Polyvinyl chloride sealing strip composition for refrigerator

A technology of polyvinyl chloride and sealing strips, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of decreased sealing performance of sealing strips, affecting the service life of materials, poor durability of sealing strips, etc., and can reduce the mold expansion ratio , Inhibit thermal oxygen aging effect, good extraction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

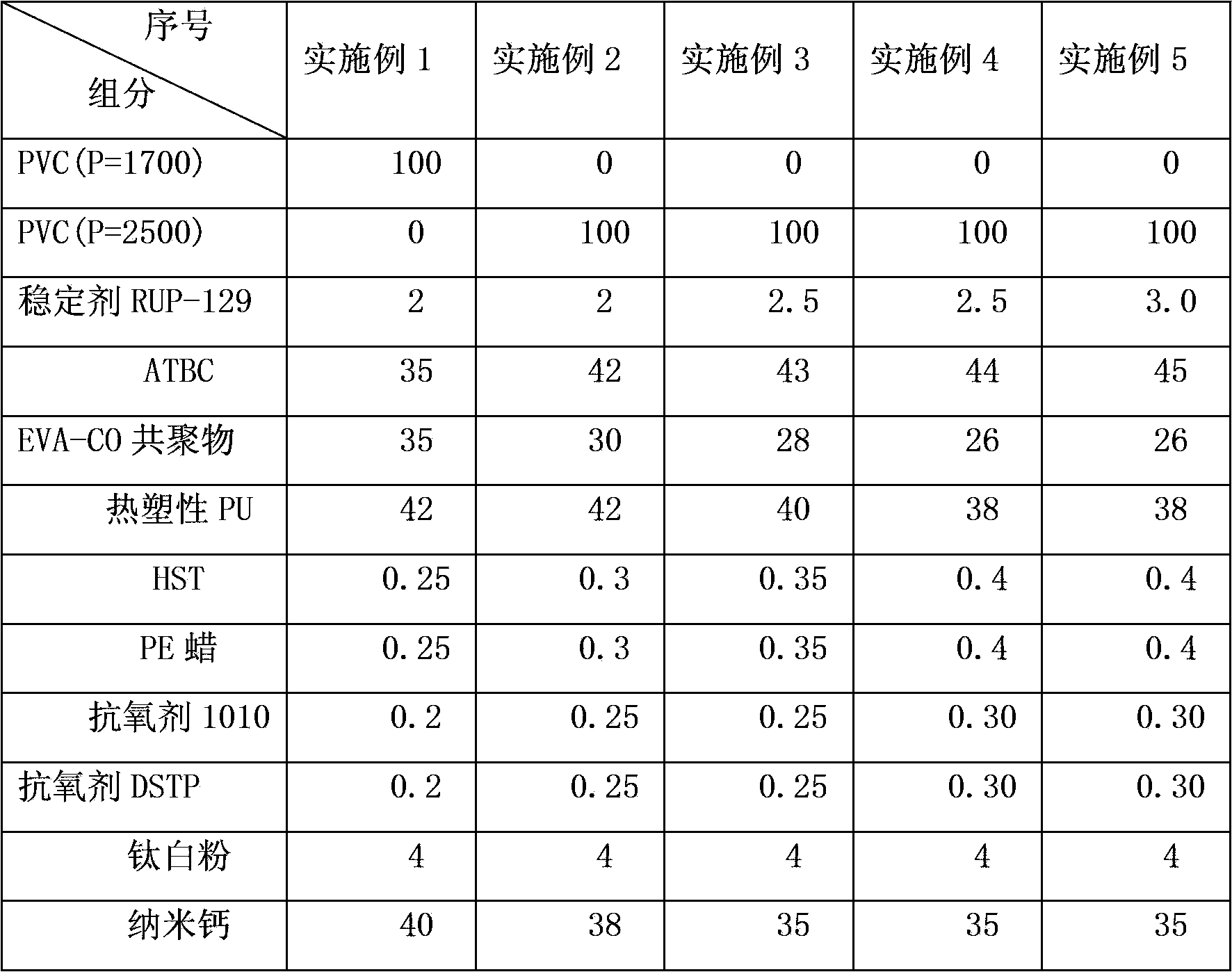

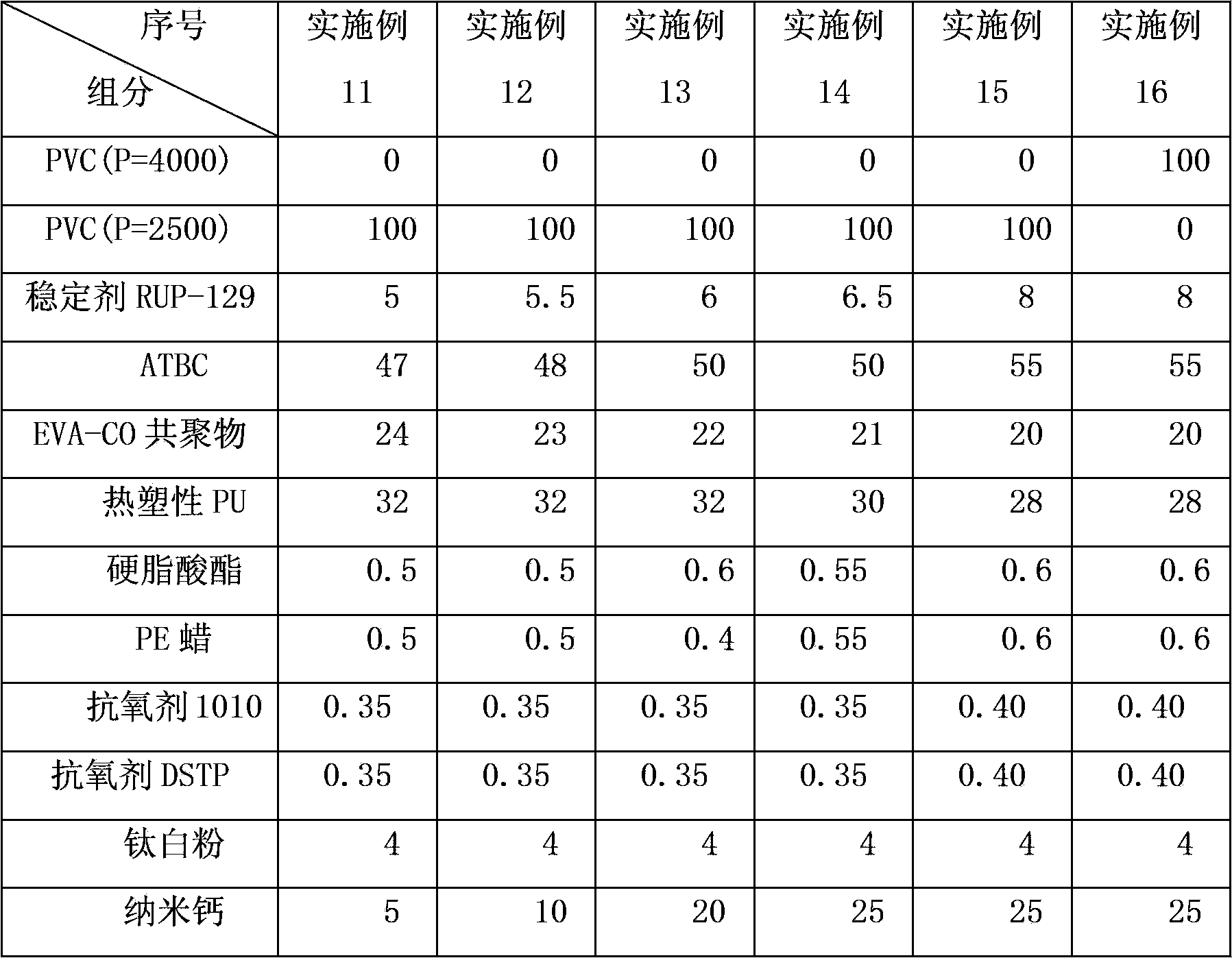

[0025] Examples 1 to 16 are the compositions of polyvinyl chloride sealing strips for refrigerators according to the present invention. See Tables 1 to 3 for the proportioning components. Among them, the stabilizer RUP-129 is a high-efficiency non-toxic calcium zinc stabilizer, and the antioxidant 1010 is tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythyl ester; The oxygen agent DSTDP is bis(octadecyl)thiodipropionate, acetyl tri-n-butyl citrate is abbreviated as ATBC, and stearic acid is abbreviated as HST. Embodiment 8 is the best implementation mode.

[0026] Table 1 Example 1-5 Refrigerator polyvinyl chloride sealing strip composition (by weight)

[0027]

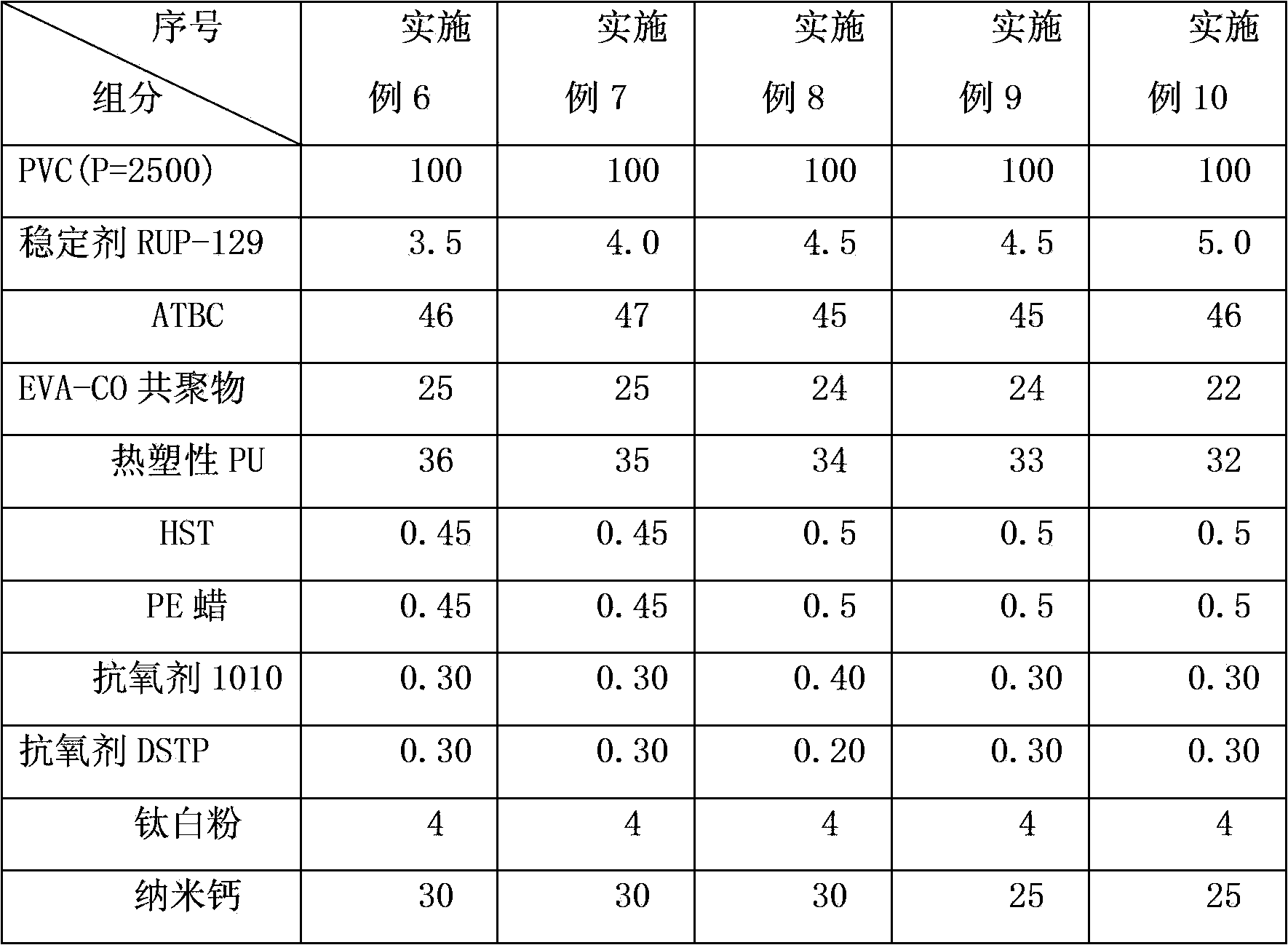

Embodiment 6~10

[0028] Table 2 Example 6-10 Polyvinyl chloride sealing strip compositions for refrigerators (by weight)

[0029]

[0030] Table 3 Example 11-16 Polyvinyl chloride sealing strip compositions for refrigerators (by weight)

[0031]

[0032] The preparation method of embodiment 1~16:

[0033] 1) Material mixing process: mix polyvinyl chloride, plasticizer, modified ethylene vinyl acetate copolymer, thermoplastic polyurethane elastomer, heat stabilizer, lubricant, antioxidant, and filler in a high and low speed mixing unit until The mixing temperature is 110°C to 120°C. Put the material into the low-speed mixer, cool down while mixing, and discharge the material when the temperature of the material is cooled to 40°C to obtain the mixed material;

[0034] 2) Granulation process: The mixed materials are granulated by a twin-screw extruder. The process parameters are shown in Table 4. After granulation, it is air-cooled, granulated, measured, and packaged to form a combination ...

Embodiment 8

[0056] Table 8 embodiment 8 by the detection performance result of sealing strip standard

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com