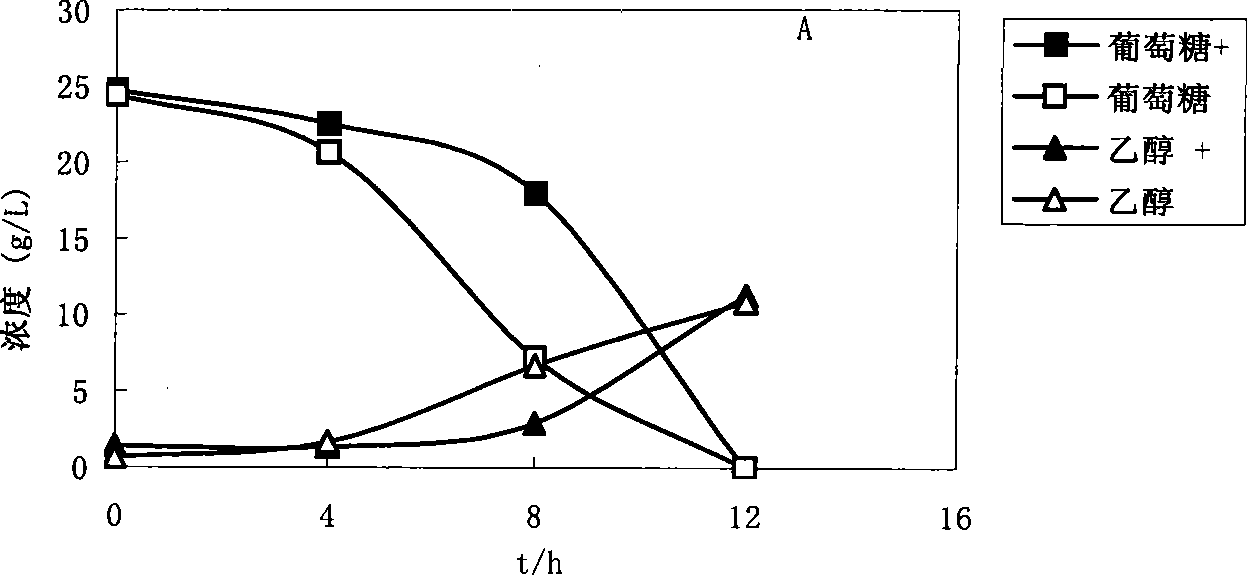

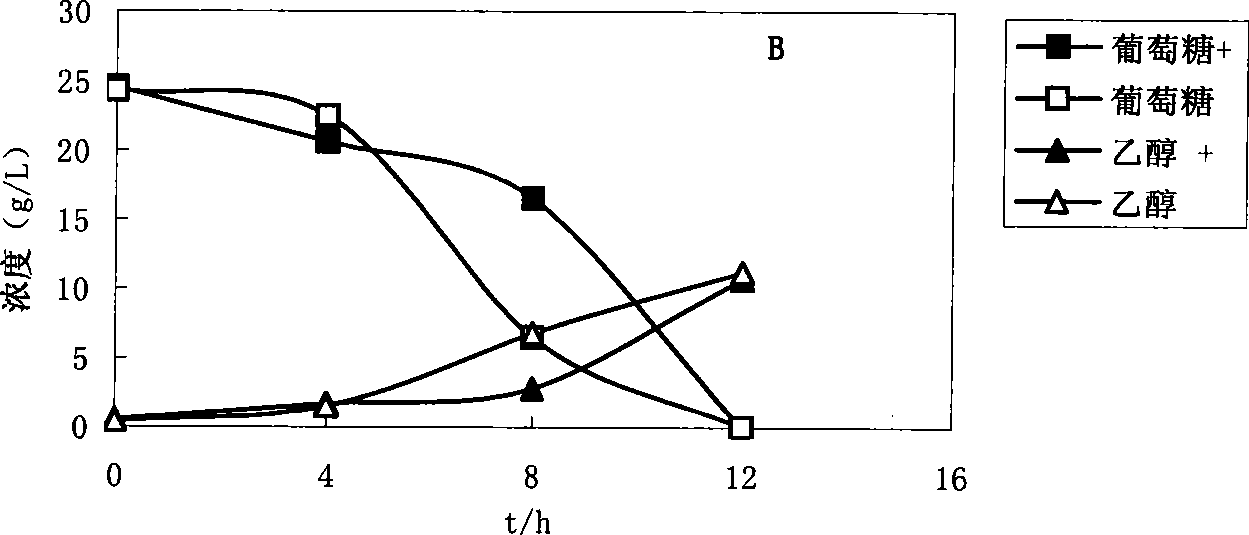

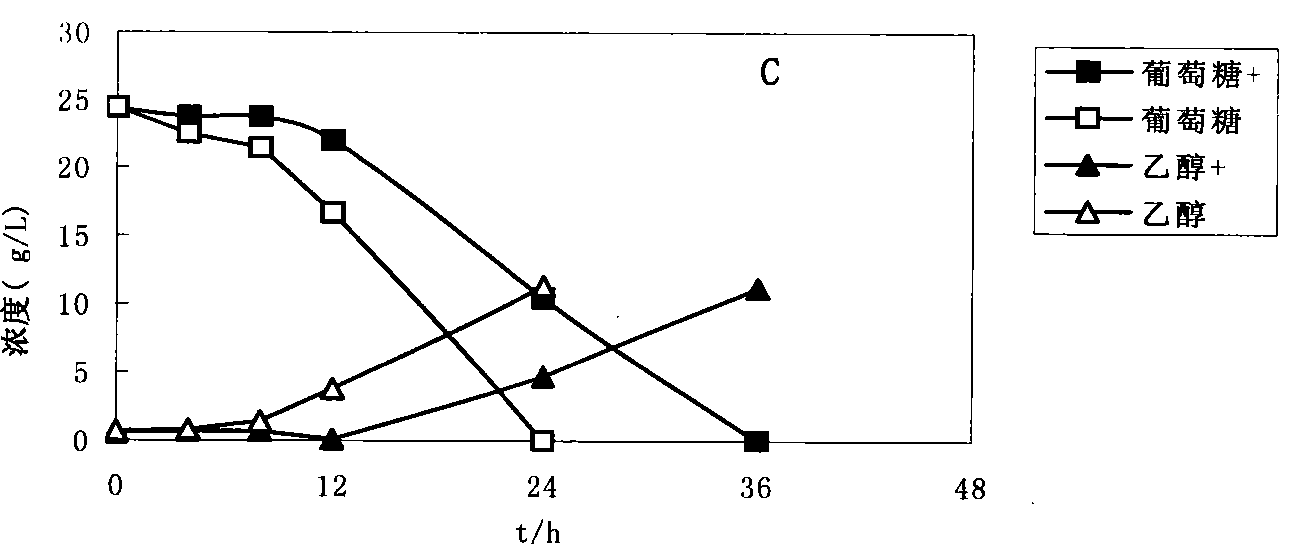

The present invention relates to an in-situ detoxification ethanol fermentation method of lignocellulose hydrolysate, which respectively inoculates Y5 and CBS6054 into fermentation culture medium containing dilute acid lignocellulose hydrolysate to carry out in-situ detoxification alcoholic fermentation. The method can efficiently metabolize glucose and xylose in the dilute acid lignocellulose hydrolysate to produce ethanol, and rapidly metabolize furfural and 5-hydroxymethylfurfural. The yield of ethanol is 0.44g / g, reaching 87.5 percent of the theoretical value. Moreover, any detoxificationprocessing is not needed, the requirement on equipment is low, the operation is convenient, and the cost is low.

Description

In situ detoxification ethanol fermentation method of lignocellulose hydrolyzate by complex strains technical field The invention relates to an in-situ detoxification ethanol fermentation method of lignocellulose hydrolyzate, in particular, a method that can efficiently metabolize glucose and xylose in dilute acid hydrolyzate of lignocellulose to produce ethanol and rapidly metabolize inhibitory factor The complex bacteria of furfural and 5-hydroxymethylfurfural were inoculated into the fermentation medium containing lignocellulose dilute acid hydrolyzate for in-situ detoxification ethanol fermentation. Background technique In the field of research and development of ethanol production using lignocellulose as raw material, dilute acid hydrolysis of lignocellulose is considered to be the most easily commercialized production process, and a lot of in-depth research has been carried out in this field at home and abroad. But so far, there are still some problems in dilute acid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C12N1/16C12P7/10C12R1/865C12R1/84

CPCY02E50/16Y02E50/10

Inventor 杨秀山

Owner CAPITAL NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com