Manual power generation device for driving actuator, and actuator drive device

An actuator, manual power generation technology, applied in the direction of electromechanical devices, electrical components, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

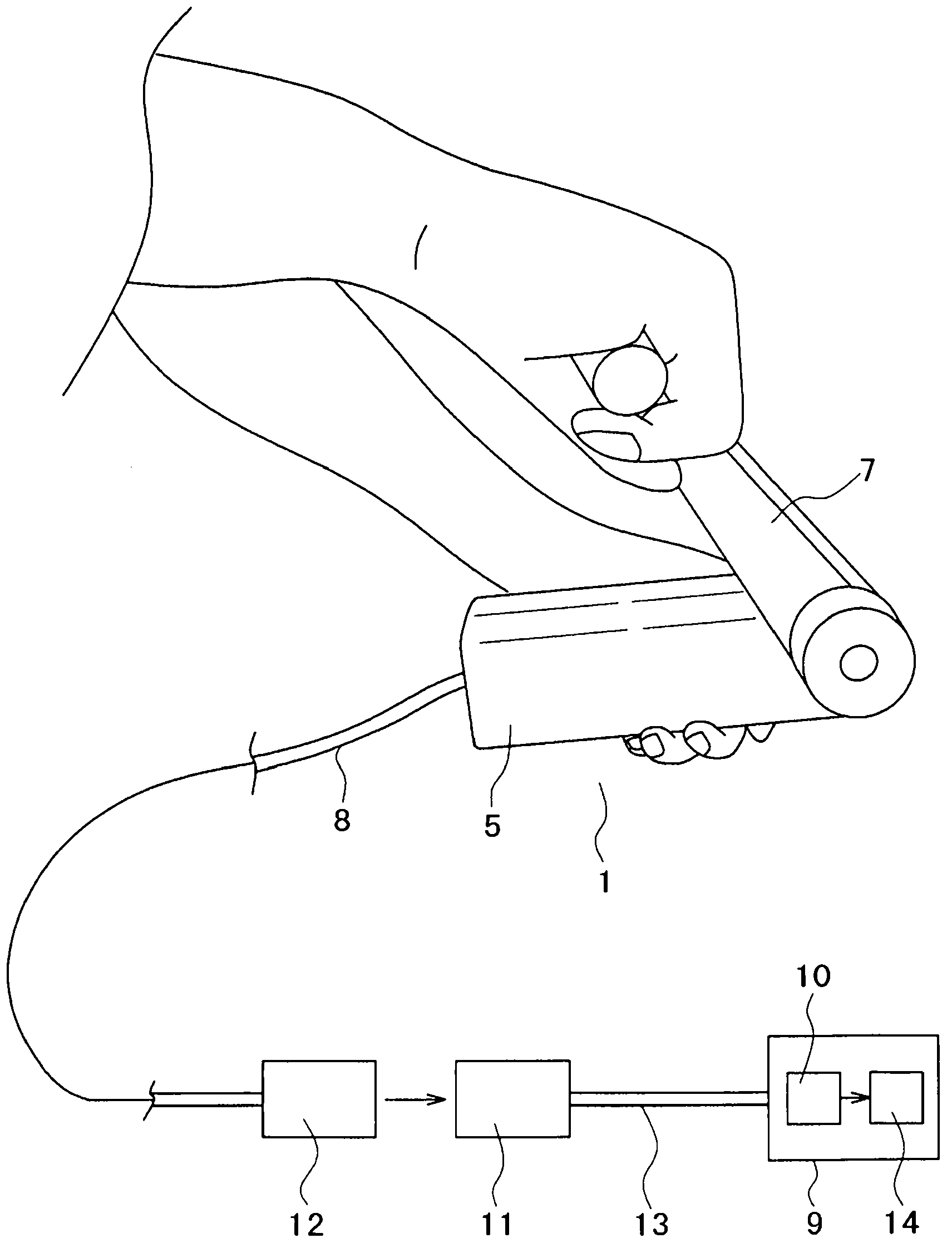

[0043]The specifications of one embodiment of the manual power generator 1 of the present invention will be described as follows.

[0044] Input obtained manually: 10~50[N]

[0045] The rotational speed of the input shaft under manual operation: 30~120[rpm]

[0046] Reduction ratio (gear ratio): 1 / 15.5

[0047] Rotational shaft speed: 465~1860[rpm]

[0048] Power generation: 10~30[VA]

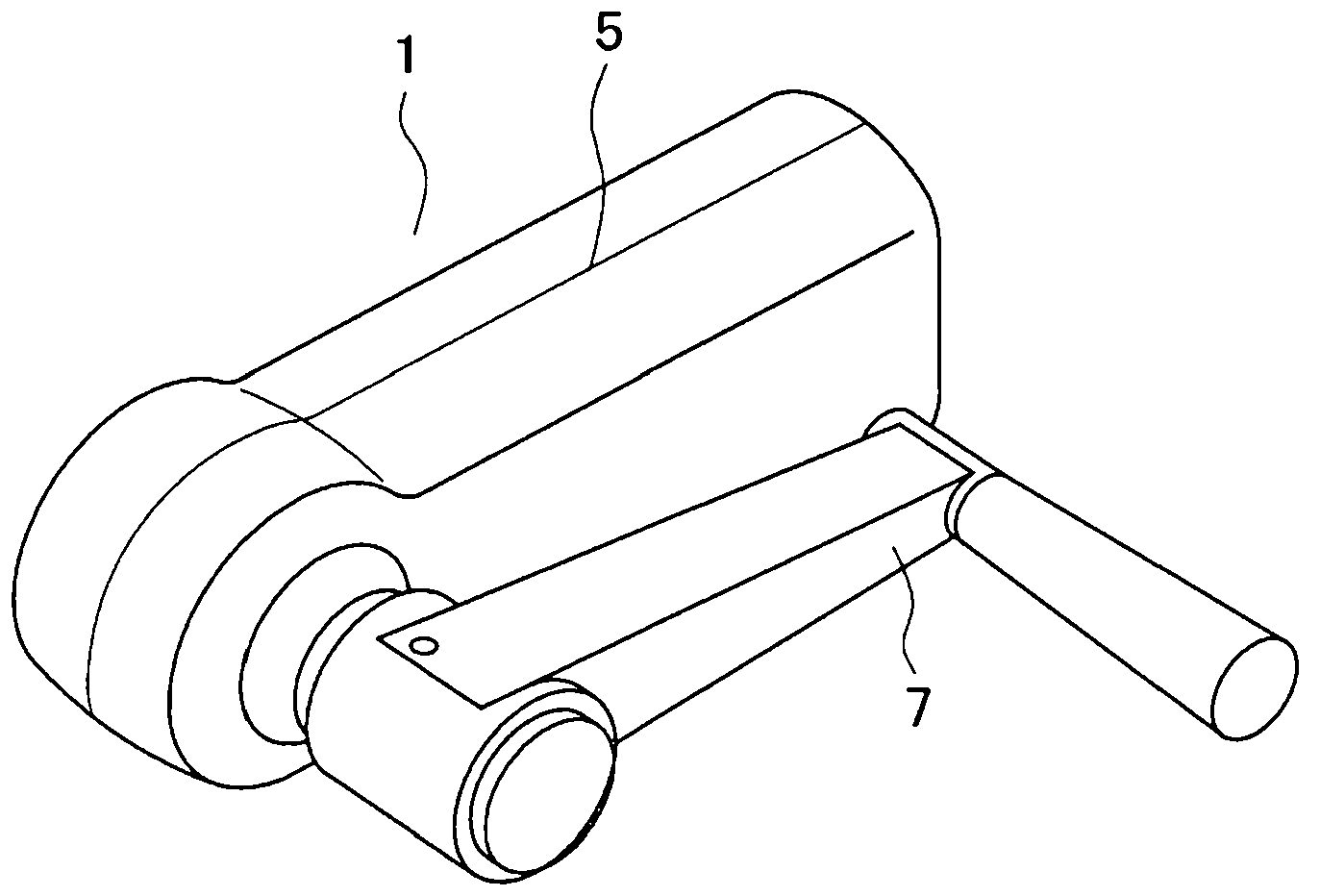

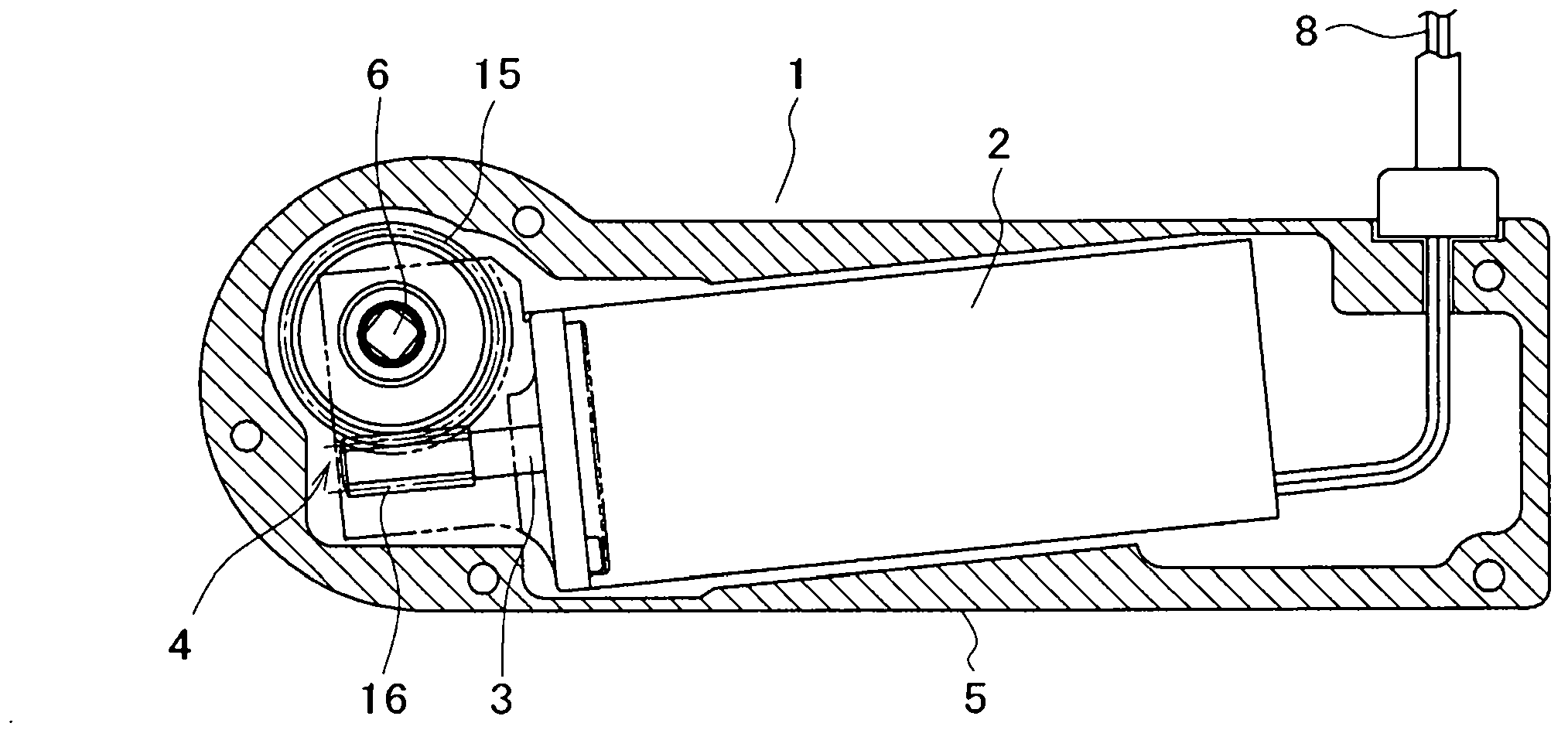

[0049] In this embodiment, the speed-up mechanism 4 constituting the manual power generator 1 is constituted by a worm gear transmission mechanism in which the side of the crank handle 7 is made into a worm wheel 15, and the side of the DC motor 2 is made into a worm screw 16 of a double thread. Since the size and weight are greatly reduced, the components can be accommodated in the device main body 5 of a size that can be held by hand, and the manual generator 1 that satisfies the above-mentioned specifications can be realized.

[0050] Here, in the present invention, the DC motor 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com