Device for treating kitchen wastewater

A technology for treating device and kitchen wastewater, which is applied in multi-stage water treatment, water/sewage treatment, special compound water treatment, etc., and can solve the problems of high requirements, unsatisfactory operation and high operation cost of anaerobic treatment units.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

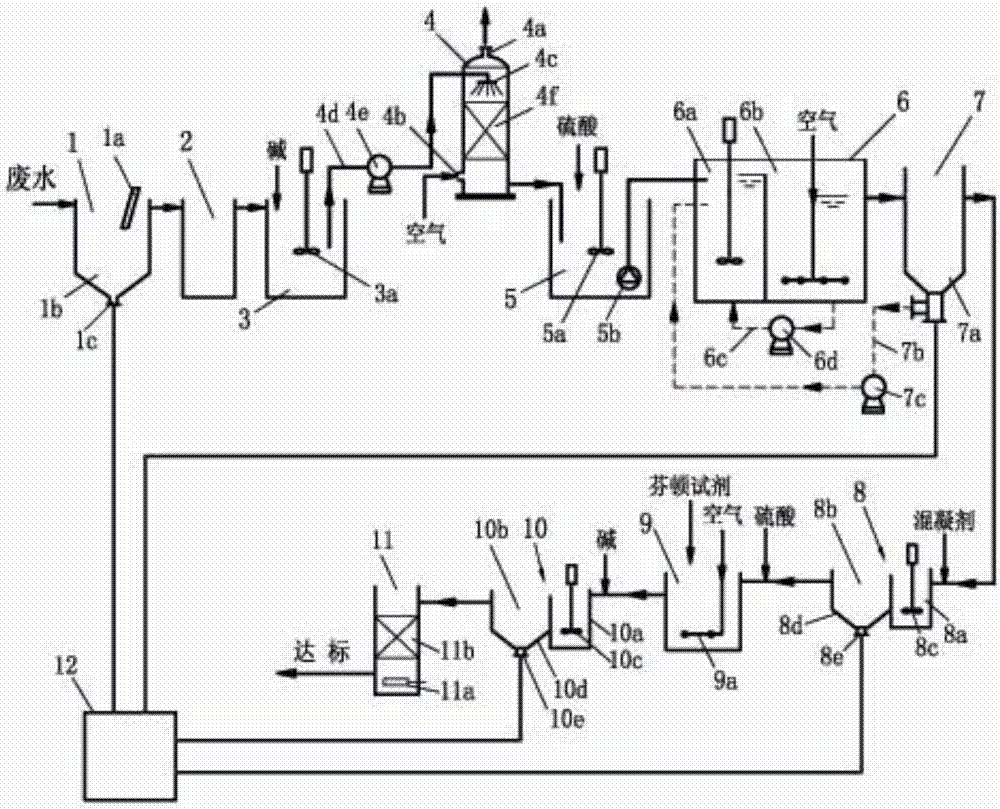

[0028] See the attached picture for a treatment scale of 100m 3 / d of kitchen waste wastewater as an example, the specific implementation is as follows:

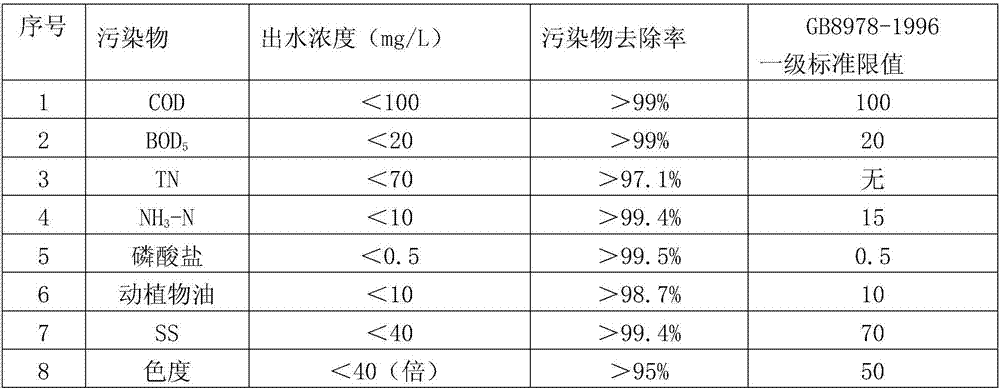

[0029] Wastewater after anaerobic digestion and dehydration of food waste slurry and waste water produced in other processes of food waste treatment Water quality: COD: 12000-15000mg / L, BOD 5 : 4500~5000mg / L, TN: 2100~2400mg / L, NH 3 -N: 1800~2000mg / L, TP: 110~130mg / L, SS: 7000~10000mg / L, animal and vegetable oil: 800~1000mg / L, pH: 7.5~8, chromaticity: 800~1000 times.

[0030] Referring to the accompanying drawings, the present invention includes an oil separation primary sedimentation tank 1, a regulating tank 2, a first pH regulating tank 3, an ammonia stripping tower 4, a second pH regulating tank 5, an A / O biochemical treatment device 6, a sedimentation tank 7, The first coagulation sedimentation tank 8, the Fenton reactor 9, the second coagulation sedimentation tank 10, and the biological aerated filter tank 11;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com