Systems and methods for improving fermentation

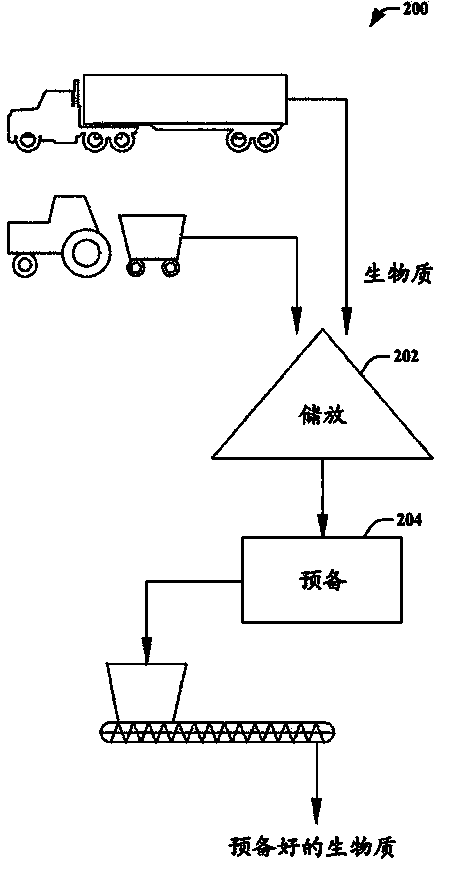

A liquid and nanofiltration technology, applied in the field of systems and methods for improving fermentation processes, can solve the problems of reducing the level of pentose alcohol inhibitors, scaling of evaporation equipment and distillation equipment, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] According to the experimental design shown in table 4A and as shown in the present embodiment Figure 9The experimental procedure shown in A was used for the acid removal experiment of the liquid component. The three different filters tested were: Dow Filmtec NF-4040, Dow Filmtec NF-270 (both available from Dow Chemical Company, Midland MI) and Koch SeIRO MPS-34 (available from Koch Membrane Systems, Inc., Wilmington, MA). All three filters utilize spiral-wound membranes with a diameter of 4 inches and a length of 40 inches. The filter operates at 25 degrees Celsius and the Dow Filmtec NF-270 operates at 32 degrees Celsius. A model of a multi-stage nanofiltration system such as Figure 9 As shown in the experimental flow for A, where the retentate 902 from the filter 904 can be recycled back into the storage / supply tank 906 and filtered again to simulate a second or consecutive filtration stage. The principle of concentration and diafiltration is as Figure 9 Shown...

Embodiment 2

[0083] According to the experimental design shown in table 5A and the present embodiment Figure 9 The experimental procedure shown in A was used for the acid removal experiment of the liquid component. Dow Filmtec NF filters (available from Dow Chemical Company, Midland MI) were used in this experiment. Dow Filmtec NF filters utilize a spiral-wound membrane that is 4 inches in diameter and 40 inches in length. The operating temperature of the filter is room temperature (approximately 22 degrees Celsius). A model of a multi-stage nanofiltration system such as Figure 9 Shown in the test flow for A, where the permeate from the filter is recycled into the storage / feed tank and filtered again to simulate a second or continuous filtration stage.

[0084] Liquid components are pre-filtered with a filter with a pore size of 1 micron. Put 30L of the pretreated biomass liquid component into the container and add about 1ml of antifoaming agent (KFO-119, purchased from Kabo Chemical...

Embodiment 3

[0086] In this example, the retentate samples from the dialysis and filtration in Example 2 were collected and fermented, so as to analyze the impact of the treatment process on fermentation anxiety. The collected samples contained varying concentrations of acetic acid and were fermented with 10 g / L (dry weight) of the genetically modified yeast strain Saccharomyces cerevisiae as described in US Patent 7,622,284 to Royal Nedalco B.V. 5 mg / L lactose (purchased from Lallemand Ethanol Technology, Milwaukee, WI), 62.5 g / L urea, and 1 g / L yeast extract were added to each fermenter, and the pH was adjusted to 5.5 with KOH. Such as Figure 16 Shown is the result after 24 hours of fermentation, ie, the graph of ethanol concentration (1602) versus fermentation time (1604). Similarly, Figure 17 Shown is a plot of ethanol production (1702) at the completion of the fermentation versus the initial acetic acid concentration (1704). The sample with an initial acetic acid concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com