Patents

Literature

33results about How to "Give full play to the synergistic flame retardant effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method and application of phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant

ActiveCN106519239AImprove thermal stabilityGive full play to the synergistic flame retardant effectFiltrationPhytic acid

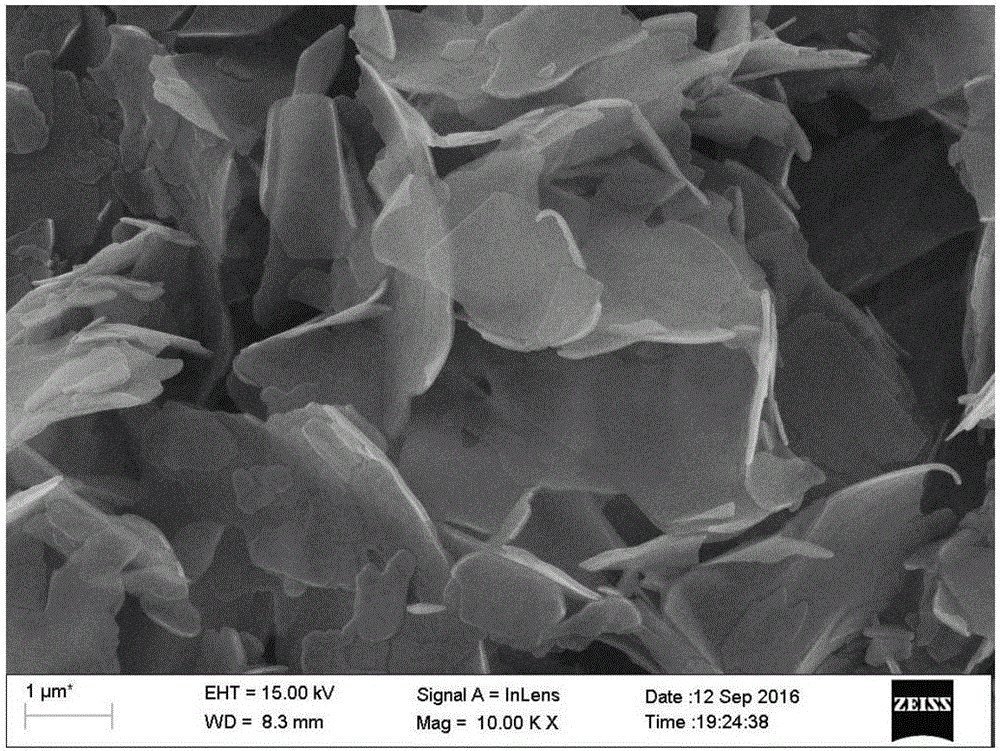

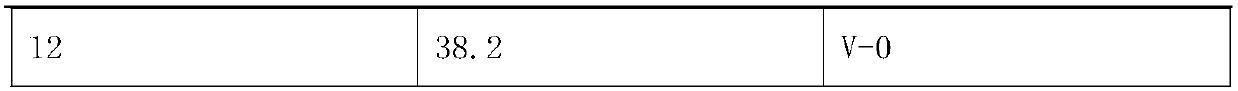

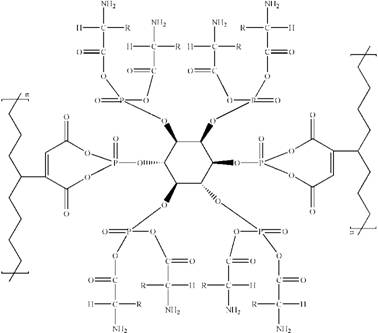

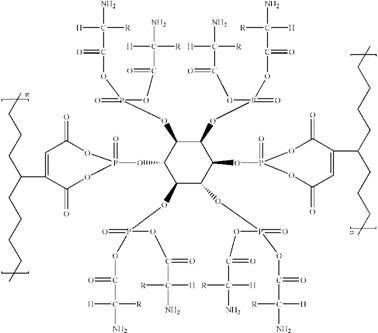

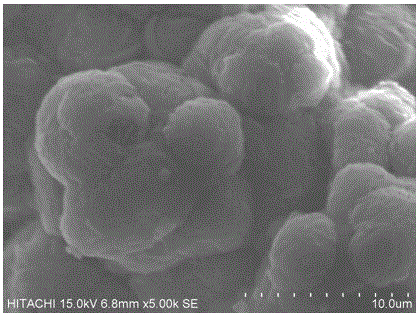

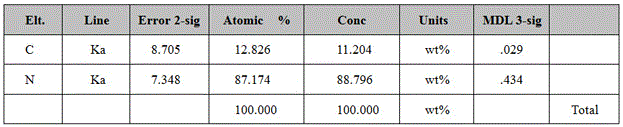

The invention discloses a preparation method of a phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant of a nano-sheet structure. The preparation method is characterized in that phytic acid, melamine and a solvent are prepared, the substance amount ratio of the phytic acid to the melamine is 1: 3 to 1: 15, and 20-50 ml of the solvent is added into every 0.01 mol of the melamine; the melamine is added into a reaction container provided with a thermometer and a stirrer, the solvent is added with stirring, the phytic acid is added at the temperature of 20-40 DEG C, and a reaction is conducted with stirring for 20-50 minutes, so that reaction liquid is obtained; and the reaction liquid is poured into a reaction still to react for 24-56 h at the temperature of 70-120 DEG C, cooling and suction filtration are conducted, solid is washed with ethyl alcohol and then washed with water till the pH is 7, and the solid is dried, so that the flame retardant is obtained. The preparation method is simple and environmentally friendly, and the synthesized phosphorus-nitrogen-carbon-containing aggregate and intumescent flame retardant of the nano-sheet structure has good compatibility with a polymer matrix and has good flame retardance.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Flame-retardant enhanced-type polypropylene composite material and preparing method thereof

Disclosed are an flame-retardant enhanced-type polypropylene composite material and a preparing method thereof. The flame-retardant enhanced-type polypropylene composite material is prepared from a polypropylene matrix, carbon nanotube modified master batch, a potassium titanate crystal whisker, a composite fire retardant, modified filler, a compatilizer and an antioxidant, wherein the carbon nanotube modified master batch is prepared through the mixed melting of the polypropylene matrix and multiwall-carbon nanotube according to a weight ratio of 10-15:1, the composite fire retardant is a nitrogen-phosphorous composite fire retardant, through the interaction of the nitrogen-phosphorous composite fire retardant and the multiwall-carbon nanotube, a combustion decomposition product of the polypropylene composite material can generate a compact, and continuously stable char layer; meanwhile, two-mechanical melt blending of the multi-walled carbon nanotube are adopted so that the multiwall-carbon nanotube can be fully dispersed in the polypropylene matrix, and two-mechanical melt blending of the multi-walled carbon nanotube are adopted. According to the flame-retardant enhanced-type polypropylene composite material and the preparing method thereof, the operation technology is simple, the added filler causes no pollution to the environment, and thus the flame-retardant enhanced-type polypropylene composite material is environmentally friendly.

Owner:DONGGUAN POLYTECHNIC

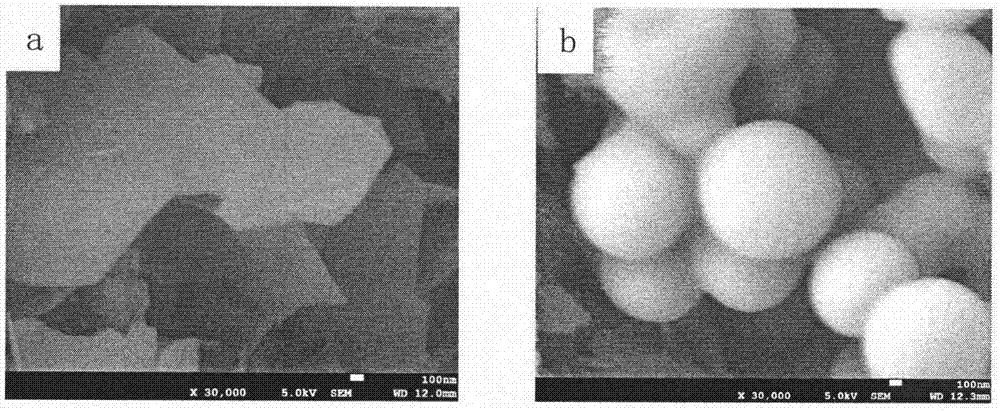

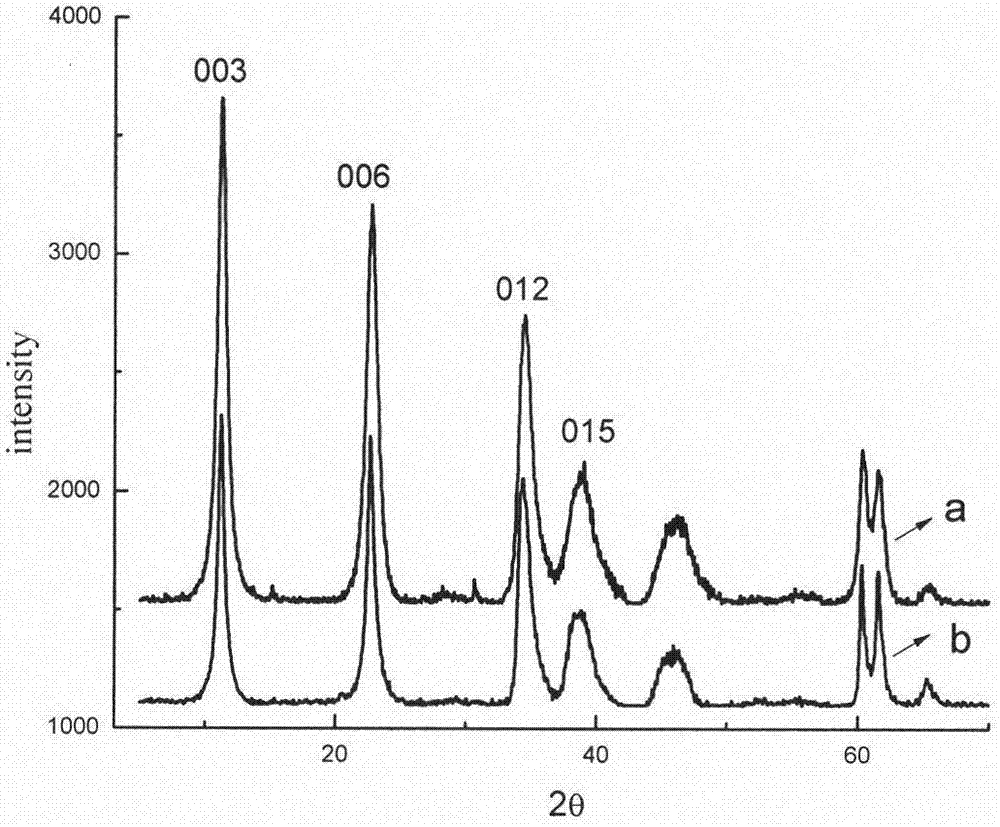

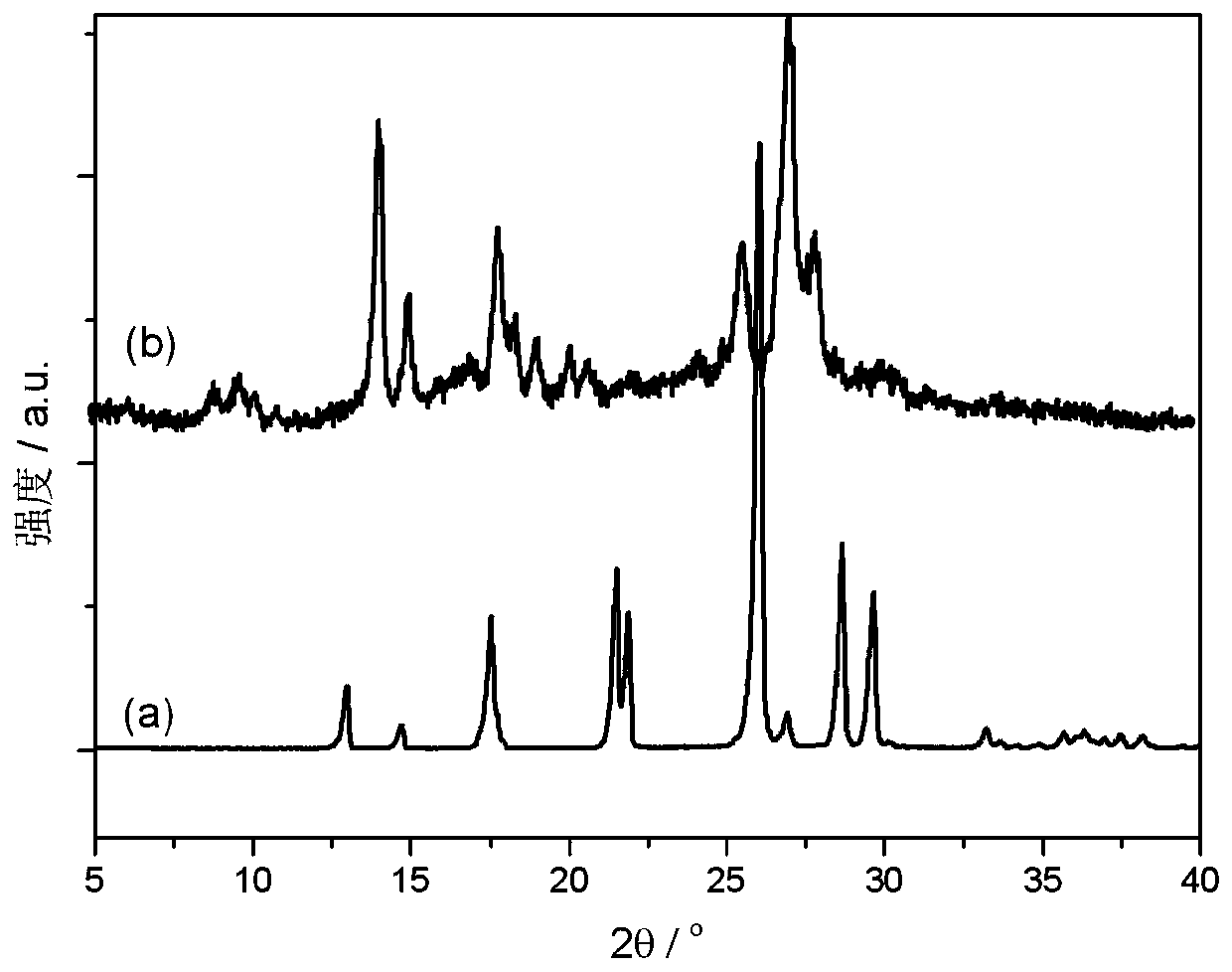

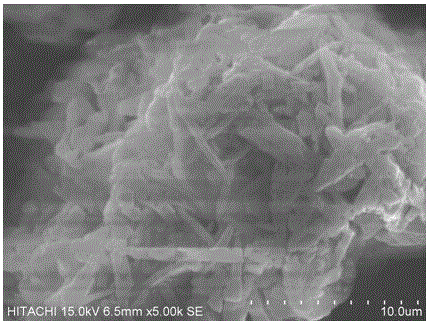

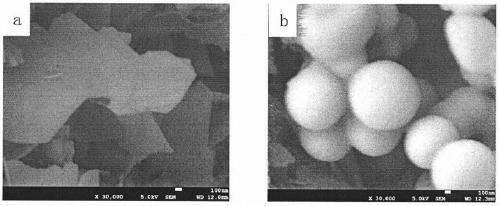

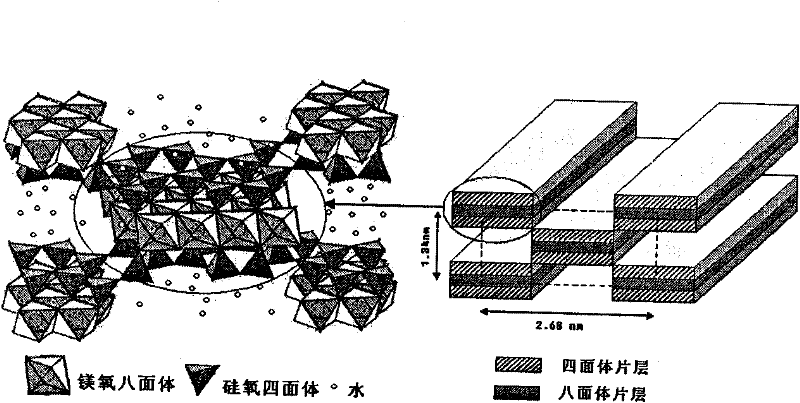

Preparation method of MF (melamine-formaldehyde) resin-coated Mg/Al-LDHs (magnesium/aluminum-layered double hydroxide) microcapsule

ActiveCN106861571AImprove heat resistanceImprove water resistanceMicroballoon preparationMicrocapsule preparationIn situ polymerizationFire retardant

The invention relates to a preparation method of an MF (melamine-formaldehyde) resin-coated Mg / Al-LDHs (magnesium / aluminum-layered double hydroxide) microcapsule. The preparation method comprises the following steps of firstly mixing melamine and formaldehyde according to a molar ratio of 1 to (2 to 4), so as to prepare a clear and transparent MF prepolymer; then, using deionized water as a dispersing medium, and preparing a flame retardant agent Mg / Al-LDHs into a core emulsion under the action of an emulsifying agent; using an in-situ polymerizing method to coat the MF prepolymer around capsule core emulsion droplets, adjusting the pH (potential of hydrogen) value of a solution to weak acid, and enabling the MF prepolymer to further complete condensation reaction at the surface of the Mg / Al-LDHs, so as to generate an insoluble latticed crosslinking structure, and form a capsule wall with certain thickness and strength; finally, using absolute ethyl alcohol to wash for multiple times, drying at the temperature of 60 DEG C, and grinding, so as to obtain the MF-coated Mg / Al-LDHs microcapsule. The preparation method has the advantages that the synergistic flame-retardant function of the nitrogen flame-retardant agent and the Mg / Al-LDHs is fully realized, and the problem of poor dispersivity and compatibility of the flame-retardant agent in a substrate is solved; meanwhile, the preparation technology is simple, and the cost is low.

Owner:NANJING FORESTRY UNIV

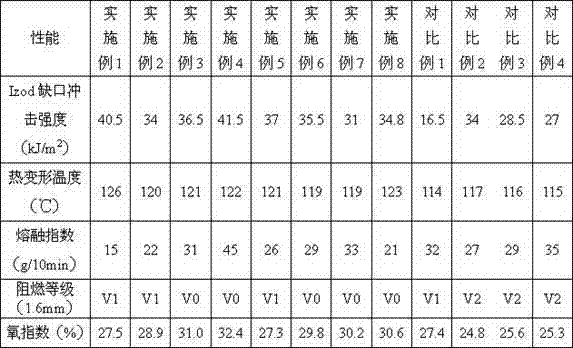

Halogen-free flame retardation polycarbonate material and preparation method thereof

A halogen-free flame retardation polycarbonate material comprises, by weight, 70-90% of polycarbonate, 5-10% of other resins, 6-15% of a halogen-free flame retardant, 5-15% of a surface modifier, 3-10% of a flexibilizer, 0.6-2.5% of an antioxidant,0.4-2.5% of a lubricant and 0.3-1.2% of a weather resisting agent. The halogen-free flame retardation polycarbonate material fully performs a synergistic flame retardation effect, substantially improves the flame retardation performance of a PC material, has the advantages of high efficiency, no toxicity, low smoke and dropping resistance, excellent flame retardation performance, excellent mechanical performances, good processing fluidity, high thermal deformation temperature, good impact resistance, moderate cost, and suitableness for industrial application.

Owner:CIXI FALAIXIN PLASTIC FACTORY

Intumescent flame retardant used for outer cover of ABS (acrylonitrile-butadiene-styrene) appliance switch as well as preparation and application of intumescent flame retardant

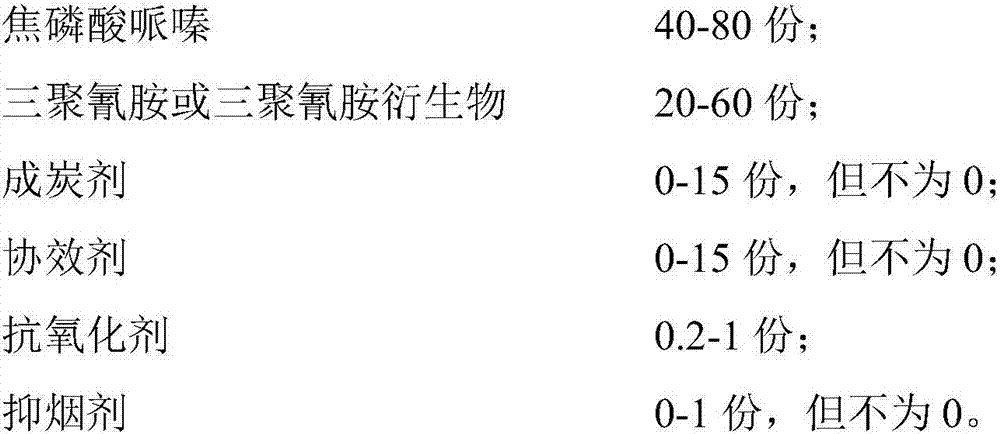

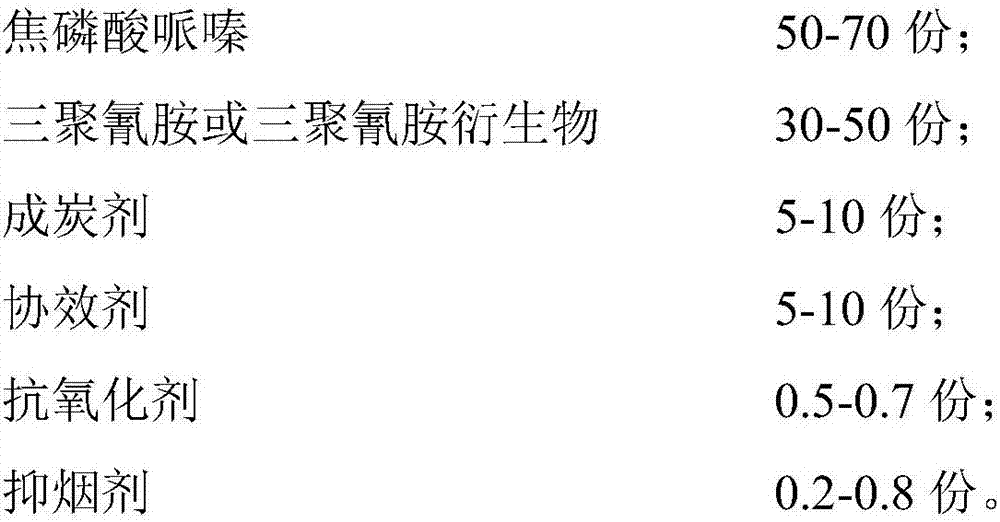

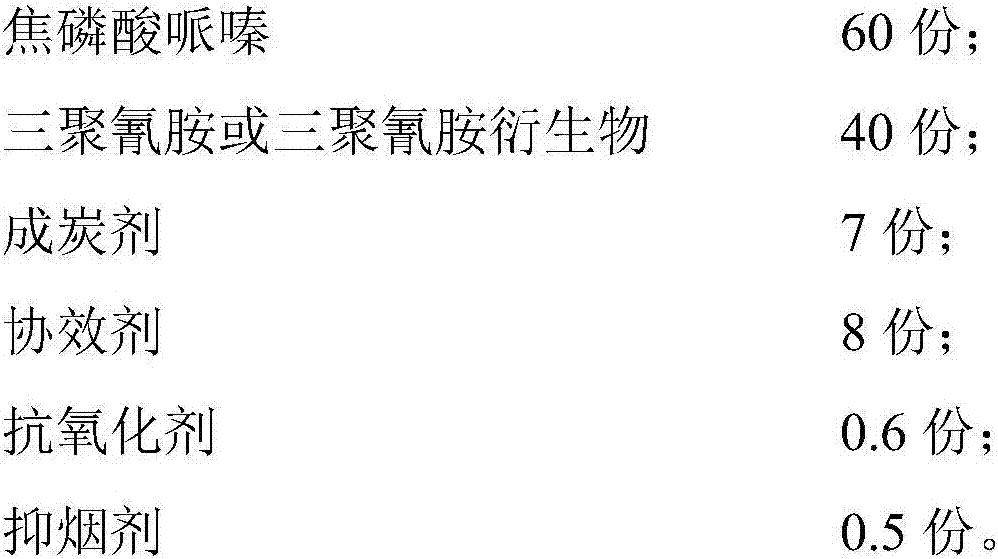

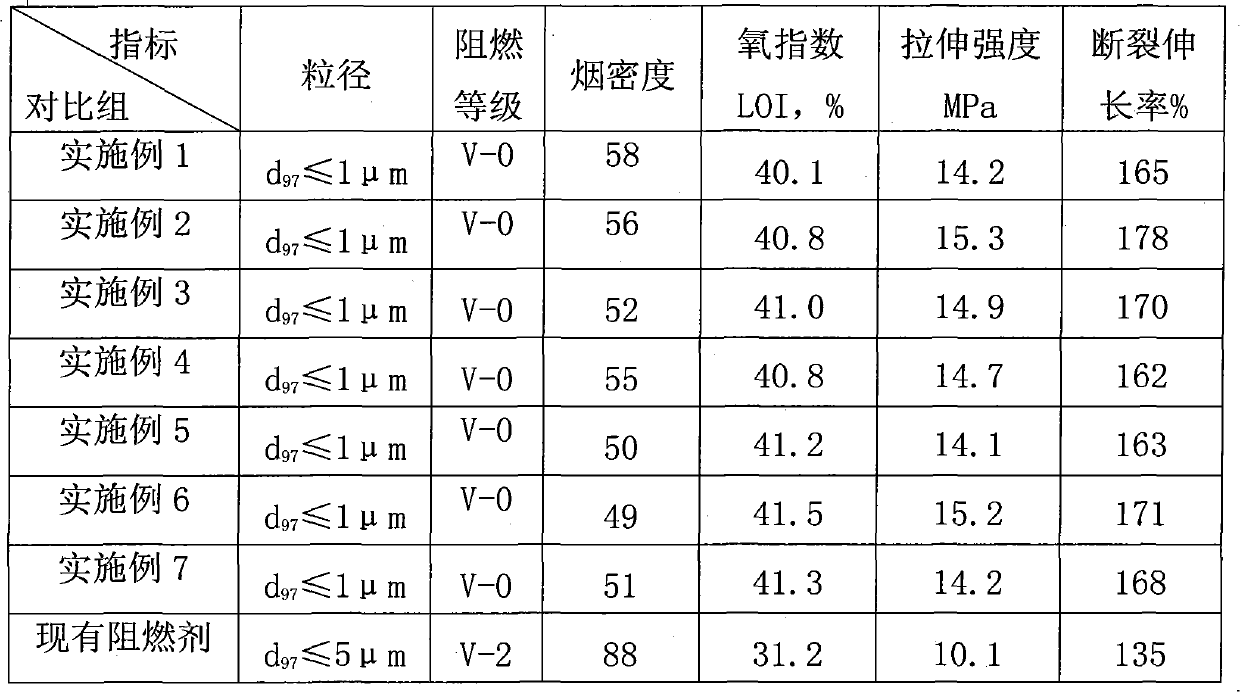

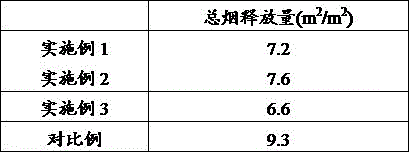

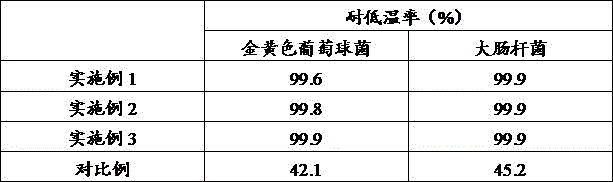

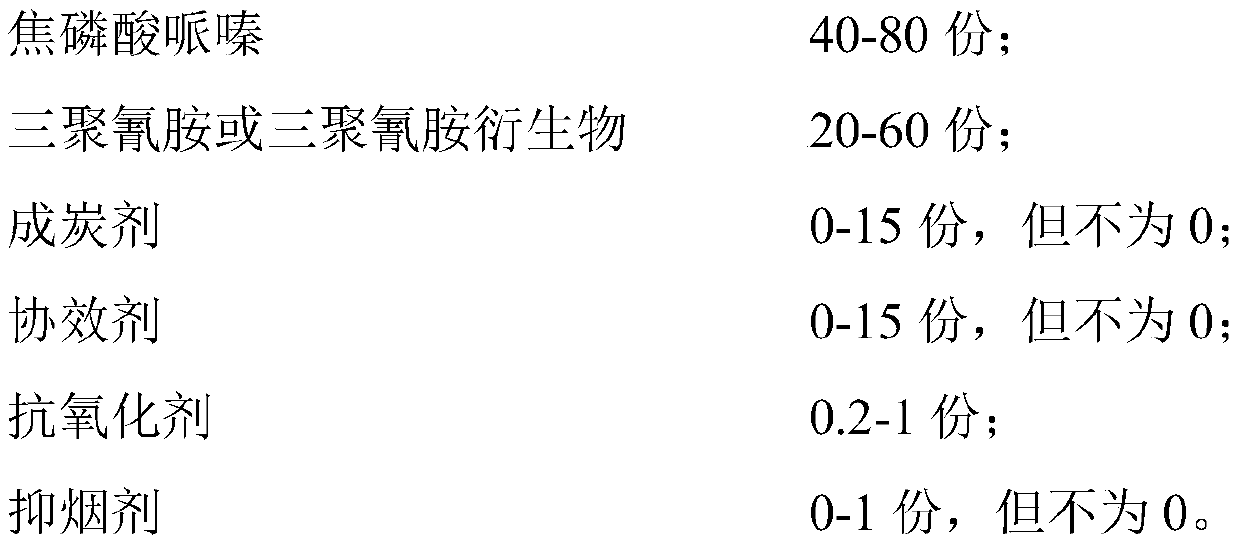

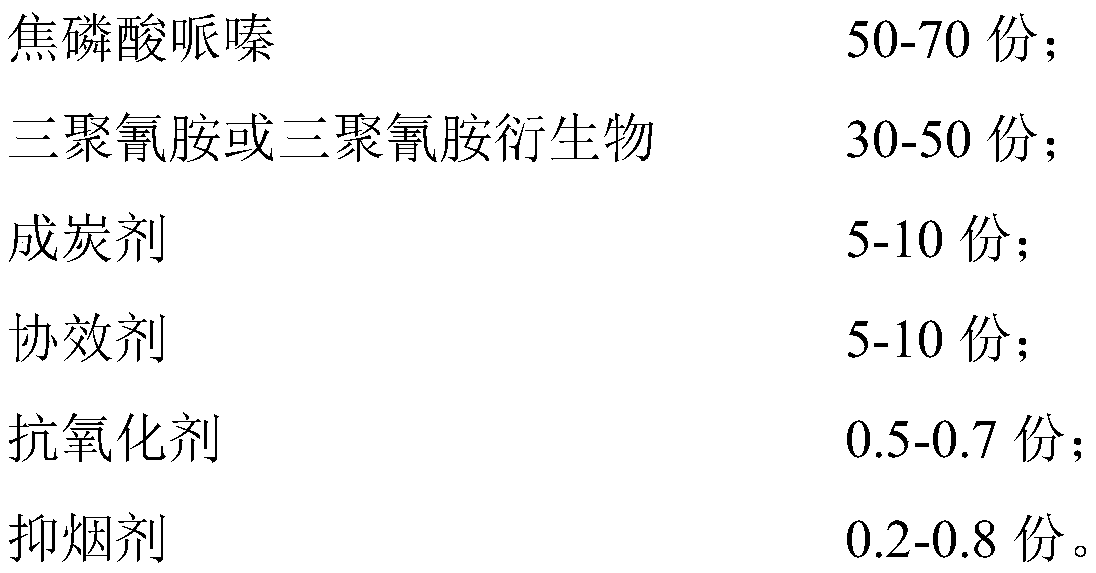

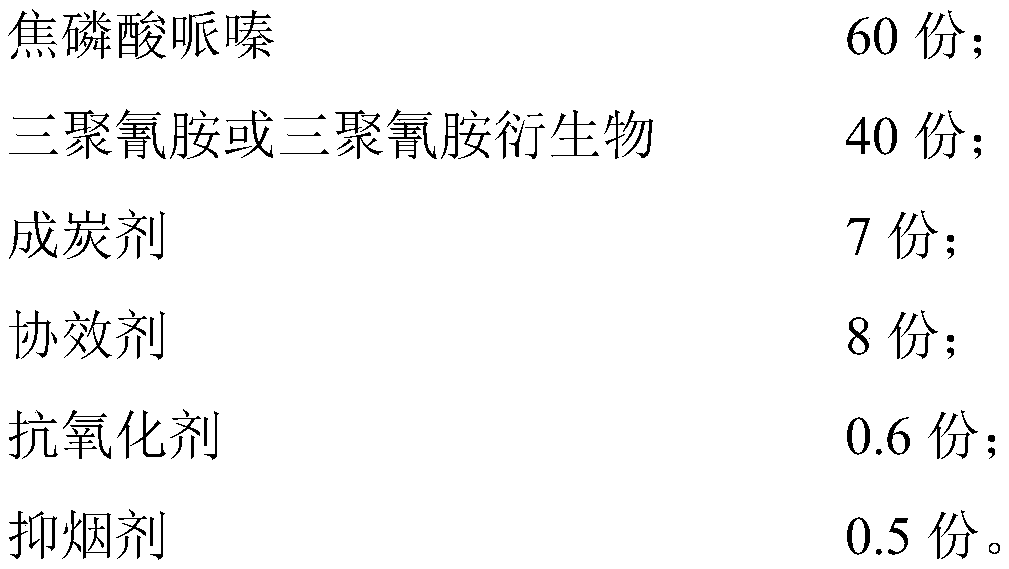

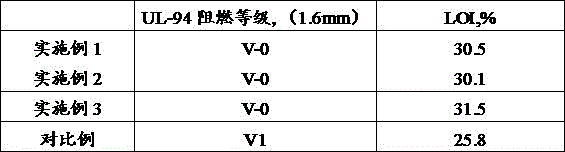

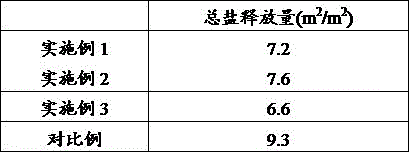

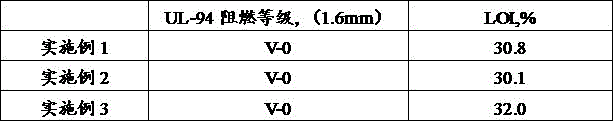

The invention relates to an intumescent flame retardant used for an outer cover of an ABS (acrylonitrile-butadiene-styrene) appliance switch as well as a preparation and an application of the intumescent flame retardant. The flame retardant is prepared from components in parts by weight as follows: 40-80 parts of piperazine pyrophosphate, 20-60 parts of melamine or a melamine derivative, 0-15 (except 0) parts of a charring agent, 0-15 (except 0) parts of a synergist, 0.2-1 part of an antioxidant and 0-1 (except 0) part of a smoke inhibitor. During preparation, substances are mixed and stirred uniformly, and the product is obtained; during application, 0.4-0.5 g of the flame retardant is added to every 1 g of ABS resin. Compared with the prior art, the flame retardant is easy to prepare and has good compatibility with an ABS matrix, the surface of a flame-retardant ABS material prepared from the flame retardant does not absorb moisture and does not migrate, and the flame-retardant ABS material can reach the UL94V-0 level, has remarkably reduced specific optical density Ds10 of smoke and can be used for processing and preparation of the outer cover of the ABS appliance switch with an injection molding process and can pass tests of 750 DEG C glowing filaments.

Owner:SHANGHAI RES INST OF CHEM IND +1

Preparation method of capsule-coated magnesium hydroxide fire retardant

ActiveCN101948637AImprove bindingGood compatibilityPigment treatment with macromolecular organic compoundsCross-linkRoom temperature

The invention relates to a preparation method of capsule-coated magnesium hydroxide fire retardant, comprising the following steps: adding magnesium hydroxide micropowder into water to prepare aqueous phase component suspension; mixing a free radical polymerization monomer, a cross-linking agent and an initiator, and evenly stirring to prepare into an oil phase component; adding the prepared oil phase component into the aqueous phase component suspension, and evenly stirring to obtain mixed liquor; heating the mixed liquor, stirring, and lowering the temperature to room temperature; filteringand separating the mixed liquor; separating out the magnesium hydroxide capsule; washing the magnesium hydroxide capsule to obtain a magnesium hydroxide capsule wet cake; and drying to obtain the capsule-coated magnesium hydroxide fire retardant, wherein the binding force of a coating layer and the magnesium hydroxide formed by the free radical polymerization monomer, the cross-linking agent and the initiator is strong. The capsule-coated magnesium hydroxide fire retardant has the advantages of good compatibility of the coating layer and a high polymer matrix material, large interface bindingforce, evenly dispersed magnesium hydroxide micropowder, cooperated inflaming retarding of the magnesium hydroxide and the capsule, and high inflaming retarding efficiency.

Owner:潍坊欣龙生物材料有限公司

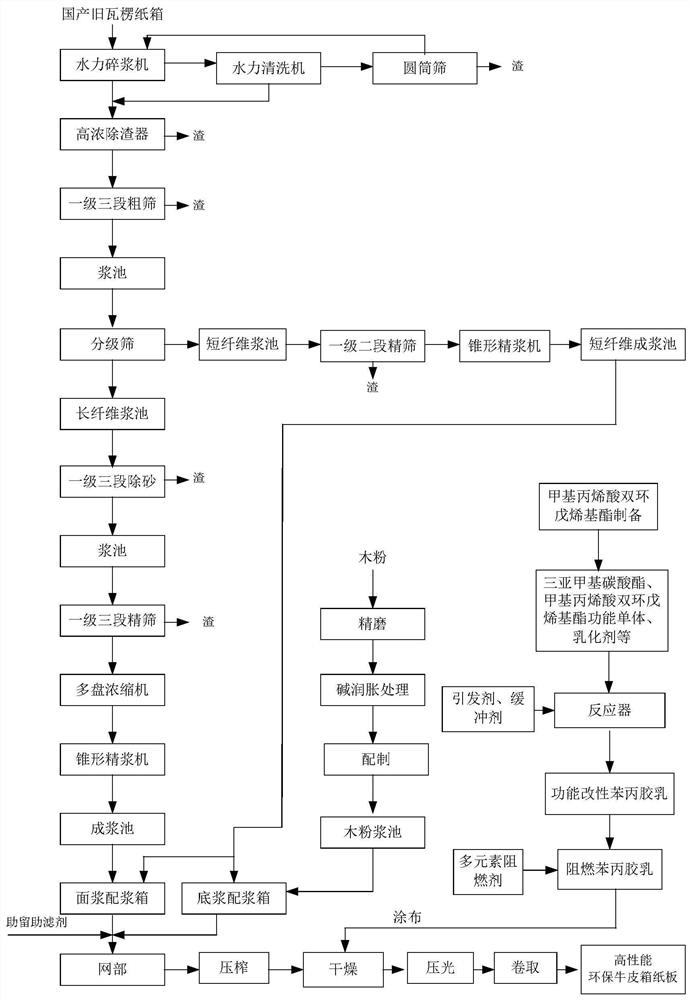

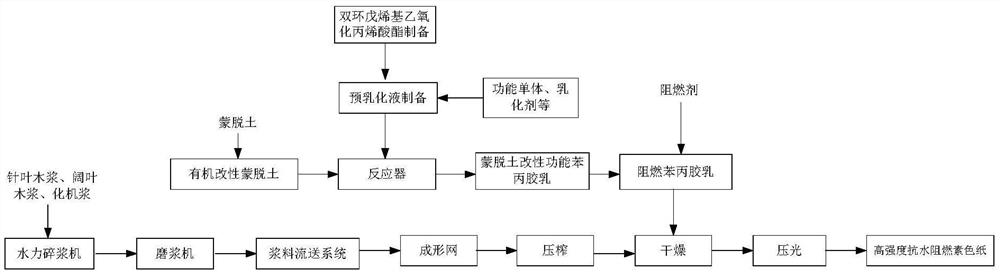

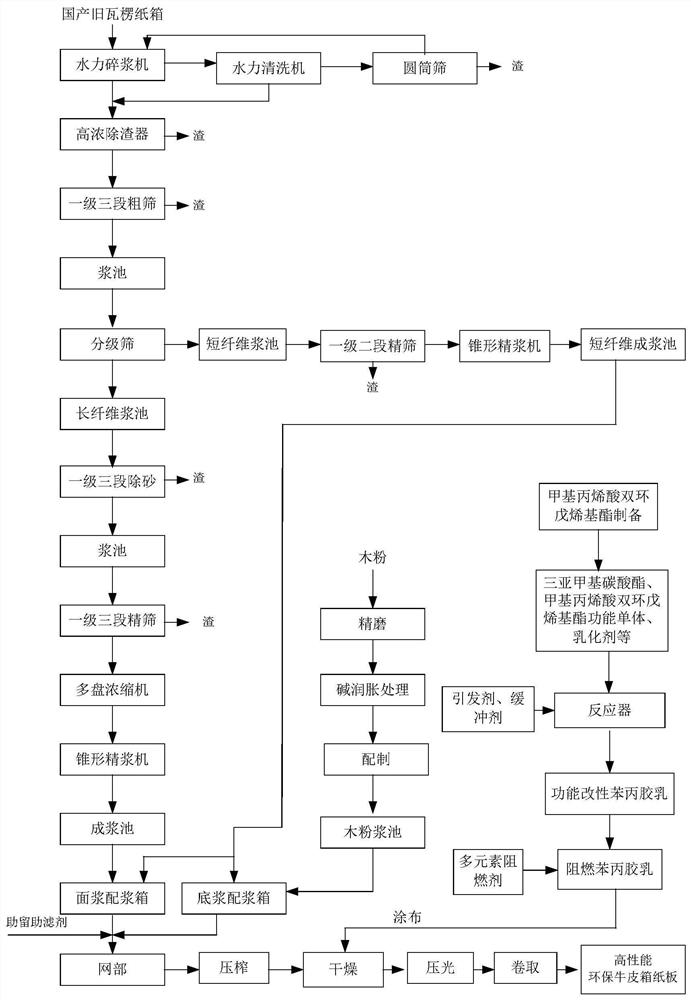

High-performance environment-friendly kraft liner paperboard and preparation method thereof

The invention discloses a high-performance environment-friendly kraft liner paperboard which comprises a bottom layer, a surface layer and a coating layer which are sequentially arranged from bottom to top. Wherein the bottom layer is prepared from a bottom layer pulp consisting of modified wood powder pulp and short fiber pulp; the surface layer is prepared from a surface layer pulp consisting oflong fiber pulp and short fiber pulp; the coating layer is formed by coating flame-retardant styrene-acrylic latex on the surface layer; the long fiber pulp and the short fiber pulp are formed by pulping domestic old corrugated cartons; a flame-retardant styrene-acrylic latex is composed of a modified composite flame retardant, functionalized modified styrene-acrylic latex and water. The flame retardant is added in a composite flame-retardant latex metering roller type coating mode, loss is avoided, the cost is low, and the addition of the flame retardant has no adverse effect on the strengthof paper. Besides, the prepared kraft liner paperboard is good in flame retardance, the kraft liner preparation product is produced from full waste paper, the process is environmentally friendly, thefunctionalized modified styrene-acrylic latex is water-soluble latex, no organic solvent exists, and the environmental protection property is improved.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

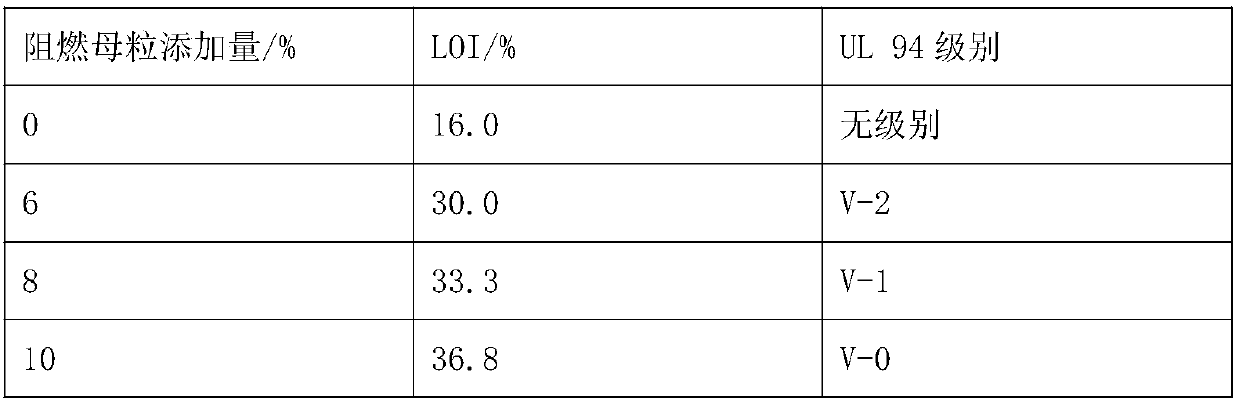

EPS flame-retardant masterbatch and preparation method thereof

The invention discloses EPS flame-retardant masterbatch and a preparation method thereof and belongs to the technical field of flame-retardant masterbatch production. The EPS flame-retardant masterbatch is prepared from the following raw materials in parts by weight: 60-80 parts of polystyrene, 30-40 parts of brominated SBS, 20-30 parts of methyl octabromo ether, 5-10 parts of graphite masterbatch, 3-5 parts of barium stearate, 3-8 parts of aluminium dioxide, 2-6 parts of polyethylene wax, 3-8 parts of talc powder and 4-9 parts of an antioxidant 1010. The flame retardance of the EPS flame-retardant is improved greatly as a result of synergistic effects of raw material components, and the EPS flame-retardant masterbatch is good in temperature resistance and small in adding amount. High performance flame retardance is achieved with a relatively low adding amount, and the production process is simplified and the cost is lowered.

Owner:山东东信新材料科技股份有限公司

Preparation method and application of a kind of phosphorus-nitrogen-carbon polymerized intumescent flame retardant

ActiveCN106519239BImprove thermal stabilityGive full play to the synergistic flame retardant effectFiltrationPhytic acid

Owner:SOUTHWEAT UNIV OF SCI & TECH

Anti-static and high-flame-retardant ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

InactiveCN107033527ALarge specific surface areaRich three-dimensional pore structureIn situ polymerizationPhosphoric acid

The invention relates to an anti-static and high-flame-retardant ABS (acrylonitrile butadiene styrene) composite material and a preparation method thereof. The anti-static and high-flame-retardant ABS composite material is prepared from following raw materials in parts by weight by processing: 60-80 parts of ABS resin, 40-60 parts of PC resin, 5-10 parts of EPDM resin, 6-10 parts of an antioxidant, 5-8 parts of nano-silver, 8-12 parts of a compound flame retardant and 5-8 parts of a low-temperature-resistant plasticizer. The compound flame retardant and an anti-static agent are used in the composite material, the ammonium polyphosphate-diatomite / magnetic ordered mesoporous nickel ferrite compound flame retardant is prepared from phosphoric acid and urea as main raw materials as well as diatomite and magnetic ordered mesoporous nickel ferrite as carriers through in-situ polymerization, and a synergistic flame retardant effect of ammonium polyphosphate with silicon, iron and nickel can be exerted sufficiently, so that the ABS composite material has good flame retardant performance and anti-static performance.

Owner:叶政朴

Flame-retarding type PVC (Polyvinyl Chloride) foaming board and preparation method thereof

The invention discloses a flame-retarding type PVC (Polyvinyl Chloride) foaming board and a preparation method thereof and belongs to the technical field of PVC foaming boards. The flame-retarding type PVC foaming board is prepared from the following raw materials in parts by weight: 100 parts of PVC with the average degree of polymerization, 2-7 parts of foaming regulator, 0.5-0.8 part of foamingagent, 3-8 parts of brominated polyphenyl ether, 2-5 parts of urea, 3-5 parts of calcium-zinc stabilizer, 2-5 parts of barium stearate, 5-12 parts of nanometer light calcium carbonate, 25-35 parts ofwood meal, 0.4-0.6 part of aluminium stearate, 0.6-0.8 part of oxidized polyethlene wax and 40-50 parts of dioctyl phthalate. The flame-retarding type PVC foaming board and the preparation method disclosed by the invention has the beneficial effects that by addition of the flame-retarding agent brominated polyphenyl ether and urea into a production formula of the PVC foaming board, the prepared PVC foaming board has good flame-retarding property, and the safety property of the PVC foaming board is improved; simultaneously, by combination with other additives, the toughness and the mechanicalstrength of the PVC foaming board are also improved.

Owner:山东源邦新材料股份有限公司

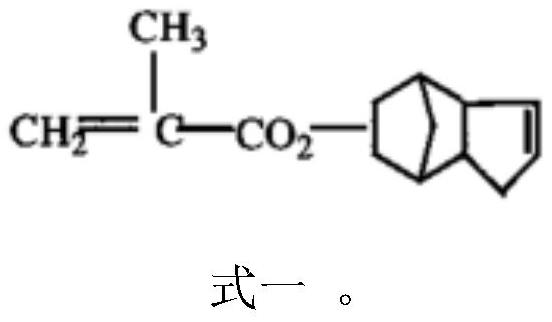

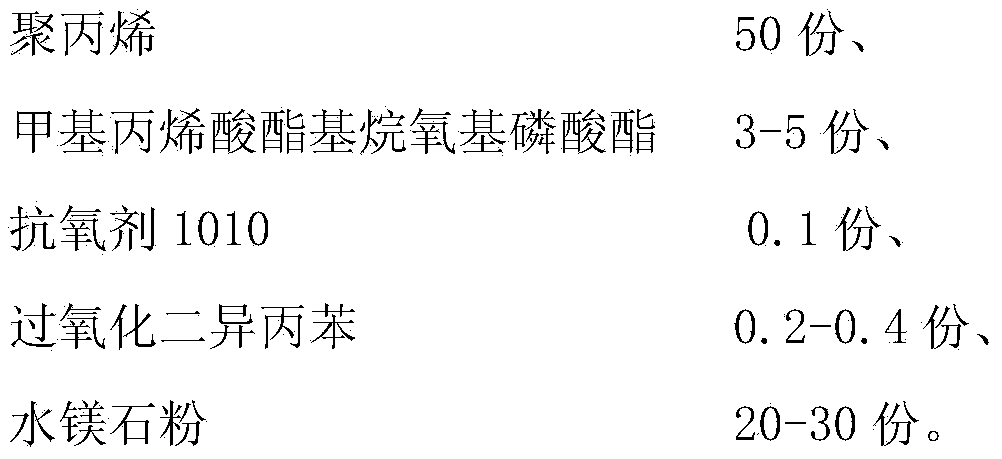

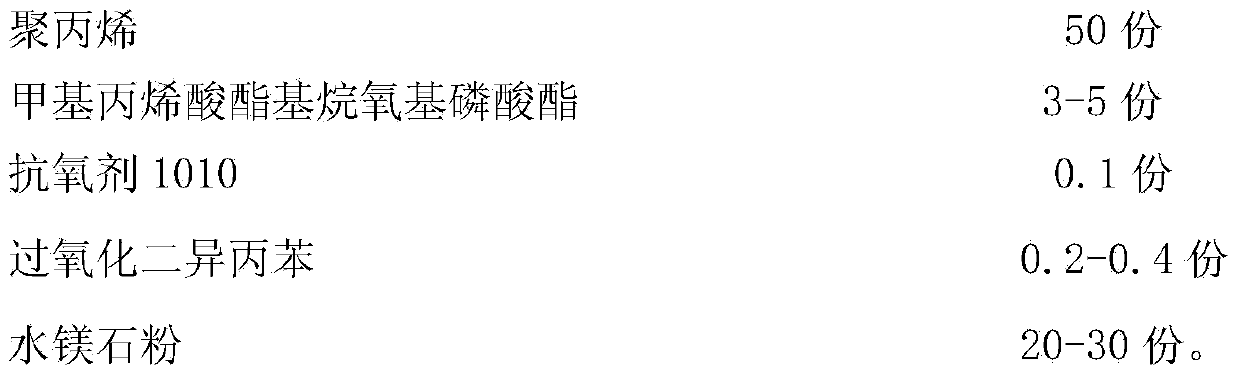

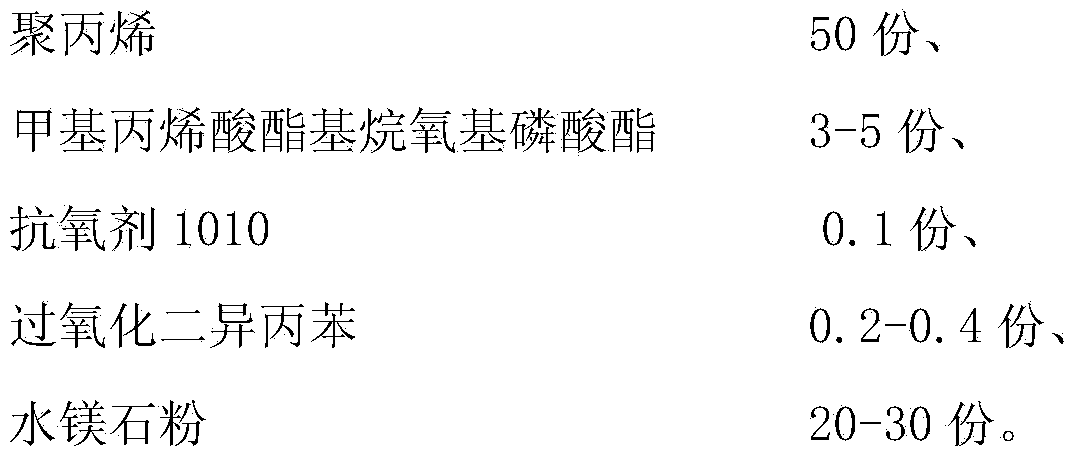

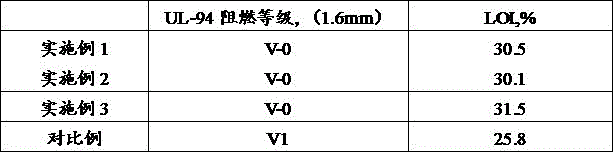

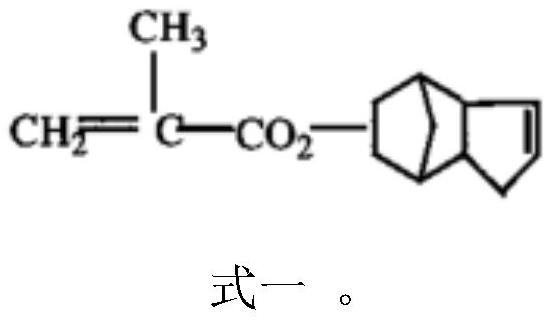

Halogen-free flame-retardant polypropylene composite material and preparation method thereof

ActiveCN104194152AEvenly dispersed and does not migrateGive full play to the synergistic flame retardant effectPolypropylene compositesMethacrylate

The invention relates to a halogen-free flame-retardant polypropylene composite material and a preparation method thereof. The method comprises the following steps: premixing polypropylene, methacrylate alkoxy phosphate, antioxidant 1010 and dicumyl peroxide, and carrying out reactive grafting and granulation with an extruder; and drying the granules, mixing with brucite powder, and carrying out mixing, plastification and granulation with the extruder, thereby obtaining the halogen-free flame-retardant polypropylene composite material.

Owner:广东道生科技股份有限公司

Low-temperature-resistant and high-flame-retardant ABS composite material and preparation method thereof

InactiveCN106589769ALarge specific surface areaRich three-dimensional pore structurePlasticizerIn situ polymerization

The invention relates to a low-temperature-resistant and high-flame-retardant ABS composite material and a preparation method thereof. The low-temperature-resistant and high-flame-retardant ABS composite material is prepared from the following raw materials in parts by weight: 60 to 80 parts of ABS resin, 40 to 60 parts of PC resin, 5 to 10 parts of EPDM resin, 6 to 10 parts of an anti-oxidant, 5 to 8 parts of nanometer silver, 8 to 12 parts of a composite flame retardant and 5 to 8 parts of a low-temperature-resistant plasticizer. According to the invention, the composite flame retardant is used in the composite material; with phosphoric acid and urea as main raw materials, and diatomite and magnetic ordered mesoporous nickel ferrite as carriers, an ammonium polyphosphate-diatomite / magnetic ordered mesoporous nickel ferrite composite flame retardant is prepared through in-situ polymerization, so synergistic and flame-retardant effects among ammonium polyphosphate, silicon element, iron element and nickel element can be fully exerted; thus, good flame retardance of the ABS composite material is obtained.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

A kind of intumescent flame retardant for ABS electrical switch cover and its preparation and application

The invention relates to an intumescent flame retardant used for an outer cover of an ABS (acrylonitrile-butadiene-styrene) appliance switch as well as a preparation and an application of the intumescent flame retardant. The flame retardant is prepared from components in parts by weight as follows: 40-80 parts of piperazine pyrophosphate, 20-60 parts of melamine or a melamine derivative, 0-15 (except 0) parts of a charring agent, 0-15 (except 0) parts of a synergist, 0.2-1 part of an antioxidant and 0-1 (except 0) part of a smoke inhibitor. During preparation, substances are mixed and stirred uniformly, and the product is obtained; during application, 0.4-0.5 g of the flame retardant is added to every 1 g of ABS resin. Compared with the prior art, the flame retardant is easy to prepare and has good compatibility with an ABS matrix, the surface of a flame-retardant ABS material prepared from the flame retardant does not absorb moisture and does not migrate, and the flame-retardant ABS material can reach the UL94V-0 level, has remarkably reduced specific optical density Ds10 of smoke and can be used for processing and preparation of the outer cover of the ABS appliance switch with an injection molding process and can pass tests of 750 DEG C glowing filaments.

Owner:SHANGHAI RES INST OF CHEM IND +1

Anti-aging and high flame retardant ABS composite material and preparation method thereof

InactiveCN106609022AAbundant specific surface areaHigh specific surface areaAmmonium polyphosphateChemistry

The invention relates to an anti-aging and high flame retardant ABS composite material and a preparation method thereof. The anti-aging and high flame retardant ABS composite material is prepared from 80 to 100 parts by weight of ABS resin, 40 to 60 parts by weight of PC resin, 5 to 15 parts by weight of EPDM resin, 6 to 10 parts by weight of an antioxidant and 8 to 12 parts by weight of a compound flame retardant. The preparation method comprises pouring concentrated phosphoric acid having a concentration of 85% into a reactor, carrying out heating stirring, adding an appropriate amount of urea into the mixture when the temperature rises to 60 to 80 DEG C, adding an appropriate amount of diatomite and magnetic ordered mesoporous nickel ferrite powder when the temperature rises to 120 to 125 DEG C, carrying out a stirring reaction process for 10 to 20min, curing the product at a temperature of 280 to 320 DEG C for 1 to 2h, and crushing the product through a nano-crusher to obtain the anti-aging and high flame retardant ABS composite material. The preparation method utilizes phosphoric acid and urea as main raw materials, diatomite and magnetic ordered mesoporous nickel ferrite as carriers and an in-situ polymerization method to prepare the ammonium polyphosphate-diatomite / magnetic ordered mesoporous nickel ferrite composite flame retardant and can give full play to synergistic flame retardant effects of ammonium polyphosphate and silicon, iron and nickel so that the ABS composite material has good flame retardant properties.

Owner:WENZHOU CHUYING TECH CO LTD

Preparation method of anti-aging high-flame-resistant ABS automotive interior trim

InactiveCN106751393ALarge specific surface areaRich three-dimensional pore structureDomestic articlesRoom temperatureAnti ageing

The invention relates to a preparation method of an anti-aging high-flame-resistant ABS automotive interior trim. The preparation method comprises the following steps: S1, putting high-flame-resistant ABS material particles in a stirring machine, carrying out stirring fusion at the temperature of 110 to 120 DEG C, and cooling a fused material to 60 to 80 DEG C for later use; S2, rolling the fused material in the step S1 to form a sheet material, using rolling equipment to roll the fused material at the temperature of 60 to 80 DEG C, then cooling the sheet material formed by rolling to room temperature, and forming the sheet material with the thickness of 5 to 10 mm; S3, cutting the sheet material to form a blank, performing hot-pressing on the blank to form the automotive interior trim, using hot-pressing equipment to perform hot-press on the blank under the hot-press pressure of 1000 to 1200 kN at the hot-press temperature of 65 to 75 DEG C, and thus forming the high-flame-resistant ABS automotive interior trim. The anti-aging high-flame-resistant ABS automotive interior trim is formed by processing the following raw material in parts by weight: 80 to 100 parts of ABS resin, 40 to 60 parts of PC resin, 5 to 15 parts of EPDM resin, 6 to 10 parts of an antioxidant and 8 to 12 parts of a composite flame retardant. The flame-resistant ABS plastic disclosed by the invention has relatively high flame resistance, is used for manufacturing the automotive interior trim, and is reliable in quality and high in safety.

Owner:WENZHOU RENHE CULTURAL ORIGINALITY CO LTD

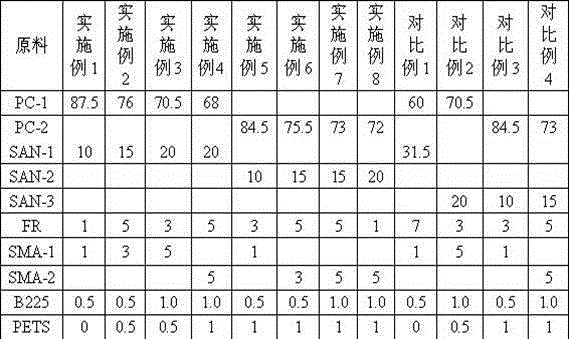

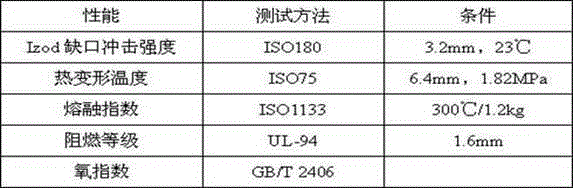

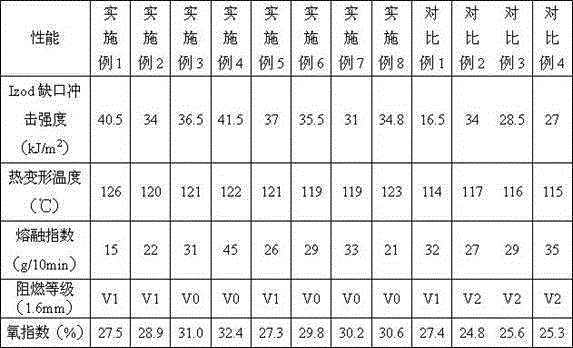

A halogen-free flame retardant PC composition and its preparation method

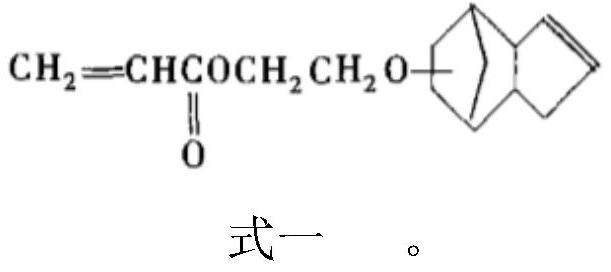

ActiveCN104119658BSolve the disadvantages of poor heat resistanceGive full play to the synergistic flame retardant effectCyclopentenePhosphate

The invention relates to a halogen-free flame retardant PC (poly carbonate) composition. The halogen-free flame retardant PC composition comprises the following components in percentage by weight: 68-87.5% of PC resin, 10-20% of styrene-acrylonitrile-N-phenyl maleic imide-cyclopentene copolymer, 1-5% of phosphorus based flame retardant, 1-5% of SMA (styrene maleic anhydride) random copolymer, 0.5-1.0% of antioxidant and 0-1.0% of lubricating agent. The halogen-free flame retardant PC composition provided by the invention fully achieves phosphorus-nitrogen synergistic flame retardant effect, flame retardant performance of a PC material is improved, addition amount of phosphate ester flame retardant is greatly reduced, the defect that heat resistance of the traditional phosphorus flame retardant PC resin is poor is overcome, and the obtained halogen-free flame retardant PC composition has excellent flame retardant property, high thermal deformation temperature, good comprehensive mechanical property and moderate cost.

Owner:NINGBO ZHETIE DAPHOON CHEM

Preparation method and application of bio-based flame-retardant compatilizer for PBAT (poly (butylene adipate-co-terephthalate))

ActiveCN114605468AImprove flame retardant performanceGood compatibilityBio-packagingGroup 5/15 element organic compoundsPolymer scienceGraft reaction

The invention discloses a preparation method and application of a bio-based flame-retardant compatilizer for PBAT (poly (butylene adipate-co-terephthalate)). The bio-based flame-retardant compatilizer is prepared by the following process: carrying out grafting reaction on Fischer-Tropsch wax and maleic anhydride to obtain Fischer-Tropsch wax acid, dispersing the prepared Fischer-Tropsch wax acid and soybean protein isolate, and reacting with phytic acid in a solution to obtain the bio-based flame-retardant compatilizer. According to the bio-based flame-retardant compatilizer prepared by the invention, a novel flame retardant chemical structure with synergistic flame-retardant and compatible effects is obtained by using raw materials from bio-based sources, and the flame retardant does not influence the biodegradability of PBAT, can also play a lubricating role in the processing process, inhibits hydrolysis in the processing process, and has the advantages of favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy and favorable flame retardancy. And the method has very important practical significance for broadening the actual application scene of the PBAT.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

A kind of coated flame retardant, its preparation method and application, and molding composition composed of it

The invention discloses a coated fire retardant. The coated fire retardant comprises a core material containing a phosphorus-nitrogen fire retardant of which the particle size is 0.5-70[mu] m, and the outer surface of the core material is covered with a coating layer coated with a dialkyl phosphinate fire retardant, the particle size of the core material of the phosphorus-nitrogen fire retardant is preferably 5-35 [mu]m. The phosphorus-nitrogen fire retardant in the coated fire retardant is a synergist of the dialkyl phosphinate fire retardant, the efficient recombination of the dialkyl phosphinate fire retardant and the phosphorus-nitrogen fire retardant can be realized by the coated fire retardant, the problem that a complex fire retardant mixture is not dispersed uniformly in a resin can be solved, the synergistic flame-retardant effect of the two components can be given into play maximally, and the coated fire restardant has a better synergism in comparison with the complex fire retardant mixture; meanwhile, dialkyl phosphinate which is uneasily separated out of a molding composition can be served as a shell which covers the surface of the phosphorus-nitrogen fire retardant, so as to solve the problem that the phosphorus-nitrogen fire retardant is easy to migrate and separate out of the molding composition in a hot and humid environment can be solved to a great extent, and the surface performance of the molding composition can be greatly optimized.

Owner:ZHUHAI WANTONG CHEM

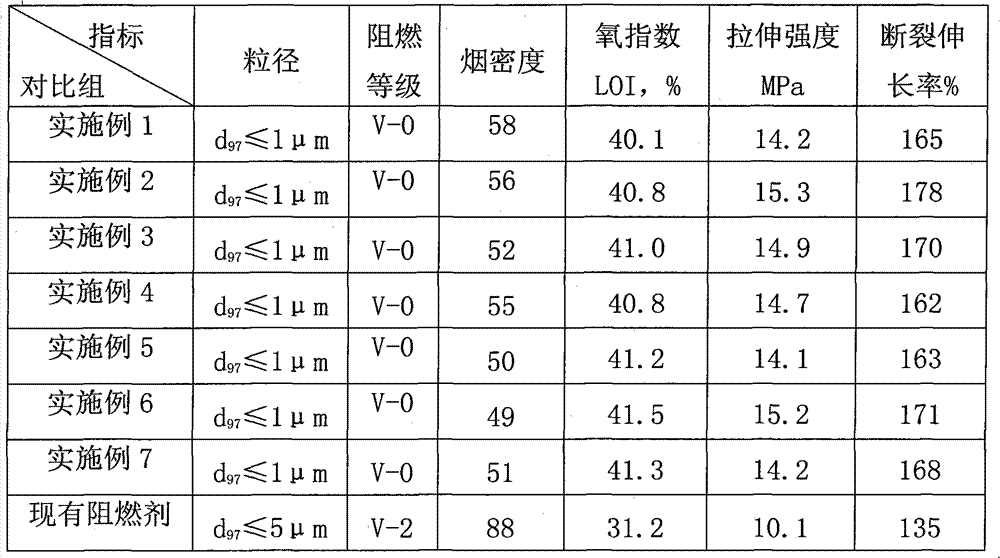

A kind of high-strength water-resistant flame-retardant plain paper and its preparation method

ActiveCN111794012BIntensity has no effectNo churnNatural cellulose pulp/paperPaper coatingSodium bicarbonatePolymer science

The invention discloses a high-strength water-resistant and flame-retardant plain paper and a preparation method thereof, and relates to the technical field of flame-retardant paper. The high-strength water-resistant and flame-retardant plain colored paper of the present invention uses styrene, butyl acrylate, etc. Sodium alkyl sulfate and nonylphenol polyoxyethylene ether were used as emulsifiers, persulfate was used as initiator, sodium bicarbonate was used as buffer, organically modified montmorillonite was used as modifier, and montmorillonite was synthesized by pre-emulsified seed emulsion polymerization Desoil modified functionalized styrene-acrylic latex; then compound it with flame retardants containing various flame-retardant elements to obtain flame-retardant styrene-acrylic latex, and then use the surface coating method to coat the flame-retardant styrene-acrylic latex on the The surface of plain paper base paper, just dry. The plain colored paper prepared by the invention has excellent dry and wet tensile strength, excellent water resistance and good flame retardancy, and the invention has advanced preparation technology, no pollution and low production cost, and has broad market application prospects.

Owner:杭州华旺新材料科技股份有限公司

Fireproof and high-temperature-resistant polyvinyl chloride (PVC) foam board and preparation method thereof

The invention discloses a fireproof and high-temperature-resistant polyvinyl chloride (PVC) foam board and a preparation method thereof, belonging to the technical field of production of PVC foam boards. The fireproof and high-temperature-resistant PVC foam board is prepared from the following raw materials in parts by weight: 100 parts of PVC with an average polymerization degree of 800-1000, 2-7parts of a foaming regulator, 0.5-0.9 part of a foaming agent, 2-7 parts of methyl octabromo ether, 1-5 parts of aluminum dioxide, 5-10 parts of polyiso-melamine ester, 2-5 parts of dibutyltin maleate, 3-5 parts of a calcium-zinc composite stabilizer, 5-8 parts of wood chips, 35-40 parts of calcium carbonate, 10-15 parts of talcum powder, 0.6-0.8 part of an internal lubricant 60, 0.6-0.8 part ofan external lubricant liquid paraffin and 40-50 parts of dioctyl phthalate. By adding a fire retardant and a thermal insulation material into a production formula of the PVC foam board, the prepared PVC foam board has good high temperature resistance and fire resistance.

Owner:山东源邦新材料股份有限公司

Halogen-free flame retardant PC (poly carbonate) composition and preparation method thereof

ActiveCN104119658ASolve the disadvantages of poor heat resistanceGive full play to the synergistic flame retardant effectCyclopenteneAntioxidant

The invention relates to a halogen-free flame retardant PC (poly carbonate) composition. The halogen-free flame retardant PC composition comprises the following components in percentage by weight: 68-87.5% of PC resin, 10-20% of styrene-acrylonitrile-N-phenyl maleic imide-cyclopentene copolymer, 1-5% of phosphorus based flame retardant, 1-5% of SMA (styrene maleic anhydride) random copolymer, 0.5-1.0% of antioxidant and 0-1.0% of lubricating agent. The halogen-free flame retardant PC composition provided by the invention fully achieves phosphorus-nitrogen synergistic flame retardant effect, flame retardant performance of a PC material is improved, addition amount of phosphate ester flame retardant is greatly reduced, the defect that heat resistance of the traditional phosphorus flame retardant PC resin is poor is overcome, and the obtained halogen-free flame retardant PC composition has excellent flame retardant property, high thermal deformation temperature, good comprehensive mechanical property and moderate cost.

Owner:NINGBO ZHETIE DAPHOON CHEM

Preparation method of capsule-coated magnesium hydroxide fire retardant

ActiveCN101948637BImprove bindingGood compatibilityPigment treatment with macromolecular organic compoundsCross-linkRoom temperature

The invention relates to a preparation method of capsule-coated magnesium hydroxide fire retardant, comprising the following steps: adding magnesium hydroxide micropowder into water to prepare aqueous phase component suspension; mixing a free radical polymerization monomer, a cross-linking agent and an initiator, and evenly stirring to prepare into an oil phase component; adding the prepared oil phase component into the aqueous phase component suspension, and evenly stirring to obtain mixed liquor; heating the mixed liquor, stirring, and lowering the temperature to room temperature; filtering and separating the mixed liquor; separating out the magnesium hydroxide capsule; washing the magnesium hydroxide capsule to obtain a magnesium hydroxide capsule wet cake; and drying to obtain the capsule-coated magnesium hydroxide fire retardant, wherein the binding force of a coating layer and the magnesium hydroxide formed by the free radical polymerization monomer, the cross-linking agent and the initiator is strong. The capsule-coated magnesium hydroxide fire retardant has the advantages of good compatibility of the coating layer and a high polymer matrix material, large interface binding force, evenly dispersed magnesium hydroxide micropowder, cooperated inflaming retarding of the magnesium hydroxide and the capsule, and high inflaming retarding efficiency.

Owner:潍坊欣龙生物材料有限公司

Anti-bacterial and high-flame-retardant ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

PendingCN107033526AImprove flame retardant performanceExtended service lifeIn situ polymerizationAntioxidant

The invention relates to an anti-bacterial and high-flame-retardant ABS (acrylonitrile butadiene styrene) composite material and a preparation method thereof. The anti-bacterial and high-flame-retardant ABS composite material is prepared from following raw materials in parts by weight by processing: 60-80 parts of ABS resin, 40-60 parts of PC resin, 5-10 parts of EPDM resin, 6-10 parts of an antioxidant, 5-8 parts of nano-silver and 8-12 parts of a compound flame retardant, wherein a preparation method of the compound flame retardant comprises the following steps: strong phosphoric acid with the concentration of 85% is poured into a reactor, heated and stirred, a proper amount of urea is added when the temperature is increased to 60-80 DEG C, proper amounts of diatomite and magnetic ordered mesoporous nickel ferrite powder are added when the temperature is increased to 120-125 DEG C, the mixture is stirred for a reaction for 10-20 min, a product is cured at 280-320 DEG C for 1-2 h and ground by a nano-grinder, and the compound flame retardant is obtained. The ammonium polyphosphate-diatomite / magnetic ordered mesoporous nickel ferrite compound flame retardant is prepared from phosphoric acid and urea as main raw materials as well as diatomite and magnetic ordered mesoporous nickel ferrite as carriers through in-situ polymerization, and a synergistic flame retardant effect of ammonium polyphosphate with silicon, iron and nickel can be exerted sufficiently, so that the ABS composite material has good flame retardant performance.

Owner:瑞安市智造科技有限公司

A kind of phosphorus, silicon polymerized flame retardant and preparation method thereof

ActiveCN107266685BOvercome the disadvantage of easy precipitationHigh flame retardant efficiencyGroup 5/15 element organic compoundsEpoxyPolystyrene

Owner:宁波塑之华塑化有限公司

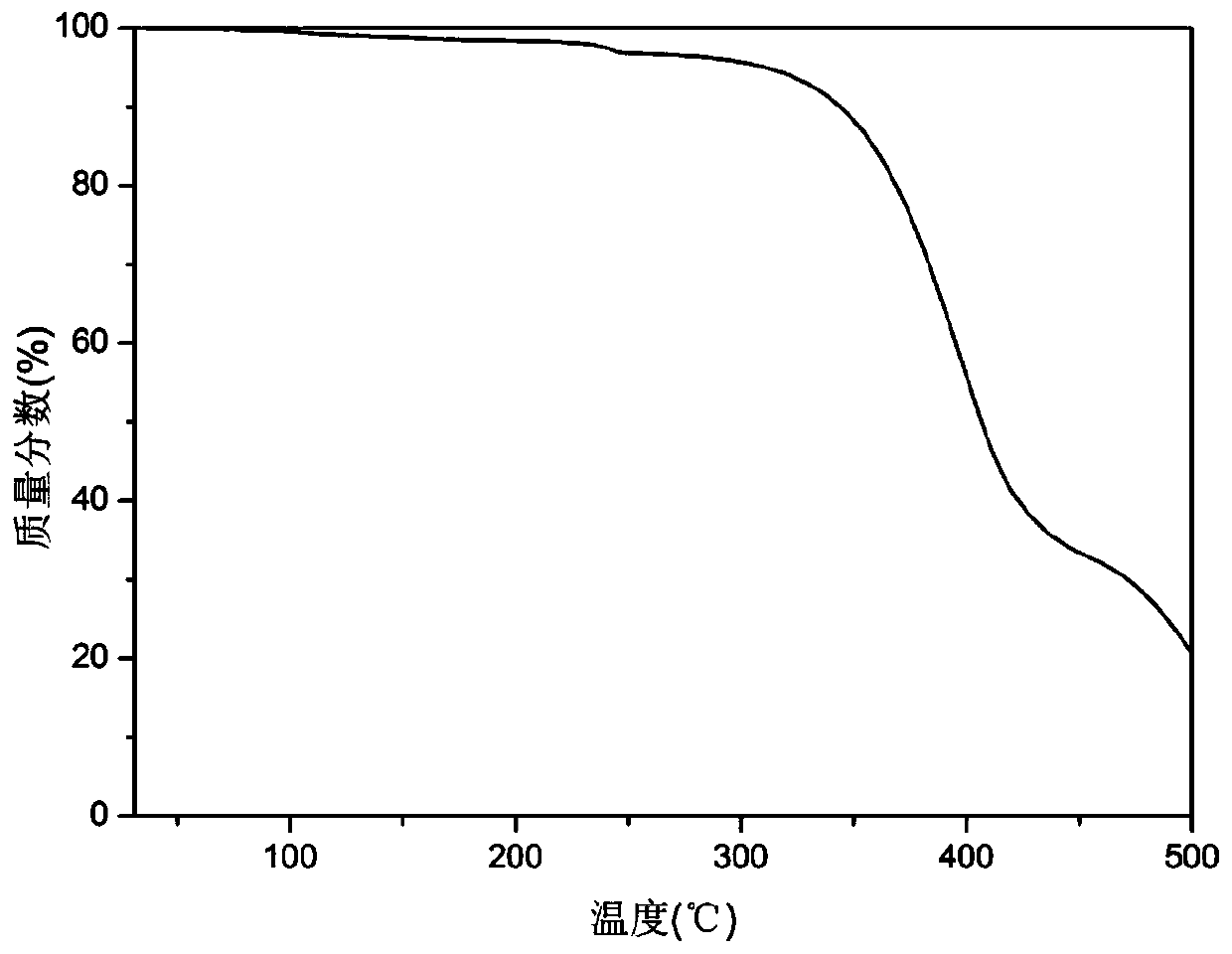

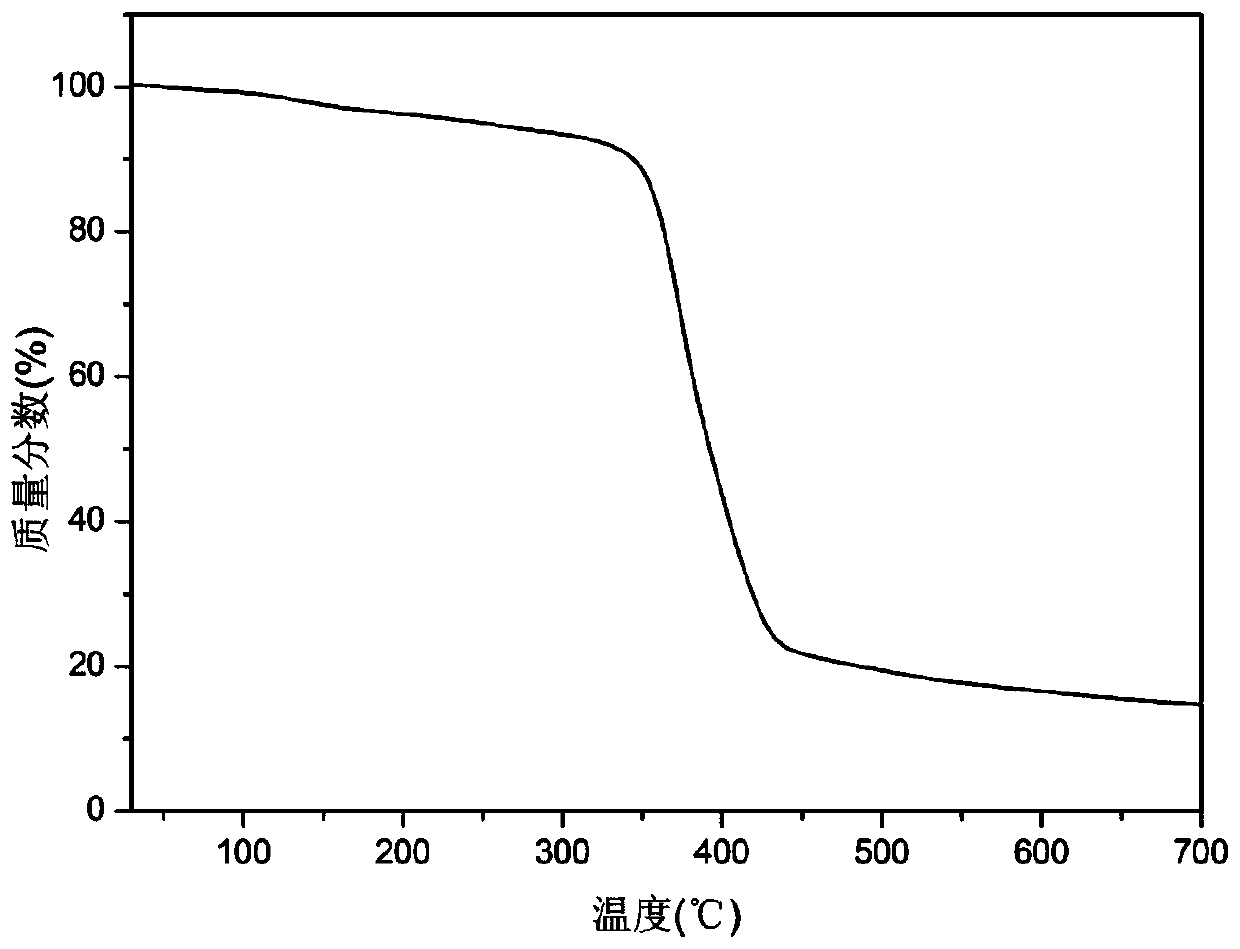

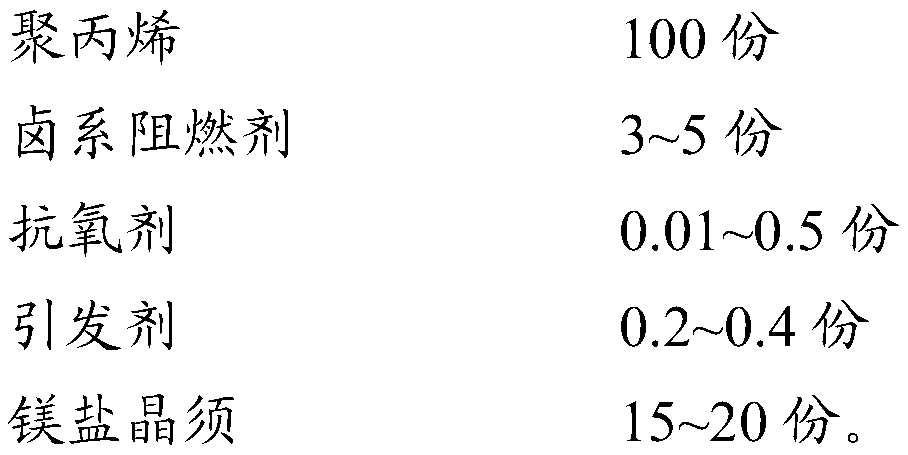

A kind of reinforced flame-retardant polypropylene composite material and preparation method thereof

ActiveCN108017868BImprove mechanical propertiesImprove flame retardant performancePolypropylene compositesPolymer science

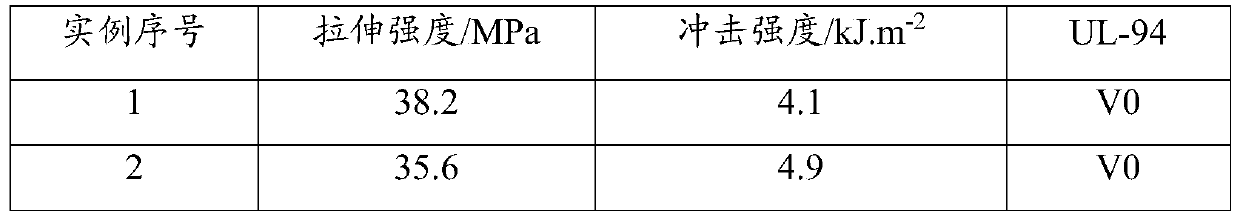

The invention provides a reinforced flame-retardant polypropylene composite. The composite is prepared from raw materials in parts by weight as follows: 100 parts of polypropylene, 3-5 parts of a halogen flame retardant, 0.01-0.5 parts of an antioxidant, 0.2-0.4 parts of an initiator and 15-20 parts of magnesium salt whiskers. The reinforced flame-retardant polypropylene composite has the tensilestrength larger than or equal to 32.4 MPa, the impact strength larger than or equal to 4.1 kJ.m<-2> and the flame-retardant performance of class V0 and has good mechanical performance and flame-retardant performance. Meanwhile, a preparation method of the reinforced flame-retardant polypropylene composite is simple, easy to control and suitable for industrial production.

Owner:FOSHAN KAIYUE GRAND SKY PLASTIC TECH CO LTD

A kind of high-performance environment-friendly kraft box cardboard and preparation method thereof

The invention discloses a high-performance environment-friendly kraft liner board, which comprises a bottom layer, a surface layer and a coating layer which are sequentially arranged from bottom to top; wherein: the bottom layer is made of modified wood flour pulp and short fiber pulp Obtain; The surface layer is made from the surface layer pulp composed of long fiber pulp and short fiber pulp; The coating layer is formed by coating the flame retardant styrene-acrylic latex on the surface layer; The long fiber pulp, The short-fiber pulp is formed by pulping domestic old corrugated boxes; the flame-retardant styrene-acrylic latex is composed of a modified composite flame retardant, functionalized modified styrene-acrylic latex and water. The invention adopts the compound flame retardant latex metering roller coating method to add the flame retardant, without loss, low cost, and the addition of the flame retardant has no adverse effect on the strength of the paper. In addition, the flame retardancy of the kraft liner board prepared by the present invention is good, because the kraft box preparation product of the present invention is produced entirely from waste paper, the process is environmentally friendly, and the functionalized modified styrene-acrylic latex is water-soluble latex without organic solvents, which improves the environmental protection.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

Highly flame-retardant ABS material for automobile interior parts and preparation method of material

InactiveCN106589773AGood flame retardant performanceImprove smoke suppressionPhosphoric acidAmmonium polyphosphate

The invention relates to a highly flame-retardant ABS material for automobile interior parts and preparation method of material. The highly flame-retardant ABS material is prepared from, by weight, 80-120 parts of ABS resin and 8-12 parts of composite flame retardant. The composite flame retardant is prepared by the steps of adding 85% strong phosphoric acid into a reactor, heating and stirring, raising the solution temperature to 60-80 DEG C, adding suitable amount of urea, continuing heating until the temperature reaches 120-125 DEG C, adding suitable amount of diatomite and magnetic ordered mesoporous nickel ferrite powder, stirring for reaction for 10-20 minutes, curing the product under 280-320 DEG C for 1-2 hours, finally pulverizing with nano pulverizer to acquire the composite flame retardant. The phosphoric acid and urea are used as the main materials, the diatomite and magnetic ordered mesoporous nickel ferrite powder are used as the carriers, and through the method of in-situ polymerization, the ammonium polyphosphate-diatomite / magnetic ordered mesoporous nickel ferrite composite flame retardant is prepared. The synergistic flame retardant functions between the ammonium polyphosphate and the elements of silicon, iron and nickel are fully exerted to make the ABS material possess prominent flame retardant performance.

Owner:蔡雨彤

A kind of preparation method of melamine-formaldehyde resin coated magnesium-aluminum layered double metal hydroxide microcapsules

ActiveCN106861571BImprove heat resistanceImprove water resistanceMicroballoon preparationMicrocapsule preparationIn situ polymerizationMelamine formaldehyde resin

The invention relates to a preparation method of an MF (melamine-formaldehyde) resin-coated Mg / Al-LDHs (magnesium / aluminum-layered double hydroxide) microcapsule. The preparation method comprises the following steps of firstly mixing melamine and formaldehyde according to a molar ratio of 1 to (2 to 4), so as to prepare a clear and transparent MF prepolymer; then, using deionized water as a dispersing medium, and preparing a flame retardant agent Mg / Al-LDHs into a core emulsion under the action of an emulsifying agent; using an in-situ polymerizing method to coat the MF prepolymer around capsule core emulsion droplets, adjusting the pH (potential of hydrogen) value of a solution to weak acid, and enabling the MF prepolymer to further complete condensation reaction at the surface of the Mg / Al-LDHs, so as to generate an insoluble latticed crosslinking structure, and form a capsule wall with certain thickness and strength; finally, using absolute ethyl alcohol to wash for multiple times, drying at the temperature of 60 DEG C, and grinding, so as to obtain the MF-coated Mg / Al-LDHs microcapsule. The preparation method has the advantages that the synergistic flame-retardant function of the nitrogen flame-retardant agent and the Mg / Al-LDHs is fully realized, and the problem of poor dispersivity and compatibility of the flame-retardant agent in a substrate is solved; meanwhile, the preparation technology is simple, and the cost is low.

Owner:NANJING FORESTRY UNIV

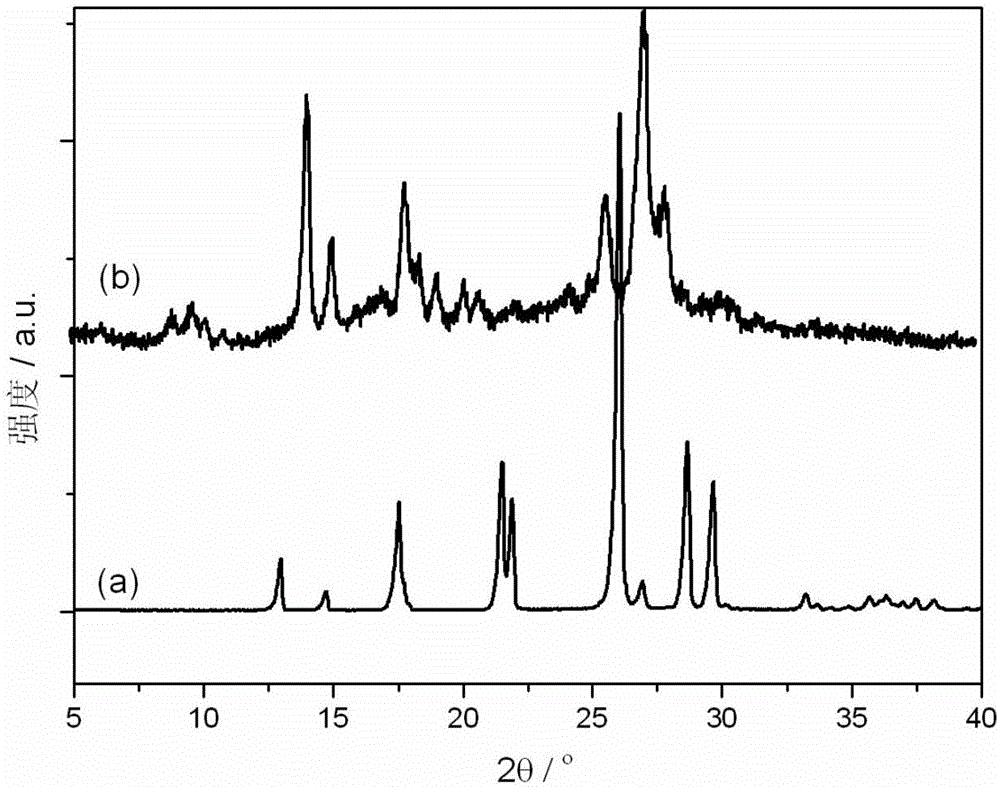

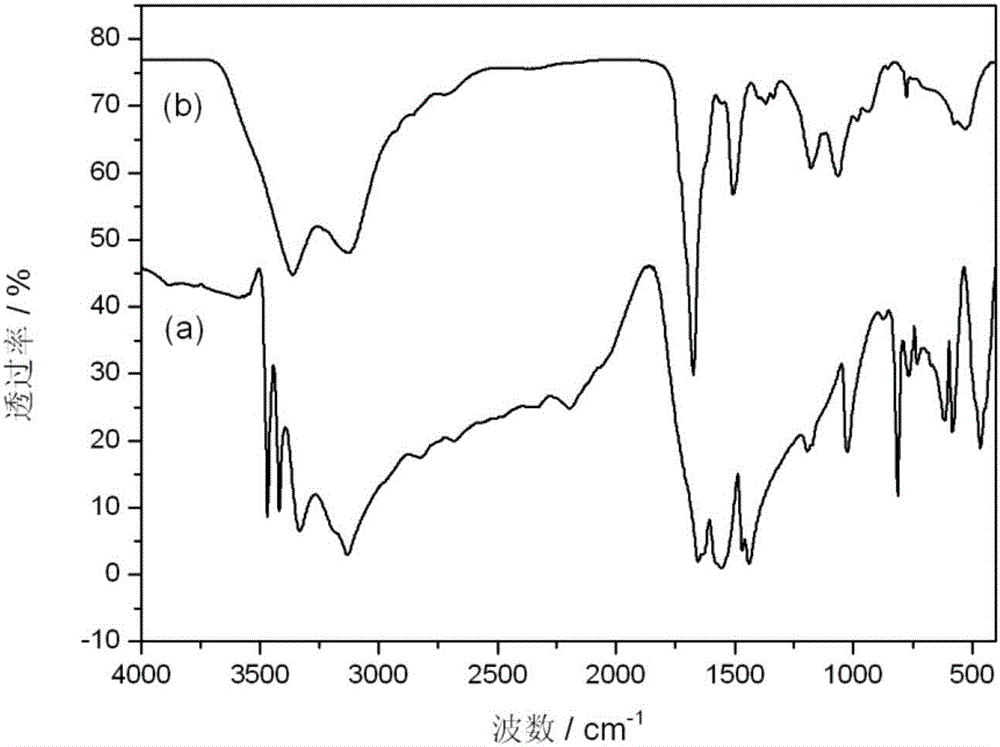

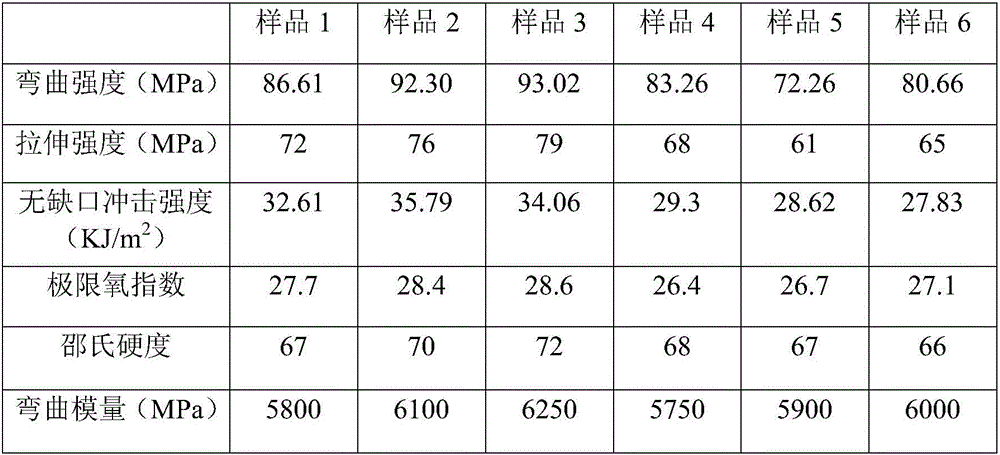

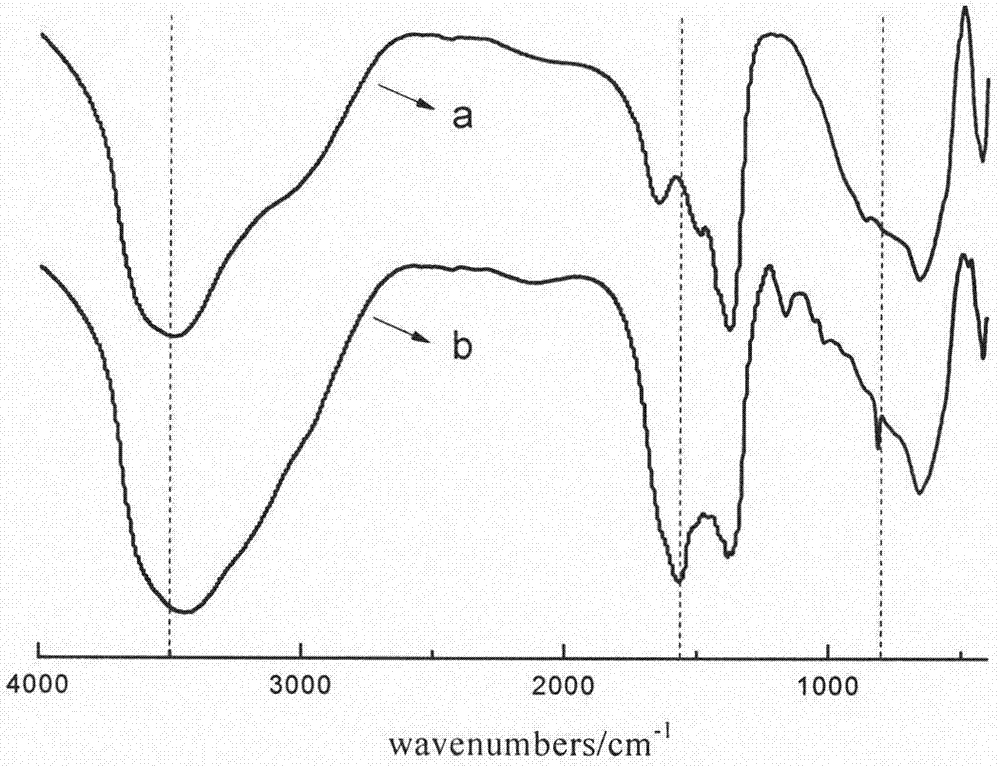

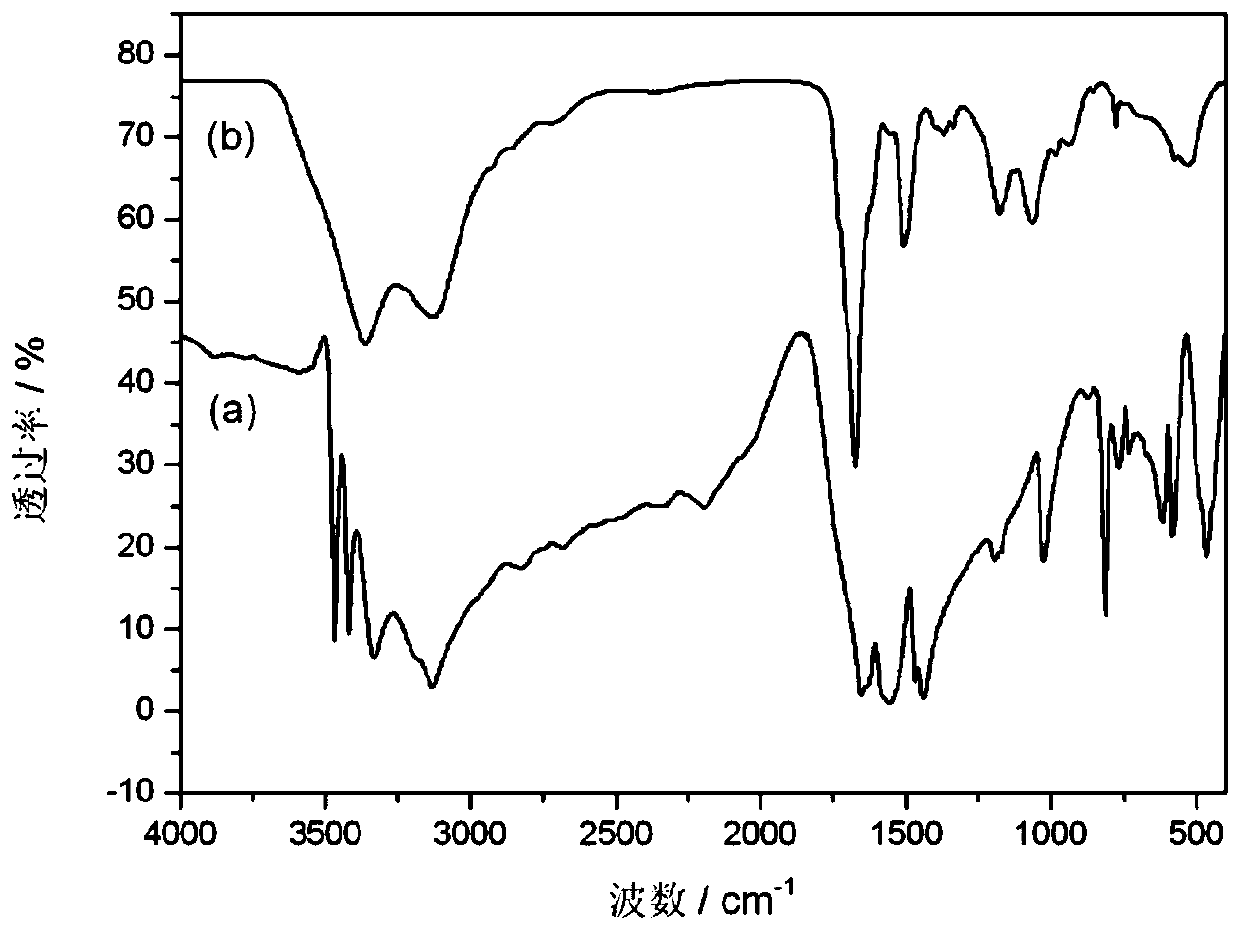

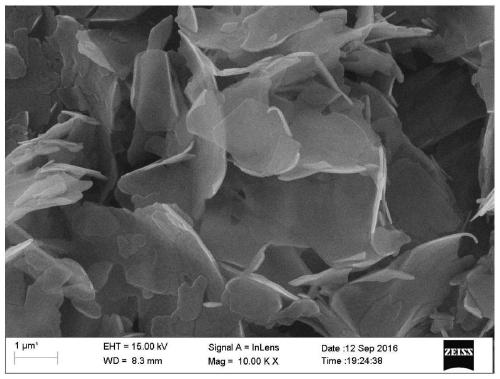

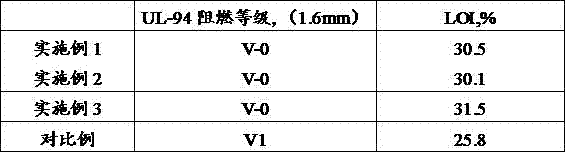

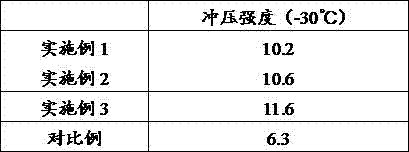

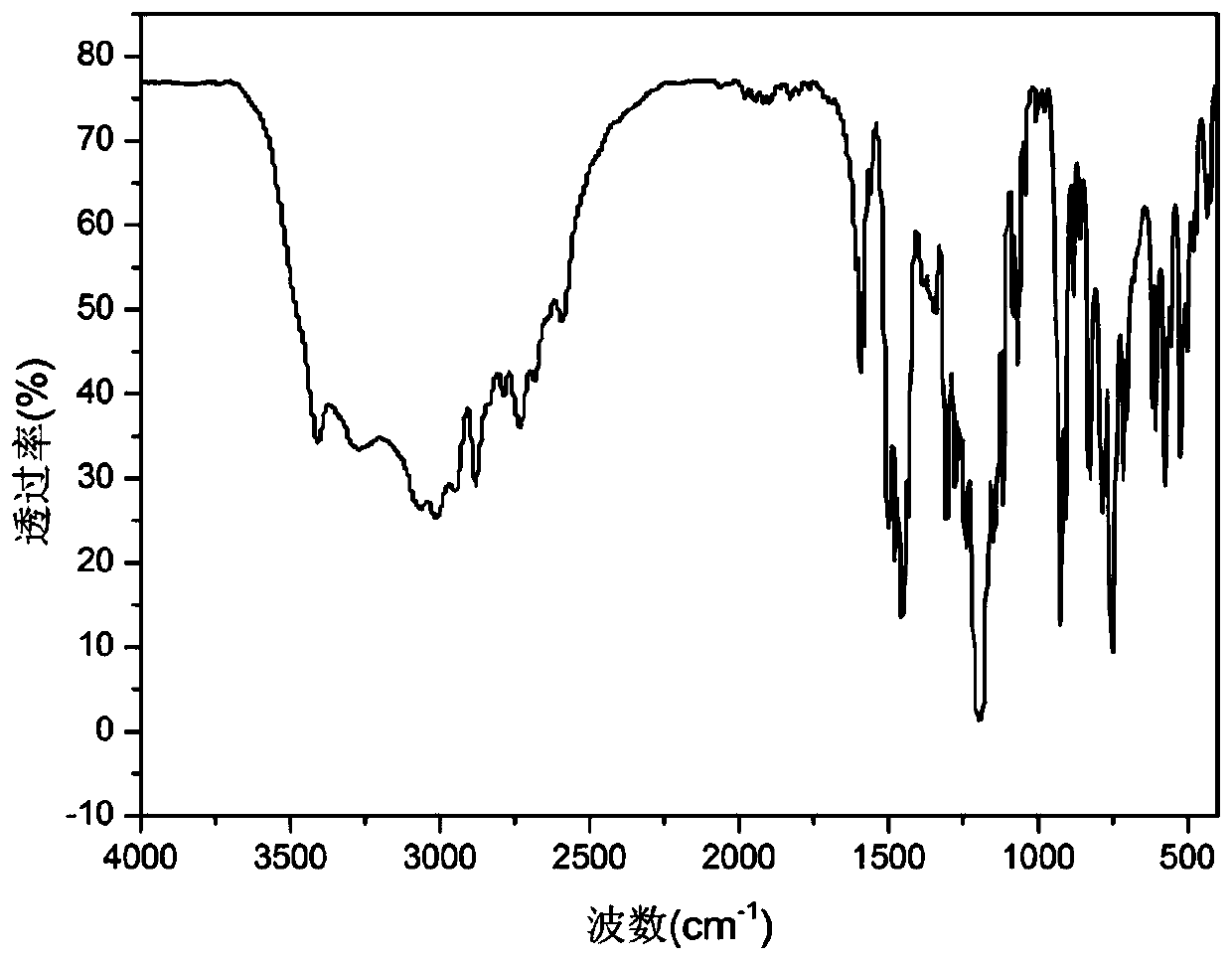

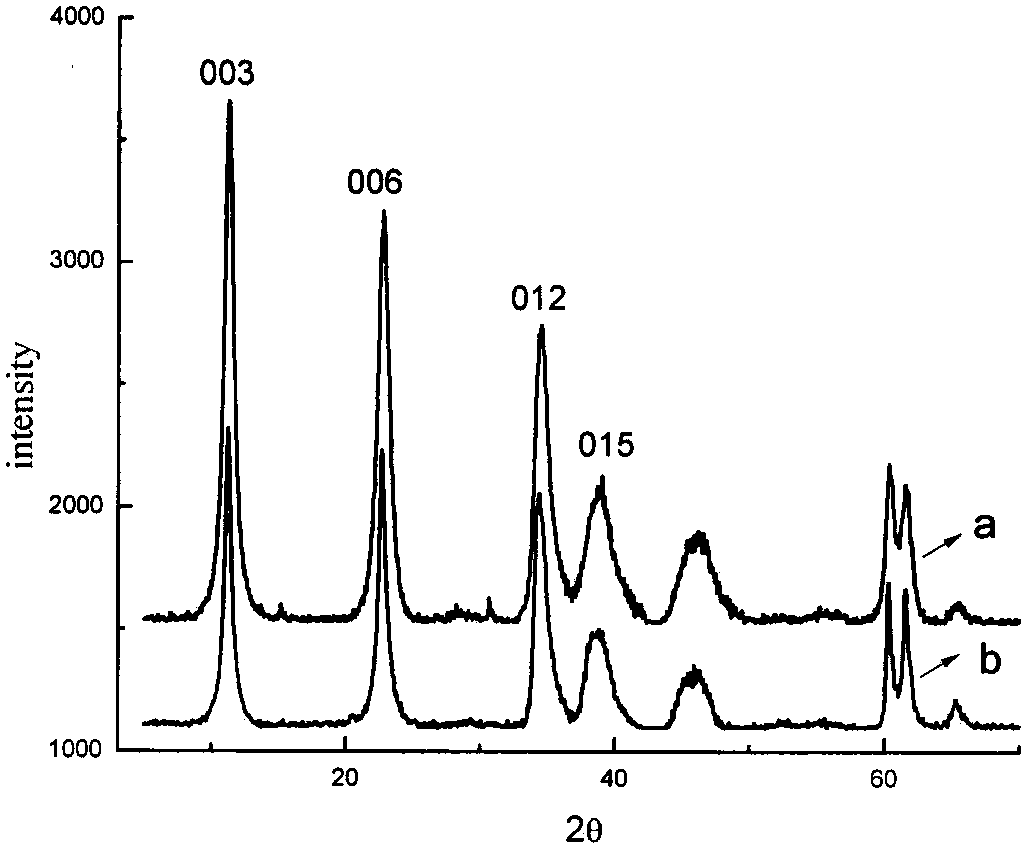

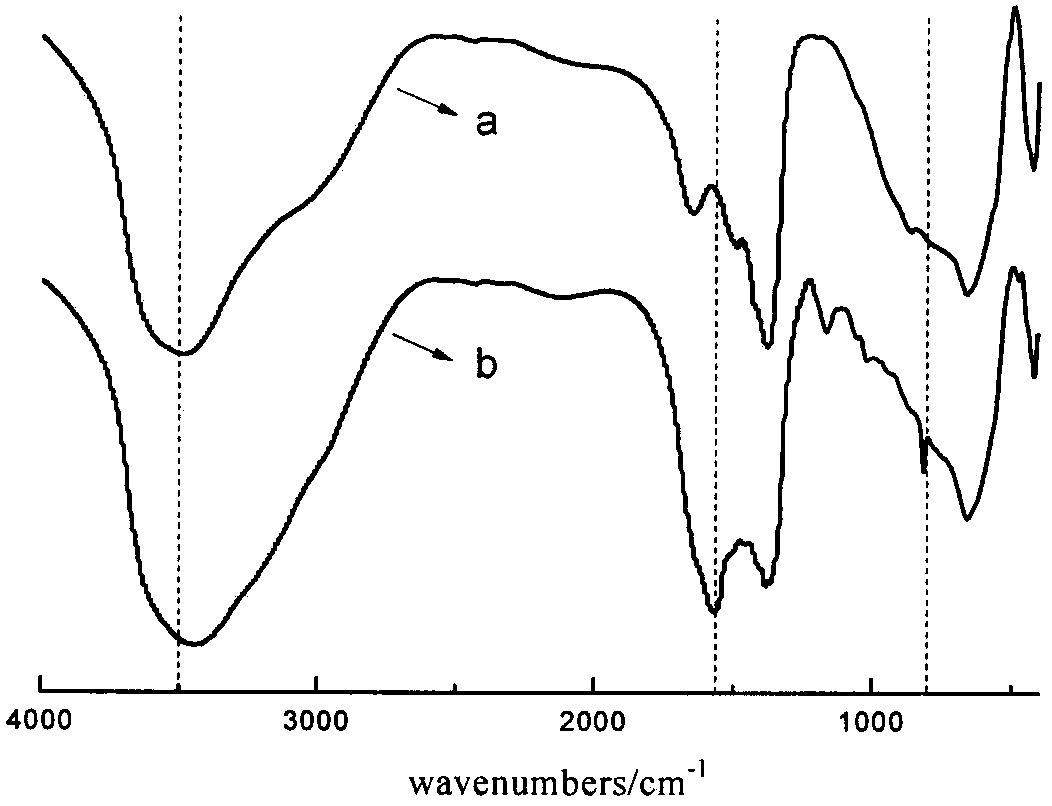

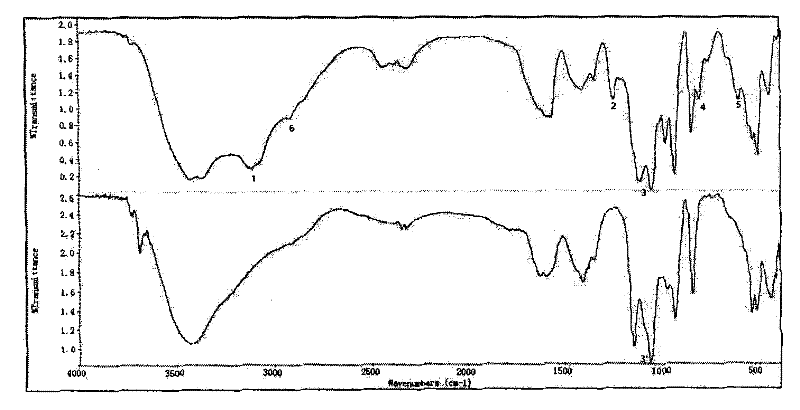

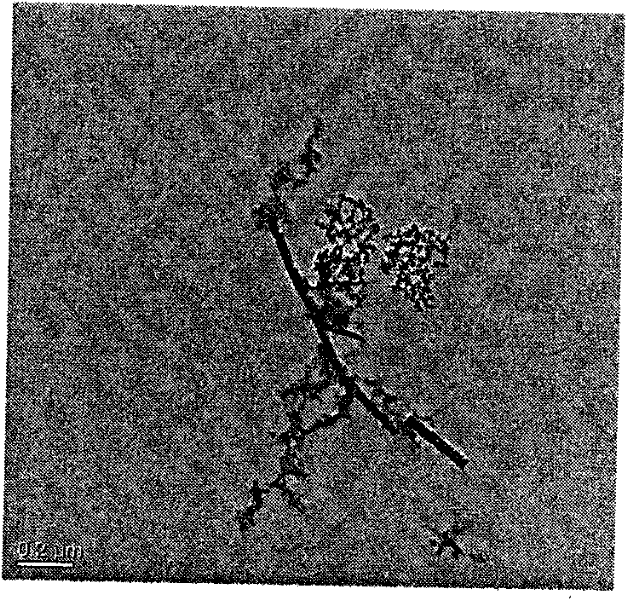

Sepiolite nano flame-retardant fiber as well as preparation method thereof and flame-retardant composite material using same for strengthening and toughening

The invention discloses a sepiolite nano flame-retardant fiber with the diameter of 10-60 nanometers, wherein the mass ratio of sepiolite nano fibers to bis-spironaphthoxazine group expanding type flame-retardant polymers is 1: 0.1-0.5; Si-O stretching vibration peaks between 900 cm<-1> and 1000 cm<-1> in an infrared spectrogram are obviously strengthened, and Si-O-Si stretching vibration peaks between 1000 cm<-1> and 1100 cm<-1> are obviously weakened. The invention also discloses a method for preparing the sepiolite nano flame-retardant fiber and a flame-retardant composite material using the same for strengthening and toughening. The invention improves the compatibility of the sepiolite nano flame-retardant fiber in a polymer base material by organically combining the sepiolite nano flame-retardant fiber with a polymeric type expansion flame-retardant agent together through grafting, thereby not only being beneficial to the uniform dispersion of the expanding type flame-retardant agent in the polymer base material, sufficiently playing the synergistic flame-retardant role between the expanding type flame-retardant agent and the polymer base material and enhancing the flame-retardant efficiency, but also playing a role of enhancing the strength and the toughness of polymer materials.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com