Highly-durable cement and production method thereof

A production method and durability technology, which is applied in the production field of high-durability cement, which can solve the problems of severe cracks, concentrated hydration heat of concrete, and large shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

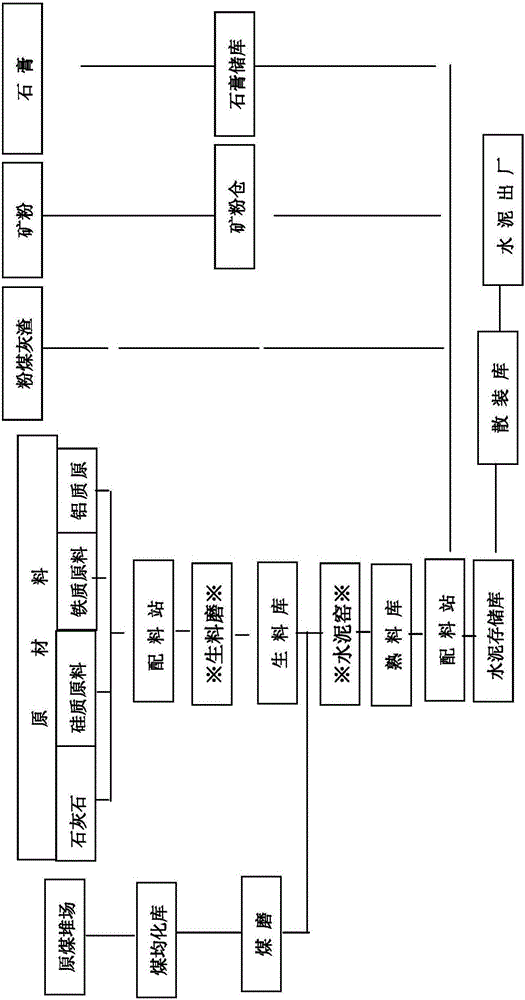

Method used

Image

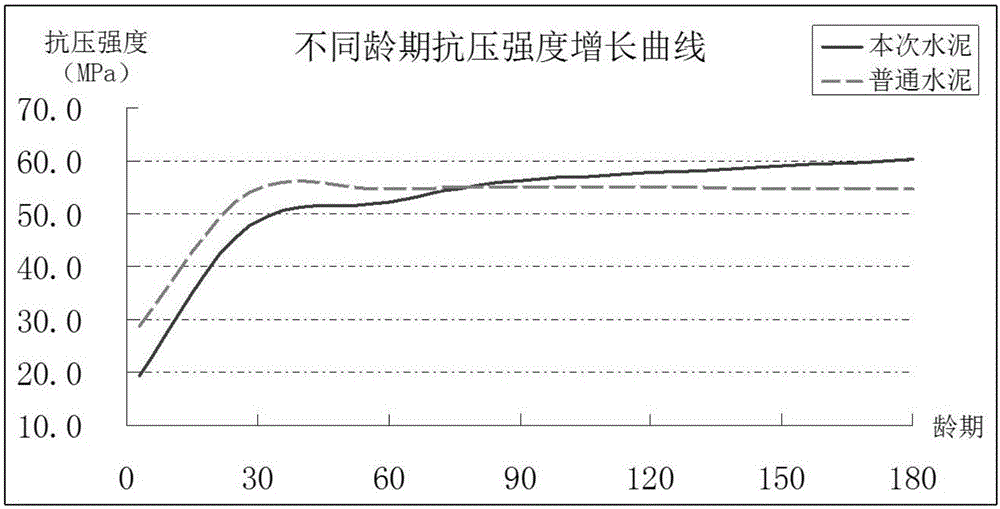

Examples

Embodiment 1

[0093] Embodiment 1: the production of high durability cement of the present invention

[0094] The implementation steps of this embodiment are as follows:

[0095] Select raw materials that meet the quality requirements described in this manual, and use the MPS3450 vertical roller mill produced by Shenyang Lifting and Transportation Machinery Factory for grinding, so that the particle size of the raw material is less than 0.08mm and is ≤15% by weight , below 0.2mm is ≤2.0% by weight.

[0096] Then, 82 parts by weight of limestone calcareous raw materials, 0.4 parts by weight of shale aluminum raw materials, 5.6 parts by weight of quartz sandstone siliceous raw materials and 5.8 parts by weight of iron ore iron raw materials are mixed to obtain a raw meal, and then this raw meal Calcined with coal powder at a calcination temperature of 1400°C in a cement kiln to obtain a high-durability clinker.

[0097] In the clinker calcination step, the temperature fluctuation range of t...

Embodiment 2

[0106] Embodiment 2: the production of high durability cement of the present invention

[0107] The implementation steps of this embodiment are as follows:

[0108] Select raw materials that meet the quality requirements described in this manual, and use the MPS3450 vertical roller mill produced by Shenyang Lifting and Transportation Machinery Factory for grinding, so that the particle size of the raw material is less than 0.08mm and is ≤15% by weight , below 0.2mm is ≤2.0% by weight.

[0109] Then, 85 parts by weight of marl calcareous raw materials, 0.8 parts by weight of bauxite aluminum raw materials, 5.0 parts by weight of river sand siliceous raw materials and 5.0 parts by weight of iron powder iron raw materials are mixed to obtain a raw meal, and then this Raw meal and coal powder are calcined in a cement kiln at a calcination temperature of 1400°C to obtain a high-durability clinker.

[0110] In the clinker calcination step, the temperature fluctuation range of the ...

Embodiment 3

[0118] Embodiment 3: the production of high durability cement of the present invention

[0119] The implementation steps of this embodiment are as follows:

[0120] Select raw materials that meet the quality requirements described in this manual, and use the MPS3450 vertical roller mill produced by Shenyang Lifting and Transportation Machinery Factory for grinding, so that the particle size of the raw material is less than 0.08mm and is ≤15% by weight , below 0.2mm is ≤2.0% by weight.

[0121] Then, 86 parts by weight of chalk calcareous raw materials, 1.0 parts by weight of fly ash aluminum raw materials, 7.4 parts by weight of Jiangsha siliceous raw materials and 7.2 parts by weight of sulfuric acid slag iron raw materials are mixed to obtain a kind of raw meal, and then this raw meal Calcined with coal powder at a calcination temperature of 1400°C in a cement kiln to obtain a high-durability clinker.

[0122] In the clinker calcination step, the temperature fluctuation ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com