Halogen-free flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of halogen-free flame-retardant polypropylene composite materials and its preparation, can solve problems such as poor dispersion, low molecular weight, and effect effects, and achieve the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

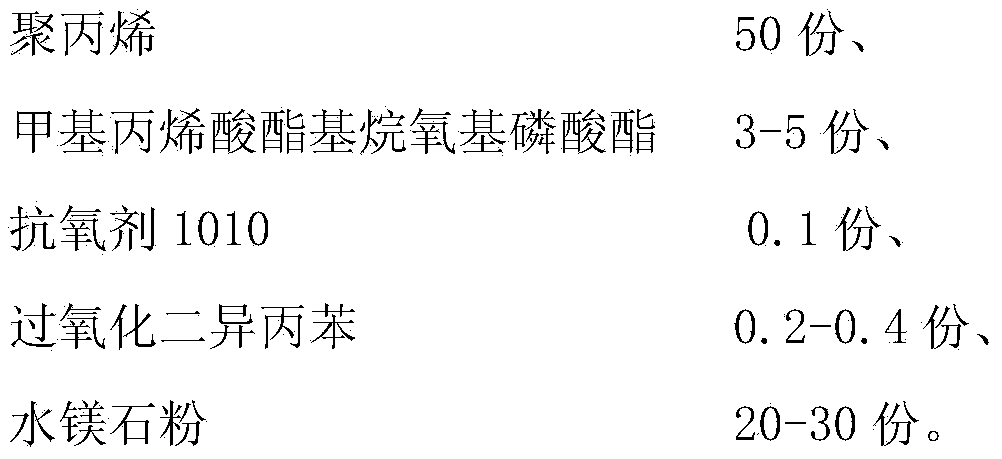

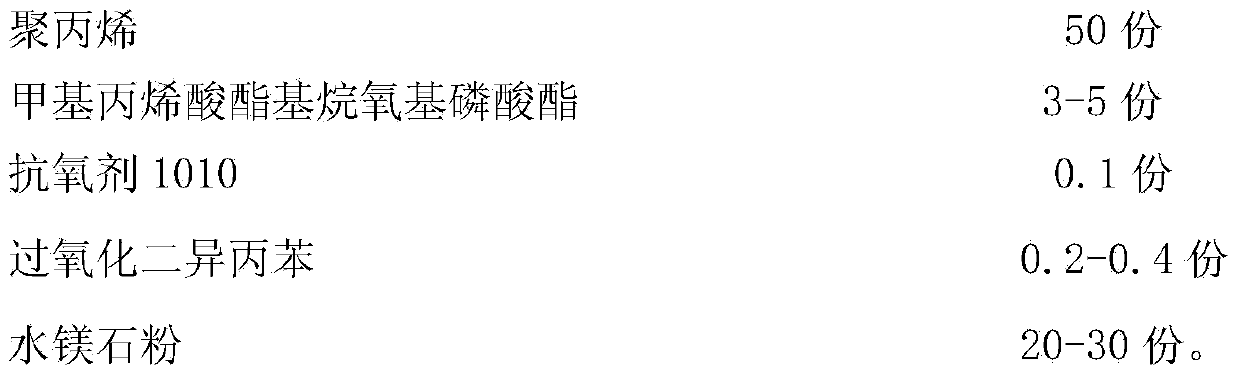

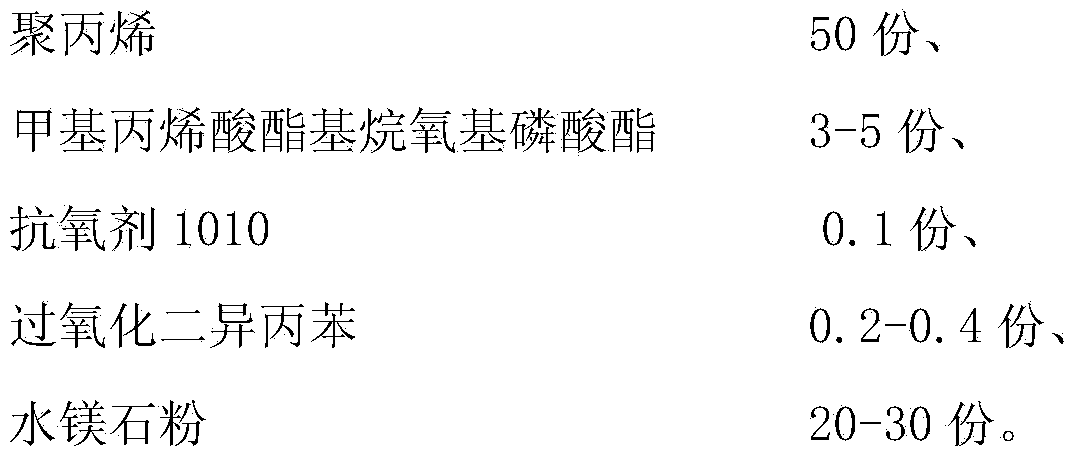

example 1

[0026] Premix 50 parts of polypropylene, 3 parts of methacrylate-based alkoxy phosphate, 10100.1 parts of antioxidant, and 0.2 parts of dicumyl peroxide, and divide the above premix into six parts with an aspect ratio of 32. Reactive extrusion granulation is carried out in a twin-screw extruder with zone temperature control. The processing temperatures in zones 1 to 6 are: 170°C, 190°C, 195°C, 200°C, 210°C, 205°C, and the head temperature is 210°C.

[0027] Dry the prepared pellets and mix them with 30 parts of brucite powder, then mix, plasticize and pelletize through a twin-screw extruder, and the extrusion mixing process is the same as before to prepare the halogen-free flame-retardant Polypropylene composite.

example 2

[0029] Premix 50 parts of polypropylene, 4 parts of methacrylate-based alkoxy phosphate, 10100.1 parts of antioxidant, and 0.3 parts of dicumyl peroxide. Reactive extrusion granulation is carried out in a six-zone temperature-controlled twin-screw extruder. The processing temperatures in the first to sixth zones are: 170°C, 190°C, 195°C, 200°C, 210°C, 205°C, and the head temperature is 210°C .

[0030] Dry the prepared granules and mix them with 25 parts of brucite powder, then mix, plasticize and granulate through a twin-screw extruder, and the extrusion mixing is the same as before to prepare the halogen-free flame-retardant polymer Acrylic composite.

example 3

[0032] Premix 50 parts of polypropylene, 5 parts of methacrylate-based alkoxy phosphate, 0.1 part of antioxidant 10100.1 part of dicumyl peroxide, and 0.4 part of dicumyl peroxide. After premixing the above raw materials, the aspect ratio is 32. Reactive extrusion granulation is carried out in a twin-screw extruder with zone temperature control. The processing temperatures in zones 1 to 6 are: 170°C, 190°C, 195°C, 200°C, 210°C, 205°C, and the head temperature is 210°C. Dry the prepared pellets and mix them with 20 parts of brucite powder, then mix, plasticize and pelletize through a twin-screw extruder, and the extrusion mixing process is the same as before to prepare the halogen-free flame-retardant Polypropylene composite.

[0033] The performance test data of examples 1-3 are shown in the following table in sequence:

[0034] instance number

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com