A novel fluorine-containing polyimide nanofiber membrane and its preparation method and application

A nanofiber membrane and polyimide technology, which is applied in fiber treatment, spinning solution preparation, filament/wire forming, etc., can solve the problem of low porosity and cannot meet the rapid charge and discharge of lithium-ion batteries Trends and requirements and other issues, to achieve outstanding heat resistance, improve wettability and liquid retention rate, and solve the effects of poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

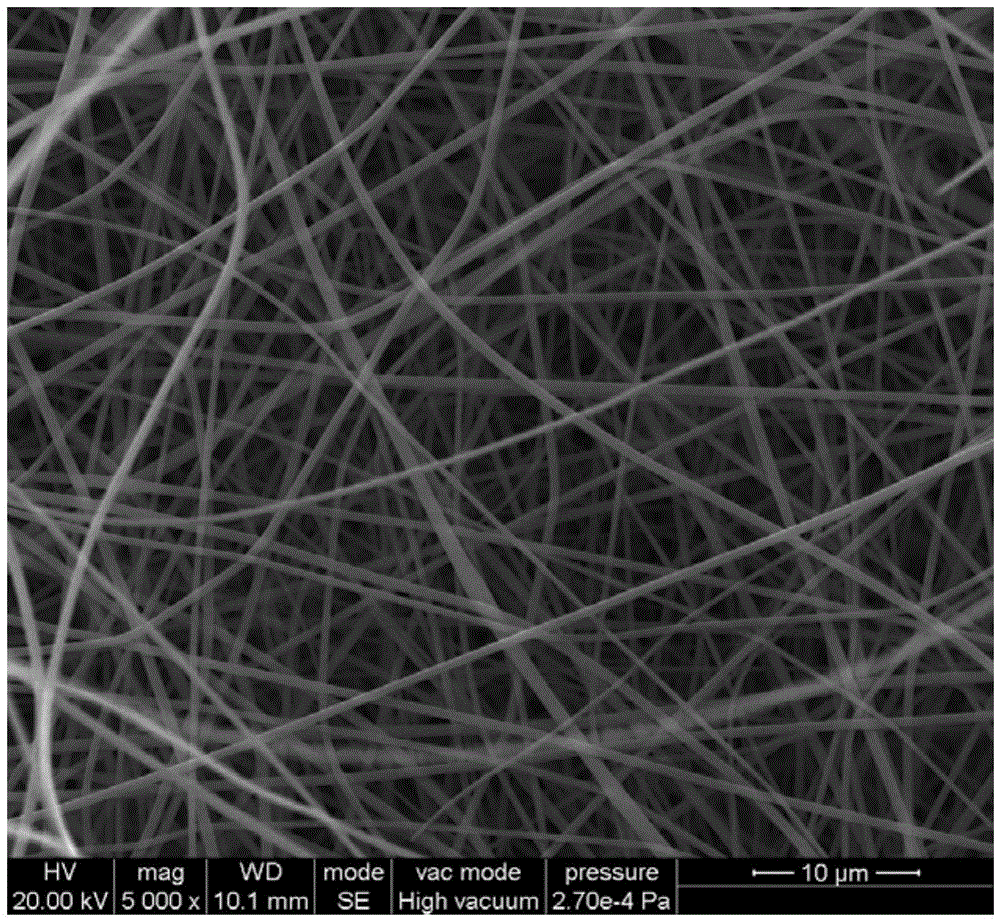

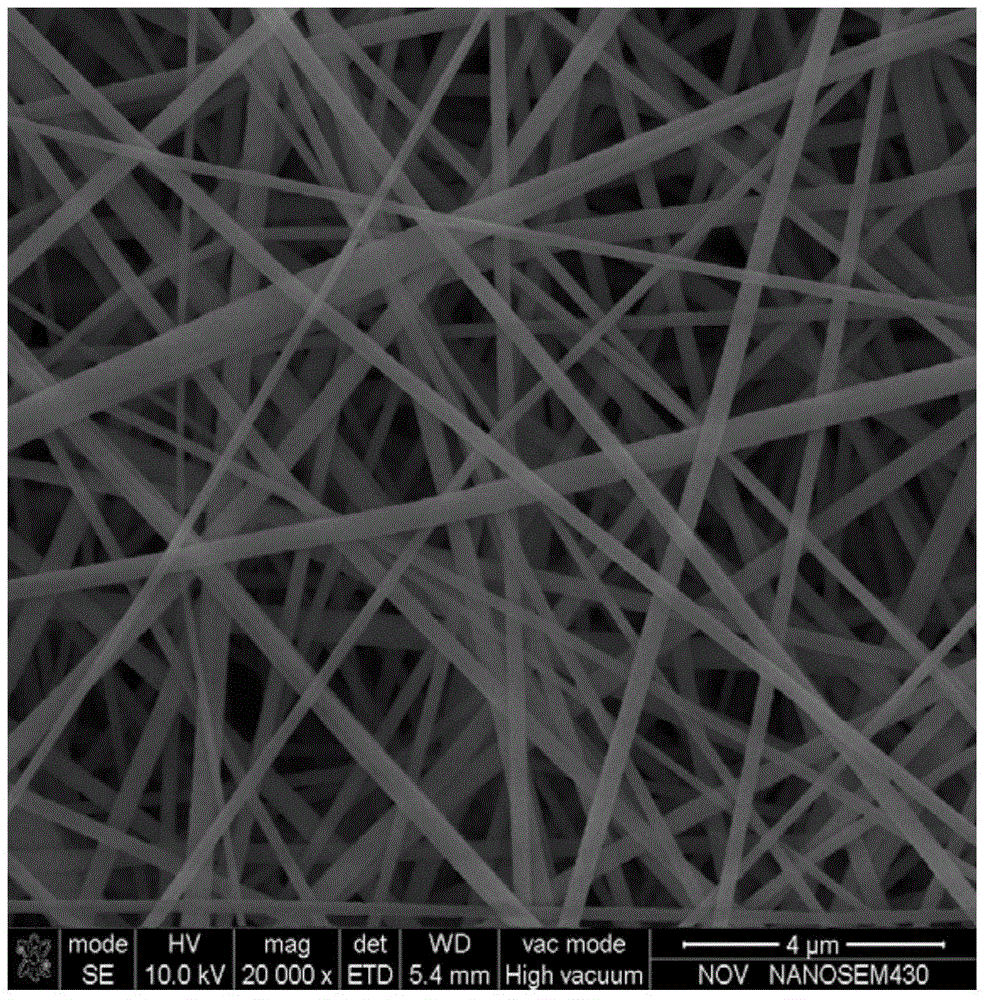

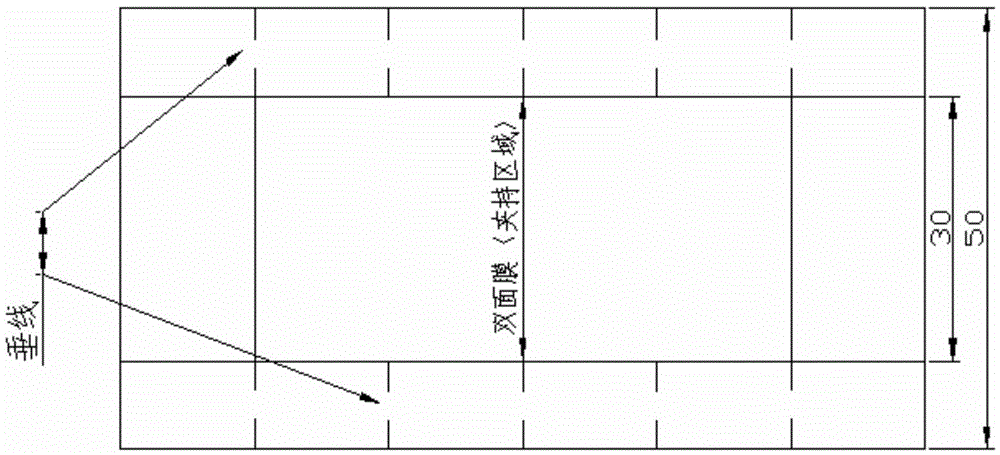

[0040]Add 1.5511g of 4,4'-diphenyl ether dianhydride, 1.3413g of 2-trifluoromethyl-4,4'-diaminodiphenyl ether and 17.5ml of N,N-dimethylacetamide into a 100ml three-necked flask, Stir and react at -5°C for 10 hours to obtain a uniform polyamic acid solution (15wt%), which is stored in a refrigerator (4°C); take 1.6667g of polyamic acid solution in a 50ml volumetric flask, add N,N-dimethyl Dilute acetamide to the mark, prepare a solution containing 0.0050 g / ml of polyamic acid, and use an Ubbelohde viscometer (Shanghai Dibo Experimental Equipment Co., Ltd., model: D01002-075; the same below.) to measure in a water bath at 30 °C Its intrinsic viscosity is 1.2dL / g; take 1ml polyamic acid solution (15wt%) and place it in the electrospinning device as the spinning stock solution (the electrospinning device is such as Figure 4 As shown, it includes three main parts of high-voltage power supply, fiber receiving device and spinneret, wherein the high-voltage power supply is a DC powe...

Embodiment 2

[0046] Add 1.5511g of 4,4'-diphenyl ether dianhydride, 1.3413g of 5-trifluoromethyl-4,4'-diaminodiphenyl ether and 9.26ml of N,N-dimethylacetamide into a 100ml three-necked flask, Stir and react at 25°C for 24h to obtain a homogeneous polyamic acid solution (25wt%), which is stored in a refrigerator (4°C); take 1g of polyamic acid solution in a 50ml volumetric flask, add N,N-dimethylacetamide Set the volume to the scale, prepare a solution containing 0.0050g / ml polyamic acid, and use an Ubbelohde viscometer to measure its intrinsic viscosity in a 30°C water bath to be 1.08dL / g; take 1ml polyamic acid solution (25wt%) as the spinning The silk stock solution was placed on an electrospinning device, and electrospun at 30°C and a relative humidity of 90%rh to obtain a polyamic acid nanofiber film; the polyamic acid nanofiber film was vacuum-dried at 150°C for 2 hours and then heated to 200 Thermal imidization at ℃ for 2 hours to obtain a polyimide nanofiber membrane; the spinning ...

Embodiment 3

[0052] Add 1.0906g of pyromellitic anhydride, 1.3413g of 2-trifluoromethyl-4,4'-diaminodiphenyl ether and 17.5ml of N,N-dimethylacetamide into a 100ml three-necked flask, and stir the reaction at 15°C After 18 hours, a homogeneous polyamic acid solution (15wt%) was obtained and stored in a refrigerator (4°C); 1.6667g of polyamic acid solution was taken in a 50ml volumetric flask, and N,N-dimethylacetamide was added to dilute to Scale, prepared into a solution containing 0.0050g / ml polyamic acid, using Ubbelohde viscometer to measure its intrinsic viscosity in a 30°C water bath to 1.1dL / g; take 1ml polyamic acid solution (15wt%) as spinning stock solution Electrospinning was carried out on an electrospinning device at 25°C and a relative humidity of 70%rh to obtain a polyamic acid nanofiber film; the polyamic acid nanofiber film was vacuum-dried at 120°C for 4 hours and then heated to 240°C for hot sub- Aminated for 4 hours to obtain a polyimide nanofiber membrane; the spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com