A kind of reinforced flame-retardant polypropylene composite material and preparation method thereof

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of reinforced flame-retardant polypropylene composite materials and its preparation, can solve problems such as increased costs, reduced flame-retardant efficiency of halogen-based flame retardants, and unsatisfactory effects, so as to ensure mechanical Performance, improved flame retardancy, improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

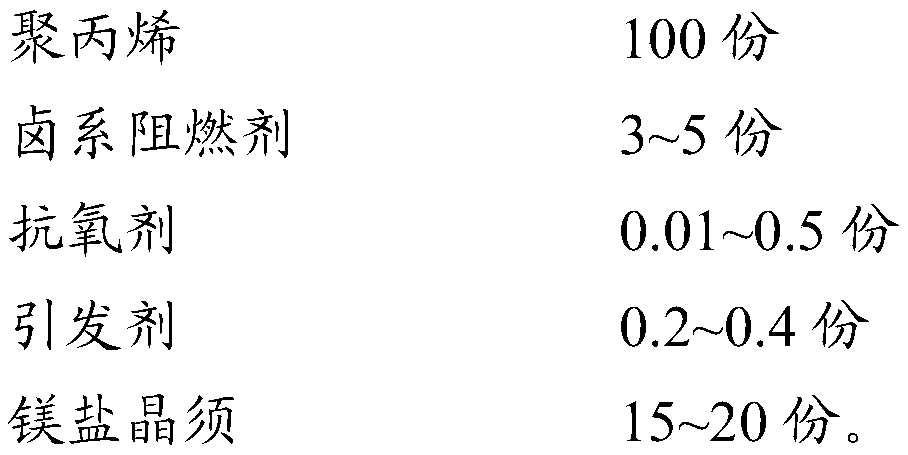

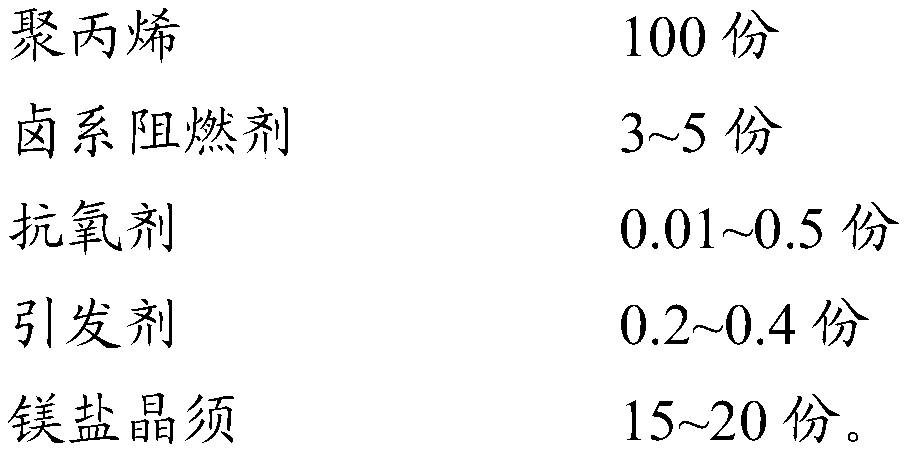

[0035] The present invention also provides a preparation method of the reinforced flame-retardant polypropylene composite material, comprising the following steps:

[0036] 1) Extrude and granulate after mixing polypropylene, halogenated flame retardant, antioxidant and initiator to obtain pellets;

[0037] 2) Extruding and granulating the pellets obtained above with magnesium salt whiskers to obtain a reinforced flame-retardant polypropylene composite material.

[0038] The invention mixes polypropylene, halogen flame retardant, antioxidant and initiator, extrudes and granulates to obtain pellets. In the present invention, the mixing temperature is preferably 25-50°C, more preferably 30-45°C, most preferably 38-42°C; in the present invention, the mixing time is preferably 10-15 minutes, More preferably, it is 11 to 14 minutes, and most preferably, it is 12 to 13 minutes. In the present invention, the mixing process is preferably carried out under stirring conditions. In the...

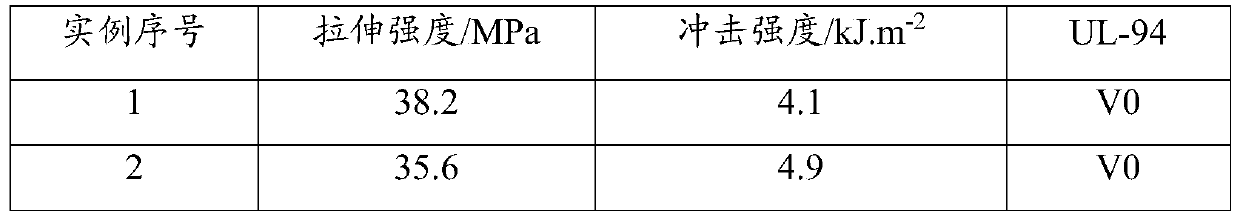

Embodiment 1

[0051] Premix 100 parts of polypropylene, 3 parts of pentachlorophenyl acrylate, 0.1 part of antioxidant 1010, and 0.2 part of dicumyl peroxide for 15 minutes. Reactive extrusion granulation is carried out in a warm twin-screw extruder. The processing temperatures in the first to sixth zones are: 170°C, 190°C, 195°C, 200°C, 210°C, 205°C, and the head temperature is 210°C. The screw speed is 180r / min, and the cutting speed is 400r / min.

[0052] After drying the prepared granules, mix them with 20 parts of magnesium salt whiskers, then carry out mixing, plasticizing and granulating through a twin-screw extruder. The extrusion granulation process is the same as before, and the reinforced flame-retardant Polypropylene composite.

Embodiment 2

[0054] Premix 100 parts of polypropylene, 4 parts of pentachlorophenyl acrylate, 0.1 part of antioxidant B215, and 0.3 part of initiator dicumyl hydroperoxide. After the above premixed material has an aspect ratio of 32, divide it into six Reactive extrusion granulation is carried out in a twin-screw extruder with zone temperature control. The processing temperatures in zones 1 to 6 are: 170°C, 190°C, 195°C, 200°C, 210°C, 210°C, and the head temperature is 210°C. The screw speed is 250r / min, and the cutting speed is 450r / min.

[0055] After drying the prepared granules, mix them with 18 parts of magnesium salt whiskers, and then carry out mixing, plasticizing and granulating through a twin-screw extruder. The extrusion granulation process is the same as before, and the reinforced flame-retardant Polypropylene composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com