Non-toxic environmentally friendly nadic anhydride polyester plasticizer and preparation method thereof

A technology of nadic acid anhydride and polyester plasticizer, which is applied in the field of unsaturated polyester plasticizers, can solve the problems of poor PVC compatibility, small molecular weight, and single performance, and achieve improved weather resistance, less by-products, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

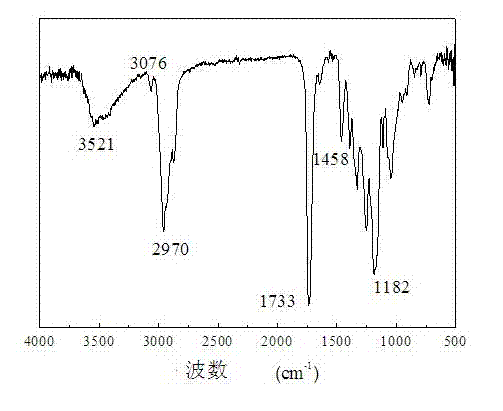

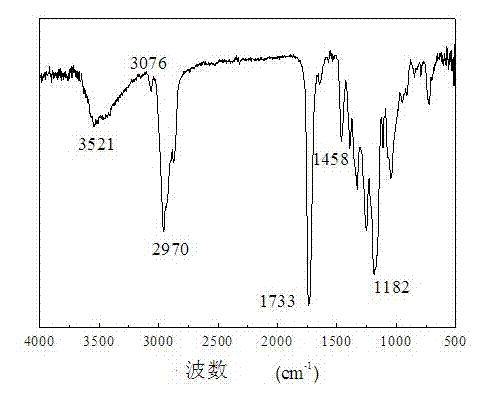

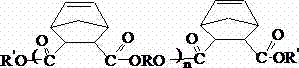

Image

Examples

Embodiment 1

[0025] Into a 250mL four-necked flask were added 0.20mol of Nadic anhydride, 0.22mol of methyl propylene glycol, 0.08mol of 2-ethylhexanol, 6.67mL of cyclohexane with water, 0.02g (0.03% of the total mass) tetratitanate n-Butyl ester, nitrogen is introduced to protect the reaction system from being oxidized and avoid causing various side reactions, start stirring, slowly heat up, start timing when water comes out, keep the heating rate at 10°C / h, when the temperature rises to At 170 °C, the nitrogen flow rate was reduced, and the maximum temperature did not exceed 220 °C to ensure the safety of the experiment. The acid value is measured every 1h, the calculation of the acid value refers to GB / T 1668-2008, the reaction is 6h, the acid value is reduced to 0.51mgKOH / g, the esterification rate is greater than 99%, the heating is stopped, and it is cooled to room temperature under nitrogen. It is a vacuum distillation device, slowly heat up to 220°C, stop heating when no liquid dr...

Embodiment 2

[0027] 0.20mol Nadic anhydride, 0.25mol methyl propylene glycol, 0.12mol 2-ethylhexanol, 6.67mL water agent cyclohexane, 0.19g (0.25% of the total mass) tetra titanate were added to a 250mL four-necked flask. N-butyl ester, nitrogen is introduced to protect the reaction system from being oxidized and avoid causing various side reactions, start stirring, slowly heat up, start timing when water comes out, keep the heating rate at 10℃ / h, when the temperature rises to 170 At ℃, the nitrogen flow rate was reduced, and the maximum temperature did not exceed 220℃ to ensure the safety of the experiment. The acid value is measured every 1h, the calculation of the acid value refers to GB / T 1668-2008, the reaction is 6h, the acid value is reduced to 0.31mgKOH / g, the esterification rate is greater than 99%, the heating is stopped, cooled to room temperature under nitrogen, and changed. It is a vacuum distillation device, slowly heat up to 220°C, stop heating when no liquid drips, and cool...

Embodiment 3

[0029] Into a 250mL four-necked flask were added 0.20mol Nadic anhydride, 0.25mol methyl propylene glycol, 0.12mol 2-ethylhexanol, 6.67mL cyclohexane with water, 0.38g (0.5% of the total mass) tetra titanate N-butyl ester, nitrogen is introduced to protect the reaction system from being oxidized and avoid causing various side reactions, start stirring, slowly heat up, start timing when water comes out, keep the heating rate at 10℃ / h, when the temperature rises to 170 At ℃, the nitrogen flow rate was reduced, and the maximum temperature did not exceed 220℃ to ensure the safety of the experiment. The acid value is measured every 1h, the calculation of the acid value refers to GB / T 1668-2008, the reaction is 6h, the acid value is reduced to 0.40mgKOH / g, the esterification rate is greater than 99%, the heating is stopped, and it is cooled to room temperature under nitrogen. It is a vacuum distillation device, slowly heat up to 220°C, stop heating when no liquid drips, and cool to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com