Antistatic high-temperature-resistant flame-retardant PC alloy, and preparation method thereof

A high-temperature-resistant, anti-static technology, which is applied in the field of anti-static, high-temperature, flame-retardant PC alloy and its preparation, can solve the problem of lowering the service temperature range of PC/ABS alloy by heat deformation temperature, reducing the mechanical properties and heat resistance of PC/ABS alloy It can reduce the impact of mechanical properties and heat resistance, excellent mechanical properties and high temperature resistance, and not easy to decompose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

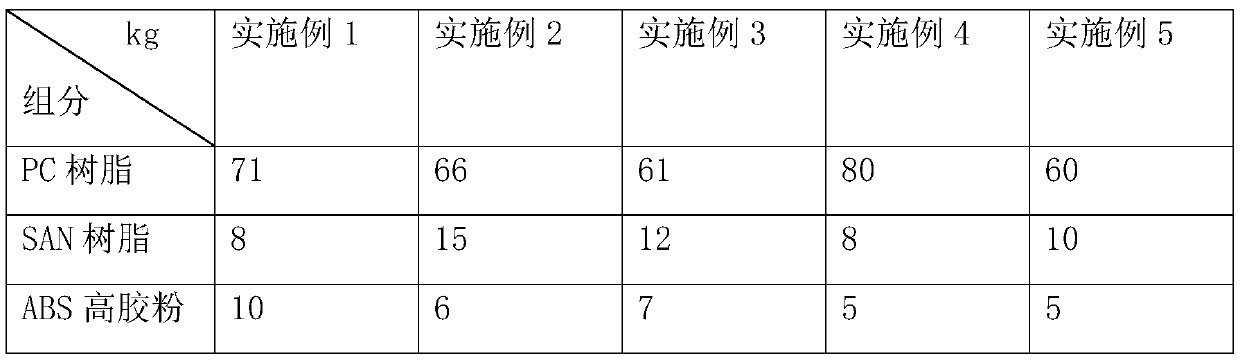

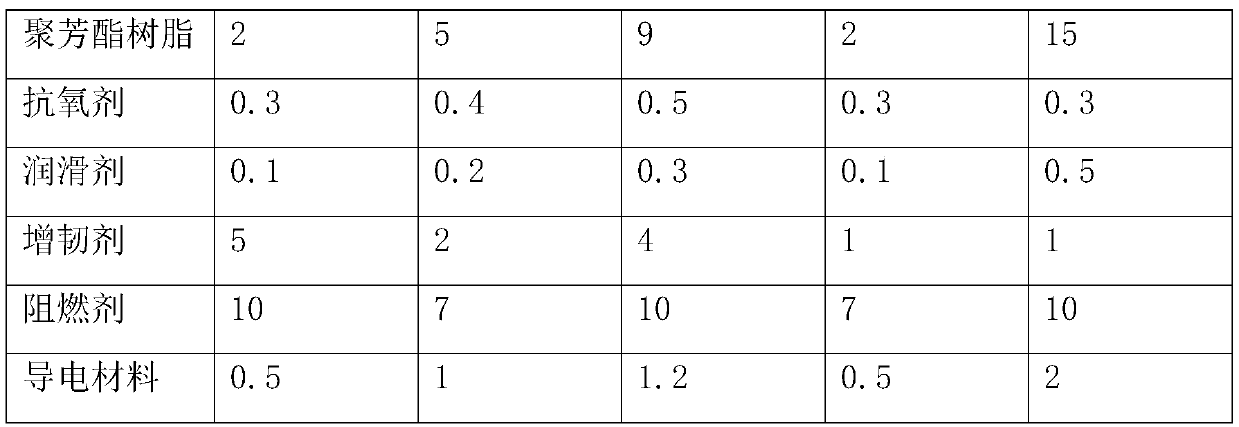

[0042] Embodiment 1: A kind of antistatic high temperature resistant flame retardant PC alloy, its raw material ratio is shown in Table 1, the preparation method of this antistatic high temperature resistant flame retardant PC alloy comprises the following steps:

[0043] (1) 71kg PC resin, 8kg SAN resin, 2kg polyarylate resin are pre-dried and dried until the water content<0.02%; PC resin is bisphenol A type PC resin, and the melt flow rate is 15g / 10min (300 ℃, under 1.2kg pressure), it is prepared by polymerizing bisphenol A and diphenyl carbonate according to the mass ratio of 1:1, extruding and granulating with an extruder, SAN resin is a copolymer of styrene acrylonitrile, melt Flow rate is 3g / 10min (200 ℃, under 5kg pressure), wherein the weight percentage of styrene is 75%, and the weight percentage of acrylic acid is 25%;

[0044] (2) Get PC resin, SAN resin and polyarylate resin after drying in step (1), with 10kg ABS high rubber powder, 0.3kg antioxidant, 0.1kg lubri...

Embodiment 2

[0050] Embodiment 2: A kind of antistatic high temperature resistant flame retardant PC alloy, its raw material ratio is shown in Table 1, the preparation method of this antistatic high temperature resistant flame retardant PC alloy comprises the following steps:

[0051] (1) 66kg PC resin, 15g SAN resin, 5kg polyarylate resin are pre-dried and dried to moisture content<0.02%; PC resin is bisphenol A type PC resin, and the melt flow rate is 18g / 10min (300 ℃, under 1.2kg pressure), it is prepared by polymerizing bisphenol A and diphenyl carbonate according to the mass ratio of 1:1, extruding and granulating with an extruder, SAN resin is a copolymer of styrene acrylonitrile, melt Flow rate is 3g / 10min (200 ℃, under 5kg pressure), wherein the weight percentage of styrene is 75%, and the weight percentage of acrylic acid is 25%;

[0052] (2) Get PC resin, SAN resin and polyarylate resin after drying in step (1), and 6kg ABS high rubber powder, 0.4kg antioxidant, 0.2kg lubricant, ...

Embodiment 3

[0055] Embodiment 3: An antistatic high temperature resistant flame retardant PC alloy, its raw material ratio is shown in Table 1, the preparation method of this antistatic high temperature resistant flame retardant PC alloy comprises the following steps:

[0056] (1) 61kg PC resin, 12g SAN resin, 9kg polyarylate resin are pre-dried and dried to moisture content<0.02%; PC resin is bisphenol A type PC resin, and the melt flow rate is 20g / 10min (300 ℃, under 1.2kg pressure), it is prepared by polymerizing bisphenol A and diphenyl carbonate according to the mass ratio of 1:1, extruding and granulating with an extruder, SAN resin is a copolymer of styrene acrylonitrile, melt Flow rate is 3g / 10min (200 ℃, under 5kg pressure), wherein the weight percentage of styrene is 75%, and the weight percentage of acrylic acid is 25%;

[0057] (2) Get PC resin, SAN resin and polyarylate resin after drying in step (1), and 7kg ABS high rubber powder, 0.5kg antioxidant, 0.3kg lubricant, 4kg tou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com