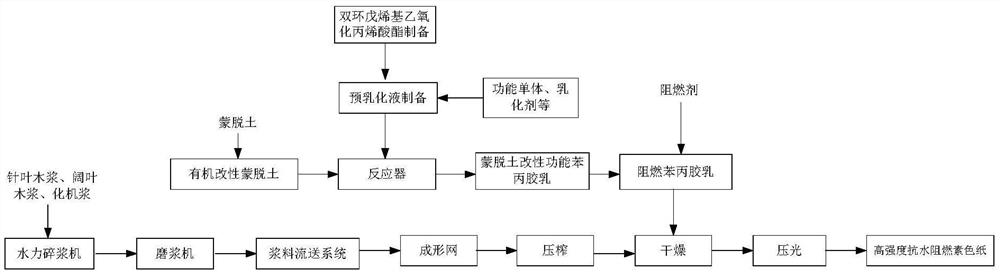

A kind of high-strength water-resistant flame-retardant plain paper and its preparation method

A plain paper, high-strength technology, applied in the field of high-strength water-resistant flame-retardant plain paper and its preparation, can solve the problems of large glue absorption, high production cost, large formaldehyde emission, etc., and achieve advanced preparation technology. , Low production cost, good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A high-strength water-resistant and flame-retardant plain paper of this embodiment is prepared by the following method:

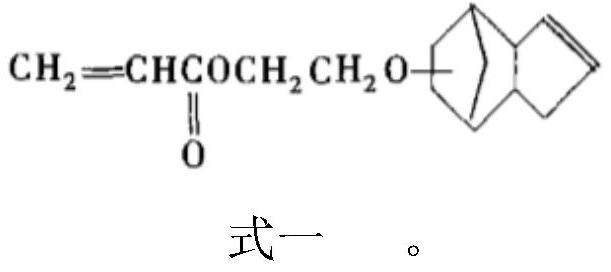

[0064] (1) Preparation of pre-emulsion

[0065] (a) Add ethylene glycol and dicyclopentadiene in the reactor 2 in sequence according to the proportion, then continue to slowly add p-toluenesulfonic acid, stir the obtained reaction solution evenly, then gradually raise the temperature of the reaction system to 116°C, and keep it warm 2.5h, after the reaction is over, cool to room temperature; finally add sodium carbonate aqueous solution, wash with distilled water, and rectify under reduced pressure to obtain ethylene glycol dicyclopentenyl ether; the ethylene glycol, dicyclopentadiene, The mass ratio of p-toluenesulfonic acid and sodium carbonate is 1:2:0.001:0.0015.

[0066] (b) In the reactor 3 according to the proportioning ratio, add successively the mixture 1 composed of ethylene glycol dicyclopentenyl ether, acrylic acid, cyclohexane and tolue...

Embodiment 2

[0086] A high-strength water-resistant and flame-retardant plain paper of this embodiment is prepared by the following method:

[0087] (1) Preparation of pre-emulsion

[0088] (a) Add ethylene glycol and dicyclopentadiene in the reactor 2 in sequence according to the ratio, then continue to slowly add p-toluenesulfonic acid, stir the obtained reaction solution evenly, then gradually raise the temperature of the reaction system to 114°C, and keep it warm 3h, after the reaction is over, cool to room temperature; finally add sodium carbonate aqueous solution, wash with distilled water, and rectify under reduced pressure to obtain ethylene glycol dicyclopentenyl ether; the ethylene glycol, dicyclopentadiene, para The mass ratio of toluenesulfonic acid and sodium carbonate is 1:2:0.001:0.0015.

[0089] (b) In the reactor 3 according to the proportioning ratio, add successively the mixture 1 composed of ethylene glycol dicyclopentenyl ether, acrylic acid, cyclohexane and toluene p...

Embodiment 3

[0109] A high-strength water-resistant and flame-retardant plain paper of this embodiment is prepared by the following method:

[0110] (1) Preparation of pre-emulsion

[0111] (a) Add ethylene glycol and dicyclopentadiene in the reactor 2 in sequence according to the ratio, then continue to slowly add p-toluenesulfonic acid, stir the resulting reaction solution evenly, then gradually raise the temperature of the reaction system to 118°C, and keep the temperature 2h, after the reaction is over, cool to room temperature; finally add sodium carbonate aqueous solution, wash with distilled water, and rectify under reduced pressure to obtain ethylene glycol dicyclopentenyl ether; wherein: the ethylene glycol, dicyclopentadiene , The mass ratio of p-toluenesulfonic acid and sodium carbonate is 1:2:0.001:0.0015.

[0112] (b) In the reactor 3 according to the proportioning ratio, add successively the mixture 1 composed of ethylene glycol dicyclopentenyl ether, acrylic acid, cyclohexa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com