Preparation method and application of bio-based flame-retardant compatilizer for PBAT (poly (butylene adipate-co-terephthalate))

A compatibilizer, bio-based technology, applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., to achieve good flame retardancy and compatibility, improve flame retardancy, and excellent phase capacitive effect

Active Publication Date: 2022-06-10

TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] So far, there is no phytic acid-based nitrogen-phosphorus synergistic flame retardant combined with PBAT through chemical reaction

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0030] Comparative example 2

[0031] Comparative example 3

Embodiment 2

[0033] Comparative example 5

Embodiment 3

[0035] Example 1 Example 2 Example 3 Example 4 Example 5 LOI (%) 42.3 34.7 30.5 38.2 31.4 Comparative example 1 Comparative example 2 Comparative example 3 Comparative example 4 Comparative example 5 Comparative example 6 LOI (%) 26.3 28.5 28.4 27.6 29.7 29.1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

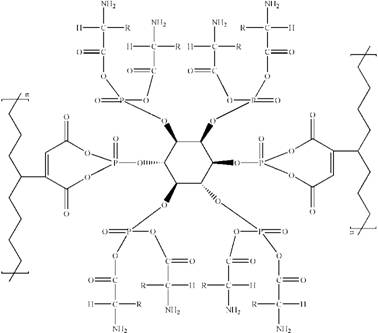

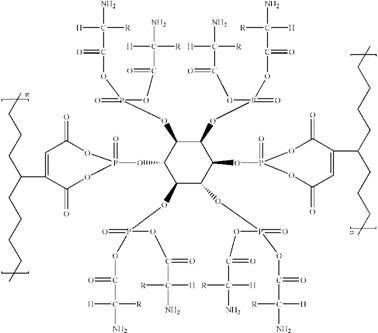

Login to View More Abstract

The invention discloses a preparation method and application of a bio-based flame-retardant compatilizer for PBAT (poly (butylene adipate-co-terephthalate)). The bio-based flame-retardant compatilizer is prepared by the following process: carrying out grafting reaction on Fischer-Tropsch wax and maleic anhydride to obtain Fischer-Tropsch wax acid, dispersing the prepared Fischer-Tropsch wax acid and soybean protein isolate, and reacting with phytic acid in a solution to obtain the bio-based flame-retardant compatilizer. According to the bio-based flame-retardant compatilizer prepared by the invention, a novel flame retardant chemical structure with synergistic flame-retardant and compatible effects is obtained by using raw materials from bio-based sources, and the flame retardant does not influence the biodegradability of PBAT, can also play a lubricating role in the processing process, inhibits hydrolysis in the processing process, and has the advantages of favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy, favorable flame retardancy and favorable flame retardancy. And the method has very important practical significance for broadening the actual application scene of the PBAT.

Description

technical field [0001] The invention relates to a preparation method and application of a bio-based flame retardant compatibilizer for PBAT, belonging to the technical field of polymer materials. Background technique [0002] At present, the copolymer of butylene adipate and butylene terephthalate (PBAT), as a biodegradable polymer, has received extensive attention in the industry, and is considered to be the most promising biodegradable polymer in the market. One of the degradable polymers. PBAT has the characteristics of both PBA and PBT. It has good mechanical properties and good heat resistance. It is widely used in disposable lunch boxes, films and other fields. However, its poor flame retardancy has also become a restrictive factor for its comprehensive application. At present, the nitrogen-phosphorus synergistic flame retardant system is considered to be the best flame retardant system for PBAT. As an organophosphorus compound extracted from plant seeds, phytic aci...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07F9/117C08K5/527C08L67/02

CPCC07F9/117C08K5/527C08L2201/02C08L67/02Y02W90/10

Inventor 王波李向阳张岩丽林福华毛双丹赵玉英

Owner TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com