Anti-bacterial and high-flame-retardant ABS (acrylonitrile butadiene styrene) composite material and preparation method thereof

A composite material and high flame-retardant technology, which is applied in the field of preparation of antibacterial and high flame-retardant ABS composite materials, can solve the problems of poor flame retardancy and antibacterial performance, reduce smoke production, have little impact on physical strength, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

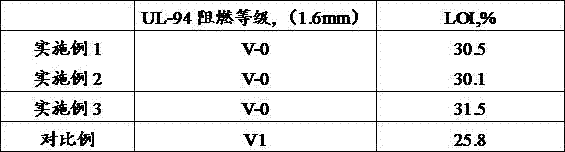

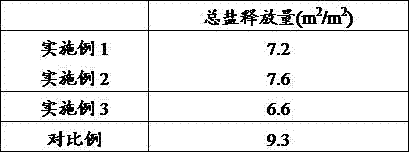

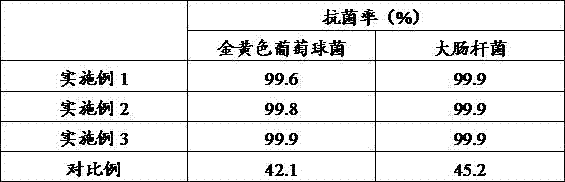

Embodiment 1

[0033] Antibacterial high flame retardant ABS composite material, said antibacterial high flame retardant ABS composite material is processed from the following raw materials by weight: 60 parts of ABS resin, 40 parts of PC resin, 5 parts of EPDM resin, 6 parts of antioxidant, 5 parts of nano silver part, 8 parts of composite flame retardant, said composite flame retardant is ammonium polyphosphate-diatomite / magnetically ordered mesoporous nickel ferrite composite flame retardant prepared by in-situ polymerization, and the preparation method of composite flame retardant is specific As follows: Pour 85% concentrated phosphoric acid into the reactor, heat and stir, add appropriate amount of urea when the temperature rises to 60°C, add appropriate amount of diatomaceous earth and magnetically ordered mesoporous nickel ferrite powder when the temperature rises to 125°C, and stir React for 10 minutes, then solidify the product at 280°C for 2 hours, and obtain a composite flame retar...

Embodiment 2

[0036] Antibacterial high flame retardant ABS composite material, said antibacterial high flame retardant ABS composite material is processed from the following raw materials by weight: 80 parts of ABS resin, 60 parts of PC resin, 10 parts of EPDM resin, 10 parts of antioxidant, 8 parts of nano silver Parts, 12 parts of composite flame retardant, said composite flame retardant is ammonium polyphosphate-diatomite / magnetically ordered mesoporous nickel ferrite composite flame retardant prepared by in-situ polymerization, the preparation method of composite flame retardant is specific As follows: Pour 85% concentrated phosphoric acid into the reactor, heat and stir, add appropriate amount of urea when the temperature rises to 80°C, add appropriate amount of diatomite and magnetically ordered mesoporous nickel ferrite powder when the temperature rises to 120°C, and stir React for 20 minutes, then solidify the product at 320°C for 1 hour, and obtain a composite flame retardant after...

Embodiment 3

[0039]Antibacterial high flame retardant ABS composite material, said antibacterial high flame retardant ABS composite material is processed from the following raw materials by weight: 70 parts of ABS resin, 50 parts of PC resin, 6 parts of EPDM resin, 8 parts of antioxidant, 6 parts of nano silver 10 parts, 10 parts of composite flame retardant, said composite flame retardant is ammonium polyphosphate-diatomaceous earth / magnetically ordered mesoporous nickel ferrite composite flame retardant prepared by in-situ polymerization, and the preparation method of composite flame retardant is specific As follows: Pour 85% concentrated phosphoric acid into the reactor, heat and stir, add appropriate amount of urea when the temperature rises to 70°C, add appropriate amount of diatomaceous earth and magnetically ordered mesoporous nickel ferrite powder when the temperature rises to 122°C, and stir React for 15 minutes, then solidify the product at 300°C for 1.5 hours, and pulverize it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com