Two-component polyaspartic acid ester sealant and preparation method thereof

A technology of aspartic acid ester and beautifying agent, applied in the field of beautifying agent, can solve the problems of large shrinkage rate of beautifying agent, poor substrate adhesion, unsatisfactory toughness, etc., and achieve good maintenance and recoating performance. , Excellent weather resistance, not easy to be scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

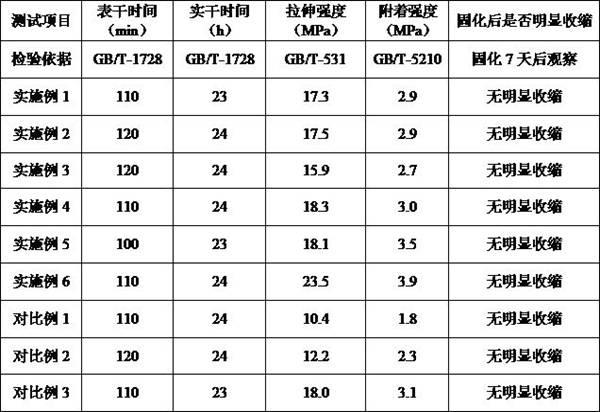

Examples

preparation example Construction

[0067] Wherein, the preparation method of the prepolymer containing polyisocyanate comprises: adding polyether diol, polyether triol and / or polyolefin into the reaction device, adding isophorone diisocyanate under stirring at 50-70°C, After mixing evenly, heat up to 80-85°C, react until the -NCO content is 9%-11%, then quickly cool down, then add hexamethylene diisocyanate trimer, and mix well to make -NCO content 15%-17% of prepolymers.

[0068] Further preferably, the polyether diol is a polyoxypropylene diol with a molecular weight of 1000-2000, the polyether triol is a polyoxypropylene triol with a molecular weight of 500-2000, and the polyolefin is a polyoxypropylene triol with a molecular weight of 2000-2500. Hydroxypolybutadiene.

[0069] Further preferably, the mass ratio of polyether diol to polyether triol and / or polyolefin is 1.5-4:1.

[0070] Further preferably, the mass ratio of polyether diol, polyether triol and polyolefin is 3-4:1:1.

[0071] Isocyanatosilan...

Embodiment 1

[0091] A two-component polyaspartic ester beauty joint agent, including A component and B component, wherein A component includes: 8kg prepolymer containing polyisocyanate, 0.9kg fumed silica, 0.4kg42.5 #Ordinary Portland cement, 0.12kg lime powder, 10g defoamer (BYK088), 50g leveling agent (BYK-306), 0.15kg 3-isocyanatopropyltriethoxysilane;

[0092] The preparation method of the prepolymer containing polyisocyanate comprises: adding in the four-necked flask that stirrer, thermometer, nitrogen protection device are housed after 4kg polyoxypropylene glycol 2000 and 1kg polyoxypropylene trihydric alcohol 1000 are dehydrated, 60 Add 5.5kg of isophorone diisocyanate under stirring at ℃, mix evenly and heat up to 80°C, react to -NCO content of 10.9% and then quickly cool down, then add 6.15kg of hexamethylene diisocyanate trimer, mix evenly Made into a prepolymer with an NCO content of 17%;

[0093] Component B includes: 8.6kg polyaspartic acid ester, 1kg titanium dioxide, 0.6kg ...

Embodiment 2

[0098] A two-component polyaspartic ester beauty joint agent, including A component and B component, wherein A component includes: 8kg prepolymer containing polyisocyanate, 0.5kg fumed silica, 0.4kg42.5 # Ordinary Portland cement, 0.2kg lime powder, 10g defoamer (BYK088), 50g leveling agent (BYK-306), 0.1kg 3-isocyanatopropyltriethoxysilane;

[0099] The preparation method of the prepolymer containing polyisocyanate comprises: adding in the four-necked flask that stirrer, thermometer, nitrogen protection device are housed after 4kg polyoxypropylene glycol 2000 and 1kg polyoxypropylene trihydric alcohol 1000 are dehydrated, 60 Add 2.85kg of isophorone diisocyanate under stirring at ℃, mix evenly and heat up to 80°C, react to -NCO content of 10% and then quickly cool down, then add 3.95kg of hexamethylene diisocyanate trimer, mix evenly Made into a prepolymer with an NCO content of 15%;

[0100] Component B includes: 7.6kg polyaspartate, 0.8kg titanium dioxide, 0.4kg molecular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com