A kind of preparation method of melamine-formaldehyde resin coated magnesium-aluminum layered double metal hydroxide microcapsules

A layered bimetal and melamine technology, applied in the chemical industry, can solve problems such as poor dispersibility and compatibility, and achieve the effects of low cost, excellent heat resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

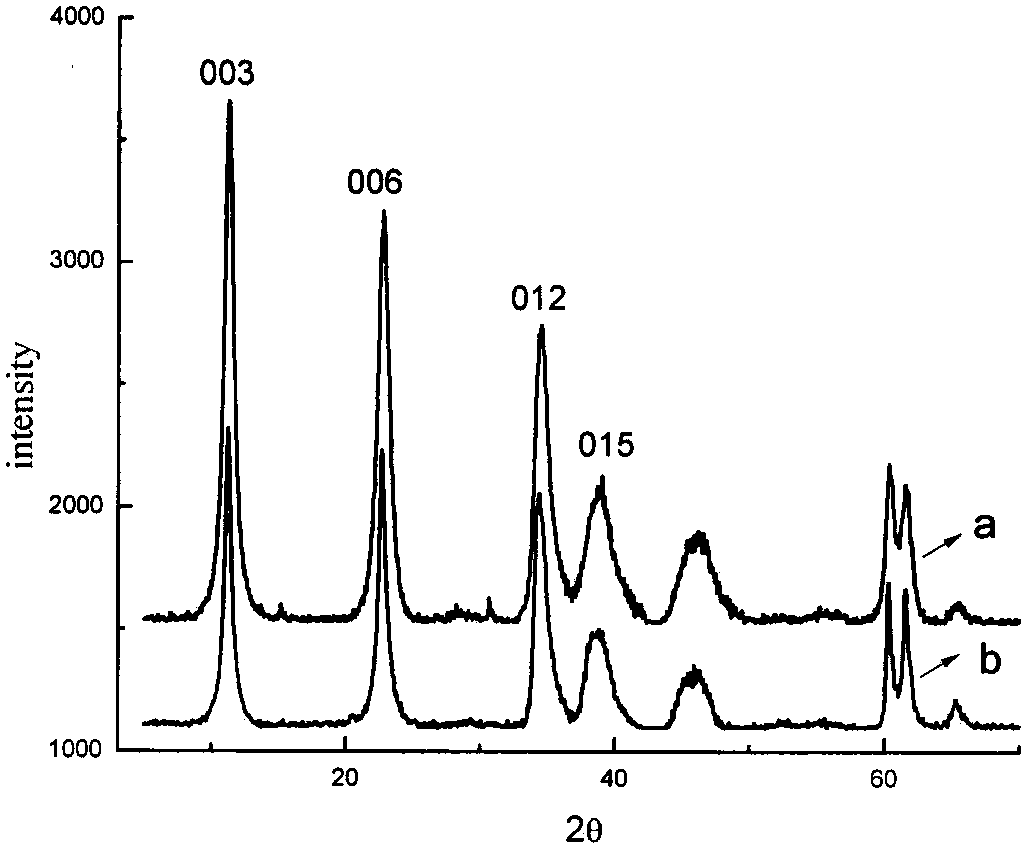

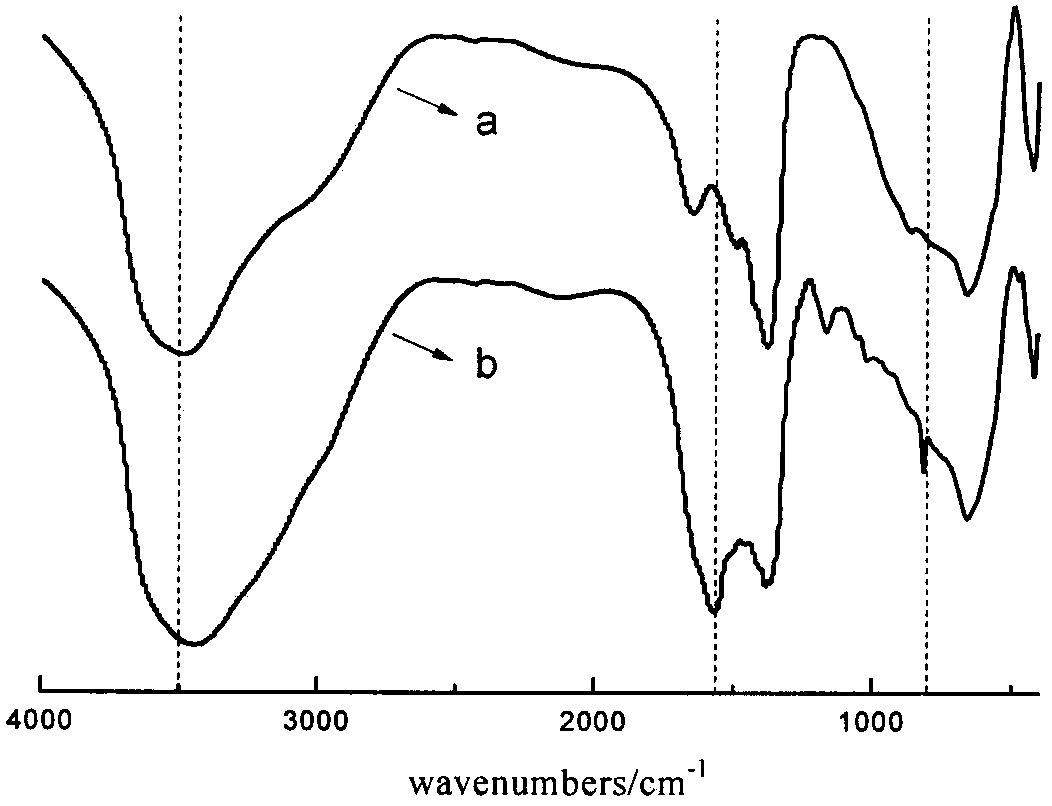

Embodiment 1

[0020] 80 g of 37% formaldehyde solution, 41.5 g of melamine and 200 g of deionized water were respectively added into the three-necked flask and stirred evenly. Raise the temperature to 70°C, adjust the pH value of the reaction system to 8.5 with 10% triethanolamine solution, stir and react in a 70°C water bath for 60 minutes, take out the solution after it is clear and transparent and reaches the required viscosity, and obtain the MF prepolymer;

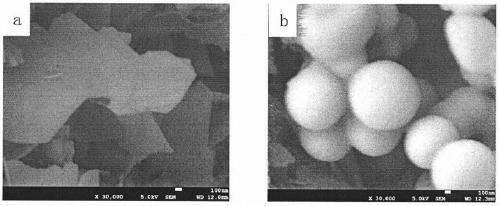

[0021] Add 2g of sodium dodecylbenzenesulfonate emulsifier into 100ml of deionized water, heat at 85°C for 1 hour to dissolve, and prepare a 2% emulsifier solution. Take a 500ml three-neck flask, add the emulsifier solution prepared therein, and then add 100ml deionized water and 6g Mg / Al-LDHs. Raise the temperature of the system to 35°C, and stir the mixing system with a multifunctional disperser at a speed of 4000r / min for 60 minutes. After thorough stirring and uniform mixing, the Mg / Al-LDHs emulsion is obtained;

[0022] 3g of...

Embodiment 2

[0024] 80 g of 37% formaldehyde solution, 41.5 g of melamine and 200 g of deionized water were respectively added into the three-necked flask and stirred evenly. Raise to 70°C, use 10% triethanolamine solution to adjust the pH value of the reaction system to 8.5, stir and react in a 70°C water bath for 60 minutes, and take out the solution after it is clear and transparent and reaches the required viscosity to obtain MF prepolymer;

[0025] Add 2g of sodium dodecylbenzenesulfonate emulsifier into 100ml of deionized water, heat at 85°C for 1 hour to dissolve, and prepare a 2% emulsifier solution. Take a 500ml three-neck flask, add the emulsifier solution prepared therein, and then add 100ml deionized water and 6g Mg / Al-LDHs. Raise the temperature of the system to 35°C, and stir the mixing system with a multifunctional disperser at a speed of 4000r / min for 60 minutes. After thorough stirring and uniform mixing, the Mg / Al-LDHs emulsion is obtained;

[0026] 6g of MF prepolymer w...

Embodiment 3

[0028] 80 g of 37% formaldehyde solution, 41.5 g of melamine and 200 g of deionized water were respectively added into the three-necked flask and stirred evenly. Then rise to 70°C, adjust the pH value of the reaction system to 8.5 with 10% triethanolamine solution, stir and react in a 70°C water bath for 60 minutes, take out the solution after it is clear and transparent and reaches the required viscosity, and obtain the MF prepolymer;

[0029] Add 2g of sodium dodecylbenzenesulfonate emulsifier into 100ml of deionized water, heat at 85°C for 1 hour to dissolve, and prepare a 2% emulsifier solution. Take a 500ml three-neck flask, add the emulsifier solution prepared therein, and then add 100ml deionized water and 6gMg / Al-LDHs. Raise the temperature of the system to 35°C, and stir the mixing system with a multifunctional disperser at a speed of 4000r / min for 60 minutes. After thorough stirring and uniform mixing, the Mg / Al-LDHs emulsion is obtained;

[0030] 12g of MF prepolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com