Growth method for high-speed and high-quality monocrystal diamond

A single crystal diamond and growth method technology, applied in the growth of high-quality single crystal diamond, epitaxial growth of single crystal diamond material, high-speed field, can solve the problem of many defects, low growth efficiency of single crystal diamond, unfavorable diamond development, and slow diamond growth rate and other issues to achieve the effect of high-speed growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

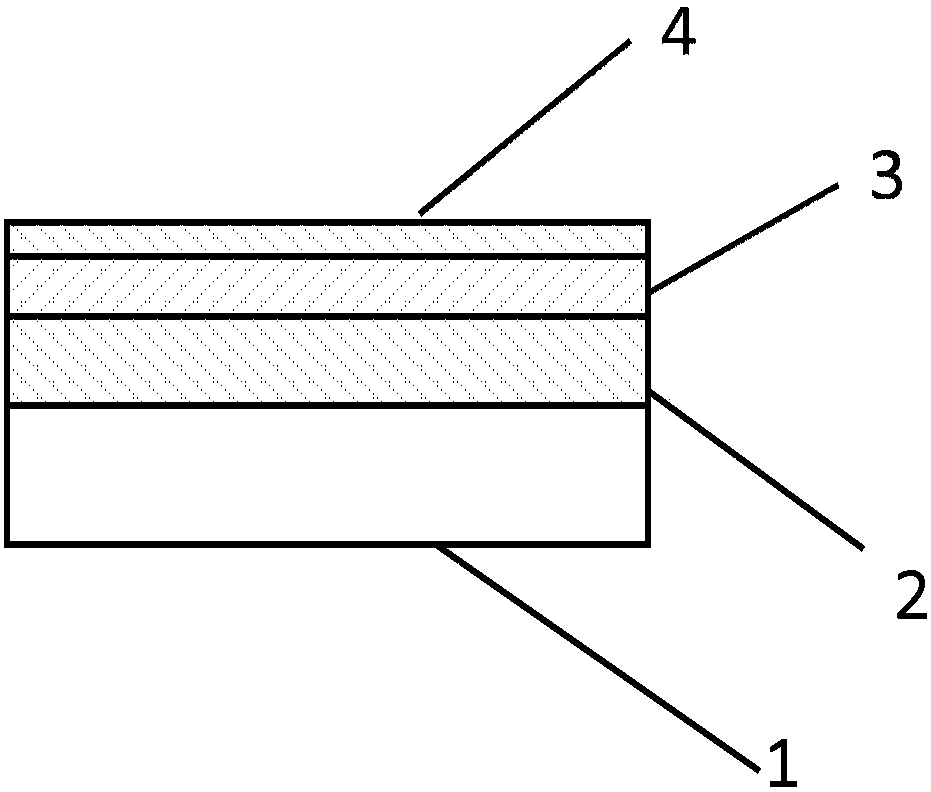

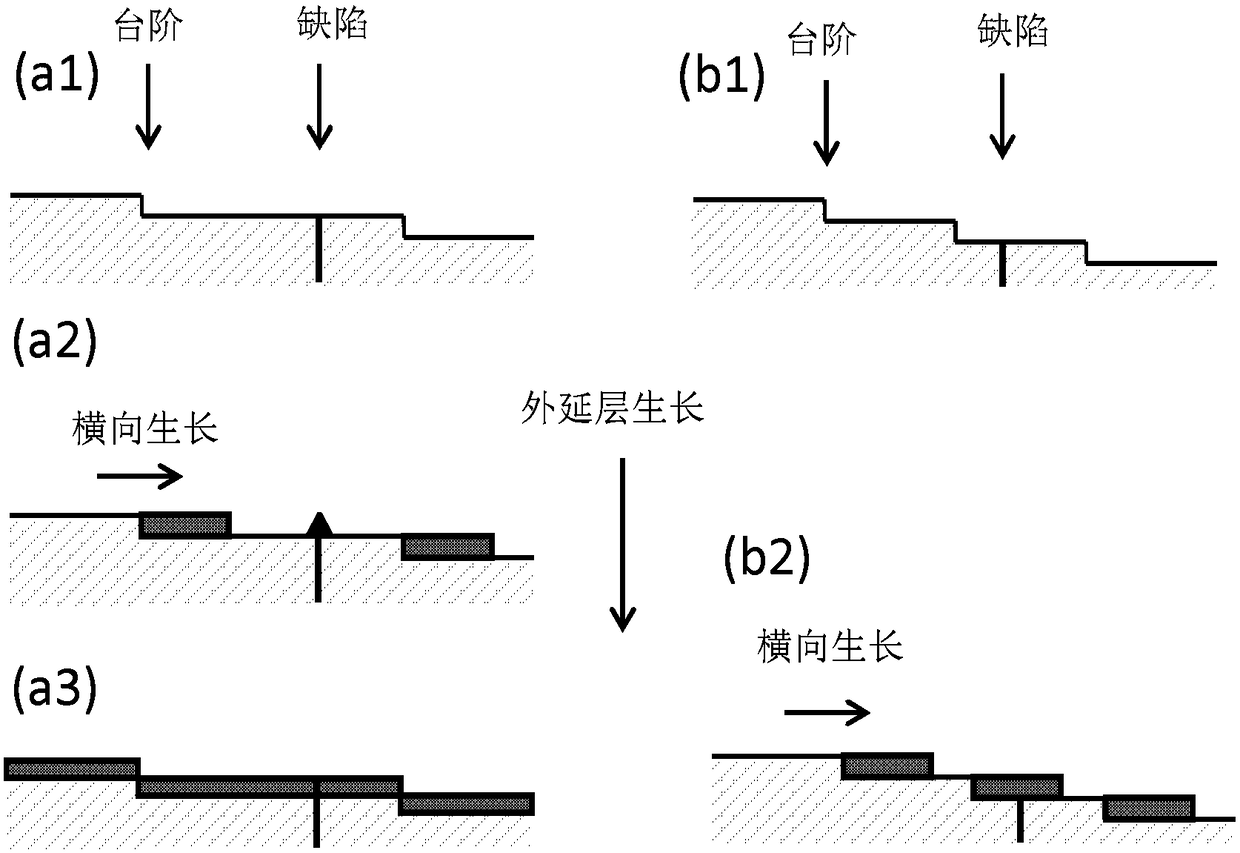

[0035] Step 11: The substrate is diamond, and the angle between the substrate and the (100) plane is 2°.

[0036] Step 12: cleaning the substrate, and finally drying the substrate with nitrogen.

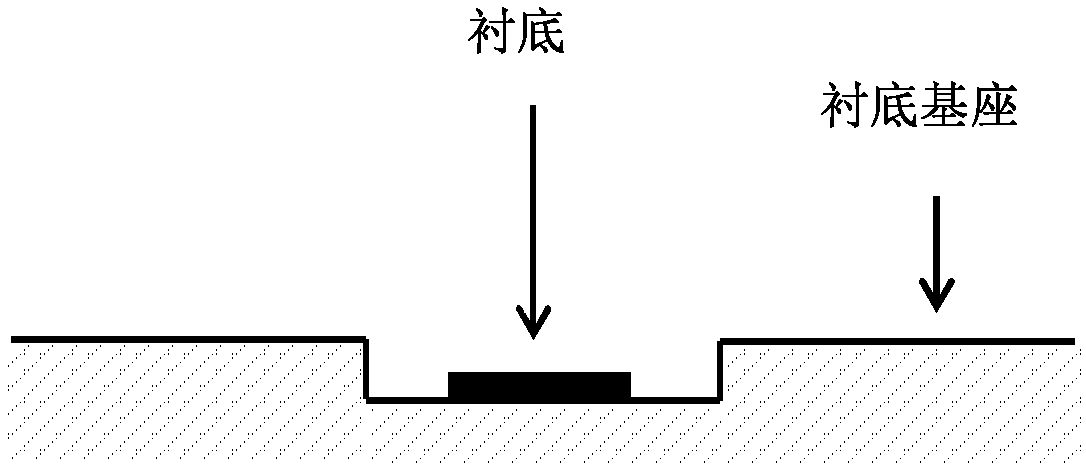

[0037] Step 13: The substrate base adopts a groove structure, and the substrate surface is 0.5 mm away from the substrate base surface.

[0038] Step 14: substrate plasma etching, the etching conditions are: etching time is 30min, the etching conditions are microwave power 5kW, air pressure 120torr, hydrogen flow rate 500sccm, and substrate etching temperature 850°C.

[0039] Step 15: The growth parameters used for high-speed growth of the diamond support layer are as follows: microwave power 5kW, growth pressure 240torr, hydrogen flow 500sccm, methane concentration 10%, growth temperature 1150°C, growth time 6h.

[0040] Step 16: Perform plasma etching on the surface of the diamond support layer, etching conditions: etching time is 60 minutes, etching conditions are microwave power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com