Preparation method of anti-aging high-flame-resistant ABS automotive interior trim

A technology of automotive interior parts and high flame retardancy, which is applied in the field of preparation of anti-aging high flame-retardant ABS automotive interior parts, can solve the problems of anti-aging and poor flame retardancy, and achieve the advantages of smoke absorption and safety Good performance and little effect on physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

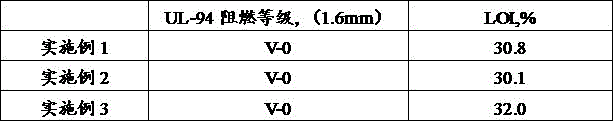

Examples

Embodiment 1

[0035] A method for preparing an anti-aging highly flame-retardant ABS automotive interior part, the steps of the preparation method are as follows:

[0036] S1: Put the anti-aging and high flame-retardant ABS material particles in the mixer, stir and melt at 110°C, and cool the molten material to 60°C for later use;

[0037] S2: Rolling the molten material in step S1 to form a plate, using rolling equipment to roll the molten material at a temperature of 60° C., and then cooling the rolled plate to room temperature to form a plate with a thickness of 5 mm;

[0038] S3: Cut the sheet to form a billet, which is hot-pressed to form an automotive interior part. The hot-pressing forming equipment is used to hot-press the billet at a hot-pressing temperature of 65°C and a hot-pressing pressure of 1000kN to form an anti-aging high flame-retardant ABS automotive interior accessories;

[0039] The anti-aging high flame-retardant ABS material particles are processed from the following...

Embodiment 2

[0042] A method for preparing an anti-aging highly flame-retardant ABS automotive interior part, the steps of the preparation method are as follows:

[0043] S1: Anti-aging high flame retardant ABS material particles are placed in a mixer, stirred and melted at 120°C, and the molten material is cooled to 80°C for later use;

[0044] S2: Rolling the molten material in step S1 to form a plate, using rolling equipment to roll the molten material at a temperature of 80° C., and then cooling the rolled plate to room temperature to form a plate with a thickness of 10 mm;

[0045] S3: Cut the sheet to form a billet, which is hot-pressed to form an automotive interior part. The hot-pressing forming equipment is used to hot-press the billet at a hot-pressing temperature of 75°C and a hot-pressing pressure of 1200kN to form an anti-aging high flame-retardant ABS automotive interior accessories;

[0046]The anti-aging high flame-retardant ABS material particles are processed from the fo...

Embodiment 3

[0049] A method for preparing an anti-aging highly flame-retardant ABS automotive interior part, the steps of the preparation method are as follows:

[0050] S1: Put the anti-aging high flame-retardant ABS material particles in the mixer, stir and melt at 115°C, and cool the molten material to 70°C for later use;

[0051] S2: Rolling the molten material in step S1 to form a plate, using rolling equipment to roll the molten material at a temperature of 70° C., and then cooling the rolled plate to room temperature to form a plate with a thickness of 8.0 mm;

[0052] S3: Cut the plate to form a billet, which is hot-pressed to form an automotive interior part. The hot-pressing forming equipment is used to hot-press the billet at a hot-pressing temperature of 70°C and a hot-pressing pressure of 1100kN to form an anti-aging high flame-retardant ABS automotive interior accessories;

[0053] The anti-aging high flame retardant ABS material particles are processed from the following r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com