Method for controlling seeding form in process of preparing large-sized sapphire single crystal by Kyropoulos method

A control method and large-scale technology, applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of low yield of crystal growth, limited popularization and application, etc., and achieve high-quality growth crystals and broad application prospects. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

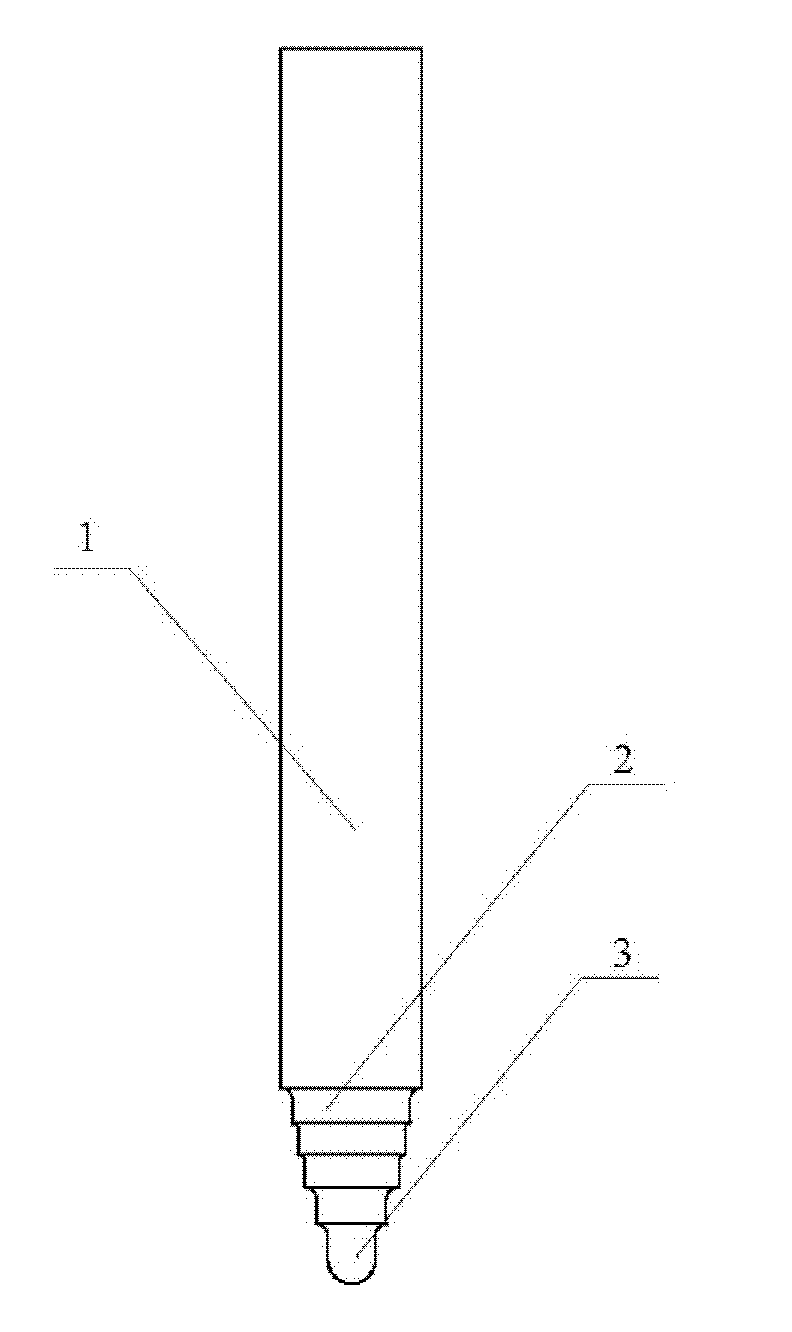

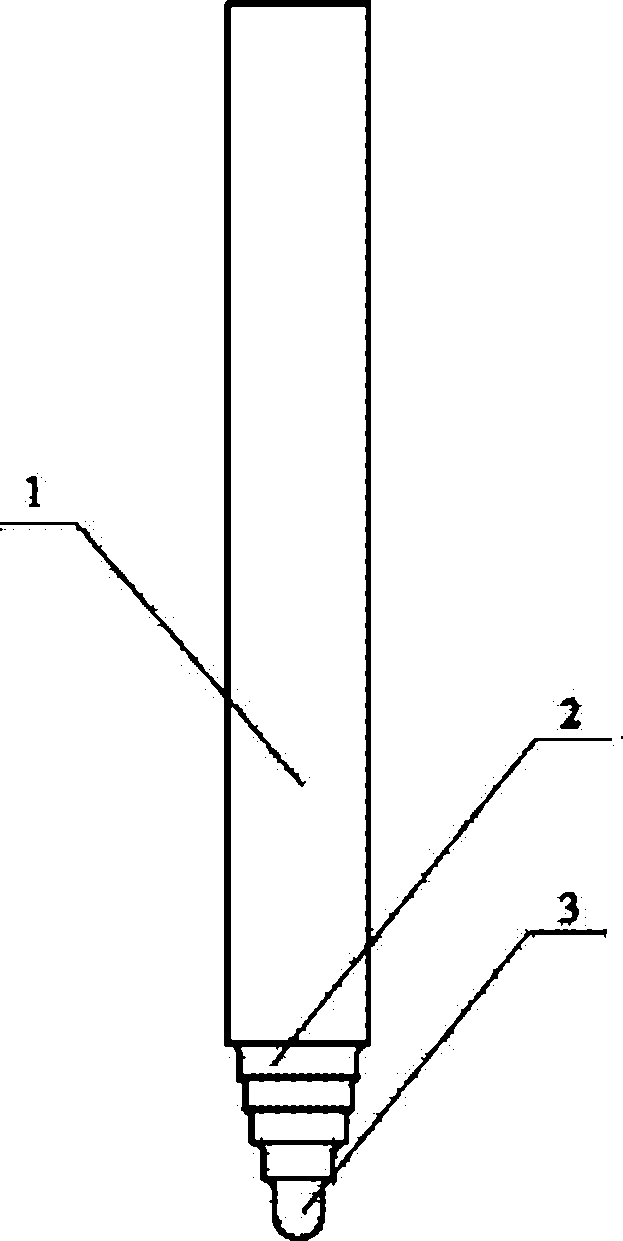

Image

Examples

Embodiment 1

[0020] Embodiment one: the specific technological process of this embodiment is as follows:

[0021] 1. Preparatory work: (1) Put 31 kg of high-purity alumina raw material with a purity of 99.996% into the crucible of the single crystal furnace, install a seed crystal with a diameter of 12 mm on the seed rod, close the single crystal furnace cover, and start Cooling water circulation system; (2) Start the vacuum system to make the pressure in the furnace reach 10 -3 Pa. (3) Start the heating system, adjust the heating voltage, and heat up. When the temperature reaches 2150°C, stop heating, and all the raw materials are melted at this time; after 3 hours of heat preservation, adjust the heating voltage, cool down to 2060°C, and observe the state of the melt level , the liquid convective state is stable at this time, and the relative deviation between the position of the cooling center in the melt and the geometric center of the crucible is less than 15 mm; The positions overl...

Embodiment 2

[0025] Embodiment two: the specific technological process of this embodiment is as follows:

[0026] 1. Preparatory work: (1) Put 85 kg of high-purity alumina raw material with a purity of 99.996% into the crucible of the single crystal furnace, install a seed crystal with a diameter of 18mm on the seed rod, close the single crystal furnace cover, and start Cooling water circulation system; (2) Start the vacuum system to make the pressure in the furnace reach 10 -3 Pa. (3) Start the heating system, adjust the heating voltage, and heat up. When the temperature reaches 2150°C, stop heating. At this time, all the raw materials are melted; after 5 hours of heat preservation, adjust the heating voltage, cool down to 2060°C, and observe the state of the melt level , the liquid convective state is stable at this time, and the relative deviation between the position of the cooling center in the melt and the geometric center of the crucible is 30 mm; The positions overlap; adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com