Flame-retardant enhanced-type polypropylene composite material and preparing method thereof

A composite material and polypropylene technology, which is applied in the field of flame-retardant reinforced polypropylene composite material and its preparation, can solve the problems of inability to have both flame-retardant and enhanced dual-functional properties, low flame-retardant and reinforcement efficiency, etc., and achieve improved Comprehensive mechanical properties, improved compatibility, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

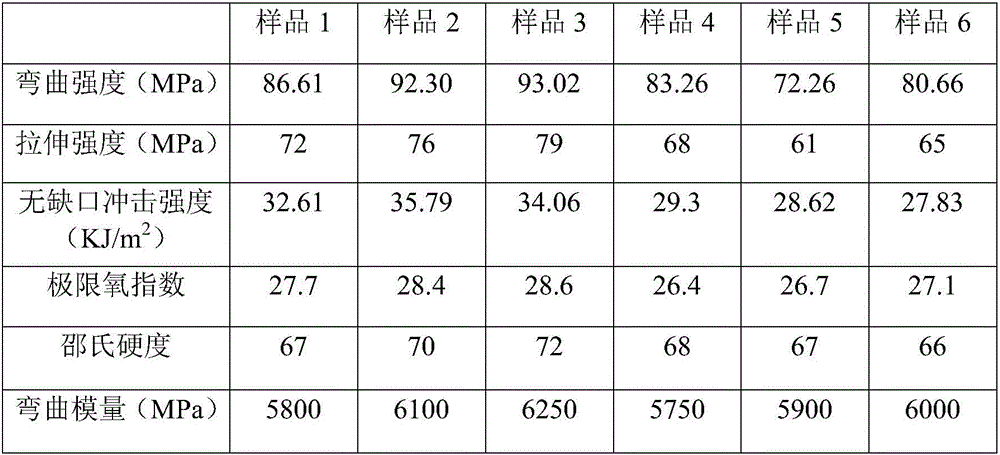

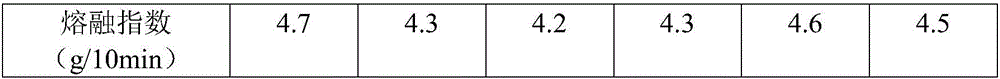

Embodiment 1

[0026] A flame-retardant reinforced polypropylene composite material is characterized in that: it is composed of polypropylene matrix, carbon nanotube modified masterbatch, potassium titanate whiskers, compound flame retardant, modified filler, compatibilizer and antioxidant Made, by weight, 50 parts of polypropylene matrix, 15 parts of carbon nanotube modified masterbatch, 8 parts of potassium titanate whiskers, 10 parts of compound flame retardant, 10 parts of modified filler, 3 parts of compatibilizer and 1 part of antioxidant; the modified filler is mixed with modified glass fiber and modified nano-silica in a weight ratio of 5:2; the compound flame retardant is a nitrogen-phosphorus compound flame retardant agent, the particle size is 5 microns; the carbon nanotube modified masterbatch is formed by mixing and melting a polypropylene matrix and multi-walled carbon nanotubes with a weight ratio of 10:1, and the multi-walled carbon nanotubes pass through other 10% by weight ...

Embodiment 2

[0035] A flame-retardant reinforced polypropylene composite material, which is made of polypropylene matrix, carbon nanotube modified masterbatch, potassium titanate whiskers, compound flame retardant, modified filler, compatibilizer and antioxidant, according to Weight ratio: 55 parts of polypropylene matrix, 18 parts of carbon nanotube modified masterbatch, 10 parts of potassium titanate whiskers, 13 parts of compound flame retardant, 13 parts of modified filler, 4 parts of compatibilizer and 1 part of antioxidant part; the modified filler is mixed with modified glass fiber and modified nano-silica in a weight ratio of 5:2; the compound flame retardant is a nitrogen-phosphorus compound flame retardant, and the particle size 10 microns; the carbon nanotube modified masterbatch is formed by mixing and melting a polypropylene matrix and multi-walled carbon nanotubes with a weight ratio of 13:1, and the multi-walled carbon nanotubes pass through 13% of its weight surface before m...

Embodiment 3

[0044] A flame-retardant reinforced polypropylene composite material, which is made of polypropylene matrix, carbon nanotube modified masterbatch, potassium titanate whiskers, compound flame retardant, modified filler, compatibilizer and antioxidant, according to Weight ratio: 65 parts of polypropylene matrix, 20 parts of carbon nanotube modified masterbatch, 12 parts of potassium titanate whiskers, 16 parts of compound flame retardant, 15 parts of modified filler, 5 parts of compatibilizer and 2 parts of antioxidant part; the modified filler is composed of modified glass fiber and modified nano-silica in a weight ratio of 5:2; the compound flame retardant is a nitrogen-phosphorus compound flame retardant with a particle size of 5 -10 microns; the carbon nanotube modified masterbatch is formed by mixing and melting a polypropylene matrix and multi-walled carbon nanotubes with a weight ratio of 15:1, and the multi-walled carbon nanotubes pass through 15% of its weight surface be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com