Polyester plasticizers with benzoic acid end-caps

A technology of benzoate and polydibenzoate, applied in the field of polyester plasticizer, can solve the problems of incompatibility and limitation of application polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0109] Polyester plasticizers of the present invention evaluated in the Examples include:

[0110] X-121 - Polyester plasticizer of the invention comprising propylene adipate with benzoate endcapping

[0111] X-124 - Polyester plasticizer of the invention comprising propylene adipate with benzoate end capping (higher molecular weight than X-121)

[0112] X-151 - Polyester plasticizer of the invention comprising propylene glycol succinate with benzoate endcapping

[0113] X-131 - Inventive polyester plasticizer comprising propylene adipate with mixed benzoate and acetate endcaps

[0114] Traditional plasticizers used for comparison in the examples include:

[0115] Diisononyl Phthalate (DINP)

[0116] Dioctyl terephthalate (DOTP)

[0117] Benzylisononyl phthalate (INBP)

[0118] Trimethyl-1-3-phthalate benzyl pentylene glycol monoisobutyrate (benzyl 3-isobutyryloxy-1-isopropyl-2,2-phthalate dimethyl benzyl 3-isobutyryloxy-1-isopropyl-2,2-dimethylpropyl phthalate or TBP) –...

example 1

[0121] Example 1: 2K polysulfide insulating glass sealant / B side evaluation

[0122] The formula and method of the sealant that this example adopts are as follows:

[0123] A side formula

[0124] ingredient type

PHR

liquid polysulfide polymer

100

INBP

35

coupling agent

1.2

155

Precipitated calcium carbonate

32

1.6

[0125] Side B formula

[0126] ingredient type

number of copies

155

Hardener

101

33

Accelerator

6

[0127] Table 1 - Methods

[0128]

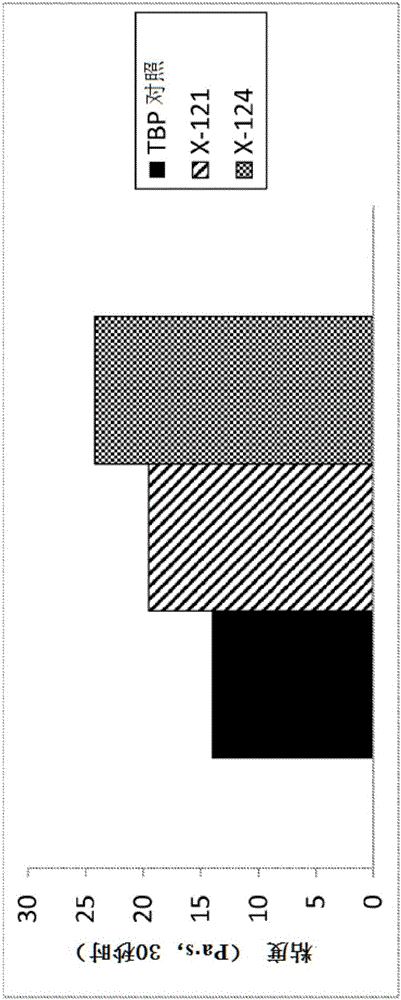

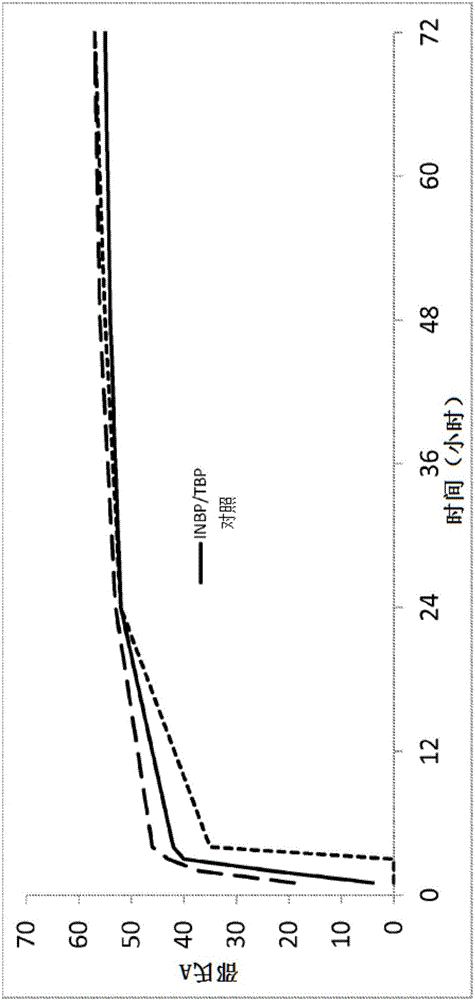

[0129] The oligomeric dibenzoates of the present invention (X-121 and X-124) of different molecular weights based on propylene glycol oxalate were combined with conventional high molecular weight Benzyl phthalate (TBP) plasticizers were compared. The plasticizer of the present invention is contained on the B side of the encapsu...

example 2

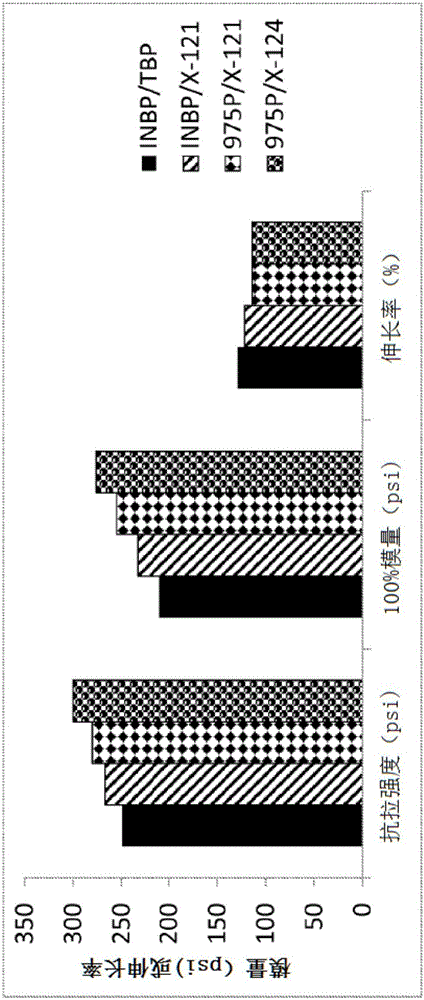

[0140] Example 2 - Propylene Glycol / Succinate Polyester with Dibenzoate Endcapping in Plastisol

[0141] Additional methods for plastisol evaluation:

[0142] Viscosity and Rheology: Low Shear – Brookfield Viscosity, 20RPM, 10 rpm reading. ASTM D1823. High Shear – TAAR2000ex was used. The parallel plates are set with a suitable gap. Cut to 1000sec -1 .

[0143] Gel / Fusion: TA AR2000ex is in shaking mode. The parallel plates are set with a suitable gap. The test starts at 40°C and heats up to 220°C at a rate of 5°C / min.

[0144] Compatibility of plasticizers with polymers: tumbling and cycling experiments, as in Table 1 above.

[0145] Effectiveness - Shore A - ASTM D2240; Tensile Strength - ASTM D638, Type IV die, 50.8 cm / minute pull rate.

[0146] Raw materials for plastisol evaluation:

[0147] Geon TM 121-A - PVC homopolymer available from PolyOne Corporation.

[0148] KRONOS TiO 2 - Titanium dioxide from Kronos, Inc.

[0149] 1221 - Ca / Zn stabilizer from Gal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com