Non-yellowing ultraviolet light curing abrasion resistant paint and preparation method thereof

A technology of wear-resistant coatings and ultraviolet light, which is applied in the field of ultraviolet light coatings and can solve problems such as yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

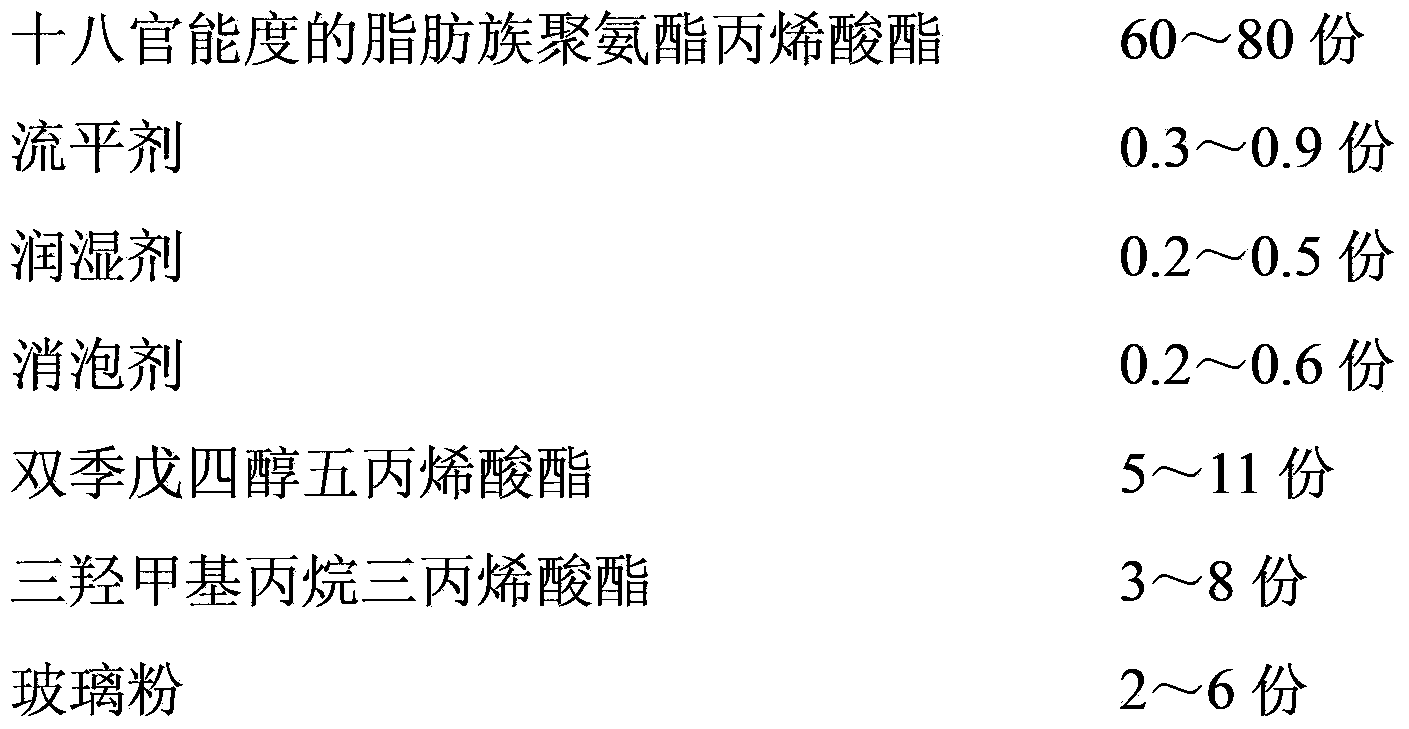

Method used

Image

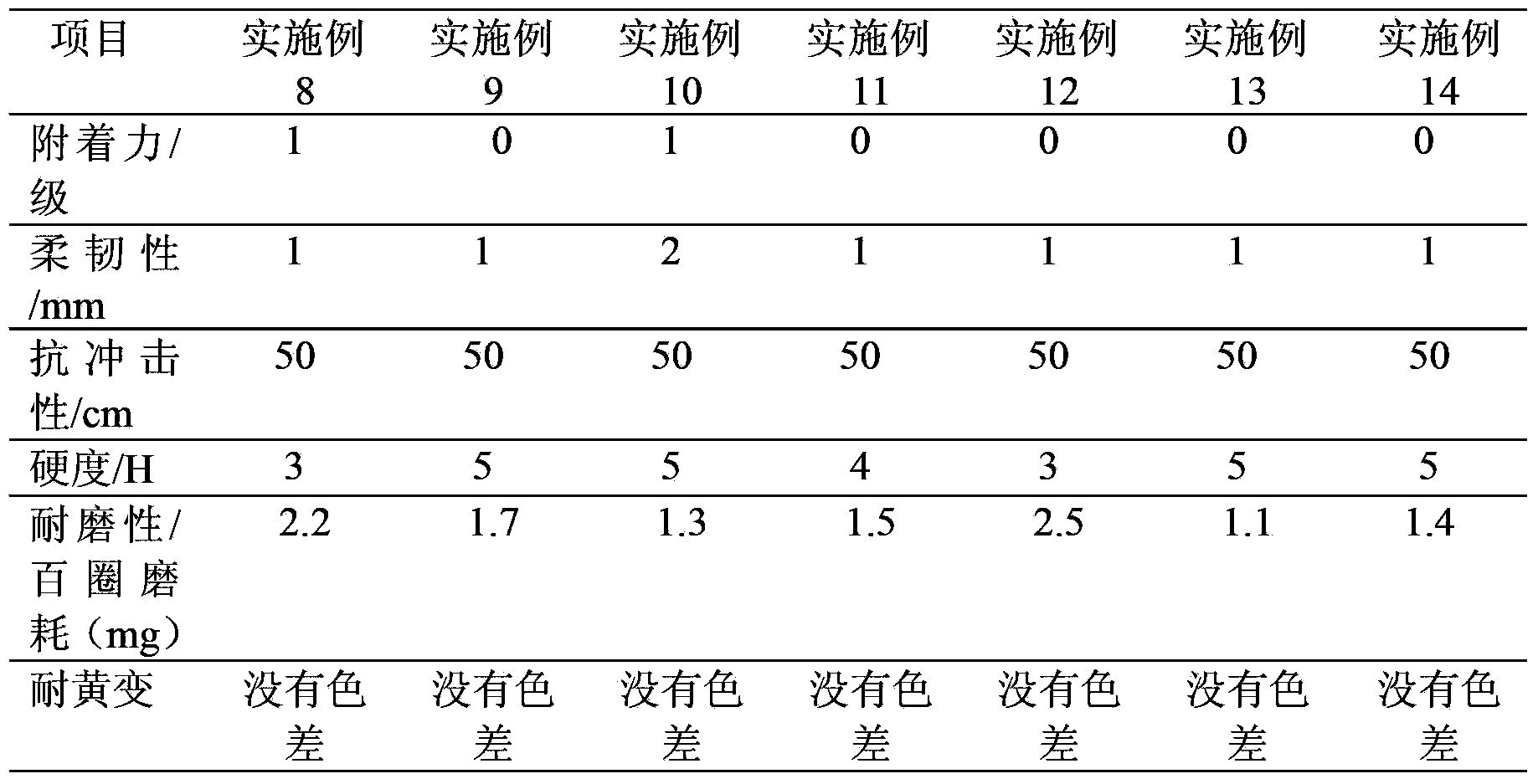

Examples

preparation example Construction

[0026] The preparation method of the aliphatic urethane acrylate of eighteen functionalities of the present invention comprises as follows:

[0027] Step 1: reacting dipentaerythritol, isobornyl methacrylate, 1,6-hexanediol diacrylate and diisocyanate at 70-80°C to obtain the first intermediate;

[0028] Step 2: reacting the polymer diol, the catalyst and the first intermediate obtained in step 1 at 75-85° C. to obtain the second intermediate;

[0029] Step 3: react pentaerythritol triacrylate with the second intermediate obtained in Step 2 at 70-85° C. to obtain octadecyl-functionality aliphatic urethane acrylate.

[0030] In step one of the present invention, dipentaerythritol, isobornyl methacrylate and 1,6-hexanediol diacrylate are first added to the reactor, and under the protection of nitrogen, the temperature of the reactor is raised to 70-80°C , and then drop diisocyanate in the reaction kettle, the dropping rate is preferably 8 to 17ml / min, after the dropping is comp...

Embodiment 1

[0047] Under nitrogen protection, add 260g of dipentaerythritol, 60g of isobornyl methacrylate, and 75g of 1,6-hexanediol diacrylate into the reaction kettle, heat to 70°C, and drop 1008g of 1,6-hexamethylene diisocyanate, after the dropwise addition, continued to react for 1.5 hours to obtain the first intermediate;

[0048] Add 5,800g of polybutylene adipate (molecular weight: 1,000 Daltons) and 0.2g of dibutyltin dilaurate catalyst to the first intermediate at one time, control the temperature at 75°C, and react for 2 hours to obtain the second intermediate body;

[0049] Add 7.5g of hydroquinone polymerization inhibitor and 1788g of pentaerythritol triacrylate to the second intermediate, control the temperature at 70°C, and react for 1.5 hours to obtain octadecyl-functional aliphatic urethane acrylate.

Embodiment 2

[0051] Under the protection of nitrogen, add 685g of dipentaerythritol, 145g of isobornyl methacrylate, 168g of 1,6-hexanediol diacrylate into the reaction kettle, heat to 80°C, and drop 3750g of di Cyclohexylmethane diisocyanate, after the dropwise addition, continued to react for 3 hours to obtain the first intermediate;

[0052] Add 11220g polybutylene adipate (molecular weight: 4000 Daltons) and 1.1g stannous octoate catalyst to the first intermediate at one time, control the temperature at 85°C, and react for 4 hours to obtain the second intermediate;

[0053] Add 16g of p-hydroxyanisole polymerization inhibitor and 4485g of pentaerythritol triacrylate to the second intermediate, control the temperature at 85°C, and react for 3 hours to obtain octadecyl-functional aliphatic urethane acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com