High-performance environment-friendly kraft liner paperboard and preparation method thereof

A kraft box, high-performance technology, applied in pulp beating/refining method, special paper, paper, etc., can solve the problems of limiting the physical properties of kraft box board, difficulty in achieving high-quality packaging and printing products, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

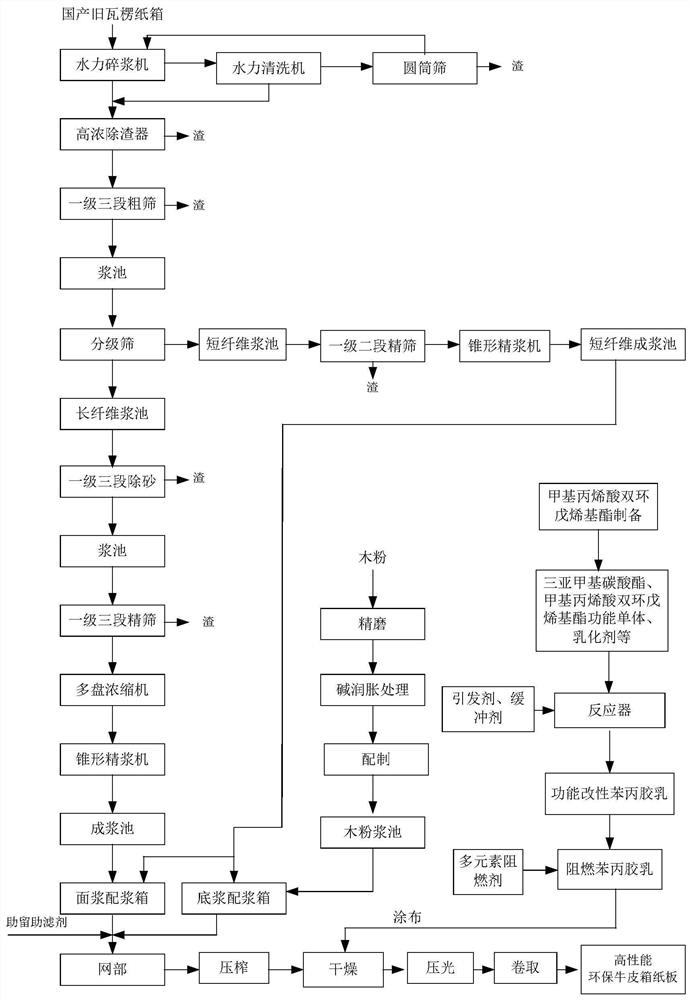

Method used

Image

Examples

Embodiment 1

[0067] A kind of preparation method of high-performance environment-friendly kraft liner board of the present embodiment comprises the following steps:

[0068] (1) Preparation of flame retardant styrene-acrylic latex

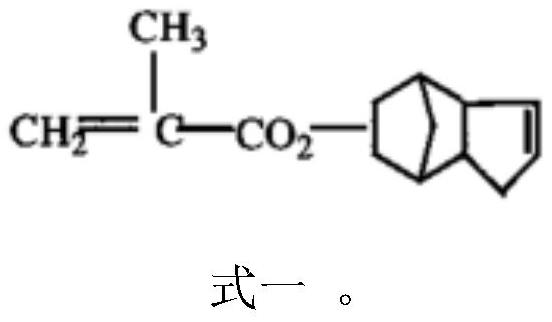

[0069] (a) preparation of dicyclopentenyl methacrylate

[0070] According to the ratio, add methacrylic acid, trifluoromethanesulfonic acid, and hydroquinone in sequence to the reactor 2 equipped with a stirrer, control the speed of the stirrer to 210r / min, heat up to 80°C after stirring evenly; continue to add bicyclic Pentadiene, the reaction temperature of the reaction system is controlled at 85°C, and the constant temperature reaction is 3.5h; after the reaction is completed, cool to room temperature, then add NaOH and stir for 1.5h, and the obtained material is washed, filtered, and distilled to obtain dicyclopentene methacrylate base ester. Wherein: the mass ratio of methacrylic acid, trifluoromethanesulfonic acid, hydroquinone, dicyclopentadiene and Na...

Embodiment 2

[0095] A kind of preparation method of high-performance environment-friendly kraft liner board of the present embodiment comprises the following steps:

[0096] (1) Preparation of flame retardant styrene-acrylic latex

[0097] (a) preparation of dicyclopentenyl methacrylate

[0098] According to the ratio, add methacrylic acid, trifluoromethanesulfonic acid and hydroquinone in sequence to the reactor 2 equipped with a stirrer, stir and mix under the condition of 100r / min, then heat up to 78°C, and continue to add to the reactor 2 Dicyclopentadiene was added to the mixture, mixed evenly, and then the temperature of the reaction system was raised to 90°C for 3 hours of constant temperature reaction. After the reaction was completed, it was cooled to room temperature, and NaOH was added to the obtained product, stirred for 1 hour, and finally the obtained mixture was washed and filtered. , distillation to obtain dicyclopentenyl methacrylate; wherein: the mass ratio of methacryli...

Embodiment 3

[0123] A kind of preparation method of high-performance environment-friendly kraft liner board of the present embodiment comprises the following steps:

[0124] (1) Preparation of flame retardant styrene-acrylic latex

[0125] (a) preparation of dicyclopentenyl methacrylate

[0126] According to the ratio, add methacrylic acid, trifluoromethanesulfonic acid, and hydroquinone to the reactor 2 equipped with a stirrer in sequence, stir and mix under the condition of 500r / min, then heat up to 82°C, and continue to feed the reactor 2 Dicyclopentadiene was added to the mixture, mixed evenly, and then the temperature of the reaction system was raised to 85°C for constant temperature reaction for 4 hours. After the reaction was completed, it was cooled to room temperature, and NaOH was added to the obtained product, and stirred for 2 hours. Finally, the obtained mixture was washed and filtered. , distillation to obtain dicyclopentenyl methacrylate; wherein: the mass ratio of methacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com