Preparation method of capsule-coated magnesium hydroxide fire retardant

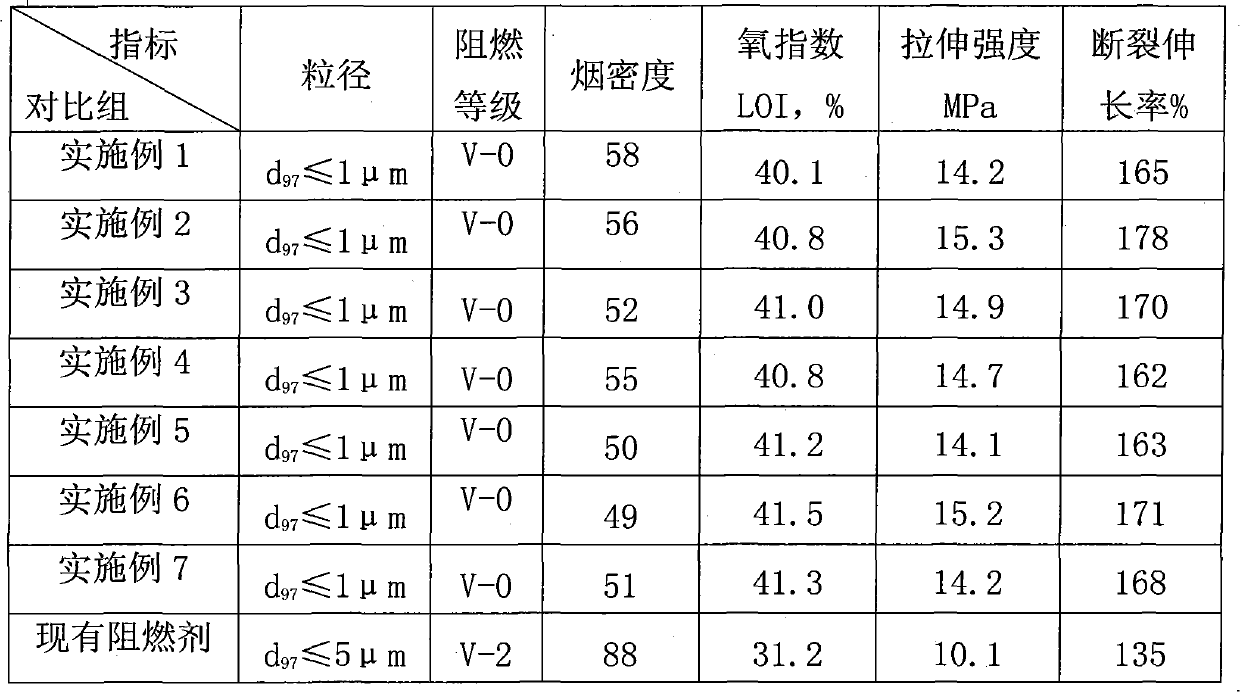

A magnesium hydroxide and capsule coating technology, applied in the chemical industry, can solve the problems affecting the processing and forming properties of polymer-based filling materials, the mechanical properties and other properties of the filling materials are decreased, and the compatibility of flame retardants is poor. Strong force, large interface bonding force, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1, 160g of magnesium hydroxide micropowder with a particle size of 0.08-1μm was added to 600mL of water, and stirred for 20min at a temperature of 40°C and a stirring speed of 600rpm to form a uniformly dispersed suspension of water phase components ;

[0025] Mix free radical polymerization monomer, crosslinking agent and initiator, free radical polymerization monomer is methyl acrylate 89g, n-butyl methacrylate 36g, styrene 45g, crosslinking agent is glycerol trimethacrylate 18g, the initiator is azobisisobutyronitrile 2g, under the condition that the temperature is 40°C and the stirring speed is 600rpm, stir evenly to make the oil phase component;

[0026] Add 190g of the oil phase component into the suspension of the water phase component, and stir to form a homogeneous mixture at a temperature of 40°C and a stirring speed of 8000rpm;

[0027] The temperature of the mixture was raised to 61°C, and the reaction was stirred for 3 hours to complete;

[0028] ...

Embodiment 2

[0029] Example 2, 300g of magnesium hydroxide micropowder with a particle size of 0.08-1μm was added to 1000mL of water, and stirred for 20min at a temperature of 50°C and a stirring speed of 500rpm to form a uniformly dispersed aqueous component suspension ;

[0030] Mix the free radical polymerization monomer, crosslinking agent and initiator, the free radical polymerization monomer is 265g of styrene, the crosslinking agent is 30g of divinylbenzene, the initiator is 5g of azobisisoheptanonitrile, at a temperature of 50°C 1. Under the condition that the stirring speed is 500rpm, stir evenly to make the oil phase component;

[0031] Add 300g of the oil phase component into the suspension of the water phase component, and stir to form a homogeneous mixture at a temperature of 40°C and a stirring speed of 9000rpm;

[0032] The temperature of the mixed solution was raised to 85°C, and the reaction was stirred for 4 hours to complete;

[0033] Stop stirring, cool down to room t...

Embodiment 3

[0034] Example 3, 400g of magnesium hydroxide micropowder with a particle size of 0.08-1μm was added to 600mL of water, and stirred for 30min at a temperature of 60°C and a stirring speed of 800rpm to form a uniformly dispersed aqueous component suspension ;

[0035] Mix free radical polymerization monomer, crosslinking agent and initiator, free radical polymerization monomer is methyl methacrylate 371g, crosslinking agent is ethylene glycol dimethacrylate 50g, initiator is benzoyl peroxide 8g, under the condition that the temperature is 60°C and the stirring speed is 800rpm, stir evenly to make the oil phase component;

[0036] Add 429g of the oil phase component into the suspension of the water phase component, and stir to form a homogeneous mixture at a temperature of 60°C and a stirring speed of 10,000rpm;

[0037] The temperature of the mixture was raised to 90°C, and the reaction was stirred for 5 hours to complete;

[0038] Stop stirring, cool down to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com