Industrial hemp scapus fiber separator

A technology of industrial hemp and stem fiber, which is applied in the directions of fiber mechanical separation, fiber treatment, and mechanical treatment, etc., can solve the problems of low hemp growth rate, large fiber loss, limited hemp stripping effect, etc., so as to increase the scraping and extrusion area. , Improve the effect of broken stems and improve the efficiency of hemp stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

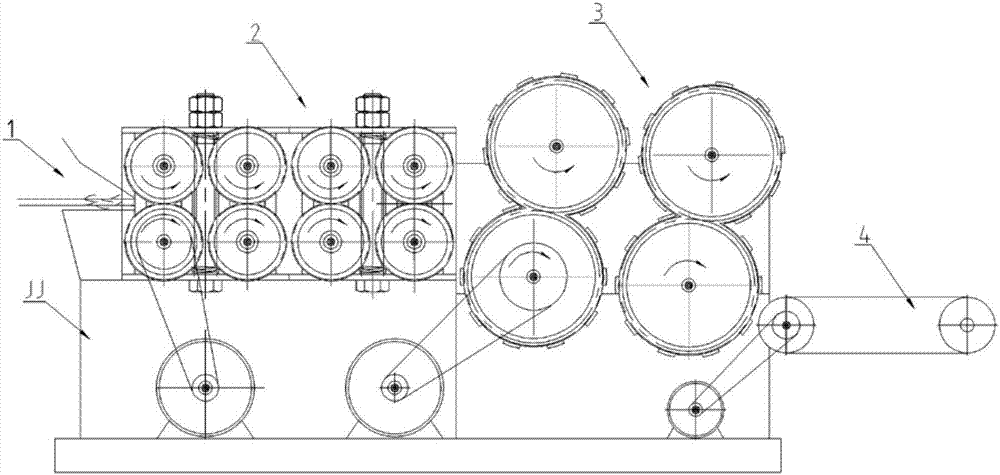

[0034] Such as figure 1 As shown, the industrial hemp dry stem fiber separator disclosed in this embodiment includes a frame JJ and a feeding table 1, a stem rolling device 2, a hemp chip combing device 3 and a fiber Conveyor belt 4.

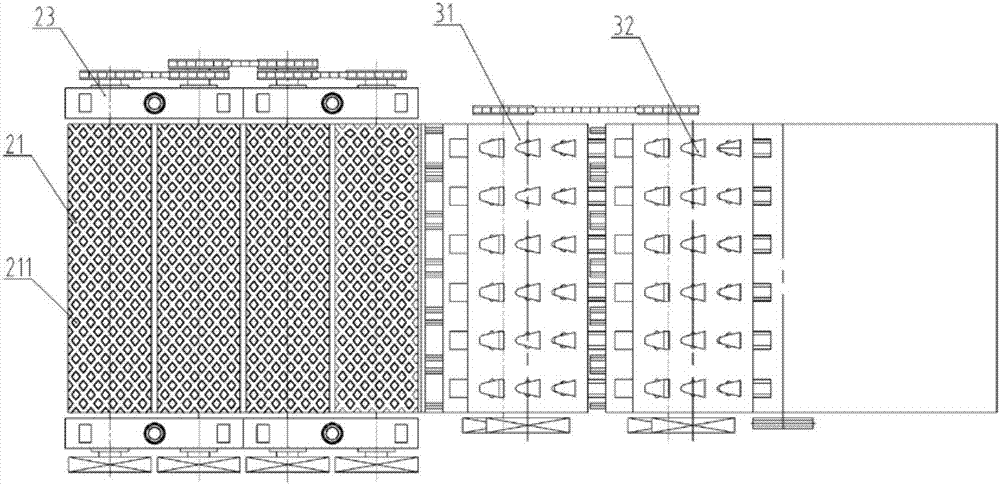

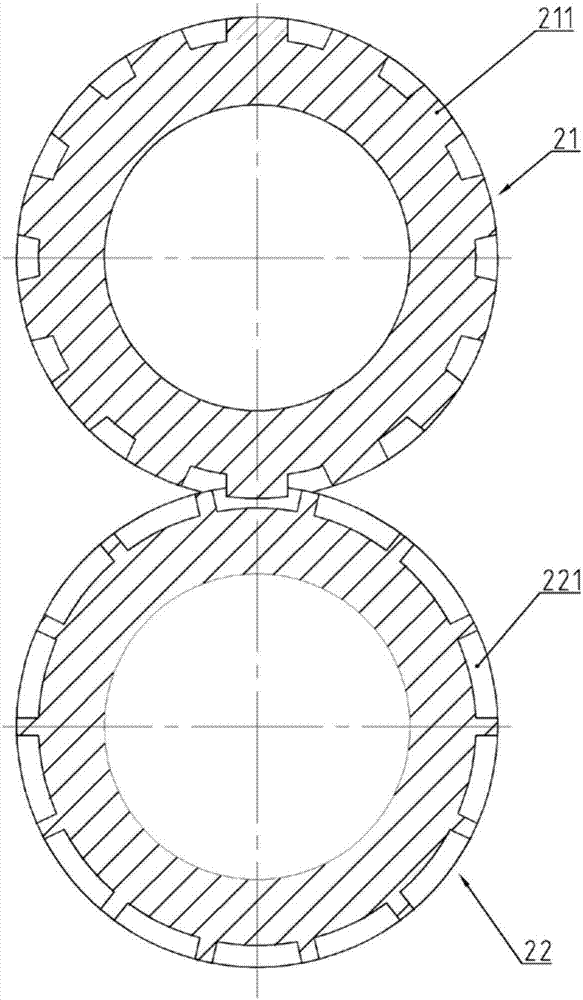

[0035] combine figure 1 , figure 2 , image 3 It can be seen that the stem rolling device 2 of this embodiment has four pairs of upper rolling rollers 21 and lower rolling rollers 22 that mesh up and down, and the two ends of each pair of rolling rollers are respectively connected with rolling pressure and gap adjustment. Mechanism 23, flax carding device 3 have two pairs of carding cylinders 31. The lower roller of the first pair of rolling rollers is driven by a V-belt to rotate, the front and rear rolling rollers are driven by a chain, and the upper and lower rolling rollers are driven by a gear pair. The lower carding cylinder of the first pair of carding cylinders is driven by a V-belt to rotate, the upper and lower carding cylinders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com