Electric bed

A technology of electric bed and DC motor, applied in the field of electric bed, can solve the problems of inability to use, high cost, difficulty in obtaining electric power, etc., and achieve the effect of reducing size and weight, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

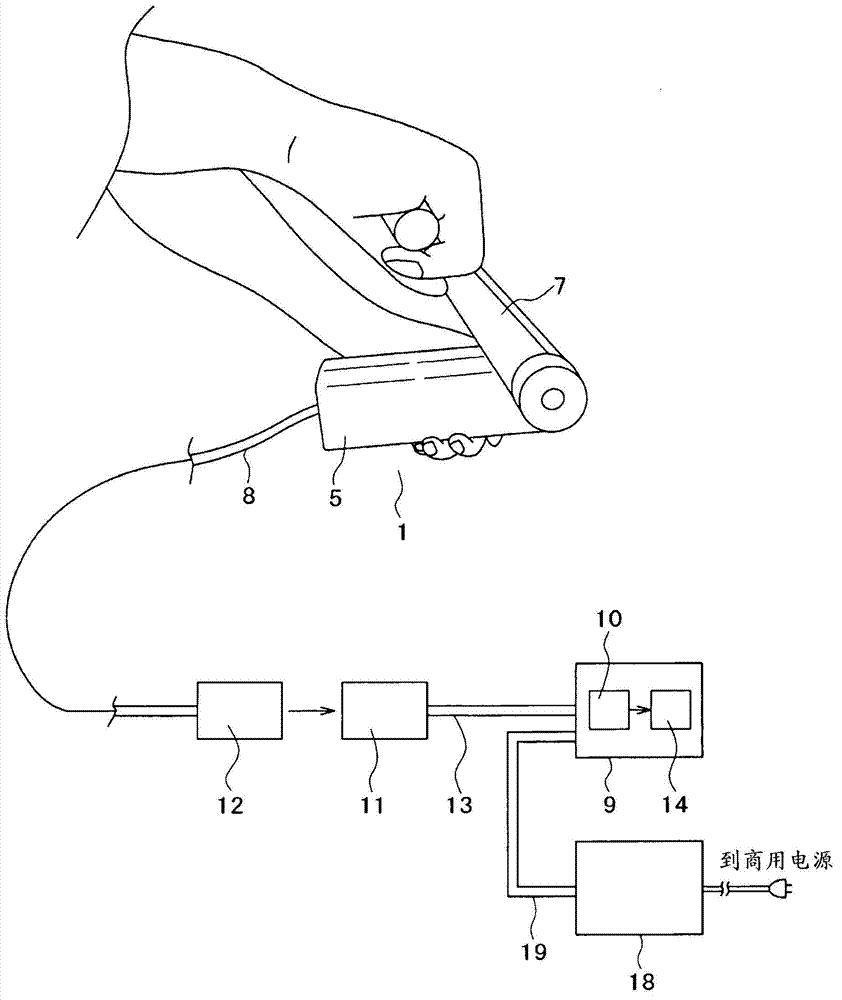

[0055] The specifications of one embodiment of the manual generator 1 described above will be as follows.

[0056] Input obtained manually: 10~50[N]

[0057] The rotational speed of the input shaft under manual operation: 30~120[rpm]

[0058] Reduction ratio (gear ratio): 1 / 15.5

[0059] Rotational shaft speed: 465~1860[rpm]

[0060] Power generation: 10~30[VA]

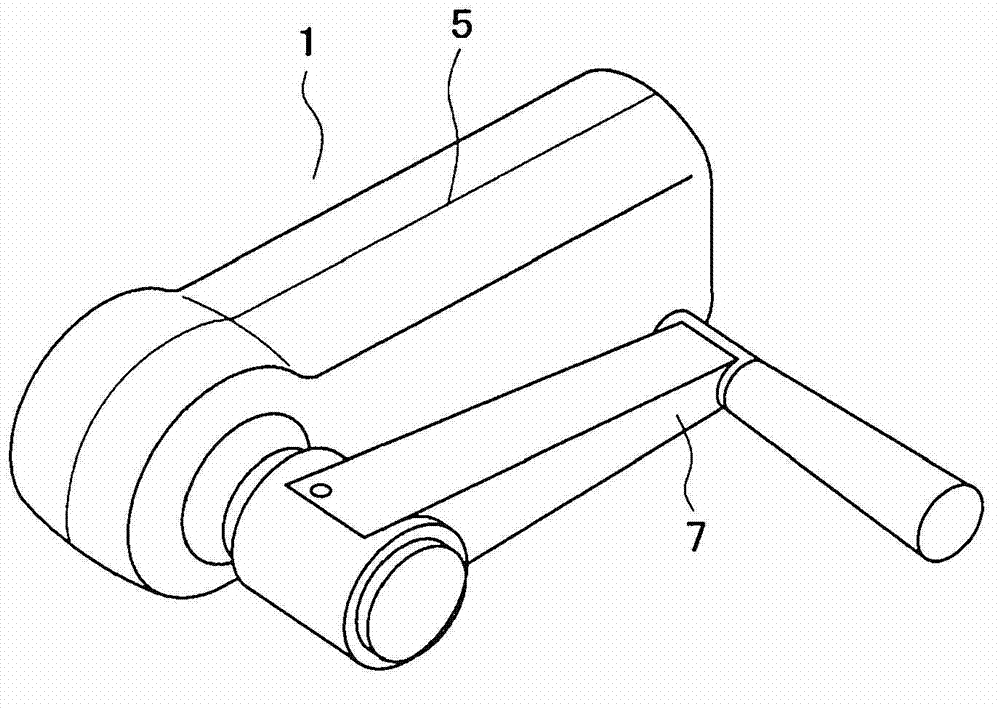

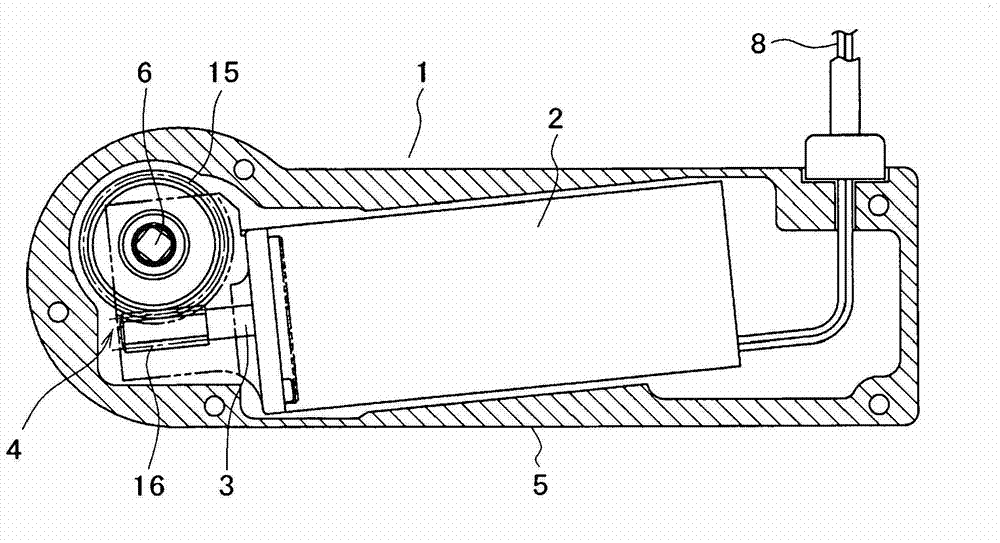

[0061] In this embodiment, since the speed-up mechanism 4 constituting the manual power generator 1 is constituted by a worm gear mechanism, the size and weight can be greatly reduced, so it can be housed in the device body 5 of a size that can be held by hand. The constituent parts can realize the manual power generator 1 that can meet the above-mentioned specifications. In the worm gear transmission mechanism, the crank handle 7 side is made into a worm wheel 15, and the DC motor 2 side is made into a double-threaded worm 16.

[0062] In addition, in the electric bed of the present invention, the DC motor 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com