Acrylic acid liquid crystal photosensitive resin and preparation method thereof

A technology of photosensitive resin and acrylic acid, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of not being suitable for parts with large thickness, and achieve the effects of poor heat resistance, high modulus, and low dimensional shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

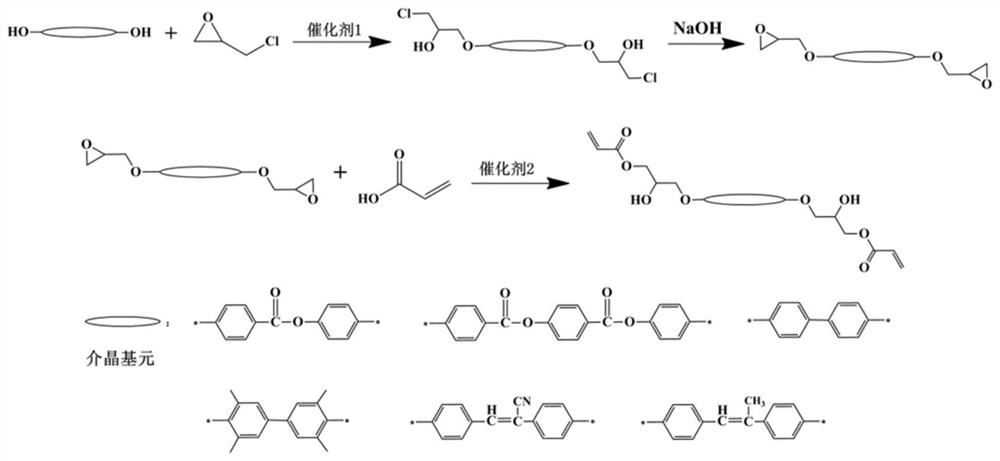

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix with 23.0g4-hydroxyphenyl 4-hydroxybenzoic acid ester, 230ml part epichlorohydrin (EHC) and 0.5g Tetramethylammonium chloride, pass into N 2 protection, and then reacted at 60°C for 12 hours to obtain solution A;

[0027] (2) then slowly drip NaOH solution (0.25mol, concentration 45%) in the solution A, the water generated by the reaction is removed under reduced pressure by a vacuum pump, and the product is poured into the separatory funnel after continuing the reaction for 0.5 hours, and the NaCl is removed by filtration, Gained filtrate utilizes rotary evaporator to remove redundant EHC, obtains solution B;

[0028] (3) Mix solution B with methanol / acetone solution (ratio 1.0:1.0), put it in the refrigerator to cool down and crystallize, the obtained crystals are washed with methanol and filtered with suction, and the product is dried in an oven at 60°C to obtain a milky white solid that is liquid crystal Epoxy resin C;

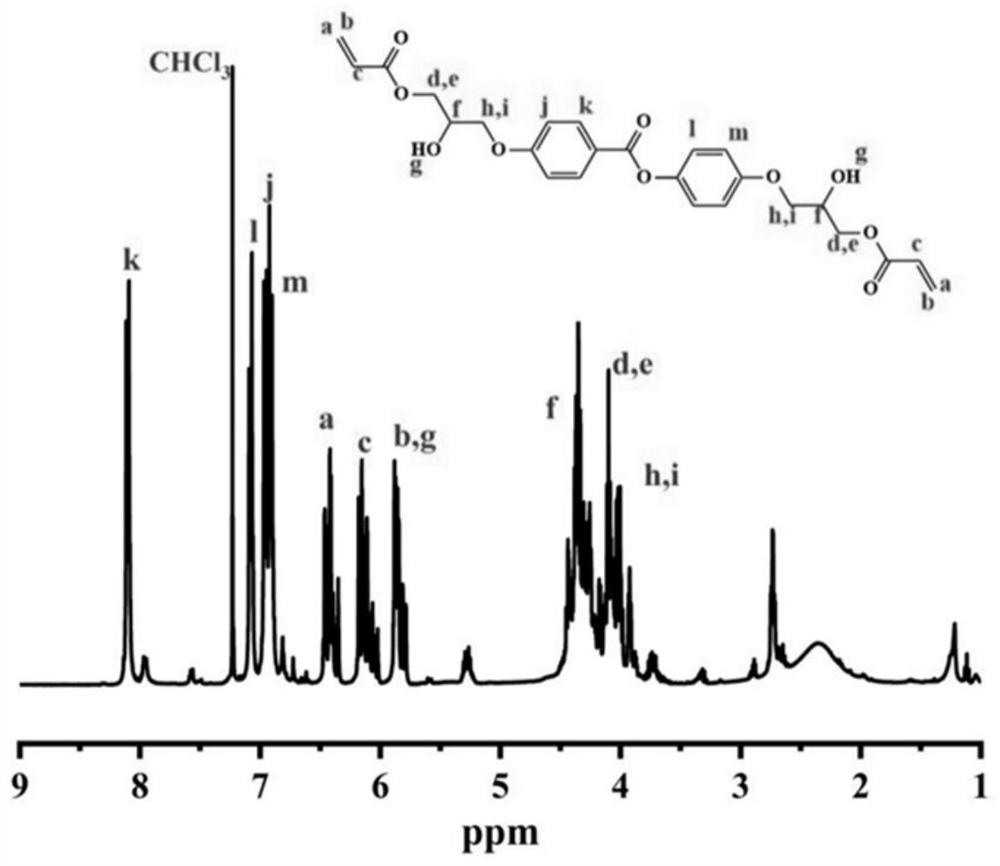

[0029] (4) Take 19.3g (0.05mol) of ...

Embodiment 2

[0036] (1) Mix 0.1mol 4,4'-diphenol, 360ml parts epichlorohydrin (EHC) and 0.003mol tetrabutylammonium bromide as raw materials, feed N 2 protection, and then reacted at 50°C for 18 hours to obtain solution A;

[0037] (2) then slowly drip NaOH solution (0.30mol, concentration 40%) in the solution A, the water generated by the reaction is removed under reduced pressure by a vacuum pump; after continuing to react for 2.5 hours, the product is poured into the separatory funnel, and the NaCl is removed by filtration. Gained filtrate utilizes rotary evaporator to remove redundant EHC, obtains solution B;

[0038] (3) Mix solution B with methanol / acetone solution (ratio 1.0:3.0), put it in the refrigerator to cool down and crystallize, the obtained crystals are washed with methanol and filtered with suction, and the product is dried in an oven at 80°C to obtain a milky white solid that is liquid crystal Epoxy resin C;

[0039] (4) Take 14.9g (0.05mol) of liquid crystal epoxy resi...

Embodiment 3

[0042] (1) Mix 0.1mol 3,3',5,5'-tetramethylbiphenol, 120ml of epichlorohydrin (EHC) and 0.006mol of tetrabutylammonium chloride as raw materials, pass into N 2 protection, and then reacted at 80°C for 6 hours to obtain solution A;

[0043] (2) then slowly drip NaOH solution (0.20mol, concentration 60%) in the solution A, the water generated by the reaction is removed under reduced pressure by a vacuum pump, after continuing to react for 4.0 hours, the product is poured into the separatory funnel, and NaCl is removed by filtration, Gained filtrate utilizes rotary evaporator to remove redundant EHC, obtains solution B;

[0044] (3) Mix solution B with methanol / acetone solution (ratio 1.0:0.5), put it in the refrigerator to cool down and crystallize, the obtained crystals are washed with methanol and filtered with suction, and the product is dried in an oven at 100°C to obtain a milky white solid that is liquid crystal Epoxy resin C;

[0045] (4) Take 17.5g (0.05mol) liquid cr...

PUM

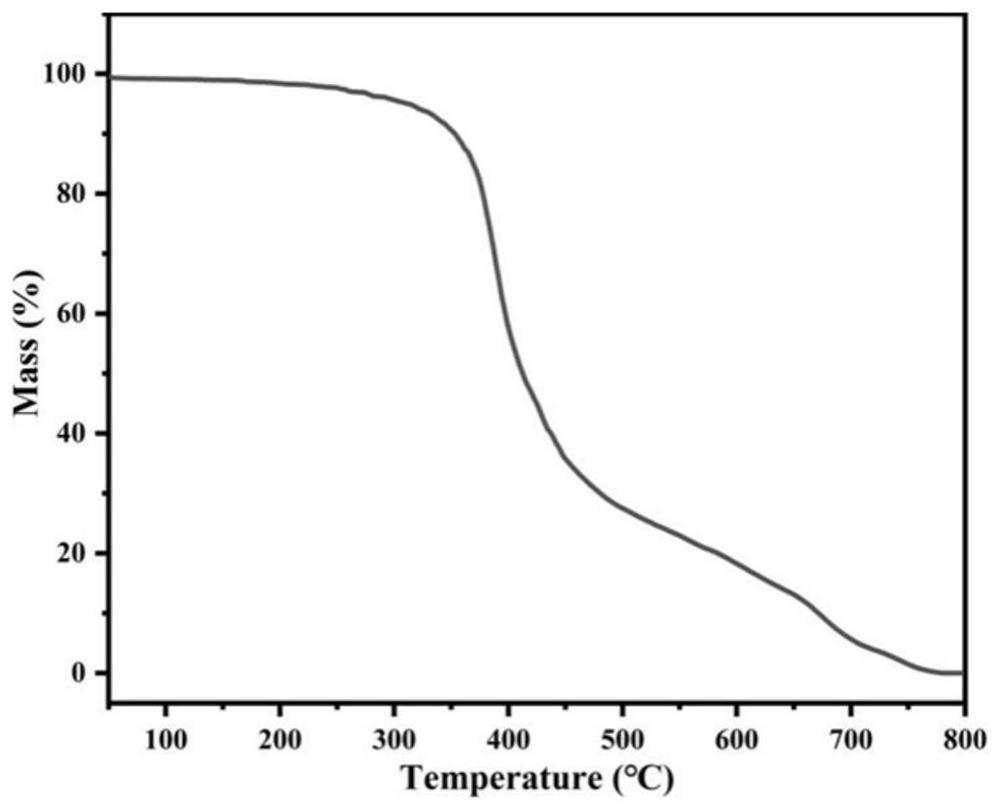

| Property | Measurement | Unit |

|---|---|---|

| Initial decomposition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Maximum decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com