Halogen-free flame retardant PC (poly carbonate) composition and preparation method thereof

A technology of composition and cyclopentene copolymer, which is applied in the field of halogen-free flame retardant PC composition, can solve the problems of complex structure of phosphorus nitrogen flame retardant monomer, increased steric hindrance of molecular chain movement, complex synthesis process and other problems , to achieve the effect of good comprehensive mechanical properties, moderate cost and high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

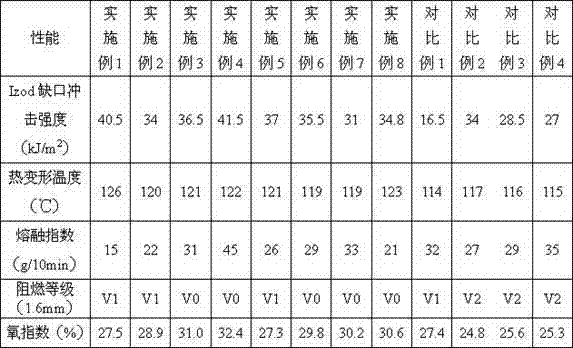

[0041] The formulations of Examples 1-8 and Comparative Examples 1-4 are shown in Table 1, wherein Comparative Examples are compared with Examples 1, 3, 5, and 7 respectively.

[0042] Table 1 Formulation

[0043]

[0044] A preparation method of a halogen-free flame-retardant PC composition is carried out according to the following steps:

[0045] 1. Dry PC resin at 120°C for 6 hours, dry styrene-acrylonitrile-N-phenylmaleimide-cyclopentene copolymer and SMA resin at 100°C for 4 hours;

[0046] 2. Take PC, styrene-acrylonitrile-N-phenylmaleimide-cyclopentene copolymer, SMA, antioxidant and lubricant by weight ratio;

[0047] 3. Put the above raw materials and additives into the high-speed mixer at 1000rpm and mix for 10 minutes at a high speed;

[0048] 4. Put the mixed raw materials into the co-rotating twin-screw extruder to extrude and granulate. The aspect ratio of the twin-screw extruder used is 36, the speed of the screw machine is 150-300rpm, the temperature of e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com