Intumescent flame retardant used for outer cover of ABS (acrylonitrile-butadiene-styrene) appliance switch as well as preparation and application of intumescent flame retardant

A technology of intumescent flame retardant and electrical switch, applied in the field of intumescent flame retardant, can solve the problems of inability to use electrical switch cover, low flame retardant efficiency, migration and moisture absorption, etc., and achieves reduced smoke specific optical density and compatibility. Good, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0027] The addition amounts listed in the data in the table below are respectively weighed for piperazine pyrophosphate, melamine or melamine derivatives, char-forming agent, synergist, antioxidant and smoke suppressant, and weighed at 500-1000 rpm Fully mix in a high-speed mixer for 15-30 minutes to prepare an intumescent flame retardant for ABS electrical switch covers.

[0028]

[0029]

[0030] Mix the PA-758 ABS resin produced by Taiwan Chimei Co., Ltd. with the above-mentioned flame retardant at a mass ratio of 7:3, and then extrude, cool, and dry at 180-220°C with a twin-screw extruder. Dry and pelletize to obtain halogen-free flame-retardant ABS particles, and then use an injection molding machine to prepare flame-retardant ABS test samples at 190-220°C, and conduct flame-retardant tests. The results are shown in the following table:

[0031]

[0032] It can be seen from the above table that the flame-retardant ABS plastic prepared by the flame retardant prepa...

Embodiment 9

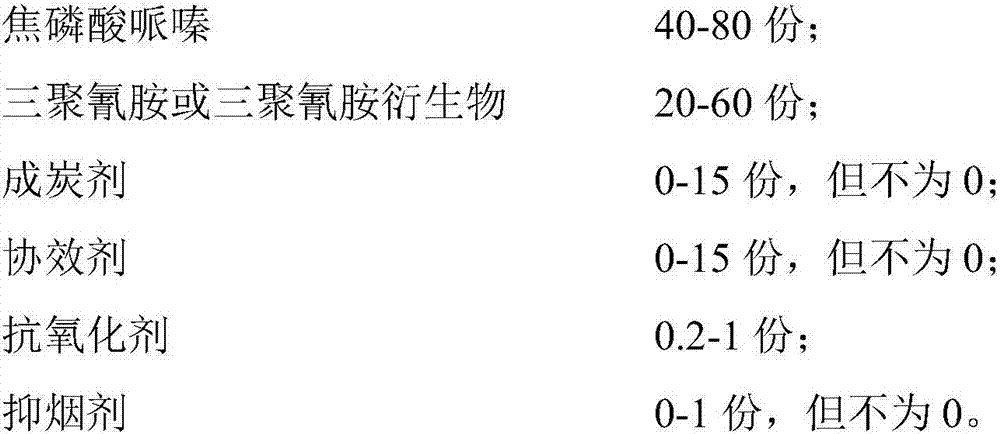

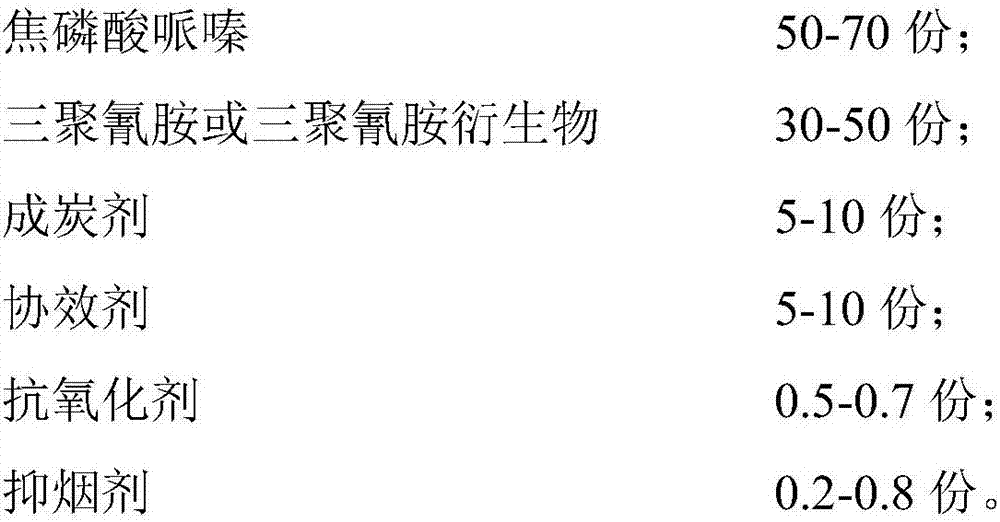

[0034] An intumescent flame retardant for an ABS electrical switch cover, the flame retardant comprises the following components and content in parts by weight:

[0035]

[0036] Among them, the particle size of piperazine pyrophosphate is D90<30 μm; the carbon forming agent is phenolic resin; the synergist includes montmorillonite; the antioxidant is 2246; the smoke suppressant is magnesium hydroxide.

[0037] The preparation method of the flame retardant is as follows: after mixing piperazine pyrophosphate, melamine or melamine derivatives, a char forming agent, a synergist, an antioxidant and a smoke suppressant, the mixture is stirred at 800 rpm for 15 minutes.

[0038] When applying, add 0.47g flame retardant to every 1g ABS resin.

Embodiment 10

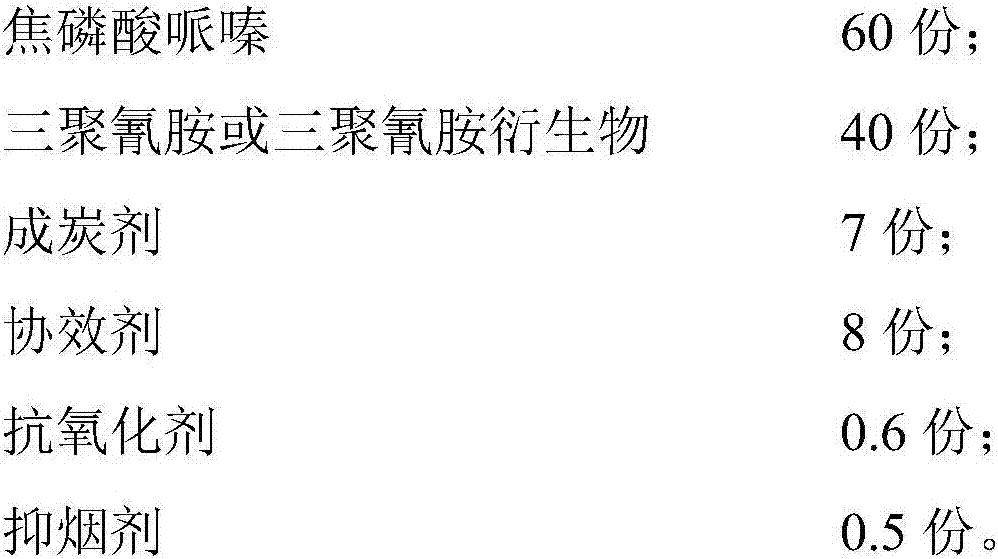

[0040] An intumescent flame retardant for an ABS electrical switch cover, the flame retardant comprises the following components and content in parts by weight:

[0041]

[0042] Among them, the particle size of piperazine pyrophosphate D90<30μm; melamine and melamine derivatives include melamine, melamine phosphate and melamine pyrophosphate; dextrin is the char-forming agent; bentonite is the synergist; 264 is the antioxidant; Aluminum hydroxide.

[0043] The preparation method of the flame retardant is as follows: after mixing piperazine pyrophosphate, melamine or melamine derivatives, a char forming agent, a synergist, an antioxidant and a smoke suppressant, the mixture is stirred at 700 rpm for 20 minutes.

[0044] When applying, add 0.43g flame retardant to every 1g ABS resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com