Polymer electrolyte based on fluorine-containing polyimide and its preparation method and application

A polyimide and polymer technology, which is applied in the field of new fluorine-containing polyimide polymer electrolyte and its preparation, can solve the problems of not significantly improving the safety of lithium-ion batteries, and achieve improved dielectric properties and Solubility, poor heat resistance, low and high temperature heat shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

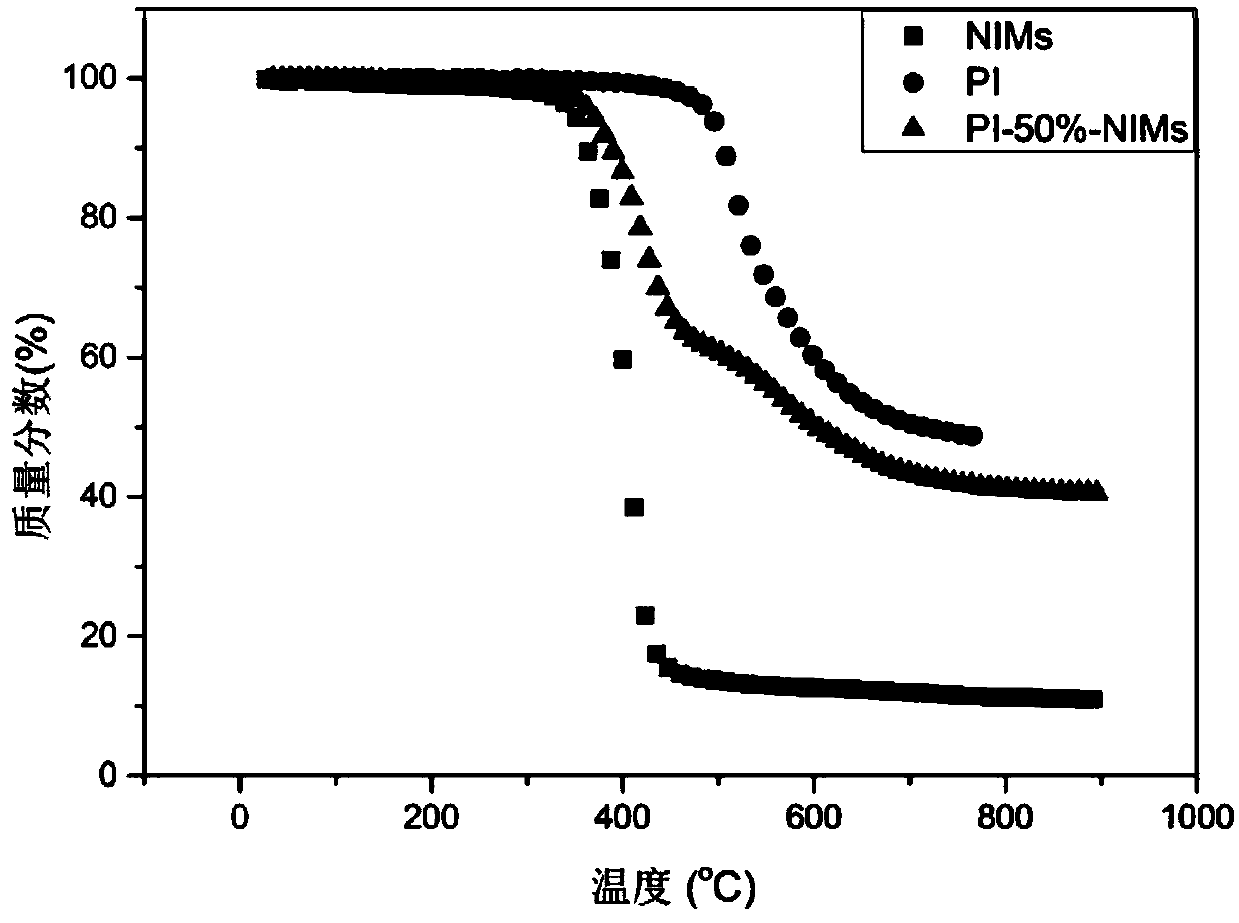

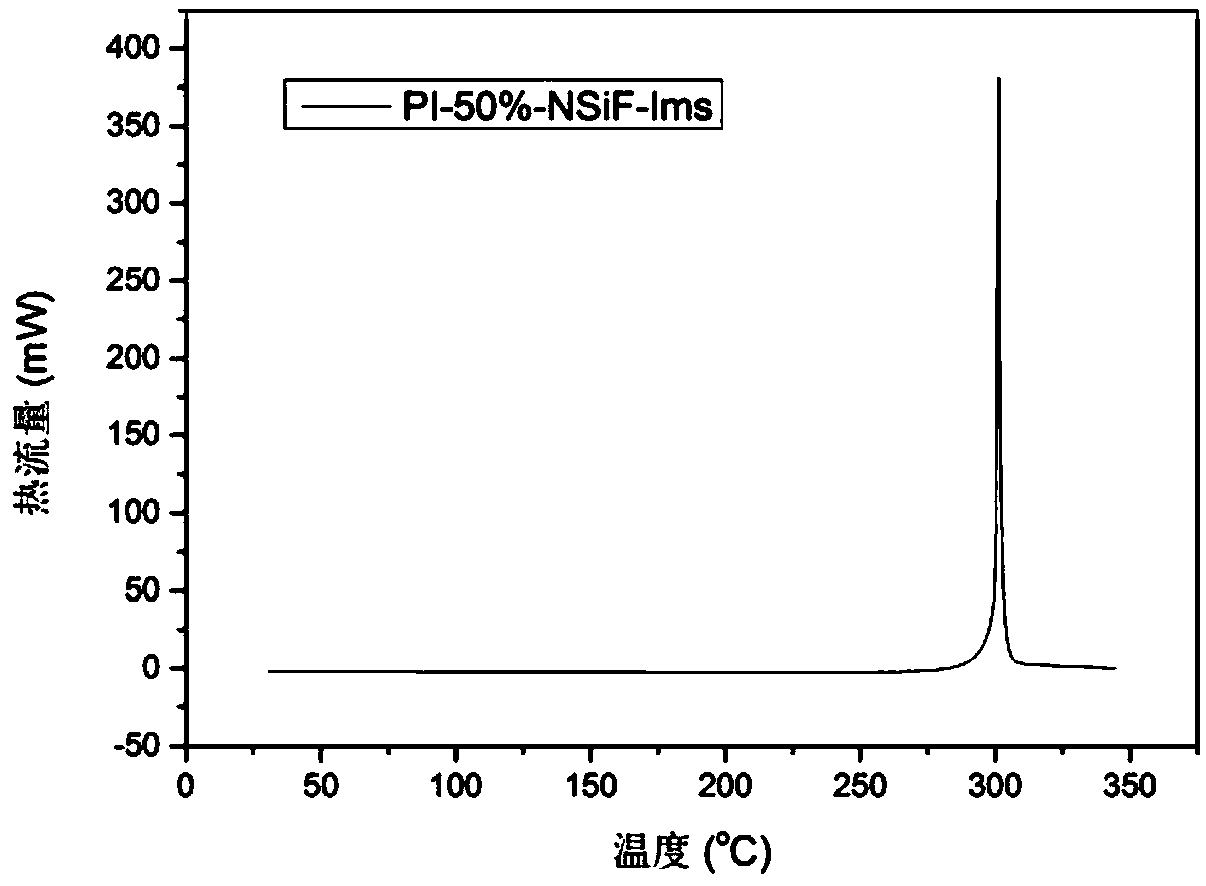

Embodiment 1

[0043] 1.3045g 4,4'-[1,4-phenylbis(oxygen)]bis[3-(trifluoromethyl)aniline], 0.9441g3,3',4,4'-diphenyl ether tetracarboxylic dianhydride Mix evenly with 15ml m-cresol to form a solution with a solid content of 15%, add 0.1wt.% isoquinoline as a catalyst for the reaction, and react at 30°C for 4h; add 15ml of toluene as a water-carrying agent, The reaction was carried out at ℃ for 18 hours to obtain a trifluoromethyl polyimide solution, which was slowly added to ethanol to extract the crude product polyimide, and the crude product polyimide was vacuum-dried at 110 ℃ for 8 hours to obtain a new type of polyimide based on Fluorine-containing polyimides and polyimides used in polymer electrolytes of nano-fluids; weigh 55.6018g of 3-chloropropyltrimethoxysilane and 28.6770g of methylimidazole and react with magnetic stirring at 80°C for 72h to obtain imidazole quaternary Ammonium salt, weigh 5.2790g of imidazole quaternary ammonium salt and 22.0731g of polyethylene glycol-4-nonylphe...

Embodiment 2

[0049] 1.3045g 4,4'-[1,4-phenylbis(oxygen)]bis[3-(trifluoromethyl)aniline], 0.9441g3,3',4,4'-diphenyl ether tetracarboxylic dianhydride Mix evenly with 15ml m-cresol to form a solution with a solid content of 15%, add 0.1wt.% isoquinoline as a catalyst for the reaction, and react at 30°C for 4h; add 15ml of toluene as a water-carrying agent, The reaction was carried out at ℃ for 18 hours to obtain a polyimide solution containing trifluoromethyl, which was slowly added to ethanol to extract the crude product polyimide, and the crude product polyimide was dried in vacuum at 110 ℃ for 8 hours to obtain a preparation based on Polyimide used in polymer electrolytes of fluoropolyimides and nano-fluids; Weigh 0.662g of epoxy silane modifier and dissolve it in 40ml of ethanol solvent, add to 1.667g of 30wt with an average nanometer particle size of 7nm .% nano-silica aqueous solution, add 30ml of water, stir and react at 70°C for 24 hours to obtain active nano-silica, add 0.519g tri-n...

Embodiment 3

[0054] 1.3045g 4,4'-[1,4-phenylbis(oxygen)]bis[3-(trifluoromethyl)aniline], 0.9441g3,3',4,4'-diphenyl ether tetracarboxylic dianhydride Mix evenly with 15ml m-cresol to form a solution with a solid content of 15%, add 0.1wt.% isoquinoline as a catalyst for the reaction, and react at 30°C for 4h; add 15ml of toluene as a water-carrying agent, The reaction was carried out at ℃ for 18 hours to obtain a trifluoromethyl polyimide solution, which was slowly added to ethanol to extract the crude product polyimide, and the crude product polyimide was vacuum-dried at 110 ℃ for 8 hours to obtain a new type of polyimide based on Polyimide used in polymer electrolytes of fluorine-containing polyimides and nano-fluids; weigh 35ml of methylimidazole, 30ml of chloroethanol and 300ml of ethyl acetate, mix them, stir and react at 100°C for 48h, and cool to room temperature After separation, the lower layer liquid was obtained and vacuum-dried at 100°C for 12 hours to obtain 1-hydroxyethyl-3-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com